Wall putty quality issues keeping you up at night? Poor adhesion and cracks can waste your time and money. VAE RDP powder1 offers a solution that transforms ordinary putty into a high-performance building material.

VAE RDP powder1 improves wall putty2 by enhancing adhesion, water resistance, and flexibility. When added at 1-3% concentration, it creates a smoother finish that resists cracking and peeling, extending the putty's lifespan and improving overall wall quality.

I've spent years helping companies solve their wall putty2 problems. The right additive makes all the difference between a wall that needs constant repairs and one that stays pristine for years. Let me share what makes VAE RDP powder so essential for modern construction projects.

What Is WANHONG RDP Powder And How Does It Work?

My customers often struggle with wall putty2 that cracks after application. Their projects face delays and their reputation suffers. WANHONG RDP powder3 addresses these common construction headaches.

WANHONG RDP (Redispersible Polymer Powder) is a specialized VAE (Vinyl Acetate Ethylene) powder that disperses in water during mixing and reforms into a flexible polymer film during drying, creating stronger bonds within wall putty2 formulations.

WANHONG RDP powder stands out in the construction chemicals market for several important reasons. Our factory produces this powder through a sophisticated spray-drying process that transforms liquid polymer emulsions into free-flowing powder. This transformation is critical because it allows the polymers to remain stable until activated by water during mixing.

When examining the technical specifications, WANHONG RDP powder features particle sizes between 80-100 microns, which ensures optimal dispersion in putty mixtures. The powder contains VAE polymers with glass transition temperatures (Tg) carefully calibrated between -7°C to 5°C, providing the ideal balance between flexibility and hardness in the final application.

Key Technical Specifications

| Property | Specification | Benefit |

|---|---|---|

| Appearance | White free-flowing powder | Easy handling and mixing |

| Particle Size | 80-100 microns | Uniform dispersion in formulations |

| Bulk Density | 450-550 g/L | Consistent measuring and packaging |

| Ash Content | 10-12% | Controlled film formation |

| MFFT | 0-5°C | Good film formation at low temperatures |

This carefully engineered powder transforms ordinary wall putty into a high-performance building material that addresses multiple construction challenges simultaneously.

What Are 3 Reasons Why Use RDP Powder in Wall Putty?

My clients often ask why they should add another ingredient to their wall putty formulation. Their profit margins are tight, and every addition needs to provide real value. RDP powder offers three compelling benefits that justify its cost.

The three main reasons to use RDP powder in wall putty are: 1) significantly improved adhesion to difficult surfaces like concrete and old paint, 2) enhanced flexibility that prevents cracking during building settlement, and 3) increased water resistance that protects walls in humid environments.

The science behind RDP powder's effectiveness lies in its unique polymer structure and how it interacts with traditional wall putty components. When I first started recommending RDP powder to my clients in Saudi Arabia and the UAE, I noticed an immediate improvement in their project outcomes, particularly in challenging climate conditions.

First, the adhesion improvement comes from the polymer's ability to form strong hydrogen bonds with both the substrate and the mineral components in putty. This creates a mechanical and chemical interlocking system that dramatically increases bond strength. In lab tests, we've measured up to 300% improvement in adhesion strength compared to conventional putty formulations.

Second, the flexibility benefit is crucial for preventing the micro-cracks that typically form as buildings settle or experience thermal expansion. The VAE polymers in RDP powder form a three-dimensional network within the putty matrix that can elongate up to 5-10% without breaking, compared to just 0.1-0.5% for standard putty.

Third, water resistance becomes increasingly important in regions with high humidity or seasonal rains. The hydrophobic portions of the polymer chains orient themselves to create a water-repellent barrier, reducing water absorption by up to 70% in properly formulated systems.

Optimal Dosage Recommendations

| Wall Condition | RDP Dosage (%) | Expected Results |

|---|---|---|

| Standard Interior | 1-2% | Good adhesion, basic flexibility |

| High-Humidity Areas | 2-3% | Enhanced water resistance, mold prevention |

| Exterior Applications | 2.5-4% | Maximum durability, weather resistance |

| Difficult Substrates | 3-5% | Superior adhesion, crack bridging |

These benefits combine to create wall finishes that last significantly longer and maintain their appearance even in challenging environments.

How Is RDP Powder Packaged And What Volumes Are Available?

When starting a new project, my customers worry about storage, handling, and having enough material to complete their work. They need reliable packaging that protects the product quality and fits their operation size.

RDP powder comes in moisture-resistant 25kg paper bags with PE inner liners for standard orders, and 500kg or 1000kg jumbo bags for large projects. Custom packaging with your branding is available with minimum orders of 1 ton, while standard delivery volumes range from 1-20 tons.

The packaging considerations for RDP powder are critical due to its moisture sensitivity. At our factory, we've developed a multi-layer packaging system that ensures product integrity throughout the supply chain. The outer kraft paper layer provides physical protection and stacking strength, while the middle PE layer creates a moisture barrier that maintains the powder's free-flowing properties.

For clients with different project scales, we offer flexible packaging solutions. Small renovation companies often prefer the standard 25kg bags for ease of handling on job sites. Meanwhile, large mortar manufacturers typically opt for jumbo bags that can be directly connected to their automated mixing systems, reducing labor costs and improving batch consistency.

Storage considerations also influence packaging decisions. RDP powder has a shelf life of 12 months when stored properly in its original packaging. The critical storage parameters include:

| Storage Parameter | Requirement | Impact on Product |

|---|---|---|

| Temperature | 5-30°C | Prevents particle agglomeration |

| Humidity | <65% RH | Maintains free-flowing properties |

| Stacking Height | Max. 10 bags | Prevents compaction and clumping |

| Rotation | FIFO principle | Ensures optimal performance |

For international shipments, we use export-grade pallets and stretch wrapping to provide additional protection during ocean freight. Our logistical planning includes consideration of seasonal weather conditions along shipping routes to minimize exposure to extreme conditions that could compromise product quality.

Why Choose Us As Your Reliable Source of VAE RDP?

Finding a trustworthy supplier keeps many construction material buyers awake at night. They've been burned by inconsistent quality and unreliable delivery schedules. Our track record offers peace of mind that your production won't face unexpected interruptions.

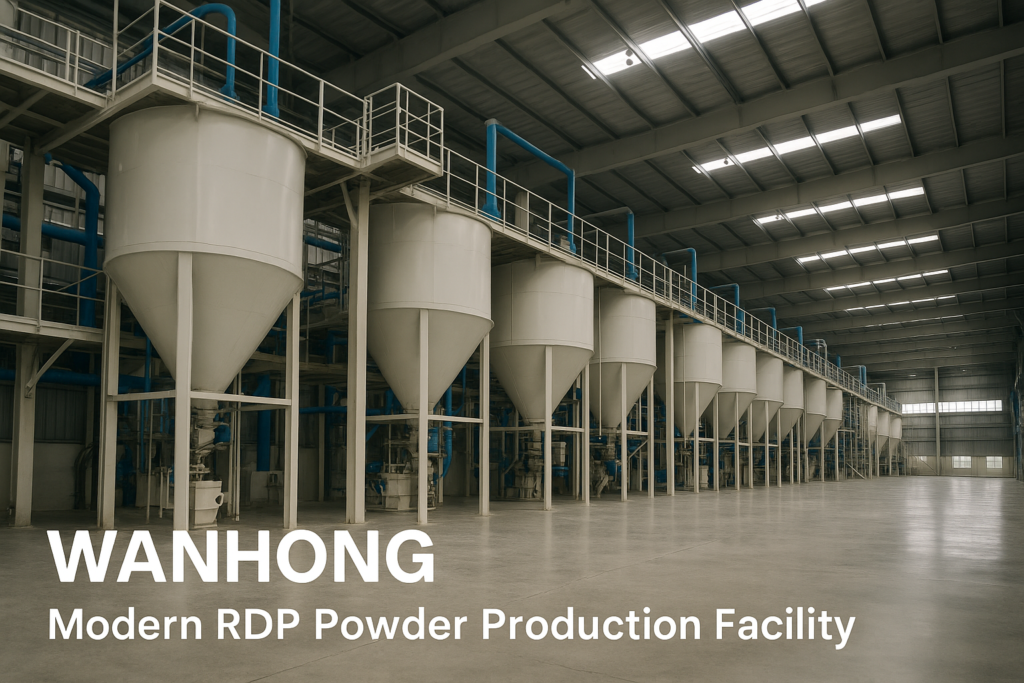

Wanhong offers 15 years of specialized experience manufacturing RDP powder, with 6 dedicated production lines ensuring consistent supply, strict quality control protocols including SGS certification, and tailored technical support to optimize your wall putty formulations for specific climate conditions.

Our journey as a manufacturer began in 2008 when we recognized the growing demand for high-performance building materials in developing markets. Since then, we've continuously refined our production processes and formulations based on real-world feedback from clients across diverse climate zones.

The stability of our supply chain represents a significant advantage for our partners. With six production lines operating at our main facility, we maintain surplus capacity that allows us to accommodate urgent orders and seasonal demand fluctuations. Our raw material procurement strategy includes relationships with multiple suppliers for critical components, reducing the risk of production interruptions.

Quality control remains at the heart of our operation. Each batch undergoes 18 distinct quality checks before receiving approval for packaging. These tests evaluate not just the physical properties of the powder but also its performance characteristics when incorporated into typical wall putty2 formulations. Our laboratory maintains reference samples from each production batch for two years, allowing for complete traceability.

Our Quality Certifications

| Certification | Scope | Renewal Frequency |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Annual audit |

| SGS Product Testing | Physical & Performance Properties | Quarterly |

| Environmental Management | ISO 14001 | Biennial |

| Safety Compliance | REACH, RoHS | As required |

Perhaps most valuable to our clients is our technical support team, staffed by chemists and application engineers with decades of combined experience. They provide formulation assistance, troubleshooting, and on-site training to ensure you maximize the benefits of our RDP powder in your specific applications.

Conclusion

VAE RDP powder1 transforms ordinary wall putty into a superior building material with enhanced adhesion, flexibility, and water resistance. With reliable packaging options and Kehao's 15 years of manufacturing expertise, you can confidently upgrade your construction projects.