Tile installation failures cause costly repairs and project delays. Without the right binding agent, even the most beautiful tiles can come loose. HPMC is your solution.

HPMC1 (Hydroxypropyl methylcellulose) enhances tile adhesive by improving water retention, slip resistance, open time, and bonding strength. It creates a perfect balance of workability and adhesion, making it essential for modern tile installation projects.

I've seen many construction projects fail because of poor adhesive performance. In my 15 years working with cellulose ethers, I've learned that the quality of your HPMC1 directly impacts your tile installation's success. Let me share what makes HPMC crucial for superior tile adhesives.

What Makes HPMC Essential for Modern Tile Adhesives?

Tile installers struggle with quick-drying adhesives and poor workability. Without proper water retention, adhesives dry too quickly, leading to weak bonds and failed installations.

HPMC1 is a cellulose ether that transforms tile adhesive2s by controlling water evaporation, extending open time, and improving vertical slip resistance. It creates a perfect balance between workability and final adhesion strength.

The chemistry behind HPMC's effectiveness is fascinating when you understand how it works at a molecular level. HPMC forms a protective colloid in the adhesive mixture that regulates water movement. This property is crucial because it prevents premature drying while maintaining the right consistency for application.

In my factory, we carefully control the degree of substitution and viscosity of our HPMC products to meet specific requirements for different tile adhesive applications. The molecular weight of HPMC directly impacts its performance – higher molecular weight typically provides better water retention but may affect workability if too high.

Technical Properties of Quality HPMC for Tile Adhesives

| Property | Optimal Range | Impact on Performance |

|---|---|---|

| Viscosity | 100,000-200,000 mPa·s | Higher viscosity improves water retention |

| Methoxyl Content | 19-24% | Affects solubility and gel temperature |

| Hydroxypropyl Content | 7-12% | Influences surface activity and compatibility |

| Particle Size | 100 mesh | Determines dissolution rate |

| Gel Temperature | 65-85°C | Controls thermal gelation properties |

These carefully balanced properties ensure that your tile adhesive remains workable long enough for proper installation while developing strong bonds as it cures.

How Does HPMC Improve Tile Adhesive Performance?

Poor adhesive performance leads to tile detachment and customer complaints. Traditional adhesives often lack the critical properties needed for modern, large-format tiles and challenging installation environments.

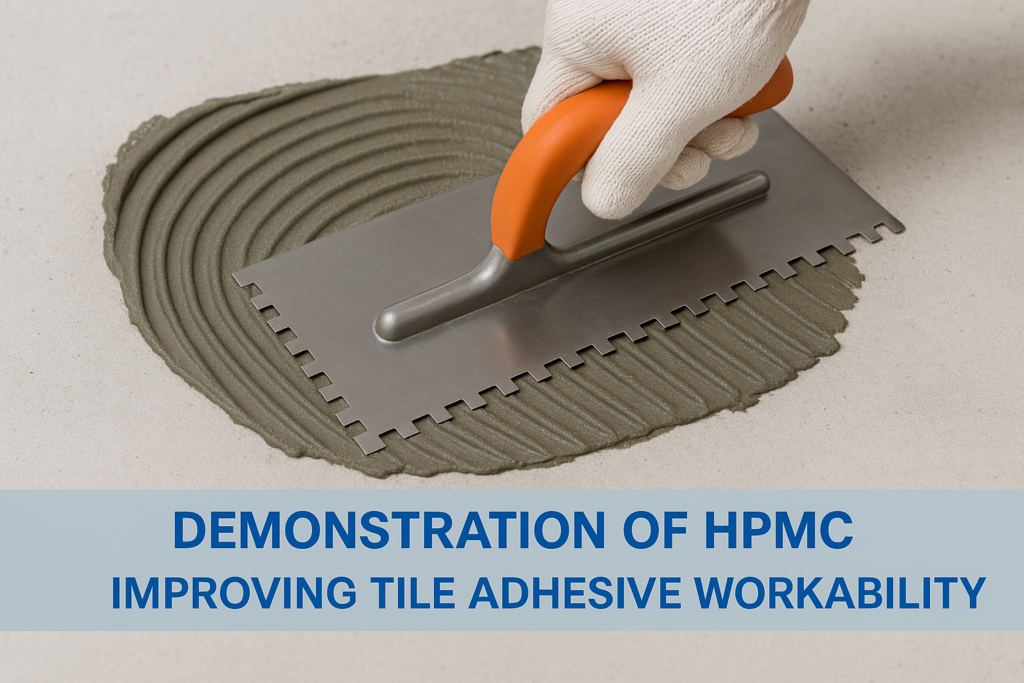

HPMC enhances tile adhesives by improving water retention (keeping adhesive workable longer), increasing open time (allowing more working time), reducing sagging on vertical surfaces, and improving overall bonding strength with various substrates.

The advantages of HPMC1 in tile adhesives go far beyond basic water retention. From my experience working with major mortar manufacturers across Saudi Arabia and the UAE, I've observed that properly formulated HPMC delivers a comprehensive set of benefits that transform ordinary tile adhesives into high-performance systems.

Water retention is perhaps the most fundamental benefit. When we test our kehao HPMC1 products, we measure water retention using standardized methods that simulate real-world conditions. An adhesive with good water retention (>95%) ensures that enough water remains available for proper cement hydration, even when applied on highly absorbent substrates or in hot, dry environments.

Sagging resistance is another critical factor, especially for wall tile installations. Our HPMC helps create thixotropic behavior in the adhesive – meaning it flows when pressure is applied but returns to a gel-like state at rest. This prevents tiles from slipping down vertical surfaces after placement. I've worked with customers in Mexico and Brazil where this property was essential for their large-format wall tile installations.

Extended open time gives installers more flexibility, reducing waste and allowing for better adjustment of tiles. In high-temperature regions like Saudi Arabia and the UAE, this property is particularly valuable as it counteracts the natural tendency of adhesives to dry too quickly in hot conditions.

Additionally, HPMC improves adhesion to difficult substrates. The polymer enhances the mechanical interlocking between the adhesive and various surfaces, creating stronger bonds with both the substrate and the tile backing.

Which HPMC1 Types Work Best for Different Tile Applications?

Selecting the wrong HPMC type can lead to application failures and wasted materials. Many contractors struggle with adhesives that perform inconsistently across different tile types and installation environments.

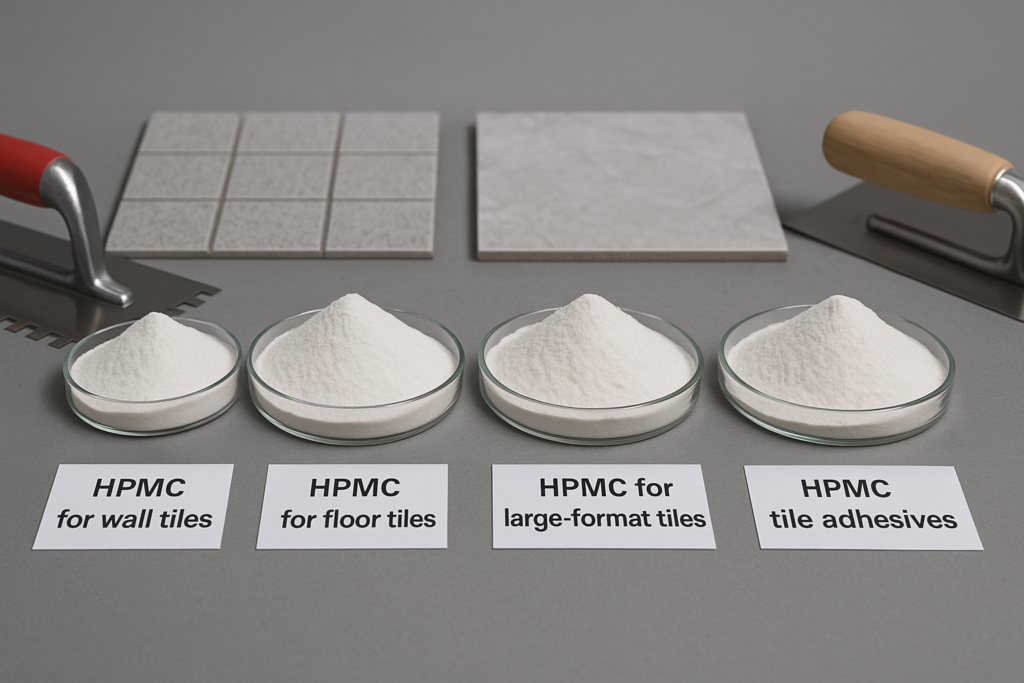

Different tile applications require specific HPMC varieties. For standard wall tiles, HPMC with viscosity of 100,000 mPa·s is ideal. Floor tiles benefit from 150,000 mPa·s types, while large format and outdoor tiles require 200,000+ mPa·s with enhanced water retention.

In my years working with clients across diverse markets like India, Pakistan, and Brazil, I've found that matching the right HPMC type to the specific application is crucial for success. The requirements for a bathroom wall tile installation3 differ dramatically from those for outdoor floor tiles in a commercial setting.

For standard ceramic wall tiles in interior applications, our kehao HPMC with medium viscosity (around 100,000 mPa·s) provides excellent performance. These applications don't typically face extreme conditions, so a balanced product that offers good water retention while remaining cost-effective is ideal.

Floor tile installations present different challenges, primarily the need for stronger adhesion to handle foot traffic and heavier loads. Here, we recommend our HPMC grades with viscosity around 150,000 mPa·s, which provide enhanced bonding strength while maintaining good workability.

HPMC Selection Guide for Various Tile Applications

| Application Type | Recommended HPMC Viscosity | Key Requirements |

|---|---|---|

| Interior Wall Tiles | 100,000 mPa·s | Good slip resistance, moderate water retention |

| Interior Floor Tiles | 150,000 mPa·s | Enhanced bond strength, good workability |

| Large Format Tiles | 200,000+ mPa·s | Superior water retention, extended open time |

| Exterior Applications | 200,000+ mPa·s with additives | Weather resistance, flexibility, high water retention |

| Glass/Mosaic Tiles | 120,000 mPa·s | Enhanced adhesion to smooth surfaces, non-sag properties |

For the most challenging applications—large format tiles and exterior installations—we've developed specialized HPMC grades with viscosities exceeding 200,000 mPa·s. These products contain carefully engineered molecular structures that maximize water retention and bond strength. I've personally worked with clients in Vietnam and the Philippines who successfully used these grades for large porcelain tile installations in high-humidity environments.

What Are the Best Practices for HPMC Dosage in Tile Adhesives?

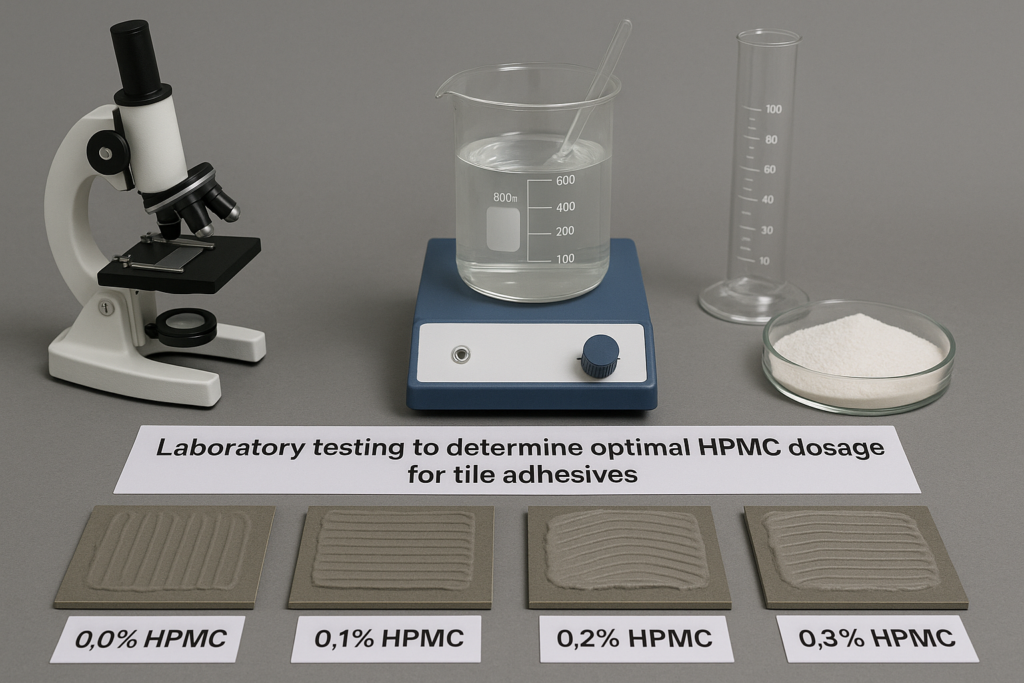

Incorrect HPMC dosage causes either poor water retention or excessive stickiness. Many manufacturers waste money by using too much HPMC or compromise performance by using too little.

The optimal HPMC dosage for tile adhesives typically ranges from 0.2% to 0.5% of the dry mix weight. Standard tile adhesives require around 0.25%, while premium formulations may use up to 0.5% for enhanced performance.

Finding the perfect dosage for HPMC in tile adhesives requires careful consideration of multiple factors. Through our extensive R&D work at our kehao factory in China, we've developed a systematic approach to determining the optimal HPMC content for different formulations.

The base dosage recommendation of 0.2-0.5% provides a starting point, but fine-tuning is essential. For standard C1-class tile adhesives4 (according to EN 12004 standards), we typically recommend 0.25-0.3% HPMC content. For premium C2-class adhesives5 with enhanced characteristics, the dosage increases to 0.35-0.5%.

Environmental conditions significantly impact the required dosage. For hot, dry climates like those in Saudi Arabia or Iran, higher dosages are necessary to counter rapid water evaporation. I remember working with a client in Riyadh who needed to increase their HPMC content by 20% during summer months to maintain consistent performance.

The substrate's porosity also affects the optimal HPMC level. Highly absorbent substrates like aerated concrete or old plaster walls pull moisture from the adhesive quickly, requiring additional water retention capability.

HPMC Dosage Adjustment Factors

| Factor | Adjustment Direction | Typical Adjustment Amount |

|---|---|---|

| Hot/Dry Climate | Increase | +10-20% |

| Humid Climate | Decrease | -5-10% |

| Highly Absorbent Substrate | Increase | +15-25% |

| Non-Absorbent Substrate | Decrease | -5-15% |

| Large Format Tiles | Increase | +10-30% |

| Vertical Application | Increase | +5-15% |

The mixing process is equally important. I always advise our customers to add HPMC to the dry components first, ensuring uniform distribution before adding water. Improper mixing can create "fish eyes" (undissolved HPMC clumps) that compromise performance. Our technical team provides detailed mixing protocols tailored to each customer's production equipment.

How to Choose the Right HPMC Supplier for Your Tile Adhesive Business?

Unreliable HPMC suppliers cause production inconsistencies and quality problems. Many manufacturers struggle with unpredictable product performance due to variable HPMC quality.

Selecting a quality HPMC supplier6 requires evaluating their manufacturing consistency4, technical support capabilities, and product certification. The best suppliers provide consistent viscosity (±10%), particle size uniformity, and comprehensive application support.

"Modern HPMC production line with quality control systems")

"Modern HPMC production line with quality control systems")

Finding a trustworthy HPMC supplier is critical for maintaining consistent tile adhesive quality. At kehao, we've built our reputation by focusing on manufacturing excellence and comprehensive technical support. When evaluating potential HPMC suppliers for your tile adhesive production, consider these essential factors:

Manufacturing consistency is paramount. A quality HPMC supplier maintains strict control over critical parameters like viscosity, substitution degree, and particle size. In our production facility, we implement rigorous in-process testing and statistical process control to ensure batch-to-batch consistency. Our viscosity variance stays within ±10%, significantly better than the industry average of ±20%.

Technical support capabilities differentiate premium suppliers from mere commodity providers. Our technical team includes specialists with extensive experience in tile adhesive formulation who provide personalized support. When one of our customers in Georgia wanted to develop a specialized adhesive for glass mosaic tiles, our team conducted multiple formulation trials and on-site testing to perfect the product.

Certification and compliance documentation are essential, especially for export markets. Reliable suppliers provide comprehensive documentation including technical data sheets, safety data sheets, and relevant certifications. All kehao products undergo rigorous testing to meet international standards like ISO, REACH, and RoHS requirements.

Supply chain reliability cannot be overlooked. Even the highest quality HPMC is worthless if it's not available when needed. We maintain strategic inventory levels and have optimized our logistics network to ensure consistent availability, even during challenging periods like the recent global supply chain disruptions.

Cost efficiency is about value, not just price. While premium HPMC may cost slightly more upfront, the enhanced performance and consistency typically result in lower overall formulation costs and fewer quality issues. I've worked with customers who initially chose cheaper alternatives but returned after calculating the true cost of inconsistent quality and technical problems.

Conclusion

Quality HPMC transforms ordinary tile adhesives into high-performance solutions. By selecting the right grade, dosage, and supplier, you'll achieve superior bonding, extended workability, and lasting installations that satisfy even the most demanding customers.

-

Explore how HPMC improves tile adhesive performance and prevents installation failures. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about effective tile adhesive techniques to ensure strong and lasting installations. ↩

-

Identify challenges in tile installation and how to overcome them for better results. ↩

-

Discover the features of C1-class tile adhesives and their applications in construction. ↩ ↩

-

Find out the differences between C1 and C2-class adhesives and their respective uses. ↩

-

Explore key factors to consider when selecting a trustworthy HPMC supplier for your business. ↩