Struggling with inconsistent construction materials that crack, shrink, or fail to perform? Many builders and manufacturers face this frustrating challenge daily. HPMC offers a reliable solution to these common problems.

HPMC (Hydroxypropyl Methylcellulose1) is a non-ionic cellulose ether2 derived from natural cellulose that acts as a thickener, binder, stabilizer, and water retention agent in various industries. It creates optimal viscosity in mixtures, improves workability, and enhances product durability.

As a factory owner with over 15 years of experience producing HPMC, I've seen firsthand how this versatile additive transforms ordinary products into superior ones. Let me share my knowledge about this remarkable material that has become essential across multiple industries.

What is HPMC and How is it Manufactured?

Are you confused by the technical jargon surrounding hydroxypropyl methylcellulose? Many professionals know they need HPMC but don't fully understand what it is or how it's made.

HPMC is a cellulose derivative created by chemically modifying cellulose fibers through a reaction with propylene oxide and methyl chloride. This process replaces hydrogen atoms in cellulose with methoxyl and hydroxypropyl groups, creating a water-soluble polymer with unique properties.

In our factory, we follow a carefully controlled production process to create high-quality HPMC. The journey begins with natural cellulose, typically derived from cotton or wood pulp. This cellulose undergoes alkaline treatment before reacting with methyl chloride to introduce methoxy groups and propylene oxide for hydroxypropyl substitution.

The degree of substitution significantly impacts the final product's properties. We can customize these parameters based on specific application requirements. For example, construction-grade HPMC3 typically has a methoxyl content of 19-24% and hydroxypropyl content of 7-12%, while pharmaceutical grades might have different specifications.

The raw product then undergoes purification steps to remove impurities and byproducts. We use advanced filtration and washing techniques to ensure our HPMC meets international quality standards. The final step involves drying and milling to achieve the desired particle size distribution, which directly affects dissolution rates and application performance.

What are the Key Properties of HPMC?

Do you find that your construction mixtures lack consistency or your pharmaceutical formulations don't have the right texture? These common problems often stem from using additives with unpredictable physical and chemical properties.

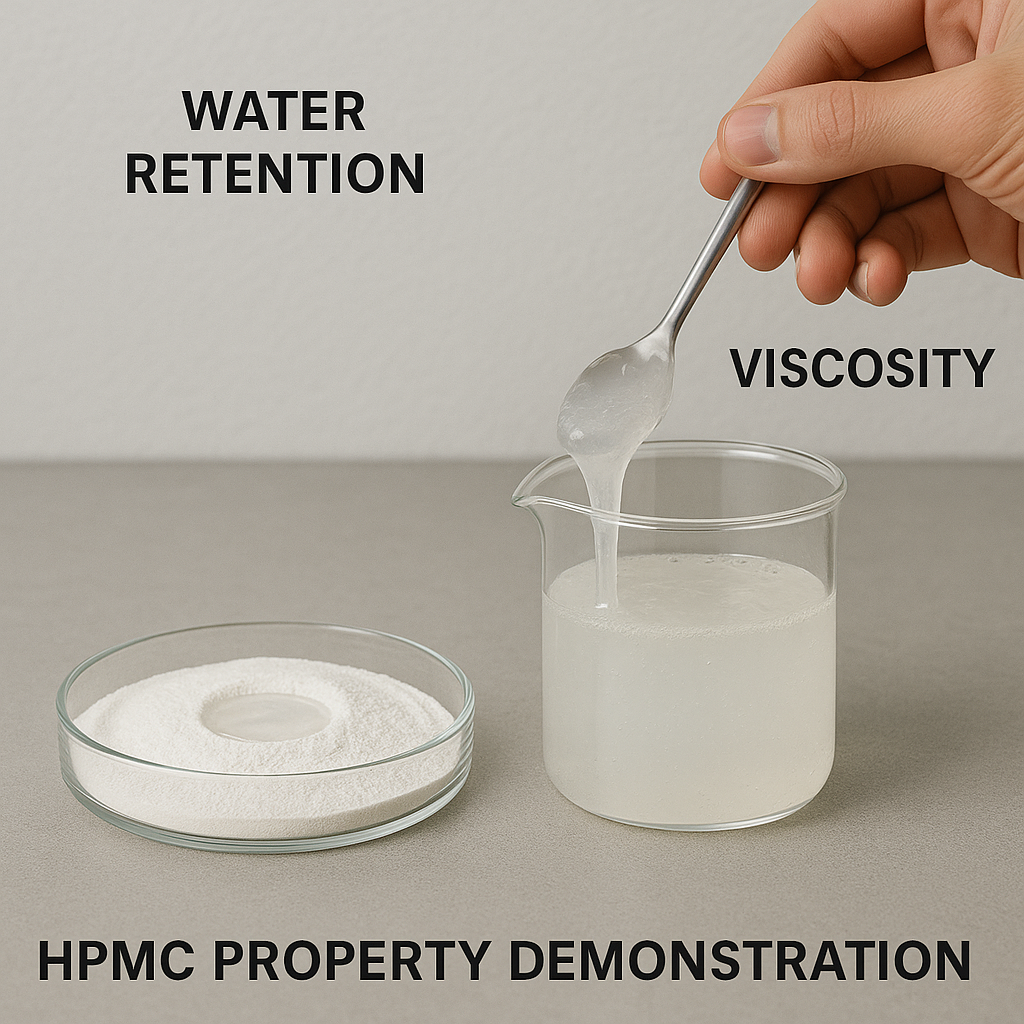

HPMC exhibits excellent water retention, thickening capability, film-forming properties, and thermal gelation. It dissolves in cold water forming clear solutions, increases viscosity at concentrations of 2-5%, maintains stability across pH 2-12, and provides controlled release functionality in various applications.

From my years of producing HPMC, I've come to appreciate the remarkable versatility of this polymer's properties. The most notable characteristic is its temperature-dependent solubility behavior – a feature that makes it indispensable in many applications.

HPMC dissolves readily in cold water but exhibits thermal gelation at higher temperatures. This property creates what we call the "reversible thermal gelation point" typically between 65-90°C depending on the grade. This means that when heated, HPMC solutions form a gel, but return to liquid state upon cooling – a property that's particularly valuable in construction applications.

The molecular weight distribution4 of HPMC directly influences its viscosity properties. In our factory, we produce various viscosity grades ranging from 5 to 200,000 mPa·s (measured as a 2% solution at 20°C). This allows customers to select the perfect grade for their specific application requirements.

Here's a breakdown of key HPMC properties by industry application:

| Property | Construction Value | Pharmaceutical Value | Food Application Value |

|---|---|---|---|

| Viscosity | Medium-High (helps workability) | Variable (depends on drug delivery needs) | Low-Medium (for proper texture) |

| Water Retention | >80% (prevents rapid drying) | N/A | N/A |

| Thermal Gelation | 65-75°C | 75-90°C | 60-70°C |

| pH Stability | 2-12 | 3-11 | 4-10 |

| Film Formation | Strong, flexible films | Smooth, controlled-release films | Thin, edible coatings |

How is HPMC Used in Different Industries?

Are you uncertain which type of HPMC would work best for your specific application? Many customers come to us confused about the wide range of grades and how to match them to their needs.

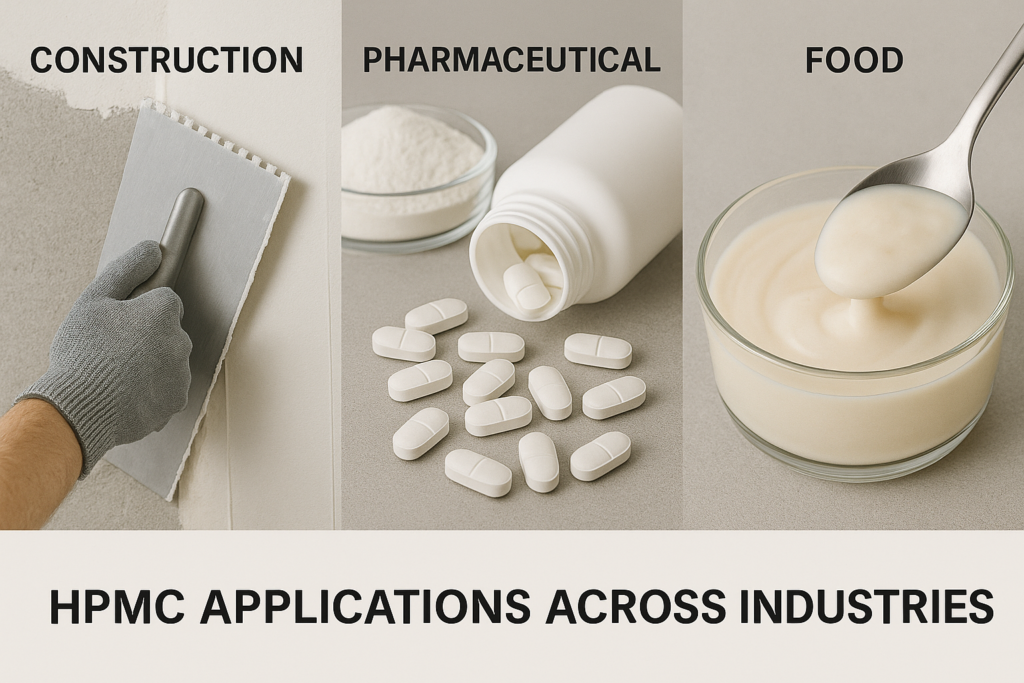

HPMC serves as a key ingredient in construction (as a water-retaining agent and rheology modifier in mortars and plasters), pharmaceuticals (for tablet coatings and controlled release matrices), food products (as a thickener and stabilizer), and personal care items (providing texture and stability).

Having supplied HPMC to customers worldwide, I've gained extensive insight into its diverse applications across different sectors. The versatility of this polymer continues to amaze me, with new uses being discovered regularly.

In construction, HPMC transforms ordinary mortar and concrete into high-performance building materials. Our construction-grade HPMC3 improves water retention significantly, preventing rapid dehydration and ensuring proper cement hydration. This results in stronger bonds, reduced cracking, and better workability. Tile adhesives containing our HPMC allow for longer open times, while renders and plasters become more sag-resistant and easier to apply.

The pharmaceutical industry relies on specific grades of HPMC for tablet manufacturing. When used as a binder, it helps maintain tablet integrity. As a coating agent, it creates smooth, easy-to-swallow tablets that can be designed for immediate or extended release depending on the HPMC viscosity. One of our pharmaceutical customers was able to extend their drug release time from 4 to 12 hours by switching to our higher viscosity pharmaceutical-grade HPMC5.

In food applications, HPMC serves as an emulsifier, stabilizer, and thickening agent. It helps maintain uniform distribution of ingredients in sauces and dressings while providing the desired texture. Its film-forming properties are particularly useful in gluten-free baking, where it helps trap gas bubbles to create texture similar to traditional wheat-based products.

Personal care and cosmetic products benefit from HPMC's ability to create smooth, stable gels and emulsions. It provides the perfect consistency for creams, lotions, and hair styling products while helping to stabilize active ingredients.

What Benefits Does HPMC Offer Over Alternative Additives?

Have you experienced inconsistent results when using other cellulose derivatives or synthetic polymers? Many manufacturers struggle with product performance variability, especially when sourcing from multiple suppliers with different quality standards.

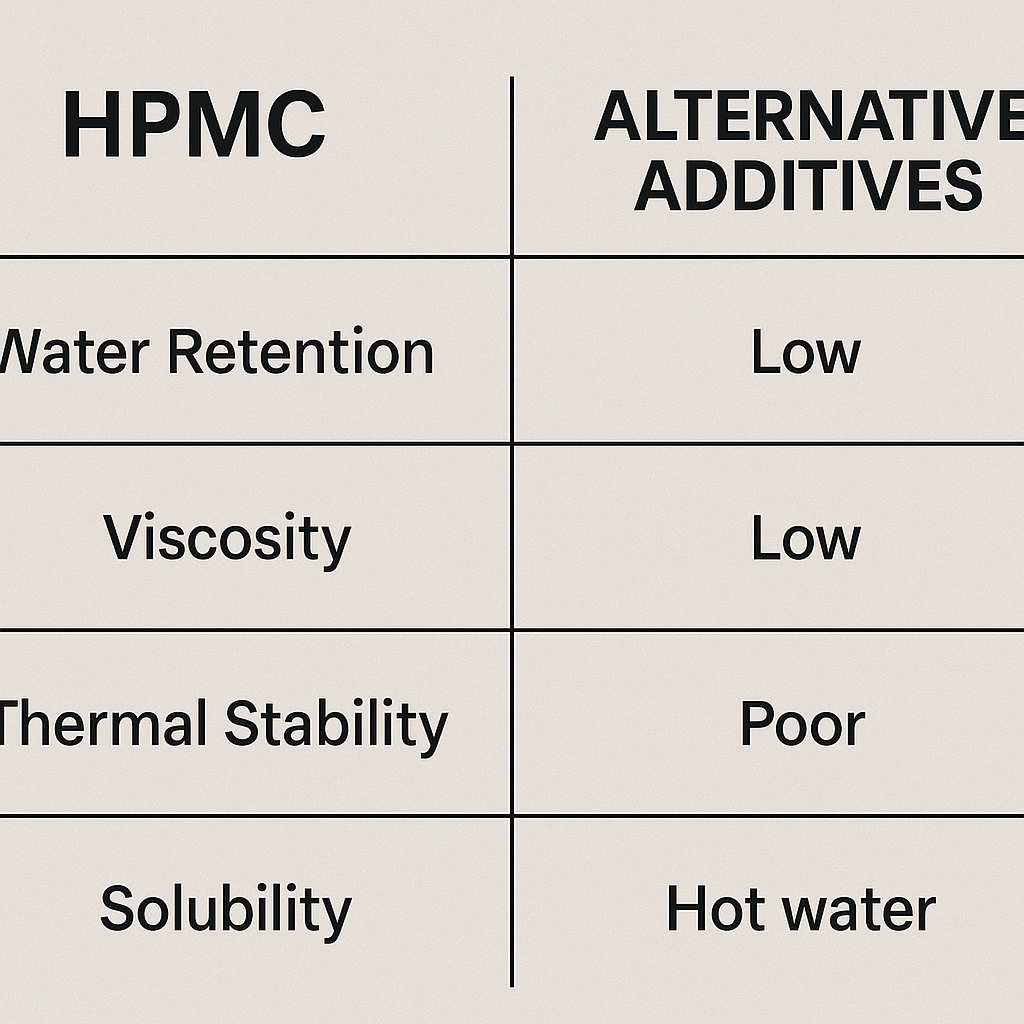

HPMC outperforms alternatives by offering superior water retention, consistent viscosity across temperature fluctuations, effective performance at lower dosages, longer shelf life, and environmental benefits as a plant-derived, biodegradable polymer. It also provides excellent compatibility with most formulation ingredients.

Through my years of HPMC production and customer support, I've collected extensive feedback on why our customers prefer HPMC over alternative options. The benefits span economic, performance, and sustainability considerations.

From an economic perspective, HPMC offers excellent cost-efficiency despite its slightly higher initial price compared to some alternatives like methyl cellulose (MC) or carboxymethyl cellulose (CMC). This is because HPMC typically requires lower dosage levels to achieve the same performance results. For example, in tile adhesive formulations, HPMC dosage is generally 25-30% lower than MC while achieving superior water retention.

Performance-wise, HPMC provides remarkable stability across varying application conditions. Unlike some synthetic polymers that may degrade under alkaline conditions common in cement-based applications, HPMC maintains its functional properties in pH environments from 2-12. This wide range of pH stability makes it versatile across multiple application types.

The sustainability profile of HPMC also deserves mention. As a cellulose derivative, it comes from renewable resources, primarily wood pulp or cotton linters. Our production process emphasizes environmental responsibility, with closed-loop systems that minimize waste and energy consumption.

Here's how HPMC compares to common alternatives:

| Feature | HPMC | Methyl Cellulose | CMC | Synthetic Polymers |

|---|---|---|---|---|

| Water Retention | Excellent | Good | Moderate | Variable |

| Temperature Stability | High | Moderate | Low | Variable |

| pH Stability | 2-12 | 3-11 | 4-9 | Limited |

| Biodegradability | Yes | Yes | Yes | Mostly No |

| Salt Tolerance | High | Moderate | Low | Variable |

| Cost-Efficiency | High | Moderate | High | Variable |

| Multi-industry Applicability | Excellent | Good | Limited | Limited |

Conclusion

HPMC stands as a versatile, high-performance additive that delivers exceptional water retention, viscosity control, and binding properties across multiple industries. Its ability to enhance product quality while offering economic and environmental benefits makes it an ideal choice for manufacturers seeking reliable, consistent results.

At Wanhong Chemical, we pride ourselves on producing premium HPMC tailored to your specific needs. Contact us today to discover how our expertise can improve your products and processes.

-

Explore how Hydroxypropyl Methylcellulose enhances construction materials and improves performance. ↩

-

Learn about cellulose ether and its diverse applications across various industries. ↩

-

Learn about the specific properties and applications of construction-grade HPMC. ↩ ↩

-

Learn about the impact of molecular weight distribution on product properties. ↩

-

Find out how pharmaceutical-grade HPMC is tailored for specific drug formulations. ↩