Struggling with uneven walls, poor adhesion, and short working time in your construction projects? These common issues often stem from using inadequate additives in your putty and plastering powders.

MHEC (Methyl Hydroxyethyl Cellulose)1 is a specialized cellulose ether that significantly improves workability, water retention, and adhesion in putty powder and plastering powder. It creates optimal consistency for smooth application while extending working time and preventing cracking during drying.

Both professional contractors and DIY enthusiasts have experienced frustration with inferior putty and plastering products. I've seen countless projects compromised by poor material performance, leading to costly rework and delays. Let's explore how the right MHEC can transform your construction materials.

What Are the Major Differences Between Putty Powder and Plastering Powder?

Many customers contact me confused about the distinction between these products. Choosing the wrong one can result in surface defects, poor durability, and wasted materials.

Putty powder is a fine-textured finishing material used to create smooth surfaces and fill minor imperfections, while plastering powder is coarser and thicker, applied as a base layer to level walls and ceilings before finishing. They differ in particle size, application thickness, and drying time.

Diving deeper into these differences helps you select the right product for your specific application. Understanding these distinctions is crucial for achieving professional results.

Key Differences Table:

| Feature | Putty Powder | Plastering Powder |

|---|---|---|

| Particle Size | Very fine (45-75 μm) | Coarser (75-150 μm) |

| Application Thickness | Thin (0.5-2mm) | Thicker (5-15mm) |

| Drying Time | Faster (2-4 hours) | Slower (24-48 hours) |

| Function | Finishing, smoothing | Base leveling, structural |

| MHEC Requirement | Lower viscosity (30,000-60,000 mPa·s) | Higher viscosity (60,000-100,000 mPa·s) |

| Surface Compatibility | Better for smooth surfaces | Suitable for rough surfaces |

| Water Resistance | Usually lower | Usually higher |

In my experience working with clients across Saudi Arabia and UAE, confusion between these products often leads to project delays. Plastering powder provides the structural foundation that addresses major surface irregularities, while putty powder2 delivers that perfect finish that makes walls ready for painting. The MHEC requirements differ significantly between these applications, which is why proper cellulose ether selection is critical for optimal performance.

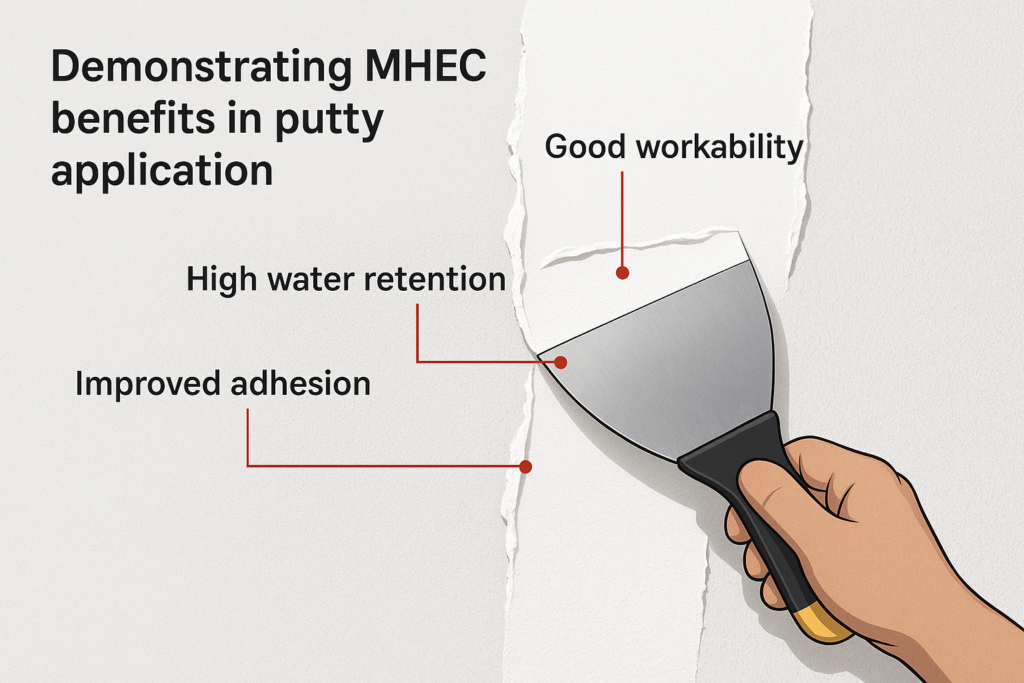

What Benefits Does MHEC Provide for Putty Powder and Plastering Powder?

When customers complain about cracking, poor adhesion, or difficult application, I immediately suspect they're using inadequate MHEC in their formulation. The right cellulose ether transforms the entire application experience.

MHEC enhances water retention in both putty and plastering powders, preventing premature drying and ensuring proper cement hydration. It improves workability by creating ideal consistency, enhances adhesion to various substrates, and reduces sagging on vertical surfaces while minimizing cracking during the drying process.

The benefits of proper MHEC integration extend far beyond basic consistency improvement. When I consult with large mortar factories in developing markets, I emphasize these critical performance enhancements.

MHEC's molecular structure creates a three-dimensional network within the mortar matrix that fundamentally changes how the material behaves during application and drying. The hydroxypropyl groups in MHEC interact with water molecules, temporarily binding them within the mixture. This controlled water release mechanism is particularly crucial in hot climates like Saudi Arabia, UAE, and Iran, where rapid evaporation can compromise material performance.

Our laboratory tests demonstrate that properly formulated MHEC can extend working time by 30-40% compared to standard formulations. This provides applicators with crucial additional time for proper leveling and smoothing, especially important for large surface areas or complex architectural features.

The thixotropic properties imparted by MHEC allow the material to flow smoothly during application yet remain stable once applied. This balance is critical for both putty and plastering applications, though the ideal viscosity profiles differ between them – putty requires greater spreadability while plastering needs enhanced stability against sagging.

Why Is Performance Optimization in Putty Powder and Plastering Putty So Important?

I've witnessed countless construction projects derailed by poor-performing materials. Surface defects, adhesion failures, and excessive shrinkage create costly rework and damage professional reputations.

Performance optimization in putty and plastering products directly impacts application efficiency, material consumption, and final surface quality. Properly optimized formulations reduce labor costs by enabling faster application, minimize material waste through better coverage, and ensure long-term durability by preventing cracking and delamination.

The consequences of overlooking performance optimization extend throughout the construction process and the building's lifetime. This is why I emphasize comprehensive formulation development with our customers.

When working with major distributors in Pakistan and India, I consistently highlight how performance optimization affects the entire construction value chain. A properly optimized putty or plaster doesn't just make the applicator's job easier – it fundamentally transforms project economics and outcomes.

Consider the mathematical reality: a 15% improvement in workability typically translates to at least 10% faster application time. For a commercial project with 10,000 square meters of wall surface, this time savings can amount to days of labor reduction. Similarly, enhanced adhesion reduces material waste from falloff by 5-8% in real-world conditions, directly impacting the bottom line.

Beyond immediate application benefits, long-term performance is equally critical. Our testing protocols simulate accelerated aging and environmental exposure, demonstrating that properly optimized formulations with quality MHEC show 30% less microcracking after thermal cycling compared to standard formulations. This directly correlates with extended service life and reduced maintenance costs.

For factory owners producing these materials, formulation optimization also impacts production efficiency. Well-dispersed MHEC reduces mixing time and energy consumption while improving batch consistency – critical factors for high-volume manufacturing operations in competitive markets like Vietnam and the Philippines.

What Are the 3 Most Common Issues During Putty Application?

I regularly hear from contractors about recurring challenges that compromise their efficiency and results. These persistent problems often have simple solutions rooted in proper material formulation.

The most common issues during putty application are poor workability causing difficult spreading and uneven surfaces, premature drying that leads to inadequate time for proper finishing, and cracking or delamination after drying due to excessive shrinkage or inadequate adhesion to the substrate.

Understanding these challenges in depth helps identify the right MHEC specifications for your specific application requirements and environmental conditions.

Issue 1: Poor Workability and Application Properties

This problem manifests as difficulty achieving smooth surfaces, excessive drag during troweling, and inconsistent material behavior. The root cause typically lies in improper viscosity profiles of the cellulose ether component. In hot climates like Saudi Arabia, this issue becomes particularly problematic as materials stiffen more quickly.

The solution involves selecting MHEC with appropriate viscosity3 (typically 40,000-60,000 mPa·s for putty applications) and ensuring proper dispersibility. Our MHEC products feature optimized particle size distribution that enables rapid dissolution without forming lumps or "fish eyes" during mixing. This creates a homogeneous mixture that maintains consistent workability throughout the application process.

Issue 2: Premature Drying and Insufficient Working Time

When putty dries too quickly, applicators cannot properly finish surfaces, leading to visible trowel marks, poor leveling, and difficulty achieving smooth transitions. This issue is particularly prevalent in low-humidity environments and areas with high airflow.

The water retention capability of MHEC directly addresses this challenge. Our higher-substitution grades provide superior water retention, extending working time by up to 45 minutes compared to standard formulations. This gives applicators crucial additional time for proper finishing while ensuring the material remains responsive to tooling. The methoxyl and hydroxyethyl substitution pattern in our MHEC products creates optimal water interaction for balanced drying profiles.

Issue 3: Post-Application Defects (Cracking and Delamination)

Perhaps the most costly issue occurs after application – when cracks develop during drying or the material separates from the substrate. These defects often require complete removal and reapplication, dramatically increasing project costs.

Proper MHEC selection addresses this by controlling the drying profile and enhancing adhesion to various substrates. Our testing shows that optimized MHEC formulations reduce shrinkage stress by creating microstructures that accommodate volume changes during drying. Additionally, the hydroxyl groups in MHEC enhance bonding with both organic and inorganic substrates, increasing adhesion strength by 20-30% compared to basic formulations.

Why Should You Choose WANHONG for High-Quality Additives for Your Putty Powder and Plastering Powder?

After testing numerous suppliers, customers often tell me they've wasted time and money on inconsistent products. Finding a reliable MHEC source is crucial for maintaining production quality and meeting customer expectations.

WANHONG4 offers superior MHEC additives with precise viscosity control, exceptional consistency between batches, and customized solutions for specific climate conditions. Our technical support team provides formulation assistance, while our six production lines ensure reliable supply and competitive pricing for markets across Saudi Arabia, UAE, India, and beyond.

My commitment extends beyond simply selling products – I partner with customers to optimize their formulations for specific market requirements and application conditions.

At WANHONG, we understand that MHEC is not a commodity but a critical performance component in your formulations. Our dedicated research team continually refines our manufacturing processes to deliver products with exceptionally narrow property distributions, ensuring that what works in your laboratory consistently performs identically in production.

Our technical capability extends to customized solutions for specific challenges. For example, when working with a major mortar manufacturer in Brazil facing extreme humidity fluctuations between seasons, we developed a specialized MHEC grade with modified substitution patterns that maintained consistent performance across varying conditions. This reduced their formulation adjustments and quality control issues throughout the year.

Our six production lines not only ensure reliable supply but also allow us to maintain dedicated equipment for specific product grades, minimizing cross-contamination risks and enabling faster transitions between production runs. This manufacturing flexibility translates directly to more responsive customer service and shorter lead times – critical advantages in fast-moving construction markets.

Beyond product quality, our comprehensive support includes on-site troubleshooting, application testing, and competitive analysis to help you gain market advantage. Many customers in developing markets particularly value our formulation expertise, which helps them compete effectively against multinational brands while maintaining healthy margins.

Conclusion

Selecting the right MHEC is crucial for optimizing putty and plastering powder performance. WANHONG provides superior additives with consistent quality, technical support, and reliable supply to enhance your products' workability, water retention, and durability across diverse applications and environments.

-

Explore how MHEC enhances construction materials, improving workability and adhesion. ↩

-

Learn about putty powder's role in achieving smooth surfaces and its application techniques. ↩

-

Explore the role of viscosity in achieving the desired consistency and workability. ↩

-

Learn why WANHONG is a trusted source for high-quality construction additives and support. ↩