Many manufacturers struggle with product cohesion and stability issues. Poor binding agents lead to crumbling products, inconsistent texture, and customer complaints. HPMC binder1 offers a reliable solution.

HPMC (Hydroxypropyl Methylcellulose2) is a versatile binding agent used across multiple industries because it creates strong bonds between particles while remaining non-toxic, water-soluble, and compatible with many formulations. Its thermal gelation properties make it ideal for maintaining product integrity during manufacturing processes.

As a manufacturer of HPMC for over two decades, I've seen countless clients transform their product quality after switching to our binding agents. The versatility and reliability of HPMC make it stand out from other binders on the market. Let's explore why this cellulose derivative has become essential across so many industries.

Why is HPMC Used as a Binder?

Inconsistent product quality3 and customer complaints often stem from poor binding choices. Many manufacturers don't realize their binding agent is the root cause of their production issues.

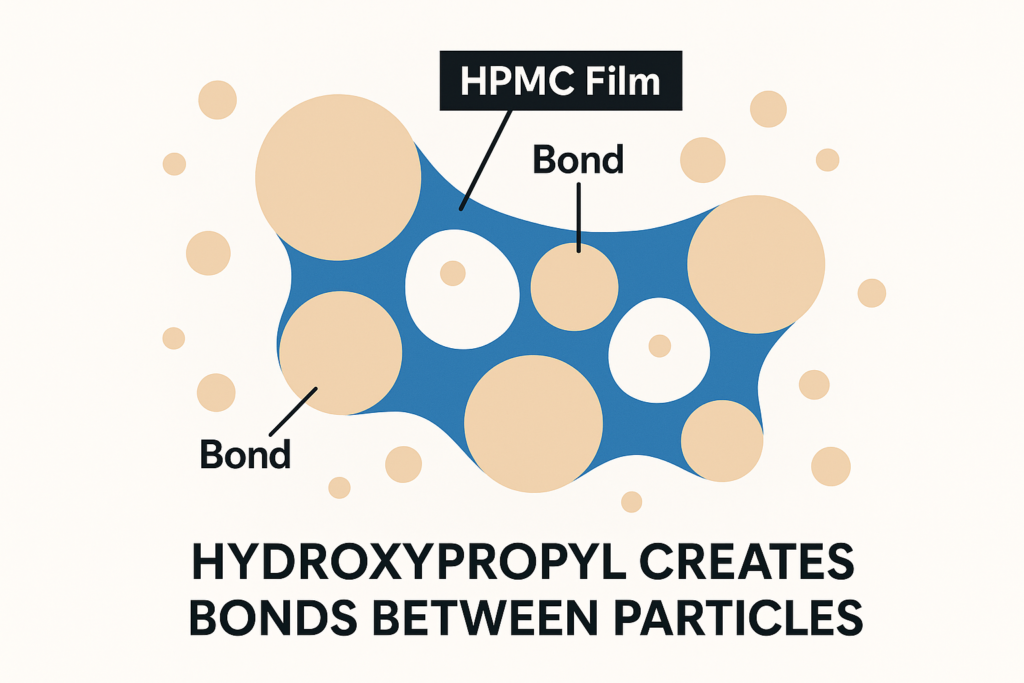

HPMC works as a binder by forming hydrogen bonds between particles while creating a thin film that locks ingredients together. Its unique chemistry allows it to function effectively in both dry and wet applications, making it versatile across products ranging from pharmaceuticals to construction materials4.

HPMC's binding capabilities stem from its unique molecular structure. Unlike traditional binders, HPMC contains both hydrophilic and hydrophobic components, giving it exceptional versatility. This dual nature allows it to interact with a wide range of materials.

In practical applications, I've observed HPMC's remarkable binding strength even at low concentrations. Typically, a 2-5% HPMC solution provides sufficient binding for most applications. This efficiency translates to cost savings for manufacturers.

The binding mechanism involves three key stages. First, HPMC molecules hydrate when mixed with water. Next, they form a viscous solution that coats particles evenly. Finally, as water evaporates, the HPMC forms strong hydrogen bonds between particles, creating a cohesive matrix.

Binding Strength Comparison

| Binder Type | Relative Binding Strength | Water Resistance | Cost Efficiency |

|---|---|---|---|

| HPMC | High | Good | Excellent |

| PVA | Medium | Poor | Good |

| Starch | Low | Poor | Excellent |

| Acrylic | High | Excellent | Poor |

This combination of properties explains why HPMC has become my most recommended binding solution across diverse applications.

HPMC Binder Solution Preparation

Improper preparation of binder solutions leads to lumping, uneven distribution, and product failure. Many production issues trace back to rushed or incorrect mixing procedures.

To prepare an HPMC binder1 solution, first disperse HPMC powder in cold water (below 20°C) while stirring continuously. Allow it to fully hydrate for 30-60 minutes, then gradually heat to desired temperature if needed. The concentration typically ranges from 1-5% depending on the application.

From my years of supporting manufacturers, I've identified several critical factors that influence HPMC solution quality. Water temperature is perhaps the most crucial element. Using water above 25°C during initial dispersion often results in lumping, as HPMC forms a gel layer around powder particles, preventing further hydration.

The mixing equipment also significantly impacts solution quality. High-shear mixers generally produce better results than standard stirrers, especially for higher viscosity grades. I recommend starting with a rapid mixing phase (300-500 rpm) during powder addition, followed by a moderate speed (150-200 rpm) during the hydration phase.

For industrial applications, we've developed a specialized preparation method:

- Create a vortex in cold water using appropriate agitation

- Slowly add HPMC powder to the vortex edge, not the center

- Continue mixing at high speed for 10-15 minutes

- Reduce speed and allow hydration for at least 45 minutes

- Adjust final viscosity by adding more water if needed

This method consistently produces homogeneous solutions free of fish-eyes or lumps, which is essential for maintaining product quality and production efficiency.

Applications of HPMC Binder:

Finding the right binder for varied applications frustrates many manufacturers. Switching binders between products increases inventory costs and complicates production processes.

HPMC binder1 finds applications in pharmaceuticals (tablet binding and film coating), construction (tile adhesives and mortars), food products (as a thickener and binder), personal care items (gels and creams), and ceramics (providing green strength). Its versatility stems from its non-toxic nature and compatibility with numerous ingredients.

Having supplied HPMC to diverse industries for many years, I've observed its remarkably broad application range. In pharmaceutical manufacturing, HPMC serves as the primary binding agent in direct compression tablets, where it creates strong bonds without requiring excessive compression force. This helps maintain quick dissolution profiles while ensuring tablet integrity.

The construction sector represents one of our largest markets for HPMC binders. In tile adhesives, HPMC provides crucial water retention, preventing rapid dehydration when applied to porous substrates. This extends open time and improves adhesion. Similarly, in renders and plasters, HPMC enhances workability while strengthening the bond between the material and the substrate.

HPMC Usage Rates by Application

| Application | HPMC Grade | Typical Usage Rate | Key Benefit |

|---|---|---|---|

| Tablet binding | Pharmaceutical grade | 2-5% | Controlled dissolution |

| Tile adhesive | Construction grade | 0.3-0.6% | Water retention |

| Food products | Food grade | 0.5-2% | Texture improvement |

| Cosmetic gels | Cosmetic grade | 1-3% | Stability enhancement |

| Ceramic extrusion | Technical grade | 0.5-1.5% | Green strength |

Beyond these applications, I've witnessed innovative uses emerging in 3D printing filaments, biodegradable packaging, and advanced wound dressings. The versatility of HPMC as a binder continues to expand as manufacturers discover its unique combination of properties.

Advantages of HPMC Binder

Manufacturers often settle for suboptimal binders, accepting product inconsistencies and high rejection rates. This compromises quality and increases production costs over time.

HPMC binder offers advantages including non-toxicity, excellent binding strength, thermal gelation capability, pH stability, and compatibility with both water-soluble and water-insoluble ingredients. It also provides good film-forming properties and consistent viscosity across production batches.

In my experience working with hundreds of manufacturers, the most frequently cited benefit of HPMC is its consistent performance across varying production conditions. Unlike many natural binders that show significant batch-to-batch variation, HPMC delivers predictable results that streamline manufacturing processes and reduce quality control issues.

The thermal gelation property deserves special attention. HPMC uniquely forms a gel when heated and reverts to solution when cooled. This property proves invaluable in applications like construction materials, where it helps retain water during initial setting stages before releasing it gradually as curing progresses. I've seen this property significantly improve the performance of tile adhesives in hot climate installations.

HPMC's chemical stability across pH ranges from 2 to 12 allows it to maintain binding effectiveness in acidic formulations like certain pharmaceutical products and alkaline environments like cement-based materials. This pH tolerance eliminates the need for multiple binders across product lines.

From a regulatory perspective, HPMC offers significant advantages. Its approval by major regulatory bodies (FDA, EFSA, JECFA) simplifies compliance documentation. For international manufacturers, this broad acceptance reduces the need for formula modifications between markets.

Environmental and Economic Benefits

| Benefit Category | HPMC Advantage | Business Impact |

|---|---|---|

| Biodegradability | Naturally degradable | Supports sustainability claims |

| Usage concentration | Effective at low concentrations | Cost savings in formulation |

| Processing energy | Low energy requirement | Reduced production costs |

| Shelf stability | Excellent stability | Less waste from expired materials |

These combined advantages explain why we've seen consistent growth in HPMC binder adoption across all major markets we serve.

Stability and Storage Conditions

Poor storage practices often degrade binder quality, leading to manufacturing inconsistencies and product failures. Many don't realize their storage methods are compromising binder performance.

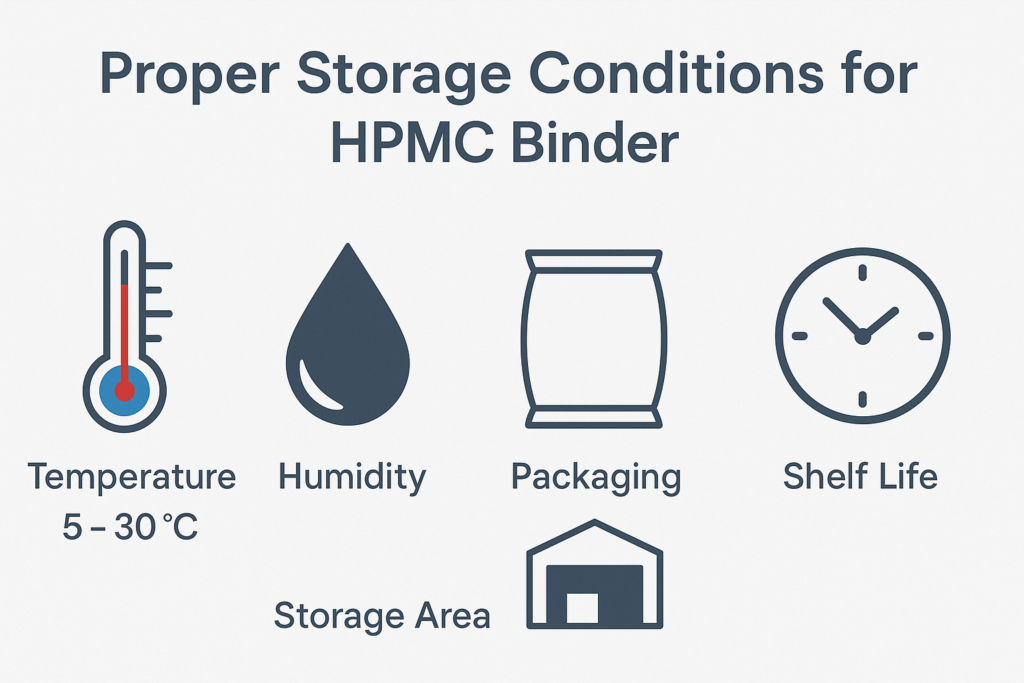

HPMC binder5 remains stable for up to 24 months when stored in its original sealed packaging in cool, dry conditions (below 25°C and 60% relative humidity). It should be protected from direct sunlight, extreme temperatures, and high moisture environments to maintain its binding properties.

Throughout my years advising clients on HPMC usage, I've noticed that storage conditions often determine the ultimate performance of the binding agent. In one memorable case, a customer experienced sudden quality issues despite using the same HPMC grade they'd successfully used for years. Our investigation revealed they had relocated their raw material storage to an area with significantly higher humidity, causing the HPMC to partially hydrate before use.

Temperature fluctuations6 pose another significant risk to HPMC stability. While the material itself is thermally stable, repeated temperature cycling can cause moisture condensation within packaging, leading to localized hydration and clumping. I always recommend maintaining consistent storage temperatures, ideally between 15-25°C.

The packaging material also plays a crucial role in maintaining HPMC quality. Our standard multi-layer kraft paper bags with a polyethylene inner liner provide excellent protection, but once opened, the material should be transferred to airtight containers if not used immediately. For clients in extremely humid environments like Southeast Asia, we sometimes recommend aluminum-lined packaging for additional moisture protection.

HPMC Stability Under Different Storage Conditions

| Storage Condition | Expected Shelf Life | Observable Changes | Performance Impact |

|---|---|---|---|

| Ideal (15-25°C, <60% RH) | 24+ months | None | No impact |

| High humidity (>70% RH) | 12-18 months | Slight clumping | Reduced dissolution speed |

| Temperature cycling | 12-18 months | Hard lumps | Inconsistent hydration |

| Improper resealing | 6-12 months | Moisture absorption | Viscosity changes |

For bulk users, I typically recommend implementing a first-in-first-out inventory system and maintaining detailed storage records that include temperature and humidity data, especially for materials stored longer than 12 months.

High-quality HPMC Binder Supplier

Finding reliable HPMC suppliers presents challenges like inconsistent quality, limited technical support, and unstable supply chains. These issues disrupt production schedules and compromise product quality.

A high-quality HPMC binder1 supplier should offer consistent product specifications, technical application support, transparent quality control processes, reliable delivery schedules, and customization options. Look for manufacturers with proper certifications (ISO 9001, GMP), extensive experience, and capability to provide documentation for regulatory compliance.

As a manufacturer with six dedicated production lines for cellulose ethers, I've learned that supplier selection significantly impacts the success of products using HPMC binder1s. Beyond basic quality considerations, several factors separate premium suppliers from average ones.

Production technology makes a substantial difference in final product consistency. Our advanced etherification reactors and precisely controlled processing parameters ensure batch-to-batch consistency that many smaller manufacturers cannot match. This translates directly to predictable performance in our customers' applications.

Quality control methodology is another critical differentiator. We implement 100% batch testing rather than statistical sampling, with each production lot undergoing comprehensive analysis including viscosity profiling, substitution degree verification, and application-specific testing. For customers in regulated industries, we provide detailed certificates of analysis with every shipment.

Technical support capability often proves decisive for manufacturers developing new products. Our team includes application specialists with industry-specific expertise who can provide formulation assistance, troubleshooting support, and optimization recommendations. This collaborative approach has helped many customers reduce development time and improve final product performance.

Evaluating HPMC Supplier Capabilities

| Evaluation Criteria | Questions to Ask | Why It Matters |

|---|---|---|

| Production capacity | Annual output and dedicated lines | Ensures supply stability |

| Quality systems | Certifications and testing protocols | Guarantees consistent quality |

| Technical expertise | Industry experience and support team | Provides application assistance |

| Customization ability | Modified grades and packaging options | Meets specific requirements |

| Supply chain reliability | Geographic distribution and logistics | Prevents production delays |

When selecting an HPMC supplier, I recommend requesting samples from multiple production batches to verify consistency, conducting site audits when possible, and establishing clear communication channels with both technical and commercial teams to ensure responsive support throughout your partnership.

Conclusion

HPMC stands as an exceptional binding agent across multiple industries due to its versatility, consistent performance, and excellent compatibility. By choosing a reliable supplier with proper technical support, manufacturers can significantly improve their product quality and production efficiency.

-

Explore the advantages of HPMC binder to enhance product quality and stability in various industries. ↩ ↩ ↩ ↩ ↩

-

Learn about Hydroxypropyl Methylcellulose and its versatile applications across multiple sectors. ↩

-

Explore strategies to enhance product quality through effective binder selection. ↩

-

Understand how HPMC enhances the performance of construction materials like tile adhesives. ↩

-

Find out more about HPMC binder and its versatile applications across various industries. ↩

-

Explore the impact of temperature changes on the stability of materials like HPMC. ↩