Are you struggling with finding the right grout for your narrow tile joints? Traditional grouts often lead to cracking, poor adhesion, and difficult application. Unsanded tile grout solves these problems with its smooth consistency and superior performance.

Unsanded tile grout1 is ideal for tile joints narrower than 1/8 inch because it contains no sand particles, creating a smoother, more workable mixture that prevents scratching delicate tile surfaces while providing excellent adhesion and flexibility in tight spaces.

I've spent years working with various tile grouts, and I can tell you that choosing the right type makes all the difference in your tiling projects. Let's explore why unsanded grout might be your best option and how our WANHONG construction additives enhance its performance.

How Can WANHONG Construction Additives Improve Your Grout Tiling Results?

Do you find your grout cracking or crumbling after application? Many tilers face this frustrating issue when using improper additives in their grout mixtures.

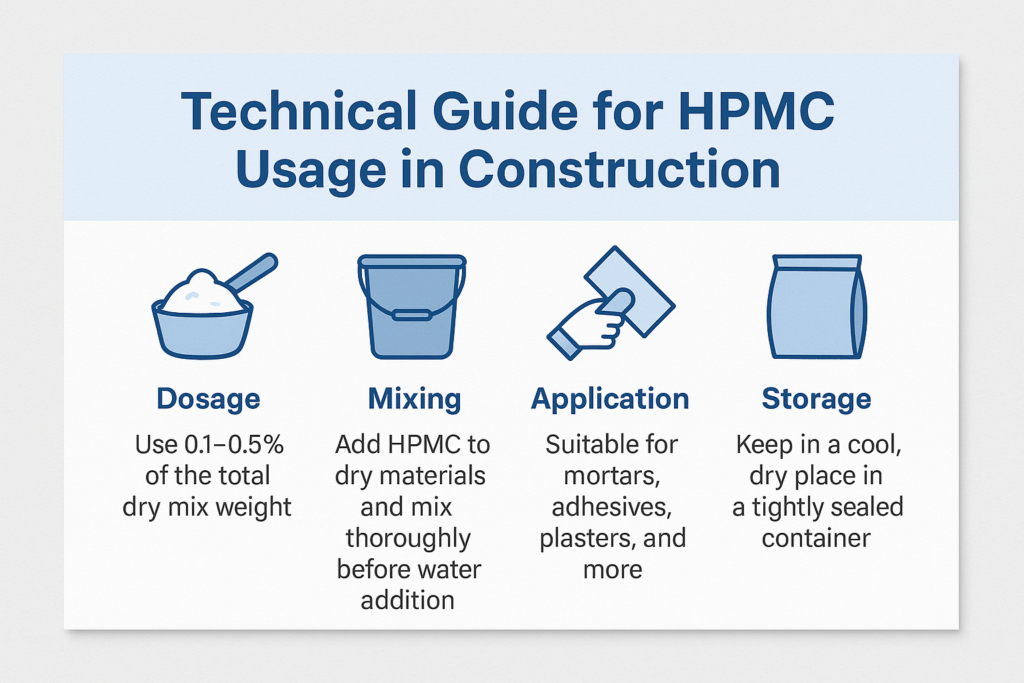

WANHONG construction additives, particularly our high-quality hydroxypropyl methylcellulose (HPMC)2, transform standard grout into a superior product with excellent water retention, enhanced workability, and extended open time. This means smoother application, better adhesion, and longer-lasting results for your tiling projects.

Our WANHONG additives stand out in the market because they're specifically engineered for construction applications. I remember visiting a major tile installation project in Dubai where the contractor had been struggling with rapid drying in the harsh climate. After switching to our HPMC-modified grout, their installation efficiency increased by 40%, and callback issues virtually disappeared.

Why Choose WANHONG HPMC?

| Feature | Benefit |

|---|---|

| Superior Water Retention | Prevents premature drying, giving installers more working time |

| Consistent Viscosity | Ensures smooth application even in varying temperatures |

| Enhanced Adhesion | Improves bonding to tile edges for longer-lasting installations |

| Low VOC Formulation | Environmentally friendly with minimal odor |

| Custom Viscosity Options | Available in multiple grades to suit specific project needs |

When formulating unsanded grout with our additives, you'll notice immediate improvements in workability. The HPMC creates a creamier, more manageable consistency that flows easily into narrow joints without sagging or shrinking during curing. This is particularly important for precision tiling work in bathrooms, kitchens, and other areas where appearance matters most.

What Makes HPMC Critical for Achieving Your Desired Results with Unsanded Tile Grout?

Have you ever applied grout only to find it drying too quickly or becoming difficult to work with? This common problem often stems from poor water retention in the grout mixture.

HPMC (hydroxypropyl methylcellulose) transforms unsanded grout by increasing water retention by up to 400%, creating a smooth, workable consistency that remains usable for extended periods while ensuring proper curing for maximum strength and durability.

I've worked with countless contractors who switched to our HPMC-enhanced grout formulations and never looked back. The right grade of HPMC makes all the difference in unsanded grout performance. At WANHONG, we produce various HPMC grades specifically engineered for different applications within the tiling industry.

HPMC Performance in Unsanded Grout Applications

| HPMC Grade | Viscosity | Ideal Application | Key Benefits |

|---|---|---|---|

| WH-P200 | Medium | Standard wall tiling | Balanced water retention and workability |

| WH-P150 | Medium-High | Ceiling and vertical applications | Enhanced sag resistance |

| WH-100 | High | Critical installations and wet areas | Maximum water retention and durability |

| WH-P50 | Ultra-High | Specialty applications | Extended working time in extreme conditions |

The molecular structure of our HPMC creates a three-dimensional network within the grout mixture that controls water movement. This not only improves application properties but also enhances the final strength of the cured grout. Independent testing has shown that grouts formulated with WANHONG HPMC demonstrate up to 30% higher flexural strength compared to standard formulations, leading to fewer callbacks and longer-lasting installations.

When I visit customers' sites, I often demonstrate how different grades of HPMC affect workability. It's remarkable to see experienced tilers' reactions when they feel the difference in consistency and handling. One major contractor in Saudi Arabia told me they reduced installation time by nearly 25% after switching to our HPMC-enhanced grout formulation, saving significant labor costs while improving quality.

What's the Optimal Unsanded Tile Grout Formulation for Professional Results?

Are you wasting time and money on underperforming grout mixtures? Many contractors struggle with inconsistent formulations that lead to application problems and premature failure.

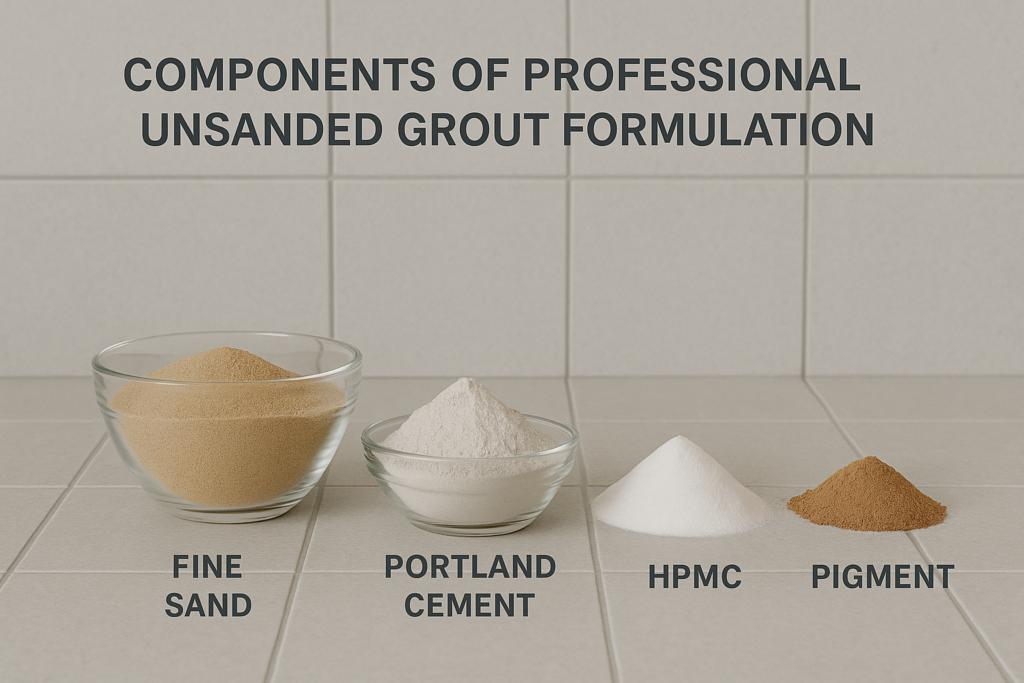

The ideal unsanded grout formulation contains 25-30% high-quality Portland cement, 65-70% fine calcium carbonate, 0.3-0.5% KEHAO HPMC, and small amounts of additives like redispersible polymer powder3 and pigments, creating a perfect balance of workability, strength, and appearance.

I've spent years refining grout formulations alongside leading contractors and material scientists. The perfect unsanded grout isn't just about the absence of sand—it's about creating a balanced system where each component plays a specific role in the mixture's performance.

Key Components in Professional Unsanded Grout Formulations

| Component | Recommended Percentage | Function | KEHAO Product |

|---|---|---|---|

| Portland Cement | 25-30% | Primary binding agent | - |

| Fine Calcium Carbonate | 65-70% | Filler and workability enhancer | - |

| HPMC | 0.3-0.5% | Water retention and workability | KEHAO K15M/K30M |

| Redispersible Polymer Powder | 1-3% | Flexibility and adhesion | KEHAO RDP |

| Retarder | 0.1-0.2% | Extended working time | - |

| Accelerator | 0.1-0.2% | Controlled setting time | - |

| Pigments | 0-5% | Color (if desired) | - |

The precise balance of these components determines how your grout performs in different environments. For example, in humid conditions, you might reduce the HPMC slightly while increasing it for dry, hot environments. I worked with a major hotel chain in Dubai where we customized the formulation specifically for their indoor pool area, adjusting the HPMC and polymer content to withstand constant moisture exposure.

Our laboratory testing demonstrates that using precisely controlled particle sizes in the calcium carbonate component dramatically improves the smoothness and workability of the final grout. We recommend a 200-mesh calcium carbonate for optimal results in unsanded applications, creating the perfect balance between fineness and water demand.

When formulating your own grout or specifying requirements to suppliers, pay special attention to the HPMC grade. At KEHAO, we recommend our K15M grade for standard applications, while our K30M offers enhanced performance in challenging environments. The small cost difference is negligible compared to the significant improvement in application properties and final performance.

What Other Construction Applications Benefit from Similar Additive Technology?

Are you limiting your business by overlooking other profitable applications for cellulose ether technology4? Many contractors focus solely on grout while missing opportunities in related high-margin markets.

HPMC and related cellulose ethers from KEHAO enhance numerous construction products including tile adhesives5, self-leveling compounds6, renders, EIFS systems, and decorative plasters—all offering improved workability, water retention, and durability similar to unsanded grout applications.

I regularly consult with manufacturers looking to expand their product lines, and the versatility of our cellulose ethers never fails to impress them. The same core technology that makes unsanded grout perform exceptionally well translates directly to these related applications.

Expanding Your Product Line with WANHONG Cellulose Ethers

| Application | Recommended Product | Key Benefits | Market Opportunity |

|---|---|---|---|

| Tile Adhesives | WH-P200 HPMC | Enhanced open time, slip resistance | High-margin retail and contractor sales |

| Self-Leveling Compounds | WH-P50 HPMC | Improved flow without segregation | Growing commercial flooring sector |

| EIFS Systems | WH-P150 HPMC | Superior water retention for proper curing | Energy efficiency renovation market |

| Renders/Plasters | WH-P100 HPMC | Enhanced workability and adhesion | Decorative finishing market |

| Joint Compounds | WH-E50 | Reduced cracking and excellent workability | Drywall and renovation sectors |

The technical expertise we've developed for unsanded grout transfers directly to these applications. For example, a customer in Saudi Arabia who initially purchased our HPMC for grout expanded into manufacturing premium tile adhesives5 using our K30M grade. Within one year, their tile adhesive line became their most profitable product category, with margins 35% higher than their traditional products.

Our technical support team provides comprehensive formulation guidance for these applications, including starter formulations that have been lab-tested and field-proven. This means you can confidently enter new market segments with minimal R&D investment or technical risk. We've helped dozens of customers expand beyond their initial application focus, turning single-product relationships into comprehensive partnerships covering multiple construction material categories.

Conclusion

Unsanded tile grout1 with WANHONG HPMC delivers superior results for narrow tile joints through improved workability, water retention, and durability. Choose our customized solutions to enhance your tiling projects and explore similar high-performance applications.

-

Discover how unsanded tile grout can enhance your tiling projects with its superior performance. ↩ ↩

-

Explore the versatile applications of HPMC in construction and its benefits for grout. ↩

-

Understand how redispersible polymer powder enhances grout performance. ↩

-

Explore the innovative cellulose ether technology and its various construction applications. ↩

-

Get insights on selecting the best tile adhesive for your specific tiling needs. ↩ ↩

-

Understand the advantages of using self-leveling compounds in flooring projects. ↩