Wall cracks1 are frustrating problems that homeowners and contractors face worldwide. These unsightly breaks not only ruin the visual appeal but can signal serious structural issues that worsen with time.

Wall cracks1 occur due to building settlement, temperature fluctuations, moisture changes, structural movement, and poor construction techniques. These issues cause the wall material to expand, contract, or shift, creating visible fissures that require proper treatment to prevent worsening.

Understanding wall cracks is the first step toward effective repair. As someone who has worked in the construction materials industry for years, I've seen countless buildings suffer from improper crack treatment. Let's examine why these cracks occur and how flexible putty provides the best solution.

What Types of Cracks Appear in Walls?

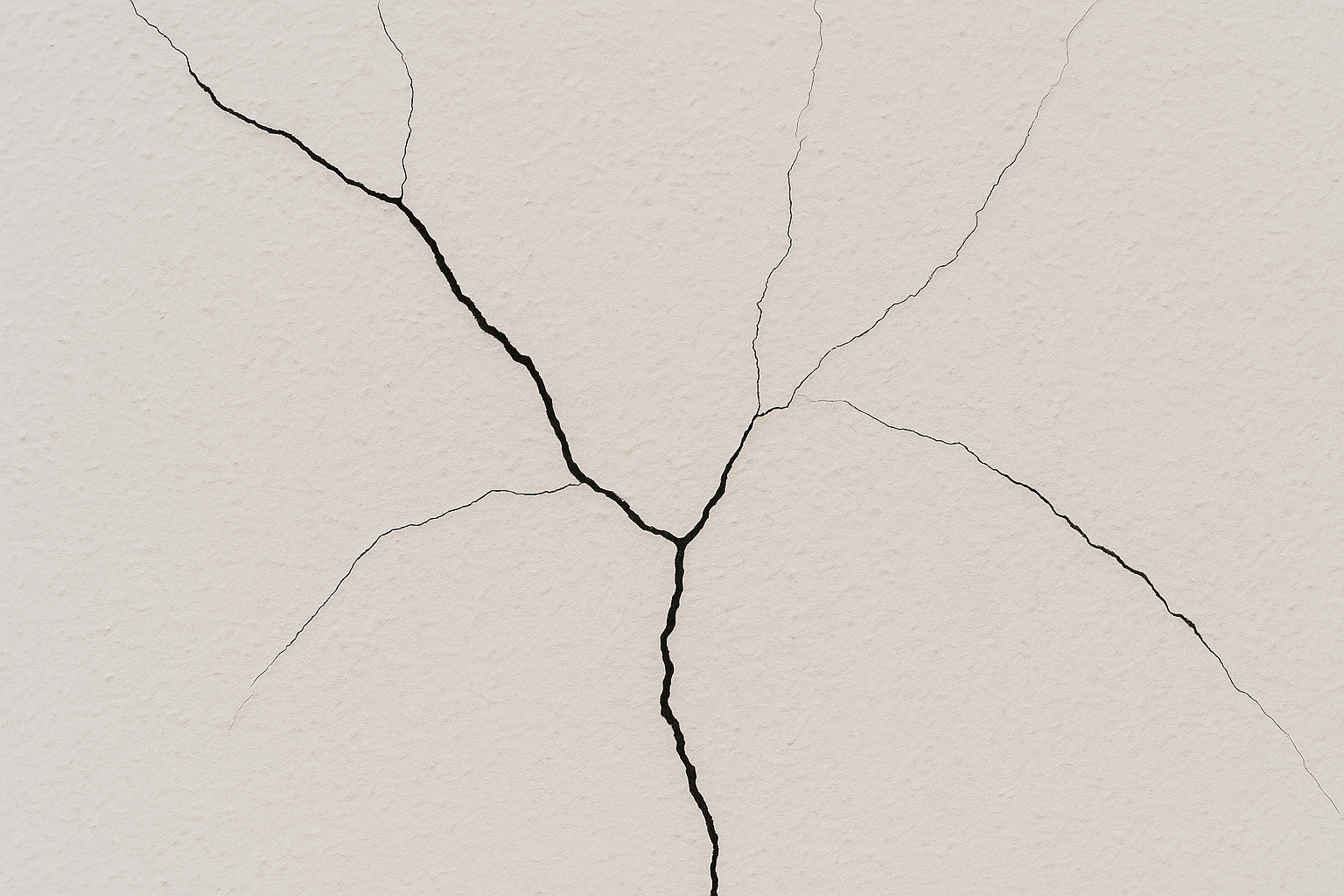

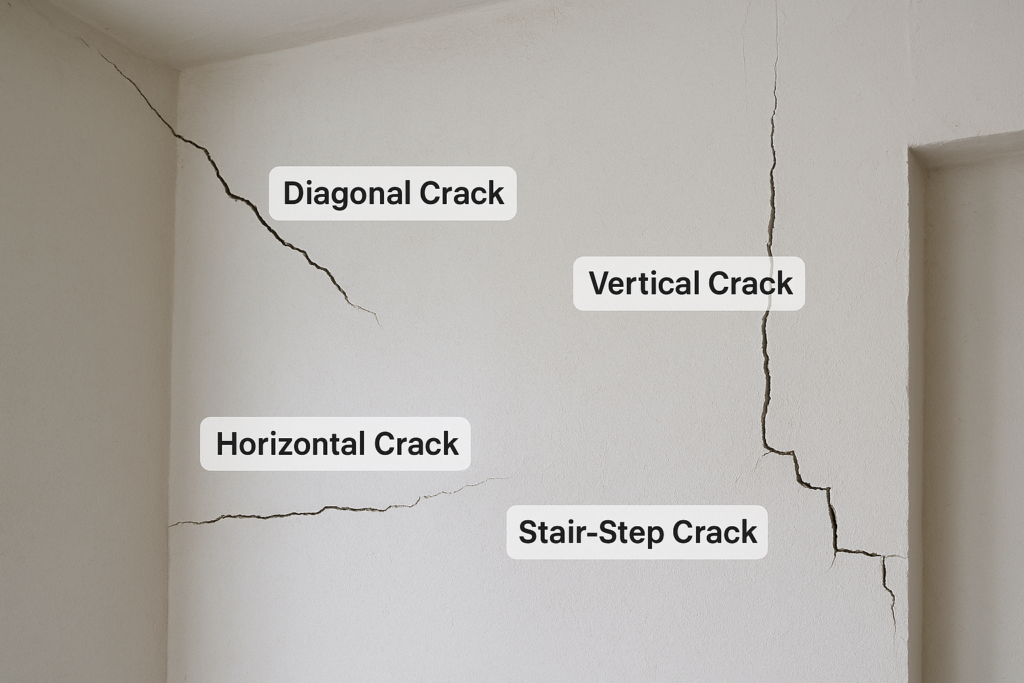

The sight of a new crack in your freshly painted wall can be alarming. Different crack patterns indicate various underlying problems that need specific treatments.

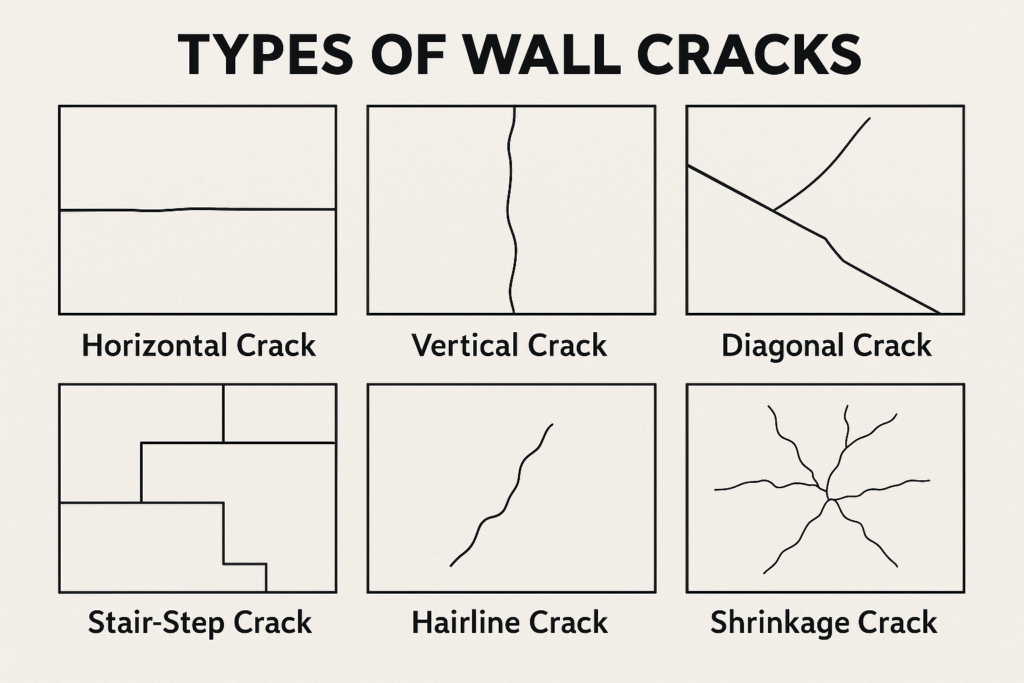

Wall cracks1 typically appear in five main forms: hairline cracks (less than 0.1mm wide), shrinkage cracks (forming patterns), settlement cracks (diagonal, wider at top/bottom), structural cracks (wider than 3mm), and cracks at joints where different materials meet.

Each crack type tells a story about what's happening within your walls. During my factory visits across Saudi Arabia and the UAE, I've seen how regional climate challenges create unique cracking patterns.

Hairline cracks, while seemingly innocent, often indicate the beginning of more serious issues. These fine lines (under 0.1mm) typically appear in new plaster or concrete as materials cure and dry. Though not structurally concerning initially, they can worsen if not addressed.

Shrinkage cracks form distinct patterns and result from materials losing moisture too quickly. I've noticed these are particularly common in hot climates like the Middle East, where rapid drying is a major challenge for contractors.

Settlement cracks appear diagonally and vary in width from one end to another. These indicate foundation movement—a serious issue requiring professional assessment. During my visits to older buildings in developing regions, I've seen how these cracks can progress to compromise structural integrity.

Structural cracks exceeding 3mm width demand immediate attention as they suggest significant structural problems. These often appear after earthquakes, major ground shifting, or in buildings with inadequate structural support.

Joint cracks occur where dissimilar building materials meet. The different expansion and contraction rates create stress points that eventually crack. This is why quality flexible materials are crucial at these junctions.

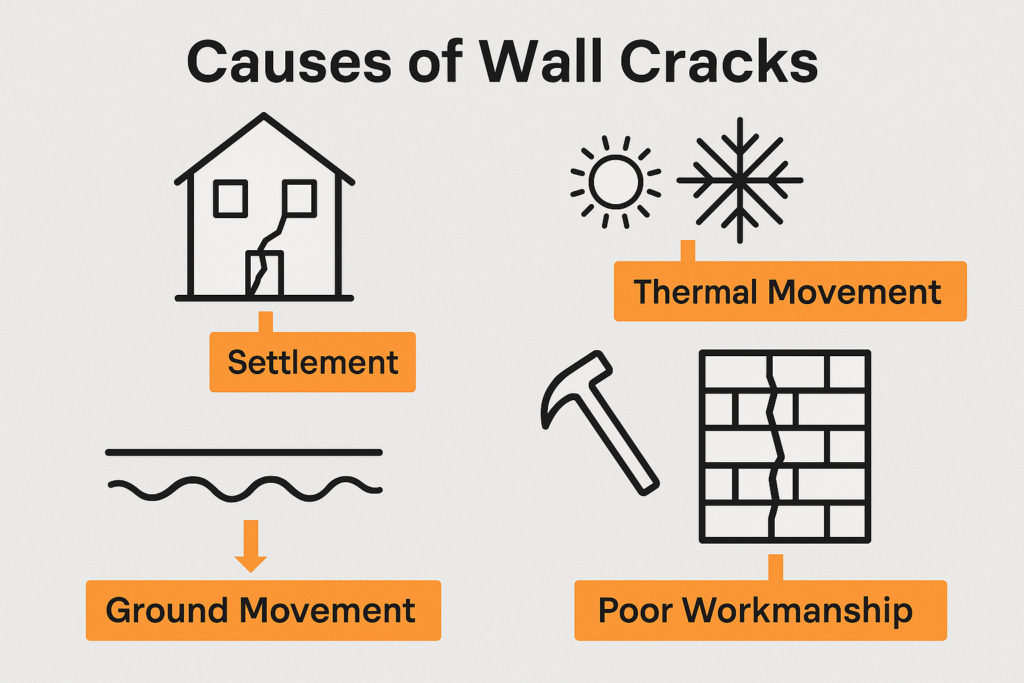

What are the Causes of Cracks in Walls?

Property owners often blame poor construction for wall cracks. While this can be true, many other factors contribute to this common problem.

Wall cracks1 are primarily caused by building settlement, temperature fluctuations, moisture changes, structural movement, and poor construction quality. These factors create stress within wall materials that exceeds their tensile strength, resulting in visible cracking.

My experience working with construction materials across different climate zones has shown me how environmental factors dramatically influence crack formation. In countries like Iran and Saudi Arabia, extreme temperature variations between day and night create significant expansion and contraction cycles in building materials.

Building settlement is a natural process where structures adjust to their weight and soil conditions beneath. This movement creates stress within walls that often results in vertical or diagonal cracks. I've observed this particularly in newer developments built on recently compacted soil.

Temperature fluctuations cause building materials to expand when hot and contract when cold. In regions experiencing extreme temperature ranges, these cycles repeatedly stress wall materials until they crack. During my visits to projects in countries with continental climates, this is consistently reported as a major challenge.

Moisture changes affect building materials similarly to temperature, causing expansion when wet and contraction when dry. This is especially problematic in seasonal climates with distinct wet and dry periods. Materials like concrete and mortar are particularly susceptible to moisture-induced cracking during their curing phase.

Structural movement from external forces such as nearby construction, heavy traffic vibration, or ground subsidence creates stress that walls weren't designed to handle. I've seen entire neighborhoods develop similar crack patterns when new construction begins nearby with heavy equipment.

Poor construction quality remains a significant factor, including improper material mixing, inadequate curing time, and substandard workmanship. I've visited countless sites where contractors rushed the drying process or used incorrect material proportions, virtually guaranteeing future cracking.

| Crack Cause | Common Locations | Appearance | Prevention Method |

|---|---|---|---|

| Settlement | Near foundations | Diagonal, wider at top/bottom | Proper foundation preparation |

| Temperature | Exterior walls | Horizontal or map-like | Expansion joints, flexible materials |

| Moisture | Bathrooms, kitchens | Random patterns | Waterproofing, moisture barriers |

| Structural | Load-bearing walls | Wide, continuous | Engineering assessment, reinforcement |

| Poor Construction | Various | Irregular patterns | Quality materials, proper techniques |

How to Fix Wall Cracks?

Facing a cracked wall can be overwhelming. Many property owners aren't sure whether to attempt repairs themselves or call professionals.

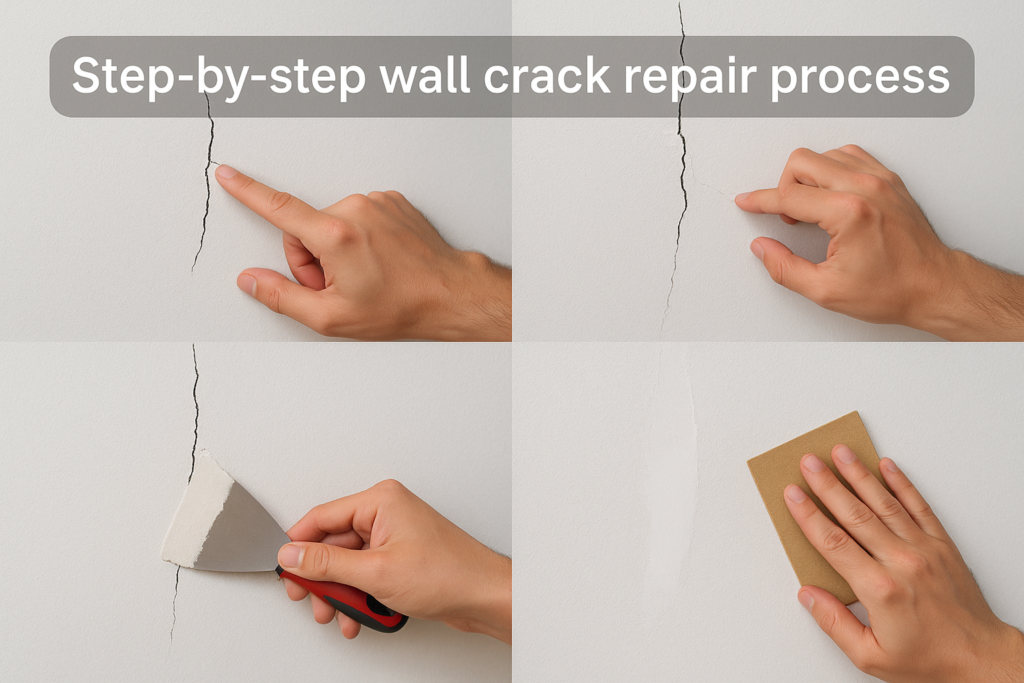

To fix wall cracks effectively, first identify the crack type and cause. Minor cracks can be repaired with flexible putty2 after cleaning and widening the crack slightly. Structural cracks require professional assessment and may need reinforcement before cosmetic repairs.

The repair process must match the crack's severity and underlying cause. Through my work with construction professionals across developing markets, I've learned that proper preparation makes the difference between temporary fixes and lasting repairs.

The first step in any crack repair is proper assessment. Cracks wider than 3mm or those that change size with seasons likely indicate structural issues requiring professional evaluation. I always advise my clients to monitor cracks by marking their ends with a pencil and dating them to track progression.

Surface preparation is critical regardless of crack size. Remove all loose material, dust, and old paint from the crack area. For a stronger bond, slightly widen the crack in a V-shape using a scraper tool. This creates more surface area for the repair material to adhere to.

For hairline and shrinkage cracks, quality flexible putty3 provides the best solution. Its elasticity accommodates minor movements while maintaining a seamless appearance. When working with clients in hot climates like Pakistan and India, I recommend putties specifically formulated with additives that enhance flexibility in extreme conditions.

Deeper cracks may require filling with a backing material before applying putty. This prevents excessive material use and ensures proper curing. For best results, apply putty in multiple thin layers rather than one thick application, allowing each layer to dry completely.

Structural cracks require a different approach, often including reinforcement methods like carbon fiber strips or epoxy injections before cosmetic repairs. These specialized techniques should be performed by qualified professionals as they affect building integrity.

After repairs, proper finishing is essential for a seamless appearance. Sand the repaired area smooth, prime, and apply paint that matches the existing wall. Quality finishing not only improves aesthetics but also protects the repair from moisture and further damage.

How Does Flexible Putty Protect Walls from Cracking?

Traditional rigid putties often fail within months in challenging environments. This creates a continuous cycle of repairs that frustrates property owners and damages reputations.

Flexible putty protects walls by accommodating building movement while maintaining adherence to the substrate. Unlike rigid putties, flexible formulations contain elastomeric polymers that stretch with minor structural movements, preventing new cracks from forming while sealing existing ones.

Over my years of supplying construction materials to major projects, I've witnessed a significant shift toward flexible putties. This trend is particularly strong in regions with extreme weather conditions or active seismic activity.

The key advantage of flexible putty lies in its ability to move with the building rather than against it. While standard putties become brittle after curing, quality flexible formulations maintain elasticity for years. During factory demonstrations, I often show clients how flexible putty can stretch up to 120% of its original size without cracking—a dramatic difference from traditional products that break at just 2-3% extension.

Temperature resistance is another critical benefit. In countries experiencing harsh summers and cold winters, wall materials expand and contract significantly. Flexible putties contain specialized polymers that maintain performance from -20°C to 70°C, preventing the seasonal cracking common with standard products.

Adhesion properties also set flexible putties apart. Enhanced binding agents create stronger bonds with various substrates including concrete, plaster, and gypsum. This improved adhesion prevents the edge-lifting and detachment problems common with rigid putties, especially on ceilings and exterior walls exposed to temperature changes.

Moisture resistance represents another significant advantage. Many wall cracks occur in high-humidity areas like bathrooms or kitchens, where conventional putties absorb water and deteriorate rapidly. Quality flexible formulations include hydrophobic components that repel moisture, maintaining performance in these challenging environments.

The longevity difference is remarkable. While standard putties might require replacement within 1-2 years in active buildings, properly formulated flexible putties often perform well for 5+ years. This durability significantly reduces maintenance costs and repainting frequency—a major consideration for commercial property managers and homeowners alike.

What Goes into a Quality Flexible Putty Formulation?

Many contractors use whatever putty is available locally, unaware that formula differences dramatically affect performance and durability.

Quality flexible putty2 formulations contain specialized additives including hydroxypropyl methylcellulose for workability, redispersible latex powder for flexibility, and fiber reinforcement4 for strength. Professional chemical additives like those from WANHONG significantly enhance flexibility and prevent wall cracking.

As someone who has worked directly with major mortar and putty manufacturers, I understand the science behind effective formulations. The difference between standard and premium flexible putties isn't just marketing—it's chemistry.

The base ingredients in flexible putty typically include mineral fillers (calcium carbonate or similar materials), binding agents (usually cement-based), and various additives that determine performance characteristics. Getting the balance right is crucial for both application properties and long-term performance.

Hydroxypropyl methylcellulose (HPMC) serves as a critical component in quality formulations. This cellulose ether improves water retention during application, providing longer working time and better adhesion. During hot weather applications, this property becomes essential—without it, putty dries too quickly, leading to poor bonding and future cracking. The quality of HPMC significantly impacts the final product, with higher-grade materials providing more consistent results.

Redispersible latex powder constitutes the heart of flexibility. These specialized polymers reform into elastic films when water is added, creating microscopic bridges that stretch rather than break when walls move. The quality and concentration of these polymers directly correlate with the putty's elasticity. In my experience supplying to premium manufacturers, those using high-quality redispersible powders consistently produce superior products.

Professional chemical additives like those from WANHONG play a crucial but often overlooked role. These specialized formulations enhance the interaction between components, improving both application properties and long-term performance. I've seen factories using identical base materials produce dramatically different results based solely on additive quality.

Fiber reinforcement provides internal structural support similar to rebar in concrete. These microscopic fibers—typically polypropylene or similar materials—create a three-dimensional network that resists crack propagation. Premium formulations often include fibers of various lengths to address different stress patterns.

The manufacturing process itself significantly impacts quality. Proper grinding, mixing sequence, and quality control testing ensure consistent performance. When visiting manufacturing facilities, I always pay attention to their testing protocols—the best producers test not just for immediate properties but also long-term performance under stress conditions.

| Component | Function | Quality Impact |

|---|---|---|

| HPMC | Water retention, workability | Affects application ease and adhesion |

| Redispersible Latex | Flexibility, adhesion | Determines crack resistance capacity |

| WANHONG Additives | Performance enhancement | Improves flexibility and durability |

| Fibers | Internal reinforcement | Prevents crack propagation |

| Mineral Fillers | Body and structure | Influences smoothness and workability |

Conclusion

Wall cracks result from five main causes: building settlement, temperature changes, moisture fluctuation, structural movement, and poor construction. Flexible putty with quality additives like WANHONG provides the ideal solution by accommodating movement while maintaining structural integrity.

-

Understanding the causes of wall cracks can help you prevent them and maintain your home's structural integrity. ↩ ↩ ↩ ↩

-

Explore how flexible putty can enhance the durability of your wall repairs. ↩ ↩

-

Understanding the components of quality flexible putty can help you make informed choices for repairs. ↩

-

Discover how fiber reinforcement enhances the strength and durability of wall repair materials. ↩