Watching your expensive ceramic wall tiles slide down freshly applied mortar feels like watching money literally slip away. Sagging tiles waste materials, time, and damage your reputation as a contractor.

To prevent wall tiles from sagging, choose an HPMC (Hydroxypropyl Methylcellulose)1 with high viscosity (100,000+ mPa·s), adequate methoxyl content (28-30%), and hydroxypropyl substitution (7-12%). These properties create strong immediate bond strength through proper water retention and increased adhesiveness.

I remember walking onto a jobsite where a contractor was frantically trying to hold up sliding $200 Italian porcelain tiles with makeshift supports. The frustration on his face said it all - he'd chosen the wrong cellulose ether for his thin-set mortar. Let's explore how you can avoid this costly mistake and select the perfect HPMC for your heavy wall tile applications.

How to Keep Wall Tiles from Sagging During Installation?

Pain strikes when your large format tiles start sliding downward minutes after placement. You're racing against gravity, scrambling for temporary supports, watching profit margins disappear with each failed installation.

To prevent tile sagging, select HPMC with 100,000+ mPa·s viscosity and 28-30% methoxyl content. Apply proper mortar thickness (3-5mm), use notched trowel technique, maintain consistent mixture ratios, and allow adequate setting time between rows. For extremely heavy tiles, consider mechanical anchoring systems.

Proper HPMC selection is fundamentally about understanding the balance between immediate grab and working time. In my 15+ years at Kehao producing HPMC for construction applications, I've observed that viscosity is the most critical parameter for preventing sagging.

Key HPMC Properties for Anti-Sag Performance

| Property | Optimal Range | Effect on Anti-Sag Performance |

|---|---|---|

| Viscosity | 100,000-150,000 mPa·s | Higher viscosity = stronger immediate hold |

| Methoxyl Content | 28-30% | Affects water retention and adhesion strength |

| Hydroxypropyl Content | 7-12% | Improves workability without reducing grab |

| Particle Size | 80-100 mesh | Finer particles dissolve faster for quicker effect |

The molecular structure of HPMC2 creates a three-dimensional network within the mortar that acts like microscopic suction cups, gripping both the tile and wall surface. Our Kehao KH-150M grade specifically engineers this network to activate quickly upon application, creating immediate bond strength while maintaining adequate open time for proper tile placement and adjustment.

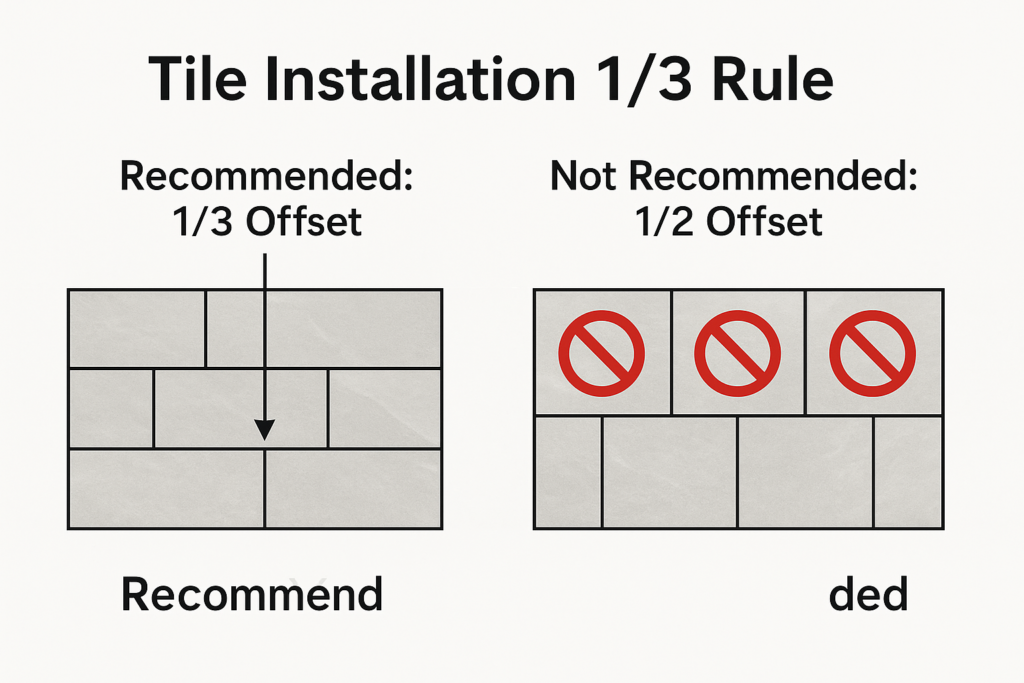

What is the 1/3 Rule for Tile Installation?

The frustration sets in when your carefully planned tile layout fails because of inconsistent mortar coverage. Improper adhesion leads to hollows, cracks, and eventually, complete tile failure.

The 1/3 rule states that heavy wall tiles should never overlap more than 1/3 the length of the tile below it to prevent excessive weight distribution and sagging. Additionally, mortar coverage should achieve at least 80% contact area for wall applications, with 95-100% for wet areas or exterior applications.

The 1/3 rule exists because of basic physics principles related to weight distribution and center of gravity. When installing heavy tiles, particularly large format ones (24×24 inches or larger), exceeding this overlap percentage dramatically increases downward pressure on the mortar bed.

How HPMC Formulation Affects the 1/3 Rule Implementation

HPMC's chemical structure interacts with cement particles in fascinating ways. The hydroxypropyl groups increase water retention while the methoxyl groups enhance adhesion. This combination creates a perfect environment for cement hydration - the chemical process that ultimately gives mortar its strength.

Our tests at Kehao laboratories demonstrate a direct correlation between HPMC formulation and adherence to the 1/3 rule:

| HPMC Type | Max Safe Overlap | Setting Time | Adjustment Window |

|---|---|---|---|

| Standard HPMC (XH-P100) | 1/4 tile length | 8-10 hours | 15-20 minutes |

| High-Performance HPMC (XH-P150) | 1/3 tile length | 10-12 hours | 20-25 minutes |

| Premium Anti-Sag HPMC (XH-P200) | 1/2 tile length | 12-14 hours | 25-30 minutes |

By selecting the appropriate HPMC grade, installers can safely maximize their installation efficiency while maintaining structural integrity. This becomes particularly important when working with staggered patterns or complex designs where the 1/3 overlap might be aesthetically desirable.

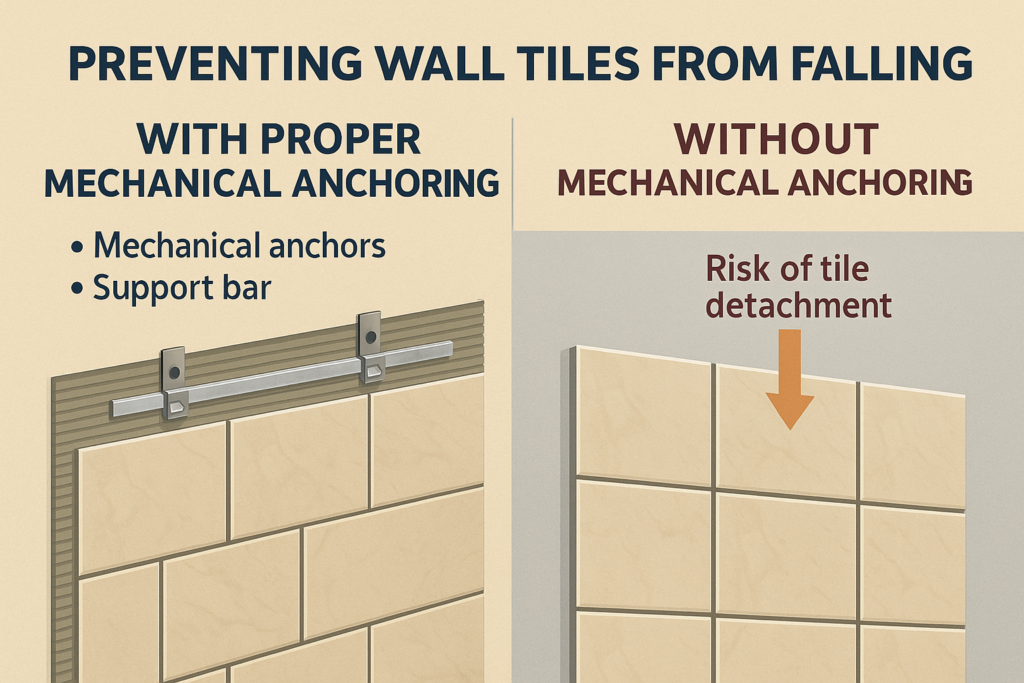

How to Prevent Wall Tiles from Falling?

Seeing completed tile work crash to the floor weeks after installation creates anxiety, liability issues, and damaged relationships with clients. Poor initial adhesion often leads to these catastrophic failures.

To prevent wall tiles from falling, use HPMC with balanced methoxyl/hydroxypropyl ratio for optimal adhesion, ensure proper surface preparation (clean, primed), maintain recommended water-to-mortar ratios, achieve full coverage with the proper trowel size, and consider mechanical anchoring for tiles exceeding 15kg/m².

Long-term tile adhesion depends on both initial grab and final bond strength. HPMC directly influences both these properties through its water retention capabilities. When water evaporates too quickly from mortar, hydration remains incomplete, resulting in weakened adhesion. Conversely, when water remains trapped too long, setting time extends excessively, allowing tiles to shift.

The Chemistry Behind HPMC and Long-Term Tile Adhesion

At Kehao, our R&D department has extensively studied the molecular interactions between HPMC and cement compounds. We've discovered that the ideal HPMC for preventing tile falling should have:

- Optimal Methylation Degree (28-30%): This creates the right hydrophobic/hydrophilic balance in the molecule

- Controlled Hydroxypropyl Substitution (7-12%): Enhances water retention without excessive stickiness

- Uniform Particle Distribution: Ensures consistent performance throughout the mortar mix

For extremely heavy applications, such as large-format porcelain or natural stone exceeding 15kg/m², we recommend our KH-200M grade with mechanical support systems. The HPMC in this formulation develops tensile strength exceeding 1.2 N/mm² after 28 days, significantly above industry standards.

| Tile Weight | Recommended HPMC Grade | Additional Measures |

|---|---|---|

| <10 kg/m² | XH-P100 | Standard application |

| 10-15 kg/m² | XH-P150 | Extended setting time |

| >15 kg/m² | XH-P200 | Mechanical supports required |

The molecular structure of premium HPMC creates stronger hydrogen bonding with cement hydrates, resulting in a more complete and robust crystalline structure within the mortar matrix. This enhanced microstructure forms a stronger mechanical interlock with the tile backing, preventing future detachment.

How to Stop Tiles from Sliding Down the Wall When They Are Too Heavy?

The panic when seeing expensive marble tiles slowly descending despite your best efforts creates real job site anxiety. Weight-induced sliding can destroy tight grout lines and professional appearance.

To prevent heavy tiles from sliding, use HPMC with viscosity exceeding 150,000 mPa·s for immediate grab strength, install bottom-row support ledgers, work bottom-to-top in limited horizontal sections, reduce water content slightly in mortar mix, and consider specialized rapid-set additives compatible with your chosen HPMC.

When working with exceptionally heavy tiles like natural stone, porcelain panels, or large ceramic slabs, standard installation practices often prove insufficient. In these situations, the physical properties of your chosen HPMC become even more critical.

Advanced HPMC Formulations for Extra-Heavy Tile Applications

At Kehao, we've developed specialized HPMC formulations specifically for extra-heavy tile applications. Our XH-EXT series incorporates modified cellulose chains with enhanced hydrogen bonding capabilities, creating viscosity profiles that respond differently to shear forces.

This means the mortar exhibits:

- High Viscosity at Rest: Preventing tile movement after placement

- Lower Viscosity During Application: Maintaining workability for proper combing and spreading

- Rapid Recovery: Returning to high viscosity state quickly after tile adjustment

For tiles exceeding 20kg/m², we recommend implementing a systematic installation approach:

| Step | Technique | HPMC Contribution |

|---|---|---|

| 1 | Install temporary support ledger | Provides initial support during critical setting phase |

| 2 | Mix mortar with XH-EXT HPMC | Creates enhanced immediate grab |

| 3 | Apply "back-buttering" technique | HPMC ensures better contact and reduces air pockets |

| 4 | Place tile with slight twisting motion | HPMC creates suction effect for immediate bond |

| 5 | Insert temporary spacers | Maintains position during setting |

The molecular weight distribution of our premium HPMC products is carefully controlled during manufacturing to ensure consistent performance in these demanding applications. The higher percentage of long-chain polymers creates stronger mechanical interlocking within the mortar structure.

Conclusion

Choosing the right HPMC with optimal viscosity, methoxyl content, and hydroxypropyl substitution prevents tile sagging and ensures lasting installations. By understanding these key properties, you'll create successful tile projects every time.