Are you struggling with tile grout that cracks, shrinks, or fails to hold up in wet areas? Poor-quality grout can ruin even the most beautiful tile installations, causing frustration and expensive repairs down the line.

Unsanded tile grout is a smooth paste-like mixture used to fill narrow joints (less than 1/8 inch) between tiles. It contains cement, water, colorants, and essential additives like HPMC1 that improve workability, water retention, and adhesion for a professional finish in bathrooms, kitchens, and decorative applications.

Let me share something that happened last month. A customer from UAE called me, desperate because his factory's unsanded grout was drying too quickly in their hot climate. After adding our HPMC to their formulation, their installation time improved by 45%. This simple change made all the difference. Let's explore why this happens and how you can achieve similar results.

How Does Grout Tiling with Wanhong Construction Additives Make a Difference?

Have you ever wondered why some tile installations look perfect years later while others fail within months? The difference often lies not in the installation technique but in the quality of the additives used in the grout.

Wanhong construction additives, particularly our HPMC (hydroxypropyl methylcellulose), transform ordinary grout into a high-performance product by enhancing water retention, improving sag resistance, and extending open time. These properties allow for proper hydration of cement and ensure excellent bonding to tile edges, even in challenging conditions.

When I first started in this industry, I was amazed by how significantly the right cellulose ether2 can impact grout performance. Our Wanhong HPMC stands out because we've engineered it specifically for tile grout applications. The molecular structure of our HPMC creates a perfect balance between water retention and workability.

Technical Comparison of Grout Additives

| Additive Type | Water Retention | Workability | Open Time | Cost-Effectiveness |

|---|---|---|---|---|

| Wanhong HPMC | Excellent | Superior | Extended | High |

| Standard HPMC | Good | Good | Average | Medium |

| Other Cellulose Ethers | Variable | Limited | Shorter | Lower |

| No Additives | Poor | Poor | Very Short | N/A |

The difference becomes particularly noticeable in extreme conditions. For example, when one of our clients in Saudi Arabia switched to our HPMC, they reported that their grout maintained workability for up to 40 minutes longer in 40°C heat. This improvement allowed their installation teams to work more efficiently and reduced waste significantly.

Moreover, the thixotropic properties of our HPMC prevent sagging in vertical applications, making it ideal for wall tile installations where precision is critical.

How Can Unsanded Tile Grout with HPMC Help You Achieve Your Desired Results?

Does your tile grout crack after drying or wash out when exposed to moisture? These common problems often stem from inadequate water retention during curing, an issue that proper HPMC integration solves effectively.

HPMC1 in unsanded tile grout creates a water-retaining matrix that ensures complete cement hydration, resulting in stronger bonds and reduced shrinkage. It also improves flexibility, allowing the grout to accommodate minor substrate movements without cracking, while enhancing stain resistance through decreased porosity.

I recall visiting a customer's factory in Brazil where they were experiencing consistent cracking issues with their premium grout line. Upon examination, I discovered they were using a low-viscosity HPMC that wasn't providing sufficient water retention. After switching to our Wanhong HPMC with 100,000 mPa·s viscosity, their problem disappeared completely.

HPMC Performance in Different Environments

The effectiveness of HPMC becomes particularly evident when comparing performance across different environmental conditions:

| Environment | Without HPMC | With Standard HPMC | With Wanhong HPMC |

|---|---|---|---|

| Hot & Dry (40°C) | Rapid drying, severe cracking | Moderate workability, some cracking | Extended workability, minimal shrinkage |

| Cold (5°C) | Slow setting, frost damage | Delayed setting, moderate strength | Controlled setting, excellent final strength |

| High Humidity | Poor adhesion, mold growth | Good adhesion, some mold resistance | Excellent adhesion, enhanced mold resistance |

Additionally, our HPMC improves the rheological properties of grout, making it creamier and easier to apply into narrow joints. This characteristic is particularly valuable for intricate mosaic work where precision is essential. The improved slip resistance also means the grout stays where it's applied, reducing cleanup time and ensuring consistent color throughout the installation.

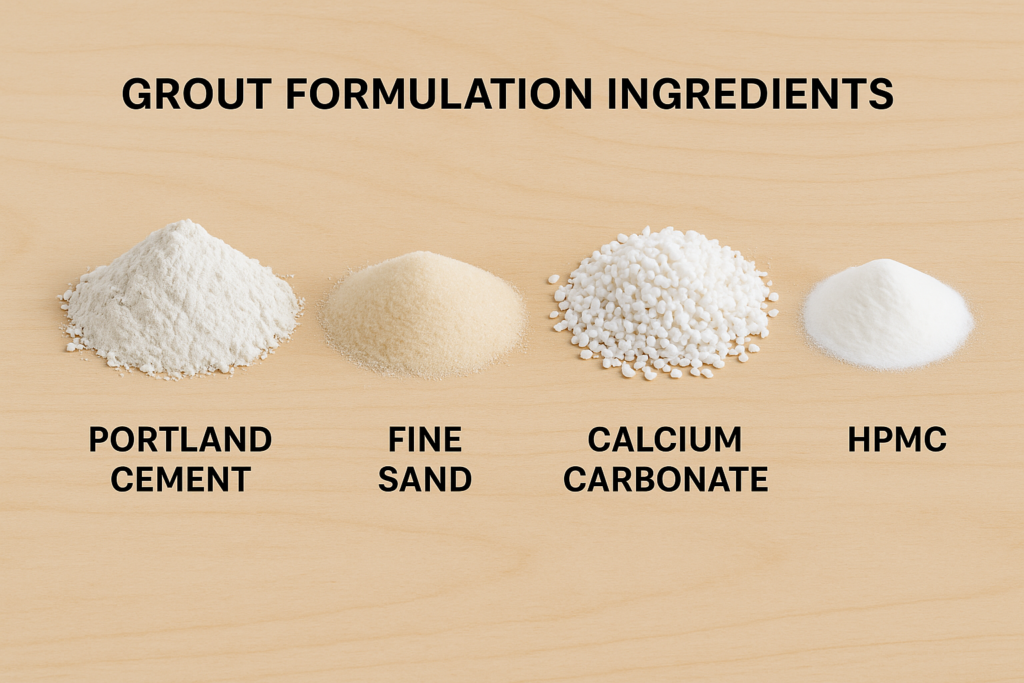

What Goes Into an Effective Unsanded Tile Grout Formulation?

Have you tried to develop your own grout formulation only to find it doesn't perform as well as commercial products? Creating the perfect balance of ingredients is both a science and an art, with HPMC playing a crucial starring role.

An effective unsanded tile grout formulation typically contains 25-35% white Portland cement, 60-65% fine calcium carbonate (200 mesh), 0.2-0.4% HPMC, 0.1-0.2% redispersible polymer powder3, plus minor additives like pigments and water repellents. This precise combination ensures optimal workability, adhesion, and durability.

When I first developed grout formulations, I made the mistake of underestimating the importance of HPMC dosage. Even a 0.1% change can dramatically affect performance. Through extensive testing in our lab, we've refined the ideal concentration for different applications.

Critical Functions of Each Component

Understanding how each ingredient contributes to the final performance helps in creating an optimized formulation:

| Component | Function | Optimal Range | Effect of Incorrect Dosage |

|---|---|---|---|

| Portland Cement | Binding agent | 25-35% | Too much: brittle, cracking Too little: weak bonding |

| Fine Calcium Carbonate | Filler, smoothness | 60-65% | Too much: weak structure Too little: rough texture |

| HPMC | Water retention, workability | 0.2-0.4% | Too much: slow setting Too little: poor workability |

| Redispersible Polymer | Flexibility, adhesion | 0.1-0.2% | Too much: excessive cost Too little: brittle results |

| Pigments | Color | 0-5% | Too much: reduced strength Too little: inconsistent color |

The molecular weight and substitution degree of HPMC also significantly impact performance. For unsanded grout, we recommend our HPMC with a methoxyl content of 19-24% and hydroxypropyl content of 7-12%, as this provides the optimal balance between water retention and setting time.

During a recent collaboration with a major mortar manufacturer in Mexico, we discovered that incorporating our HPMC into their formulation not only improved performance but also allowed them to reduce the amount of redispersible polymer powder3, resulting in significant cost savings without compromising quality.

What Other Similar Applications Can Benefit from HPMC?

Are you maximizing the potential of HPMC across your product line? Many manufacturers don't realize that the same additive that enhances their grout can transform multiple other products as well.

Beyond unsanded tile grout, HPMC significantly improves sanded grout, thin-set mortars, self-leveling compounds, and decorative renders. The water retention, workability, and adhesion properties that benefit grout are equally valuable in these applications, allowing manufacturers to streamline raw material sourcing while enhancing product performance.

I remember consulting with a client who initially purchased our HPMC just for their unsanded grout line. After seeing the impressive results, they decided to test it in their tile adhesives as well. The feedback from their customers was so positive that they eventually reformulated their entire product range to include our HPMC.

Application-Specific HPMC Recommendations

Different applications require slightly different HPMC properties for optimal performance:

| Application | Recommended HPMC Type | Viscosity Range | Key Benefits |

|---|---|---|---|

| Unsanded Grout | WH-P150 | 75,000-100,000 mPa·s | Smooth texture, excellent joint filling |

| Sanded Grout | WH-P100 | 50,000-75,000 mPa·s | Enhanced particle suspension, durability |

| Thin-Set Mortars | Wh-P100 | 15,000-50,000 mPa·s | Superior sag resistance, extended open time |

| Self-Leveling Compounds | WH-E40 | 380-400 mPa·s | Improved flow, reduced bleeding |

| Decorative Renders | WH-P50 | 30,000-60,000 mPa·s | Excellent workability, crack resistance |

The versatility of HPMC extends even further. Some of our customers have successfully integrated it into specialty products like epoxy grouts, where it improves rheology without affecting chemical resistance. Others have developed innovative colored grouts with enhanced stain resistance by combining our HPMC with specialized pigments and water-repelling additives.

By understanding the specific properties of each HPMC variant, manufacturers can select the optimal type for each application, resulting in a comprehensive product range with consistent quality and performance.

FAQ: Common Questions About Unsanded Tile Grout and HPMC

Do you have questions about using HPMC in your tile grout formulations? These are the most common queries I receive from manufacturers looking to optimize their products.

The most frequent questions about unsanded tile grout concern the differences between sanded and unsanded types, proper joint width applications, mixing ratios, and how HPMC affects setting time. Understanding these factors helps manufacturers formulate products that meet specific application requirements and perform reliably across various conditions.

One question I'm frequently asked is whether increasing HPMC content will always improve grout performance. The answer is no - there's a delicate balance. During a technical workshop I conducted in India last year, I demonstrated how excessive HPMC actually extended setting time too much, creating problems with project timelines.

Detailed Answers to Key Questions

Here's a comprehensive breakdown of the most important information manufacturers need to know:

| Question | Answer | Additional Information |

|---|---|---|

| What's the ideal HPMC dosage for unsanded grout? | 0.2-0.4% by weight | Higher percentages for hotter climates, lower for humid environments |

| How does HPMC affect setting time? | Generally extends setting time by 15-45 minutes | Can be balanced with appropriate cement type selection |

| Can different HPMC grades be mixed? | Yes, for custom performance profiles | Combining high and low viscosity types can optimize both workability and setting |

| How does temperature affect HPMC performance? | Higher temperatures accelerate dissolution but reduce efficacy | Pre-hydration techniques can improve hot-weather performance |

| Is HPMC compatible with colored grouts? | Yes, with no adverse effects on pigments | Actually improves color consistency by preventing water migration |

Another critical consideration is storage stability. Our HPMC remains effective in properly formulated dry-mix grout4 for up to two years when stored in appropriate conditions. This long shelf life is particularly valuable for manufacturers in regions with seasonal construction patterns.

It's also worth noting that the particle size distribution of HPMC is crucial for proper dispersion in dry mixes. Our manufacturing process ensures consistent particle size, eliminating the clumping issues that often plague lower-quality cellulose ethers.

Conclusion

Unsanded tile grout with quality HPMC transforms ordinary installations into long-lasting, professional results. By using the right Wanhong additives in your formulations, you'll deliver products that outperform competitors and build loyal customer relationships based on reliable performance.

-

Learn how HPMC enhances water retention and workability in grout formulations. ↩ ↩

-

Understand how cellulose ether improves the performance of grout products. ↩

-

Explore how redispersible polymer powder enhances grout flexibility and adhesion. ↩ ↩

-

Learn about the benefits of using dry-mix grout for construction projects. ↩