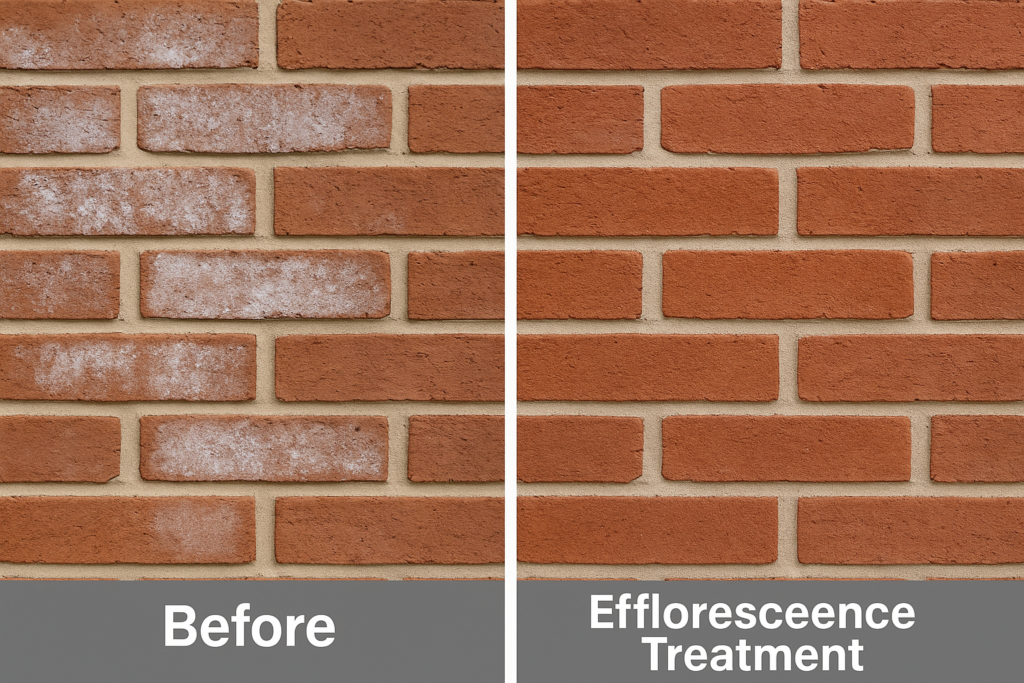

Are you tired of unsightly white deposits ruining the look of your masonry projects? Efflorescence—that frustrating white powdery substance—appears when soluble salts migrate to the surface and crystallize, damaging both appearance and structural integrity.

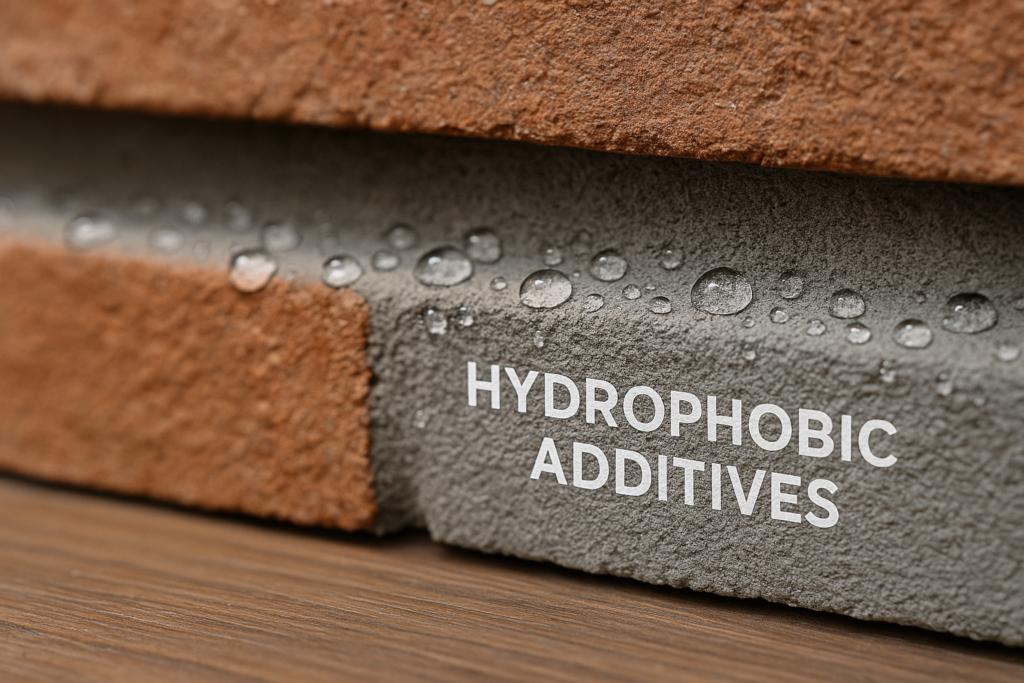

To prevent efflorescence, incorporate water-repellent admixtures like silicones or stearates into your mortar mix, and use redispersible polymer powder1 (RDP) or silica fume2 to densify the matrix. These additives block water movement and seal pore networks, preventing salt migration to the surface.

I've seen countless beautiful masonry projects ruined by efflorescence. As someone who's spent years manufacturing the very additives that prevent this problem, I want to share what really works—and what doesn't. Let's dig into how you can stop those annoying white stains before they start.

How Can Efflorescence Be Prevented?

Have you noticed those chalky white deposits forming on your clients' walls after completion? These deposits not only look bad but can also signal moisture problems that may lead to structural damage down the line.

Efflorescence prevention requires a two-pronged approach: reducing water penetration with hydrophobic agents and minimizing available soluble salts in your materials. Using high-quality raw materials with low alkali content and incorporating water-repellent additives like HPMC3 with hydrophobic properties creates an effective barrier system.

My factory has been producing hydroxypropyl methylcellulose (HPMC) for over 15 years, and I've learned that fighting efflorescence is like waging a two-front battle. We need to "block the water path" and "close the salt gate." Let me explain this in practical terms.

When water moves through masonry, it carries dissolved salts to the surface. Once there, the water evaporates, leaving behind those unsightly salt deposits. By adding hydrophobic agents like silicone-based additives or stearates to your mortar mix, you essentially outfit each capillary pore with an "invisible raincoat." This waterproofing effect prevents moisture from penetrating the material.

Additionally, we recommend using pore-blocking additives like our redispersible polymer powder1s (RDP) which fill and seal the internal void spaces in mortar. These work by forming a polymer film during hydration that seals micropores, effectively closing off the "escape routes" for salt-laden water.

For best results, I suggest a combination approach using both HPMC with hydrophobic properties (0.2-0.3% by weight) and RDP (2-3% by weight) in your mortar formulations. This dual-action system has proven effective for our customers across Saudi Arabia, UAE, and other regions with challenging climate conditions where efflorescence is particularly problematic.

What Concrete Sealer Prevents Efflorescence?

Are you confused by the countless concrete sealers on the market? With so many options claiming to prevent efflorescence, it's hard to know which actually deliver results rather than empty promises.

The most effective concrete sealers for preventing efflorescence are silicate-based penetrating sealers and acrylic sealers with hydrophobic properties. Silicate sealers react chemically with concrete to form an insoluble barrier, while quality acrylic sealers create a protective film that blocks moisture movement while allowing vapor transmission.

When it comes to concrete sealers, not all products are created equal. I've worked with hundreds of mortar manufacturers across developing markets, and I've seen firsthand which sealers actually prevent efflorescence and which just make temporary promises.

Penetrating sealers, particularly silicate-based ones, work by reacting with free calcium in concrete to form calcium silicate hydrate (CSH) crystals that block pores from within. These don't just sit on the surface—they become part of the concrete matrix itself. One customer in Iran was facing severe efflorescence problems until we recommended incorporating our modified HPMC with a silicate-based penetrating sealer. The combination reduced their efflorescence cases by nearly 85% within three months.

Film-forming sealers like acrylics can also be effective, but they need to strike the right balance. They must repel liquid water while still allowing water vapor to escape—otherwise, you'll trap moisture inside that will eventually cause more problems. Our carboxymethyl cellulose (CMC) products can be combined with acrylic dispersions to create such balanced sealers.

Here's a comparison of different sealer types for efflorescence prevention:

| Sealer Type | Moisture Blocking | Breathability | Durability | Cost Effectiveness |

|---|---|---|---|---|

| Silicate Penetrating | Excellent | Excellent | 15-20 years | High |

| Acrylic | Very Good | Good | 3-5 years | Medium |

| Polyurethane | Excellent | Poor | 7-10 years | Low |

| Epoxy | Excellent | Poor | 10-15 years | Low |

| Silicone-based | Good | Very Good | 5-8 years | Medium |

For most applications, I recommend either silicate penetrating sealers for long-term solutions or acrylic sealers when budget constraints exist but regular maintenance is possible.

What Is Used To Reduce The Salt Content Of Mortar Materials To Help Prevent Efflorescence?

Is your mortar mix secretly harboring the very salts that will later emerge as efflorescence? Many builders don't realize their materials might be the source of their efflorescence problems.

To reduce salt content in mortar materials, use low-alkali cement, washed sand free from salt contamination, and clean water without dissolved minerals. Chemical salt blockers like barium compounds can be added to react with and immobilize sulfates, while pozzolanic materials like fly ash or metakaolin can bind free alkalis.

Salt reduction in mortar materials is often overlooked, but it's crucial for preventing efflorescence. In my years supplying additives to large-scale mortar plants, I've found that addressing salt content directly can eliminate up to 70% of efflorescence issues before they start.

The first step is selecting high-quality raw materials. Low-alkali cement (with Na₂O equivalent under 0.6%) significantly reduces efflorescence potential. When selecting aggregates, always use washed sand that's been tested for soluble salt content. I once visited a customer in Pakistan who couldn't figure out why their products kept developing efflorescence despite using our water-repellent additives. We tested their sand and found it contained high levels of sodium chloride from being sourced near a coastal area. After switching to properly washed inland sand, their efflorescence problems disappeared.

Chemical additives like barium compounds work by converting soluble sulfates into insoluble barium sulfate, effectively immobilizing these salts. Our hydroxyethyl cellulose (HEC) products can be modified with these barium compounds to provide dual functionality—water retention plus salt blocking.

Another effective approach is using pozzolanic materials like silica fume, fly ash, or metakaolin. These materials react with and bind free calcium hydroxide, reducing its availability for efflorescence formation. When properly proportioned, they also densify the mortar matrix, creating fewer paths for salt migration.

For customers in especially challenging environments, we recommend this comprehensive approach to salt content reduction:

- Use low-alkali cement (Na₂O equivalent < 0.6%)

- Wash aggregates thoroughly and test for salt content

- Use clean mixing water (or add barium compounds if water quality is questionable)

- Incorporate 5-10% pozzolanic material by weight of cement

- Add 0.2-0.3% HPMC3 with hydrophobic properties

- Include 2-3% redispersible polymer powder1 for pore blocking

This multi-layered approach has shown consistent success even in the challenging salt-laden environments of our Middle Eastern customers.

What Is The Best Solution For Efflorescence?

Do you feel like you've tried everything to prevent efflorescence, but those stubborn white stains keep coming back? You're not alone—but there is a comprehensive solution that actually works.

The best solution for efflorescence combines preventive measures and remediation techniques. Preventively, use high-quality materials with hydrophobic additives like silicone-treated HPMC and redispersible polymer powders. For existing efflorescence, apply diluted acid cleaners followed by neutralization and then seal with a penetrating hydrophobic sealer.

After supplying additives to construction markets across 20+ countries, I've found that the most effective approach to efflorescence is a systematic one that addresses both prevention and remediation. Let me share what I've learned works best.

For prevention, we must create what I call a "dual defense system." First, block water movement with hydrophobic agents. Our silicone-modified HPMC creates an internal waterproofing system throughout the mortar matrix. When water can't move freely through the material, it can't transport salts to the surface. Second, seal the pore network with polymer-based additives like our redispersible polymer powder1s. These create flexible polymer films that bridge across pores and microcracks, preventing both water ingress and salt migration.

For existing efflorescence, I recommend a three-step process:

-

Clean: Use a diluted acid solution (typically 1 part muriatic acid to 10 parts water) to dissolve the salt deposits. Always pre-wet the surface and test in an inconspicuous area first.

-

Neutralize: Thoroughly rinse with clean water, then apply an alkaline neutralizer to stop any acid reaction and prevent damage to the masonry.

-

Seal: Once completely dry (allow at least 48 hours), apply a penetrating siloxane or silane-based sealer that will prevent future water penetration.

I've seen this approach work even in extreme cases. One of our clients in Saudi Arabia was dealing with severe efflorescence on exterior walls due to high groundwater salinity. After implementing our custom HPMC with hydrophobic properties in their new construction and following the three-step remediation process for existing structures, they reported a 95% reduction in efflorescence problems.

For large-scale projects, I recommend this preventive formula based on our extensive testing:

| Component | Purpose | Recommended Dosage |

|---|---|---|

| Low-alkali cement | Reduce available salts | Base material |

| Washed sand | Minimize salt contamination | Base material |

| Hydrophobic HPMC | Water repellency + workability | 0.2-0.3% |

| Redispersible polymer powder | Pore sealing + flexibility | 2-3% |

| Silica fume | Pozzolanic activity + densification | 5-8% |

| Polypropylene fibers | Crack reduction | 0.1% |

This formulation has delivered consistent results across different climate zones and construction practices, making it my go-to recommendation for manufacturers serious about preventing efflorescence.

Conclusion

Preventing efflorescence requires blocking both water and salt movement using hydrophobic additives like silicone-treated HPMC and pore-sealing agents like RDP. With proper material selection and these key additives, you can ensure your masonry stays efflorescence-free for years to come.

-

Explore the benefits of redispersible polymer powder in enhancing mortar performance and preventing efflorescence. ↩ ↩ ↩ ↩

-

Find out how silica fume can improve the durability of your masonry and prevent efflorescence. ↩

-

Discover the benefits of hydroxypropyl methylcellulose (HPMC) in preventing efflorescence in masonry. ↩ ↩