Water retention issues plague construction projects worldwide. Poor water retention leads to cracked surfaces, weak adhesion, and wasted materials—problems that cost contractors thousands in repairs and reputation damage.

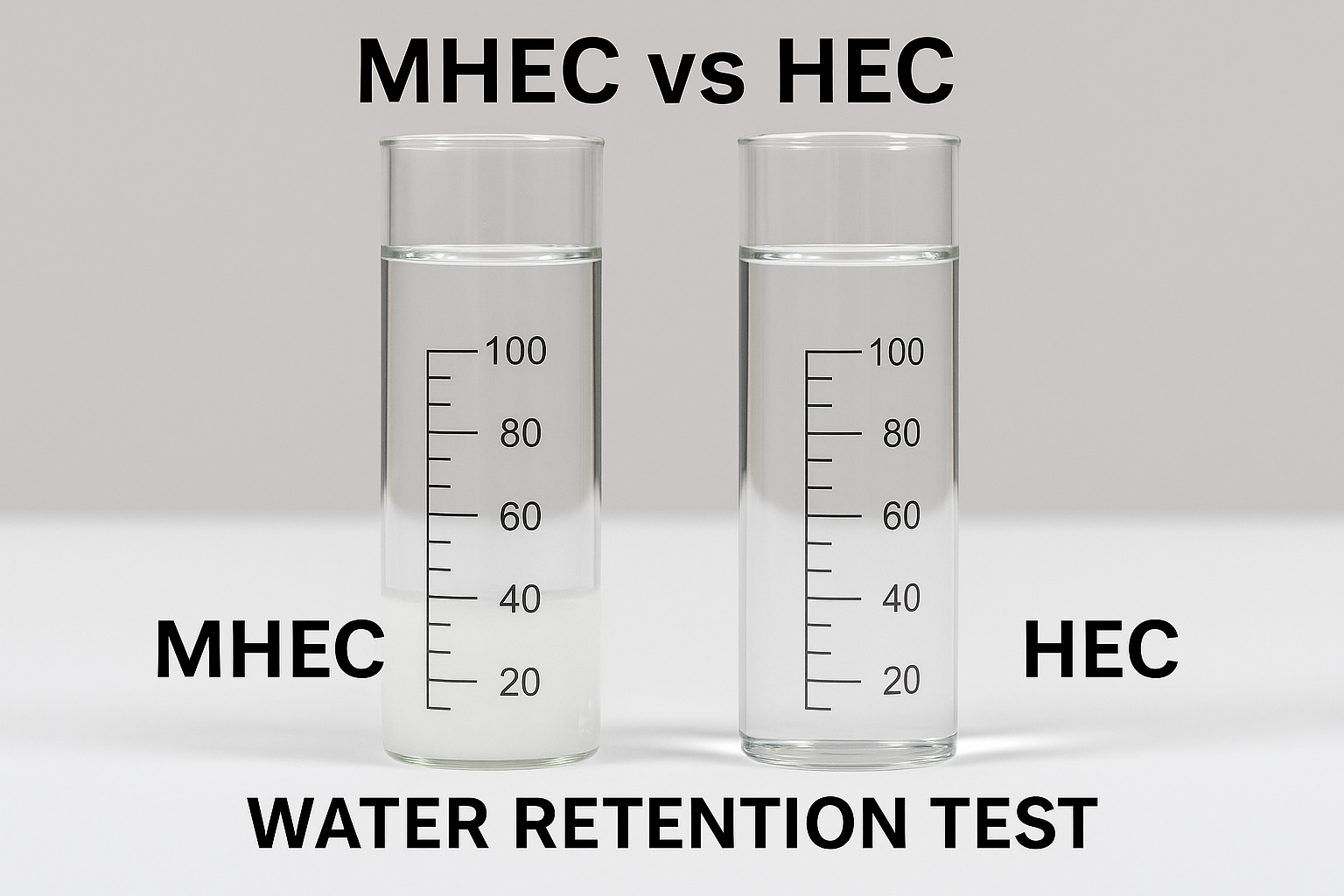

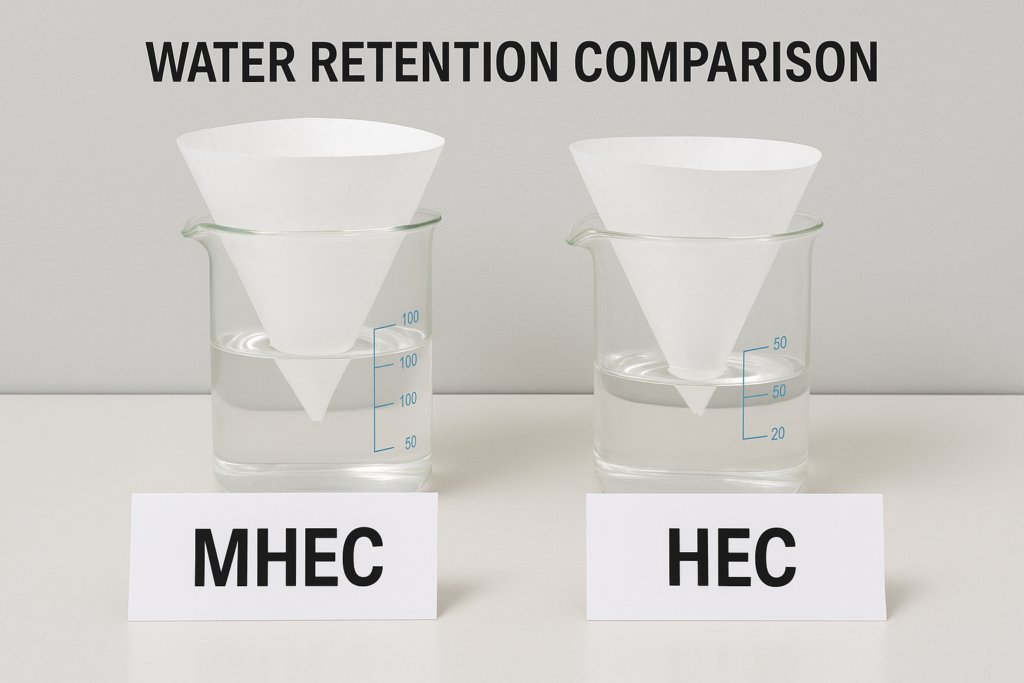

When comparing MHEC1 and HEC for water retention, MHEC2 typically provides superior performance due to its methyl groups creating a denser, more resilient water-locking network in alkaline environments like cement mortars, while HEC offers more basic water-holding capabilities through hydroxyl groups alone.

I've tested dozens of cellulose ether3 formulations in our laboratory over the years. The difference between MHEC and HEC became crystal clear when I saw how differently they behave in high-alkaline cement mixtures. Let me show you what makes these two additives so different and why it matters for your construction projects.

Introduction - What Makes Cellulose Ethers Essential in Construction?

Poor water management in building materials can lead to rapid setting, insufficient hydration, and compromised structural integrity. These issues can turn what should be routine applications into costly nightmares.

Cellulose ethers like MHEC1 and HEC function as water retention agents in construction materials by forming a molecular network that physically slows water evaporation and migration. This controlled water release ensures proper cement hydration, extended working time, and stronger final products.

The chemistry behind cellulose ethers fascinates me because these modified natural polymers transform ordinary mortar into high-performance building materials. I remember visiting a construction site in Saudi Arabia where the contractor switched from standard mortar to one with properly formulated cellulose ether. The difference was remarkable - workers gained an extra 30 minutes of adjustability time despite the scorching desert heat.

Cellulose ethers work by creating a temporary barrier that regulates water movement within the mixture. This regulation is critical because cement needs water to properly cure through hydration. Too little water, and the cement particles can't fully react; too much uncontrolled water loss, and the mixture weakens.

How Cellulose Ethers Transform Basic Mortar Performance

| Property | Without Cellulose Ether | With Cellulose Ether |

|---|---|---|

| Working Time | 15-20 minutes | 30-90 minutes |

| Water Retention | 70-75% | 95-98% |

| Sag Resistance | Poor | Excellent |

| Bond Strength | Basic | Enhanced |

This performance difference explains why virtually all modern tile adhesives, renders, and EIFS systems rely on cellulose ethers as core ingredients.

Similarities Between HPMC & MHEC1 in Construction Chemicals - Are They Really That Different?

Contractors often ask me why they should care about the difference between cellulose ether types when they all claim similar benefits. The confusion costs them money when they choose the wrong product for specific applications.

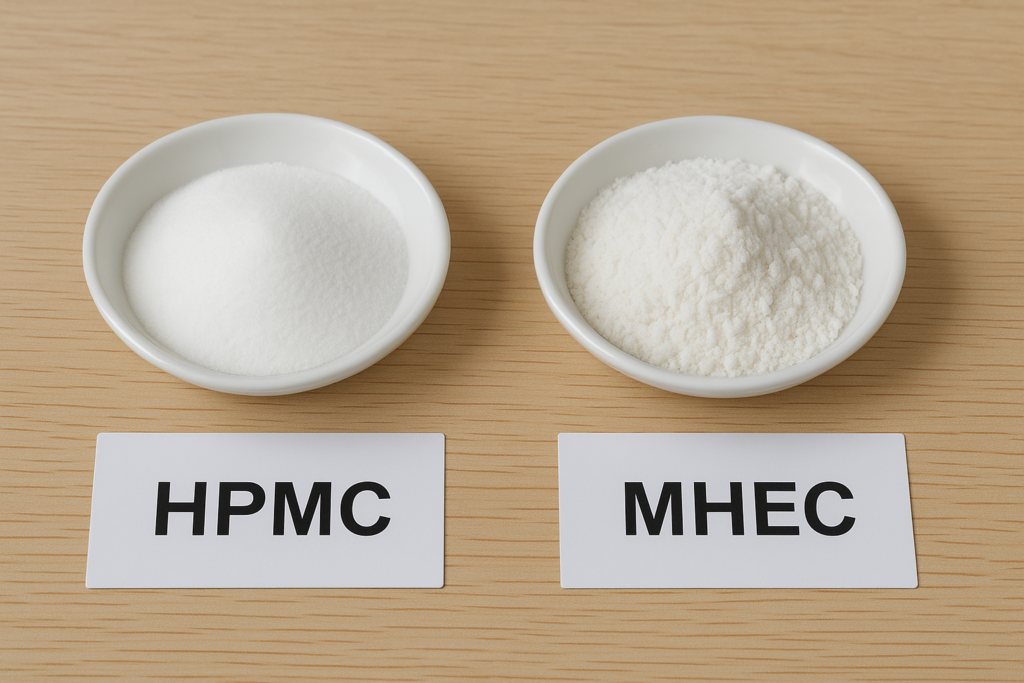

HPMC and MHEC share important similarities: both are white powders derived from cellulose, both dissolve in cold water to form viscous solutions, both provide water retention, workability improvement, and sag resistance, and both are commonly used in construction applications at 0.1-0.5% dosages.

When examining HPMC and MHEC under an optical microscope, their physical appearance is remarkably similar. Both form white, fibrous powders that can be easily mistaken for one another, which explains why many builders and even some manufacturers treat them as interchangeable products. However, this surface-level similarity masks important functional differences.

I've worked with both products extensively in formulating tile adhesives for different climate conditions. At the molecular level, both HPMC and MHEC are cellulose derivatives where hydroxyl groups on the cellulose backbone have been modified with substituent groups. This modification transforms the natural cellulose from a water-insoluble fiber into a water-soluble polymer with thickening and water retention properties.

Common Performance Characteristics of HPMC and MHEC

| Property | HPMC | MHEC |

|---|---|---|

| Appearance | White powder | White powder |

| Viscosity Range | 5-200,000 mPa·s | 5-200,000 mPa·s |

| Typical Dosage | 0.1-0.5% | 0.1-0.5% |

| Open Time Extension | Yes | Yes |

| Workability Improvement | Yes | Yes |

| Thermal Gelation | Yes | Yes |

Both chemicals also exhibit thermal gelation, a property where they form temporary gels at elevated temperatures. This property helps prevent sagging in vertical applications like wall tiling. The primary differences emerge when we examine their specific chemical structures and how they perform under different application conditions.

Key Differences Between HPMC & MHEC2 - Why Chemical Structure Matters

Many contractors have complained to me about inconsistent mortar performance despite using the "same type" of cellulose ether. The problem often stems from misunderstanding the fundamental differences between these additives.

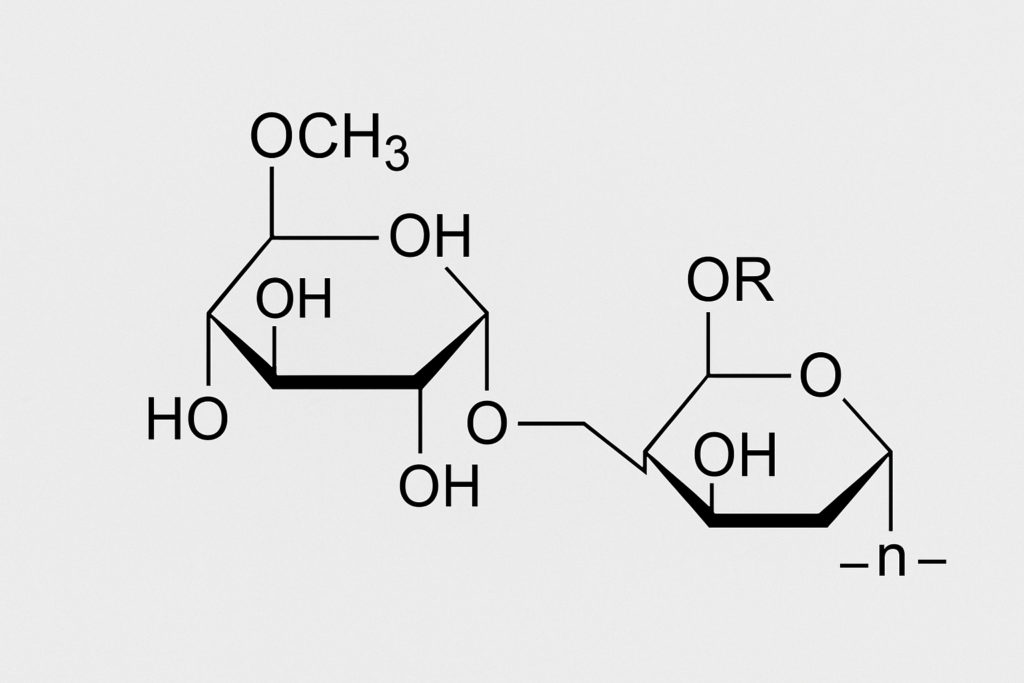

The key difference between HPMC and MHEC lies in their chemical structure: HPMC contains hydroxypropyl and methyl groups, while MHEC features hydroxyethyl and methyl groups. This structural difference affects their water retention mechanisms, especially in highly alkaline environments like cement mortars.

The molecular architecture of these polymers creates distinctly different water retention mechanisms. I've conducted numerous laboratory tests comparing MHEC and HEC specifically, and the results consistently show that MHEC outperforms HEC in water retention capacity under identical conditions.

HEC (hydroxyethyl cellulose) relies solely on its hydroxyethyl groups to capture water molecules. These groups are hydrophilic (water-loving) and form hydrogen bonds with water molecules. It's like using a basic fishing net to catch water - effective to a point, but limited in capacity.

MHEC1 (methyl hydroxyethyl cellulose), by contrast, incorporates both hydroxyethyl groups and methyl groups into its structure. While methyl groups themselves aren't particularly hydrophilic, their presence fundamentally changes the polymer's behavior in alkaline environments. This modified structure creates a denser, more robust "water-locking network" - more like an engineered aquaculture cage than a simple net.

Comparative Performance of MHEC vs HEC

| Property | MHEC | HEC |

|---|---|---|

| Water Retention in Neutral pH | Good (95-97%) | Good (92-95%) |

| Water Retention in Alkaline pH | Excellent (97-99%) | Moderate (85-90%) |

| Thermal Stability | High | Moderate |

| Salt Tolerance | Better | Good |

| Cost | Higher | Lower |

| Effectiveness in Tile Adhesives | Superior | Adequate for basic formulations |

In my testing, when I prepared identical mortar samples with 0.3% MHEC and 0.3% HEC of the same viscosity grade, the MHEC sample retained approximately 98% of its water after 30 minutes, while the HEC sample retained only about 88%. This difference becomes even more pronounced in highly alkaline environments typical of cement-based materials.

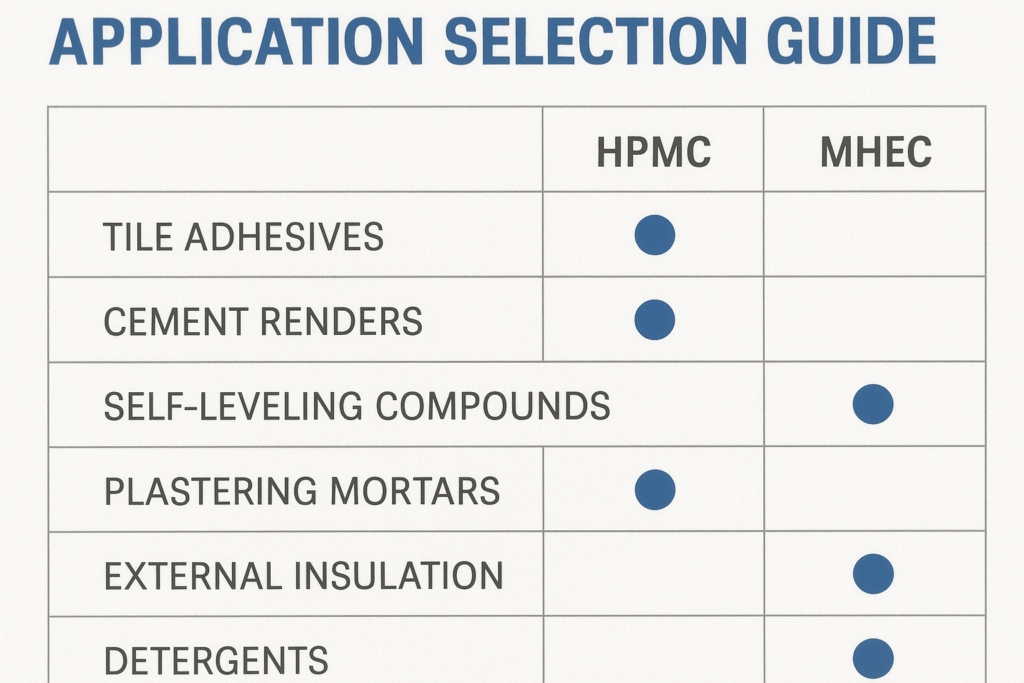

Choosing Between HPMC & MHEC1 for Construction Applications - How to Make the Right Choice?

I've seen companies waste thousands of dollars using the wrong cellulose ether for their specific application. Making an informed choice requires understanding which product delivers the best performance for your specific needs.

Choose MHEC2 over HEC when maximum water retention is critical, especially in high-performance tile adhesives4, renders, and skim coats used in hot or dry conditions. HEC is more appropriate for less demanding applications, basic formulations, or where cost constraints are significant.

The selection process should always begin with understanding the application requirements. I recently consulted with a factory in Mexico that was struggling with their exterior render formulation. They were using HEC because it was less expensive, but experiencing frequent failures in the hot, dry climate. After switching to MHEC, their product performance improved dramatically despite the slightly higher raw material cost.

For practical guidance, I recommend considering these factors when making your selection:

Application-Specific Selection Guidelines

| Application Type | Recommended Choice | Rationale |

|---|---|---|

| High-performance tile adhesives (C2TE class) | MHEC/HPMC | Superior water retention ensures proper cement hydration even on porous substrates |

| Standard tile adhesives (C1) | HEC | Adequate performance at lower cost for basic applications |

| Exterior renders in hot/dry climates | MHEC/HPMC | Enhanced water retention prevents rapid drying and cracking |

| Interior plasters | Either | Less critical water retention requirements |

| EIFS basecoats5 | MHEC/HPMC | Better adhesion and flexibility |

| Joint compounds | Either | Choose based on specific performance requirements |

The construction environment also matters significantly. When working in hot, dry conditions (above 35°C with low humidity), the superior water retention of MHEC becomes essential rather than optional. I've documented cases where renders made with HEC failed completely in Saudi Arabian summer conditions, while MHEC-based formulations performed excellently.

Budget constraints are always a reality, but the cost difference between HEC and MHEC is usually 15-25%. This premium is easily justified when considering the performance benefits and reduced risk of application failures.

Conclusion

MHEC outperforms HEC in water retention due to its special molecular structure that creates a stronger "water-locking network" in alkaline environments. For demanding applications like high-performance tile adhesives and hot-climate renders, MHEC is worth its higher cost.

-

Learn about MHEC's unique properties and its advantages in enhancing water retention for construction materials. ↩ ↩ ↩ ↩ ↩

-

Discover the key differences between HEC and MHEC to make informed choices for your construction projects. ↩ ↩ ↩

-

Understand the role of cellulose ethers in improving the performance of construction materials. ↩

-

Discover the features that make high-performance tile adhesives essential for construction projects. ↩

-

Discover the advantages of EIFS basecoats for improved adhesion and flexibility in construction. ↩