Are you struggling with wall putty that cracks, peels, or doesn't adhere properly? Poor-quality cellulose additives1 might be sabotaging your product performance, costing you customers and reputation in the competitive construction market.

Wall putty MHEC (Methyl Hydroxyethyl Cellulose) additives are essential thickening agents that provide workability, water retention, and adhesion to wall putty formulations. Quality MHEC ensures smooth application, prevents sagging, extends working time, and creates durable finishes that resist cracking and peeling.

At Kehao, we've spent years perfecting our MHEC formulations specifically for wall putty applications. Our customers consistently report that switching to our high-performance additives has transformed their product quality. Let me walk you through why MHEC is crucial for wall putty and how our solutions stand out in the market.

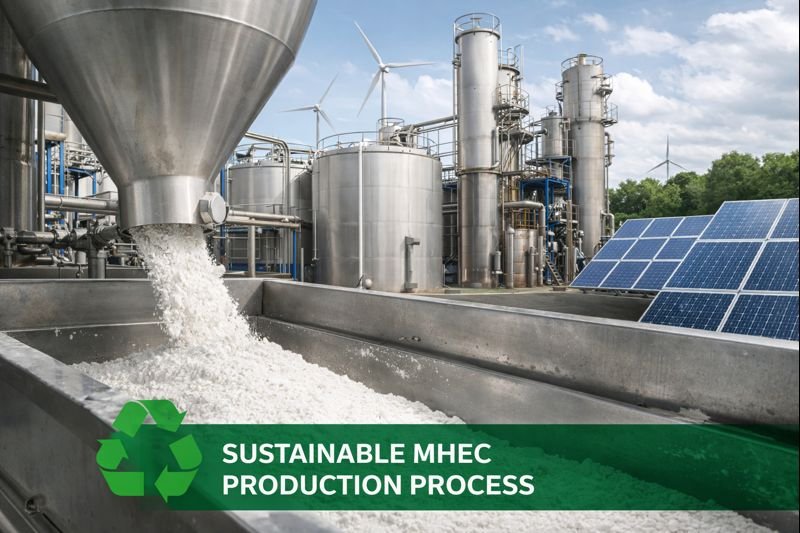

Wall Putty MHEC - Sustainable Solutions: How Can They Benefit Your Business?

Are you concerned about meeting increasing environmental regulations while maintaining product performance? Many manufacturers struggle to balance sustainability with functionality in construction chemicals.

Sustainable MHEC solutions for wall putty combine biodegradable cellulose derivatives2 with optimized manufacturing processes to reduce environmental impact. These eco-friendly additives maintain excellent water retention, workability, and adhesion while having lower carbon footprints and meeting green building certification requirements.

The construction industry is rapidly shifting toward sustainable practices, and wall putty manufacturers can't afford to be left behind. Our sustainable MHEC solutions3 address multiple environmental concerns while enhancing product performance.

Benefits of Sustainable MHEC in Wall Putty

The transition to eco-friendly MHEC doesn't mean compromising on quality. In fact, our sustainable formulations offer several advantages:

| Environmental Benefit | Technical Performance | Business Impact |

|---|---|---|

| Lower carbon footprint | Equivalent or better water retention | Access to green building projects |

| Reduced water consumption in production | Improved sag resistance | Regulatory compliance advantage |

| Biodegradable nature | Consistent viscosity | Premium market positioning |

| Less packaging waste | Extended shelf life | Reduced carbon tax liabilities |

Our sustainable MHEC production uses optimized processes that conserve energy and reduce waste. We've implemented closed-loop water systems that cut water usage by 40% compared to traditional methods. Additionally, our packaging options include recyclable materials and bulk delivery systems that minimize packaging waste. These improvements don't just benefit the environment—they translate to real cost savings and marketing advantages for our customers. Many of our clients have successfully leveraged these sustainable attributes to win contracts for green building projects across Saudi Arabia, UAE, and other Gulf countries.

Wall Putty MHEC Additives Target all Imperfections: How Do They Work?

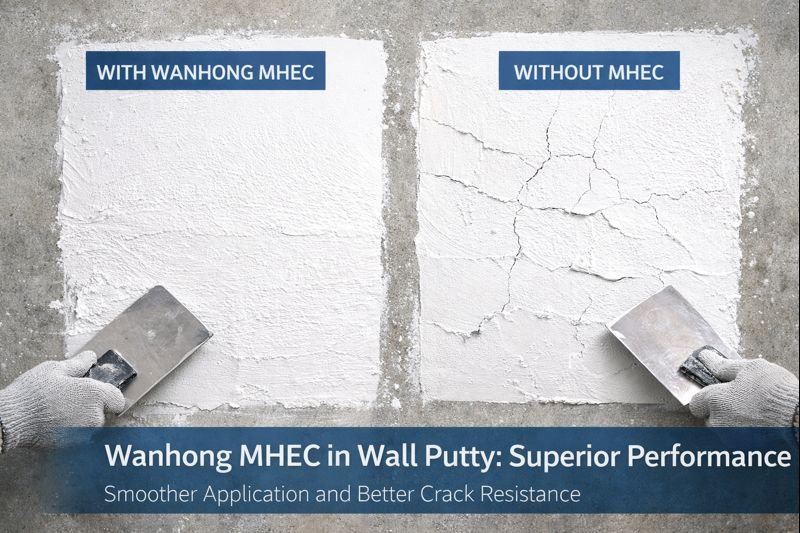

Are you tired of customer complaints about wall finishes that show cracks, bubbles, or poor adhesion? These common issues can damage your reputation and lead to costly callbacks and repairs.

MHEC additives in wall putty create a three-dimensional network that controls water movement, prevents air entrapment, and enhances adhesion to substrates. This mechanism effectively eliminates common imperfections like cracking, sagging, bubbling, and poor bonding, resulting in flawlessly smooth finished surfaces.

When I visit customer sites, I often demonstrate how our specialized MHEC grades interact with other wall putty components to provide superior performance. The science behind this is fascinating and directly impacts your bottom line.

How MHEC Prevents Common Wall Putty Problems

Understanding the mechanisms behind MHEC's effectiveness helps in selecting the right grade for specific applications. Our technical team has developed this comprehensive breakdown:

| Imperfection | Cause | How MHEC Resolves It | Kehao Solution |

|---|---|---|---|

| Cracking | Rapid water loss | Water retention capacity slows drying | Our 150K viscosity grade with enhanced water retention |

| Sagging | Poor rheological properties | Provides thixotropic behavior | MHEC with optimized molecular weight distribution |

| Poor adhesion | Insufficient bond to substrate | Creates hydrogen bonding with substrates | Our modified MHEC with adhesion promoters |

| Bubbling | Air entrapment during mixing | Controlled air detrainment properties | Low-air entrainment MHEC formulation |

| Inconsistent texture | Poor workability | Improves spreadability and leveling | Medium viscosity grades with balanced properties |

We've conducted extensive testing in our laboratory facilities, subjecting wall putty samples to accelerated aging, temperature fluctuations, and humidity cycling. Our data shows that putties formulated with our premium MHEC grades maintain structural integrity even after 500 hours of weathering tests. This translates to walls that stay beautiful for years, not months. During my recent visit to a customer's facility in Dubai, we demonstrated how our MHEC-enhanced putty maintained perfect adhesion even on challenging glossy surfaces where their previous formulation had failed repeatedly.

Wall Putty MHEC Grades: Which One Is Right for Your Formulation?

Are you overwhelmed by the variety of MHEC options and unsure which grade will optimize your wall putty performance? Selecting the wrong viscosity or substitution type can lead to processing issues and product failures.

Wall putty MHEC grades vary primarily by viscosity (from 15,000 to 100,000 mPa·s) and methoxyl/hydroxyethyl substitution ratios. Interior putties typically use 30,000-50,000 mPa·s grades for workability, while exterior formulations benefit from higher viscosity4 grades (60,000-100,000 mPa·s) for enhanced water resistance.

In my 15 years working with cellulose derivatives, I've noticed that many manufacturers struggle with grade selection. Let me share some practical insights to help you navigate this complex decision.

Comprehensive Guide to MHEC Grade Selection

Choosing the right MHEC grade requires understanding both technical requirements and practical application considerations. Our expertise in this area has allowed us to develop this detailed framework:

| MHEC Grade (Viscosity) | Ideal Application | Key Benefits | Substitution Type | Processing Considerations |

|---|---|---|---|---|

| Low (15,000-25,000 mPa·s) | Machine-applied putties | Easy pumpability, fast mixing | Low MS/High DS | Requires less water, faster dissolution |

| Medium (30,000-50,000 mPa·s) | General interior putties | Balanced workability and water retention | Medium MS/Medium DS | Standard processing conditions |

| High (60,000-80,000 mPa·s) | Exterior putties, vertical applications | Enhanced water resistance, sag resistance | High MS/Medium DS | May require specialized mixing equipment |

| Very High (85,000-100,000 mPa·s) | Premium textured finishes, extreme weather conditions | Maximum durability, excellent crack resistance | High MS/Low DS | Longer dissolution time, higher energy mixing |

Beyond viscosity, the molecular structure of MHEC significantly affects performance. Our technical team can analyze your specific formulation and recommend the optimal substitution pattern. For example, when working with a major putty manufacturer in Saudi Arabia, we discovered their high-calcium carbonate formulation performed better with our high-methoxyl substitution grade, increasing open time by 40% while maintaining the same viscosity profile.

We've also developed specialized grades for challenging environments. Our MHEC-90K-Plus grade maintains consistent performance even in the extreme temperature fluctuations common in desert regions, preventing the premature drying that often plagues exterior applications in the Gulf region.

Wanhong Is Your Trusted Partner for MHEC Supply: What Makes Us Different?

Are you frustrated with inconsistent quality from your current MHEC supplier? Batch variations, delayed shipments, and technical support gaps can severely impact your production efficiency and product quality.

Wanhong distinguishes itself as an MHEC supply partner through six production lines with 15,000-ton annual capacity, rigorous quality control with batch-to-batch consistency, responsive technical support, and flexible logistics solutions including custom packaging and expedited shipping options.

I remember when a customer from Pakistan contacted us in a panic after their regular supplier couldn't deliver a critical MHEC shipment. Within three days, we had produced, tested, and shipped a replacement batch that perfectly matched their specifications.

Why Leading Wall Putty Manufacturers Choose Wanhong

Our partnership approach extends beyond simply providing quality MHEC. We've built our reputation on being a true manufacturing partner:

| Partnership Aspect | Wanhong Advantage | Customer Impact |

|---|---|---|

| Production Capacity | Six dedicated production lines with 15,000-ton annual output | Guaranteed supply security even during peak demand |

| Quality Assurance | 100% batch testing, ISO 9001 certification, in-line monitoring | Consistent performance across all production runs |

| Technical Support | Dedicated formulation team with putty expertise | Custom formulation assistance and troubleshooting |

| Supply Chain Flexibility | Multiple packaging options, expedited shipping | Adapts to your production schedule and storage constraints |

| R&D Collaboration | Joint development projects, testing facilities | Access to latest innovations and formulation improvements |

| Market Knowledge | Presence in 35+ countries, regional experts | Insights on regional requirements and emerging trends |

Our laboratory facilities don't just test our products—they test them in your specific formulations. When a major Indian putty manufacturer was experiencing inconsistent drying times, our technicians replicated their exact production conditions and identified that a slight adjustment to the MHEC grade's methoxyl content would stabilize performance. This collaborative approach saved them months of trial-and-error and prevented potential market complaints.

We've also invested in regional technical centers that understand local conditions. Our Middle East technical team has extensive experience with the specific challenges of high-temperature application and storage, helping our customers develop formulations that remain workable even in extreme summer conditions.

Wanhong Hydroxyethyl Methyl Cellulose Highlights in Wall Putty: What Are Our Best Features?

Do inconsistent cellulose additives cause quality variations in your wall putty products? Unreliable MHEC performance can lead to customer complaints, increased returns, and damage to your brand reputation.

Wanhong MHEC for wall putty features exceptional water retention capability (>95% at 30 minutes), superior workability with extended open time, excellent adhesion to various substrates including smooth surfaces, controlled rheology that prevents sagging, and remarkable batch-to-batch consistency with less than 5% viscosity variation.

Last year, I visited a customer's site where they were conducting side-by-side tests of different MHEC brands. The difference in performance was immediately visible—our MHEC created a putty with noticeably smoother application and better surface finish.

Technical Performance Comparison

Our continuous investment in R&D has resulted in MHEC formulations specifically optimized for wall putty applications. Here's how our products perform against industry standards:

| Performance Parameter | Industry Standard | Wanhong MHEC | Benefit to Putty Formulation |

|---|---|---|---|

| Water Retention (30 min) | 85-90% | >95% | Extended working time, reduced cracking |

| Viscosity Consistency | ±10% between batches | <±5% between batches | Predictable production process |

| Gel Temperature | 65-75°C | Customizable 60-80°C | Adaptable to different climate conditions |

| Dissolution Rate | 20-30 minutes | 15-25 minutes | Faster production cycle |

| Adhesion Strength | 0.5-0.7 MPa | >0.8 MPa | Superior bonding to difficult substrates |

| Anti-sagging Performance | 2-3mm thickness | Up to 5mm thickness | Allows single-coat thick applications |

| Workability Duration | 30-45 minutes | 45-60 minutes | More time for perfect finishing |

These technical advantages translate directly to practical benefits. For example, our enhanced water retention capability allows workers to apply putty even in hot, dry conditions without worrying about premature drying—a critical advantage for our customers in Middle Eastern markets. The superior adhesion strength has enabled customers to eliminate primer in some applications, saving both time and material costs.

We've also developed specialized MHEC grades5 for specific challenges. Our MHEC-WP series is specifically engineered to provide exceptional compatibility with high-filler formulations, maintaining performance even with calcium carbonate loadings above 80%. This allows manufacturers to optimize their formulations for cost without sacrificing quality—a key competitive advantage in price-sensitive markets like India and Pakistan.

OEM Manufacturer for Wall Putty Grade MHEC Cellulose: How Can We Customize Solutions for You?

Are you struggling to find an MHEC supplier willing to develop products specifically for your unique wall putty formulation? Standard off-the-shelf additives often fail to address specific regional conditions or special formulation requirements.

OEM manufacturing of wall putty grade MHEC begins with understanding your specific requirements, followed by lab-scale customization, production-scale validation, and continuous technical support. Customization options include viscosity adjustments (15,000-100,000 mPa·s), modified substitution patterns for specific climates, and specialized dissolution profiles.

One of my most rewarding experiences was working with a Brazilian customer who needed an MHEC grade that could withstand the extreme humidity of the Amazon region while maintaining workability in the drier central areas. Through collaborative development, we created a solution that transformed their market position.

Our Custom Development Process

Creating tailored MHEC solutions involves a systematic approach that ensures both performance and manufacturing efficiency:

| Development Phase | Process Details | Customer Involvement | Timeline |

|---|---|---|---|

| Requirement Analysis | Detailed assessment of technical needs, regional conditions, and formulation constraints | In-depth consultation, formulation review | 1-2 weeks |

| Laboratory Development | Small-batch formulation trials, performance testing against benchmarks | Approval of test parameters, sample evaluation | 2-4 weeks |

| Scale-up Validation | Production-scale trial, consistency verification | On-site testing in actual formulations | 2-3 weeks |

| Production Implementation | Full-scale production with enhanced quality monitoring | Final approval, integration guidance | 1-2 weeks |

| Ongoing Support | Regular performance reviews, adaptation to changing needs | Feedback on market performance | Continuous |

This collaborative approach has led to remarkable success stories. When a major putty manufacturer in the UAE was experiencing inconsistent performance between summer and winter months, our technical team developed a seasonal adjustment program with two complementary MHEC grades optimized for different temperature ranges. This eliminated seasonal quality variations and reduced the need for field adjustments by their application teams.

Our laboratory includes specialized testing equipment that simulates diverse environmental conditions—from the extreme heat and dryness of Saudi summers to the monsoon humidity of India. This allows us to validate performance under your specific regional challenges before finalizing formulations. For a customer serving the high-end residential market in Dubai, we developed an MHEC grade with enhanced open time that allowed for perfect finishing even in air-conditioned environments that typically accelerated drying.

Wall Putty MHEC for Types of Putties: Which Formulation Needs Which Grade?

Are you uncertain which MHEC grade to use for different putty types? Using a one-size-fits-all approach to cellulose additives can lead to suboptimal performance and wasted resources in specialized applications.

Different putty types require specific MHEC grades: acrylic putties need medium viscosity (40,000-60,000 mPa·s) grades with excellent compatibility with latex; cement-based putties require higher viscosity (60,000-80,000 mPa·s) with enhanced water retention; gypsum putties work best with specialized low-methoxyl grades; and texture putties need very high viscosity (80,000+ mPa·s) for pattern stability.

During technical consultations with customers, I frequently observe that mismatched MHEC grades are a major cause of performance issues. Let me share our specialized approach to each putty type based on years of formulation experience.

Optimizing MHEC Selection for Different Putty Types

Each putty system has unique requirements that demand specific MHEC properties. Our application specialists have developed comprehensive guidelines based on extensive testing:

| Putty Type | Optimal MHEC Characteristics | Recommended Viscosity | Key Performance Requirements | Kehao Recommended Grade |

|---|---|---|---|---|

| Acrylic Putty | Balanced water retention, latex compatibility | 40,000-60,000 mPa·s | Smooth mixing with acrylic emulsions, minimal impact on film formation | MHEC-K45A with modified hydroxyethyl content |

| Cement-based Putty | High water retention, extended workability | 60,000-80,000 mPa·s | Prevent cement flash setting, enhance hydration, reduce cracking | MHEC-K75C with enhanced water retention |

| Gypsum Putty | Fast dissolution, controlled workability | 30,000-45,000 mPa·s | Compatible with rapid setting, maintaining spreadability | MHEC-K35G with low methoxyl substitution |

| POP-based Putty | Medium water retention, good workability | 40,000-55,000 mPa·s | Balance between setting time and application properties | MHEC-K50P with optimized dissolution profile |

| White Cement Putty | Very high water retention, excellent sag resistance | 75,000-90,000 mPa·s | Prevent moisture loss to porous substrates | MHEC-K85WC with maximum water retention |

| Texture Putty | Very high viscosity, pattern stability | 80,000-100,000+ mPa·s | Maintain textured patterns, resist slumping | MHEC-K100T with enhanced thixotropy |

We've conducted extensive application testing that reveals the critical importance of matching MHEC properties to specific putty types. For example, when working with a major manufacturer in Pakistan who was transitioning from traditional POP putty to cement-based formulations, we discovered that simply switching to a higher-viscosity MHEC wasn't sufficient. The cement-based system required a fundamentally different methoxyl/hydroxyethyl substitution ratio to properly interact with the cement hydration process and prevent premature drying.

Our specialized texture putty grade MHEC-K100T contains modified particle morphology that provides exceptional suspension properties for heavy aggregates and texturing materials. This allows decorative putties to maintain consistent patterns without sagging or settling, even in vertical applications. During a demonstration at a trade show in Dubai, our texture putty maintained perfect pattern definition for over 8 hours in the display, while competing products showed noticeable pattern degradation within 3-4 hours.

Wall Putty MHEC Packaging and Volume: How Do We Meet Your Logistical Needs?

Are you facing challenges with MHEC packaging that doesn't match your production requirements? Inefficient packaging leads to material waste, increased handling time, and potential contamination risks during production.

Wall putty MHEC packaging options include 25kg moisture-resistant paper bags (standard), 500kg jumbo bags for high-volume operations, 20kg PE-lined aluminum bags for extreme climates, and customized packaging with private labeling. Volume discounts begin at 1 metric ton with significant savings at 5+ ton orders.

I remember visiting a customer's facility and noticing their team struggling with re-sealing partially used MHEC bags, leading to clumping issues. We immediately offered our resealable packaging option which eliminated this problem and reduced their material waste by nearly 15%.

Comprehensive Packaging and Volume Solutions

Our flexible approach to packaging and order volumes is designed to accommodate diverse production environments:

| Packaging Type | Capacity | Best For | Special Features | Minimum Order |

|---|---|---|---|---|

| Standard Paper Bags | 25kg | Most manufacturing setups | Moisture-resistant multi-layer kraft paper with PE liner | 1 metric ton (40 bags) |

| Jumbo Bags | 500kg | High-volume continuous production | Reinforced handles, discharge spout, lift loops | 2 metric tons (4 bags) |

| Aluminum-PE Bags | 20kg | Extreme climate regions, extended storage | Enhanced moisture protection, UV resistance | 1 metric ton (50 bags) |

| Customized Packaging | 5-1000kg | Special production requirements | Size, material, and closure system to specification | Varies by specification |

| Private Label Options | Any size | Distributors, white-label manufacturers | Your branding, technical specs, and contact information | 5 metric tons |

Volume pricing tiers are structured to benefit both smaller manufacturers and large operations:

- 1-4 metric tons: Standard pricing

- 5-9 metric tons: 5-8% discount

- 10-19 metric tons: 8-12% discount

- 20+ metric tons: Custom volume pricing

Our logistics expertise extends beyond just packaging. For customers in challenging regions like Saudi Arabia or UAE, we've developed specialized heat-resistant packaging that prevents clumping even when containers reach extreme temperatures during transit. When a customer in Riyadh reported material degradation during the summer shipping season, we implemented our aluminum-PE composite bags with additional thermal insulation layers, completely resolving the issue.

We also offer inventory management solutions for regular customers. Our VMI (Vendor-Managed Inventory) program maintains appropriate stock levels at your facility or at regional warehouses, ensuring you never face production delays due to material shortages. This has been particularly valuable for our customers in regions with unpredictable shipping times, such as during recent global logistics challenges.

FAQ: What Do Customers Most Often Ask About Wall Putty MHEC?

Do questions about MHEC usage in wall putty keep coming up in your technical meetings? Understanding the answers to common concerns can help you optimize your formulations and avoid costly mistakes.

The most common wall putty MHEC questions involve optimal dosage rates (typically 0.2-0.5% for most formulations), compatibility with other additives (generally excellent with most raw materials), storage stability (12-24 months in original packaging), and dissolution techniques (pre-mixing with other dry ingredients before water addition is recommended).

In our technical support center, we receive dozens of questions each week about MHEC usage in wall putty. Let me address the most frequent inquiries to help you avoid common pitfalls.

Essential Information About Wall Putty MHEC

Our technical support database reveals patterns in customer questions that highlight key information needs:

| Frequently Asked Question | Expert Answer | Additional Insights |

|---|---|---|

| What is the optimal MHEC dosage for wall putty? | Generally 0.2-0.5% for most formulations; acrylic putties typically use 0.2-0.3%, while cement-based putties may require 0.3-0.5% | Increasing beyond optimal range rarely improves performance and increases cost |

| How does MHEC interact with other additives? | Compatible with most additives; shows synergistic effects with redispersible powders; may require adjustment when used with superplasticizers | Preliminary lab testing recommended when introducing new additives |

| What's the shelf life of MHEC in putty formulations? | 12-24 months for MHEC powder in original packaging; finished putty typically 6-12 months depending on packaging and preservative system | Proper storage in cool, dry conditions extends shelf life |

| What's the best dissolution method? | Pre-mix with other dry ingredients before adding water; use water at 20-25°C; allow 15-20 minutes for complete hydration | Hot water can cause lumping; cold water slows dissolution |

| How does MHEC affect drying time? | Extends drying time by 20-40% depending on grade and dosage; higher viscosity grades generally extend drying more | Consider seasonal adjustments—lower dosage in humid seasons |

| Is MHEC compatible with all pigments? | Generally yes, but some iron oxide pigments may require specialized dispersing agents | Preliminary testing recommended with high pigment loads |

| How does MHEC prevent sagging on vertical surfaces? | Creates thixotropic structure that resists flow under gravity but allows spreading under shear force | Higher viscosity grades provide better sag resistance |

Beyond these common questions, we've compiled application guides for specific regional challenges. For instance, our "Gulf Region Application Guide" addresses the unique challenges of applying putty in extremely hot and dry conditions, with specific recommendations for MHEC grade selection and application techniques. This resource has been invaluable for our customers in Saudi Arabia and the UAE, where standard application practices often fail due to extreme conditions.

Another frequent concern involves troubleshooting inconsistent results. We've developed a systematic diagnostic approach that helps identify whether issues stem from the MHEC itself, other formulation components, or application techniques. This has helped numerous customers resolve quality issues without expensive reformulation efforts. When a major customer in Iran experienced sudden changes in their putty workability, our diagnostic process quickly identified that the issue wasn't with the MHEC but with a change in their calcium carbonate particle size distribution.

Conclusion

Wall putty MHEC additives are critical for achieving high-quality, durable finishes that meet modern construction demands. By selecting the right grade, partnering with a reliable supplier like Kehao, and understanding optimal usage techniques, you can create superior products that outperform competitors and build customer loyalty.

-

Learn about the role of cellulose additives in enhancing the performance of construction materials. ↩

-

Understand the advantages of using biodegradable materials in construction chemicals. ↩

-

Find out how sustainable MHEC solutions can benefit your business and the environment. ↩

-

Explore the impact of viscosity on the workability and performance of wall putty. ↩

-

Understand the various MHEC grades and their specific applications in wall putty. ↩