Choosing between wall putty and gypsum plaster leaves many builders and homeowners confused. The wrong choice can waste thousands of dollars and cause endless headaches when walls crack or need constant repairs.

Wall putty1 and gypsum plaster serve different purposes rather than being alternatives. Gypsum plaster2 is more cost-effective for uneven surfaces (>5mm irregularities) as it levels walls in one application, while putty is economical for final smoothing of already-level surfaces.

This isn't an "either-or" decision but a "what comes first" question. Many people focus only on material costs and miss the bigger picture. Let me break down what I've learned from years in the construction materials industry to help you make the right choice for your next project.

Wall Putty (Cement-based or Acrylic): When Is It Actually Cheaper?

Builders often reach for putty first because the price per bag seems lower. But this apparent saving can cost you more in the long run when applied incorrectly.

Wall putty1 works best as a thin finishing layer (1-2mm) on already smooth surfaces. It's cost-effective for minor surface corrections, creating a smooth paint-ready finish, and small repair work, costing $0.15-0.30 per square foot including labor.

The real cost considerations for wall putty go beyond the sticker price. I've seen customers try to save money by using putty to fill large gaps, and it always ends badly. Wall putty1 is designed for fine finishing, not structural leveling.

Types of Wall Putty and Their Cost-Effectiveness

| Type | Cost Range (per kg) | Best Use Case | Durability | Labor Requirements |

|---|---|---|---|---|

| Cement-Based | $0.50-1.00 | Exterior walls, high-moisture areas | High | Medium |

| Acrylic | $1.20-2.00 | Interior decoration, smooth finish | Medium | Low |

| POP-Based | $0.40-0.80 | Quick fixes, interior walls | Low-Medium | Low |

When I visit construction sites, I often notice contractors using wall putty as a substitute for proper wall leveling. This is like using expensive makeup to hide structural skin issues—it works temporarily but doesn't solve the underlying problem. Wall putty shines in its proper role: creating that perfect, smooth finish on already level surfaces. Using it properly means applying thin layers (usually 1-2mm thick) over surfaces that are already structurally sound and roughly level.

Gypsum Plaster: Is The Higher Initial Cost Worth It?

The higher price tag of gypsum plaster makes many contractors hesitate. But looking only at material cost is a common and costly mistake in construction.

Gypsum plaster2 provides a one-step wall finishing solution that eliminates multiple layers of traditional cement-sand plaster and putty. Despite costing $0.30-0.50 per square foot for materials, it reduces overall project costs by saving 30-40% on labor and cutting completion time by up to 50%.

I've watched the transformation in construction practices across developing markets. When I first started supplying HPMC to construction companies in Saudi Arabia, few were using gypsum plaster. Now it's becoming standard because the total project economics make sense.

Why Gypsum Plaster Often Wins the Long-Term Cost Battle

Gypsum plaster offers significant advantages that translate to real cost savings:

- One-step application: Eliminates the traditional three-coat process (rough, brown, and finish coats)

- Faster setting time: Walls are ready for paint in 48 hours versus 7+ days for cement plaster

- Lower labor costs: Requires fewer worker-hours per square meter

- Reduced material waste: Pre-mixed formulations mean more precise application

- Better thermal properties: Can contribute to energy savings over building lifetime

During a recent project in Dubai, I saw a contractor complete an entire apartment building two weeks ahead of schedule by switching to gypsum plaster. The material cost was 15% higher, but they saved over 30% on the total wall finishing budget.

Cost-Effectiveness Summary: When To Choose Each Option

The right choice depends on your specific project needs, not just which material is cheaper per bag or kilogram.

Choose gypsum plaster for new construction or major renovations where walls need significant leveling (>5mm variance). Select wall putty for minor repairs, already level surfaces, or as a finish coat over cement plaster for optimal cost-effectiveness.

When I consult with large construction firms, I always emphasize looking at the total applied cost rather than just material cost. This includes labor, time value, durability, and future maintenance requirements.

Real-World Application Scenarios

The choice between these materials becomes clearer when we consider specific scenarios:

- New construction with brick/block walls: Gypsum plaster is typically more cost-effective despite higher material costs

- Concrete walls with minor imperfections: Wall putty over a thin cement render is usually most economical

- Renovation projects: Depends on the condition of existing walls - major unevenness favors gypsum

- High-humidity areas: Specialized water-resistant gypsum or cement-based putty may be required

I've supplied materials to projects across the Middle East and Asia, and the pattern is consistent: contractors who choose the right material for the specific wall condition save money overall, even when they spend more initially on materials.

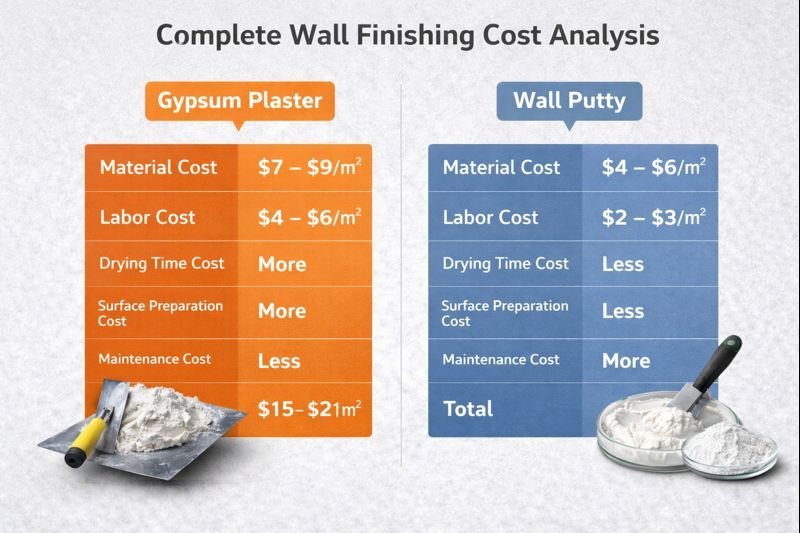

Cost Breakdown: Gypsum Plaster vs. Wall Putty

Understanding the full cost picture helps make better decisions for your specific project requirements.

A complete wall finishing with traditional cement plaster plus putty typically costs $1.20-1.80 per square foot including labor. Gypsum plaster finishing costs $0.90-1.40 per square foot all-inclusive, potentially saving 15-30% on total project costs.

I remember a project in Pakistan where the contractor insisted on using cement plaster with putty for a large housing development because the material cost was lower. Six months later, they switched to gypsum plaster after calculating that they were spending 22% more overall due to labor costs and time overruns.

Hidden Costs to Consider

When budgeting for wall finishing, several factors are often overlooked:

| Cost Factor | Cement Plaster + Putty | Gypsum Plaster |

|---|---|---|

| Water consumption | High | Low (30-40% less) |

| Curing time | 7-21 days | 1-2 days |

| Project delays | Common | Minimal |

| Crack development | Moderate-High | Low |

| Need for rework | Higher probability | Lower probability |

| Painting preparation | Additional primer often needed | Less primer required |

The time value of these differences is substantial. On large projects, the ability to move to the next construction phase quickly can save thousands of dollars in overhead costs and financing charges.

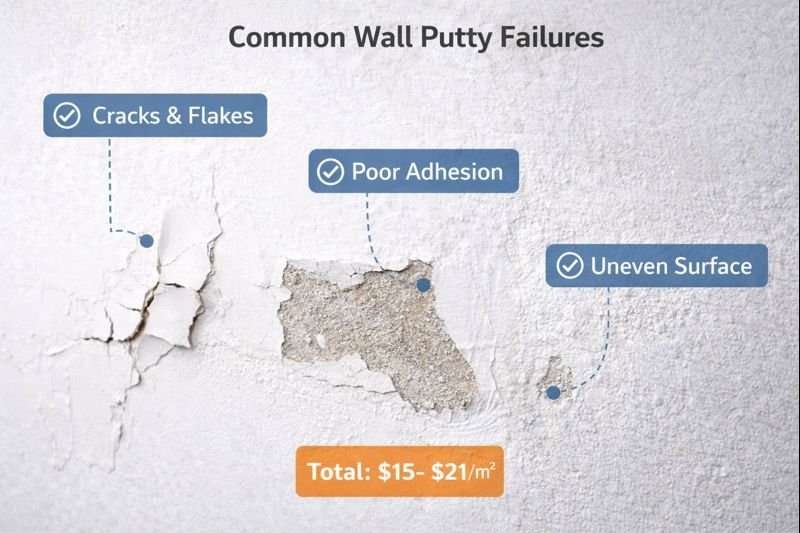

What are the disadvantages of putty?

When looking at wall putty, many focus only on its advantages. But knowing its limitations is crucial for making informed decisions and avoiding costly mistakes.

Wall putty's main disadvantages include inability to fill deep cracks or level uneven surfaces, poor durability when used incorrectly, susceptibility to moisture damage, and higher total cost when used as a substitute for proper plastering work.

In my factory, we manufacture both HPMC for wall putty and gypsum additives, so I've seen the technical limitations of both materials. Wall putty simply wasn't designed to handle structural wall imperfections.

When Wall Putty Becomes More Expensive Than Alternatives

Using wall putty incorrectly leads to several problems that ultimately increase costs:

- Multiple applications: Deep imperfections require many layers, increasing material and labor costs

- Premature failure: Thick putty applications often crack and peel, requiring repairs

- Poor adhesion: When applied too thickly, putty may not bond properly to the substrate

- Extended drying time: Multiple thick layers can take days to dry fully

- Uneven absorption: Leads to patchy paint appearance, requiring more paint coats

During a visit to a construction site in UAE last year, I saw workers applying layer after layer of putty to try to level a badly finished concrete wall. The contractor later told me they ended up spending three times more than if they had used gypsum plaster from the start.

Wall putty performs excellently when used correctly - as a thin finishing layer on already level surfaces. But when pushed beyond its capabilities, it becomes both technically inadequate and financially inefficient.

Conclusion

The smart choice isn't about picking the cheapest material but using each product for its intended purpose. Gypsum plaster for leveling uneven walls saves on labor costs, while putty is economical for final smoothing of already level surfaces.