Paint failures in hot climates are causing headaches for contractors worldwide. Cracking, peeling, and poor film formation waste time and money while damaging reputations. The solution might be in understanding one critical aspect of your cellulose ether.

The substitution degree (DS) of hydroxypropyl methylcellulose1 (HPMC) directly impacts paint performance in hot climates because it determines the material's gelation temperature. Higher DS values create HPMCs that maintain their water retention and thickening properties even when wall temperatures exceed 60-70°C.

After 15 years manufacturing HPMC for global markets, I've seen countless formulation failures traced back to improper cellulose ether selection. Let me share what I've learned about substitution degree and why it matters so much when your paints face extreme heat.

What is the Degree of Substitution of HPMC?

Paint formulators often overlook this technical parameter until they experience field failures. Poor substitution degree selection leads to immediate paint destabilization, causing separation and cracking that ruins projects and reputations.

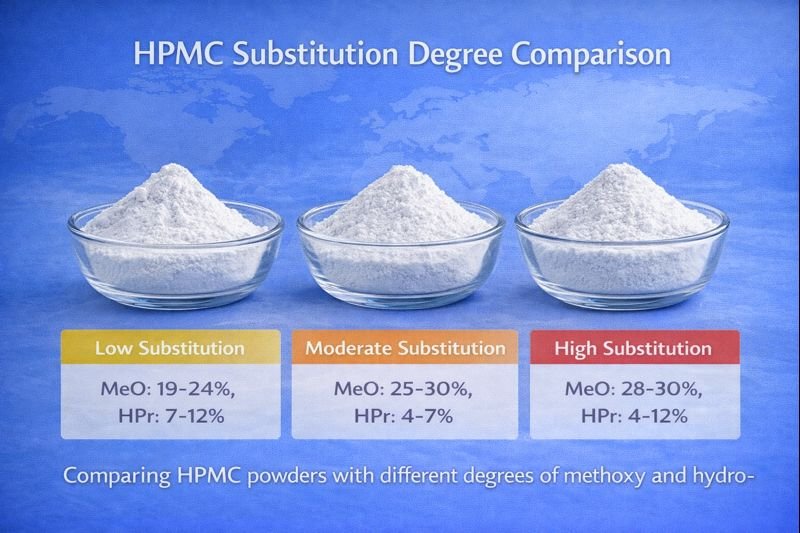

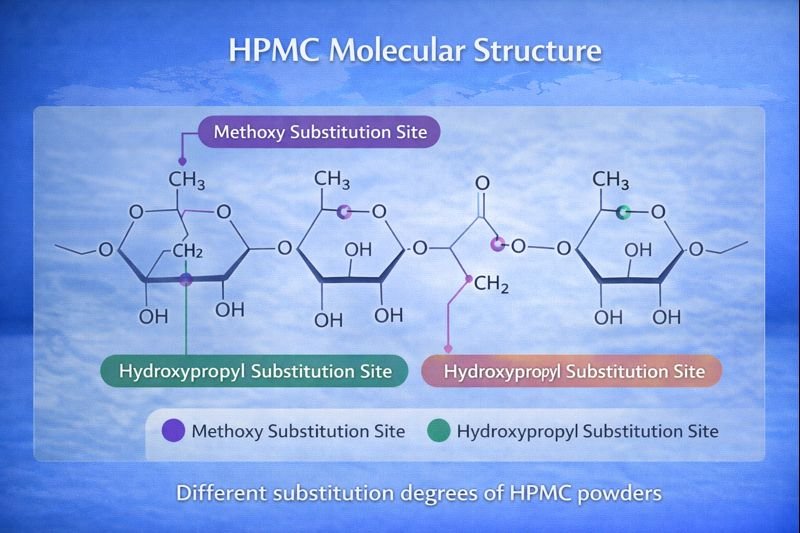

The substitution degree2 (DS) of HPMC refers to how many hydroxyl groups on the cellulose backbone have been replaced with methoxyl or hydroxypropyl groups. It's typically expressed as a percentage or decimal (0-3), with higher values indicating more substitution and different performance characteristics.

When we talk about substitution degree, we're actually discussing two separate measurements: the degree of substitution (DS) and the molar substitution (MS). DS measures how many hydroxyl groups have been substituted, while MS represents the average number of moles of hydroxypropyl groups per glucose unit. For paint applications in hot climates, both values matter enormously.

A higher methoxyl substitution makes HPMC more hydrophobic, while higher hydroxypropyl substitution improves solubility in cold water. These substitutions aren't just chemical details—they fundamentally change how the polymer behaves in your paint formulation. When temperatures rise above 60°C on sun-exposed walls, HPMCs with low substitution degrees quickly lose their critical functions.

In our Kehao production facilities, we carefully control these substitution parameters to produce HPMCs specifically designed for hot-climate applications. The difference between DS 1.8 and DS 2.2 might seem small on paper, but on a building exterior in Saudi Arabia at midday, it's the difference between success and failure.

What is the Degradation Temperature of HPMC?

When summer hits and wall temperatures soar, standard cellulose ethers break down quickly. This sudden degradation causes paint to lose viscosity, leading to sagging, uneven application, and poor hiding power.

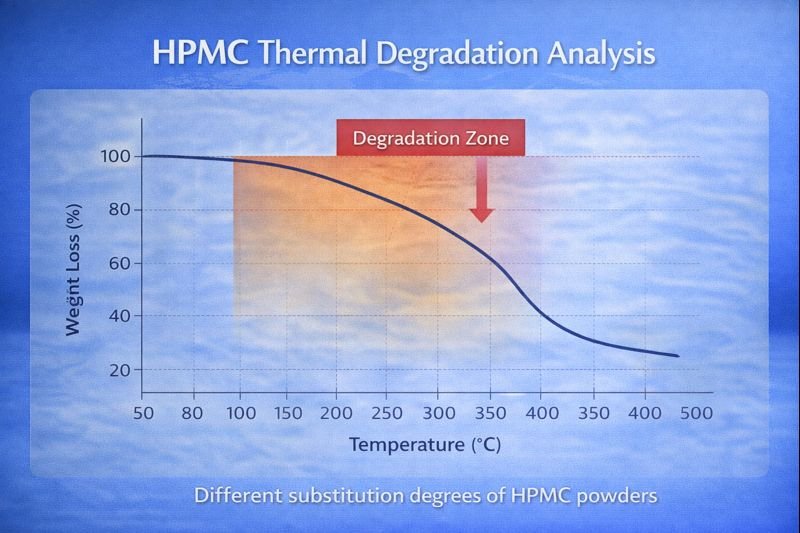

HPMC typically begins thermal degradation between 190-200°C, but its functional properties change at much lower temperatures. This degradation temperature far exceeds application conditions, but the gelation temperature (50-85°C depending on substitution degree) is frequently reached in hot climates.

Thermal stability directly impacts how your paint performs in extreme conditions. While complete chemical breakdown occurs at temperatures above 190°C, the functional changes that affect your paint happen much earlier. As temperatures climb, HPMC molecules undergo conformational changes that alter rheology, water retention, and binding properties.

These changes happen in stages. First, at temperatures approaching the gelation point, water molecules associated with the HPMC begin to dissociate, causing loss of hydrogen bonding. Next, hydrophobic interactions between polymer chains increase, leading to aggregation. Finally, the network structure changes dramatically, affecting the entire paint system.

I've seen firsthand how different HPMC grades perform in our climate chambers. Products with higher methoxyl substitution consistently maintain their functional properties at higher temperatures. This isn't theoretical chemistry—it's practical knowledge that determines whether your paint will maintain workable viscosity throughout application and proper film formation during curing in hot environments.

The ideal substitution pattern creates a balance between thermal stability and other required properties like water retention. This is why custom-formulated HPMCs are often necessary for paints destined for extreme climate regions.

What is the Gelation Temperature of HPMC?

Project failures often happen when painters apply product during the hottest part of the day. The sudden gelation makes proper application impossible, wastes product, and requires complete rework.

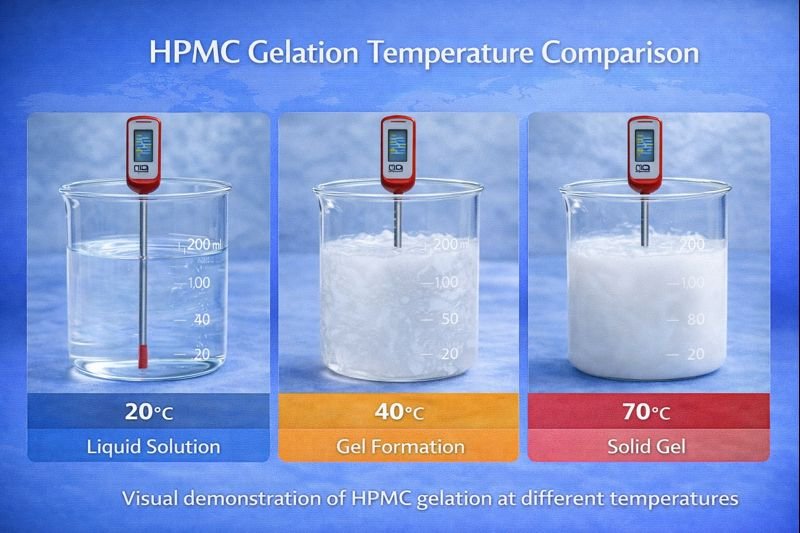

Gelation temperature is the point at which HPMC transitions from a soluble state to a gel as temperature increases, typically between 50-85°C depending on substitution degree. Higher substitution degree (DS) HPMCs have higher gelation temperatures, making them suitable for applications in hot climates.

Gelation temperature represents the critical threshold where your paint formulation's behavior changes dramatically. This temperature-dependent phase transition occurs when the polymer's hydrophobic segments associate, causing the solution to transform from a flowing liquid to a gel structure. For paint applications, this can be catastrophic if it happens during application.

The fascinating aspect of HPMC gelation is its reversibility—once the temperature drops below the gelation point, the solution returns to its original state. However, in real-world painting scenarios, this reversibility doesn't help if gelation occurs during application, as the damage to film formation is already done.

Different substitution patterns create different gelation temperature profiles:

| Substitution Type | Typical Gelation Range | Best Climate Application |

|---|---|---|

| Low methoxyl DS | 50-65°C | Temperate climates |

| Medium methoxyl DS | 65-75°C | Warm climates |

| High methoxyl DS | 75-85°C | Hot/tropical climates |

Our laboratory testing consistently shows that HPMCs with higher methoxyl content maintain their functional properties at higher temperatures. For clients in Saudi Arabia, UAE, and other Gulf regions, we specifically recommend high-substitution grades that won't gel even when wall temperatures exceed 70°C.

Why is HPMC Widely Used for Film Coating?

Many formulators have tried alternatives to HPMC in hot climates, often with disappointing results. Other thickeners and film formers lack the unique combination of properties that make HPMC indispensable in high-temperature applications.

HPMC is widely used for film coating because it forms transparent, flexible films with excellent oxygen and moisture barrier properties. Its unique combination of water retention, controlled gelation, and compatible film-forming capabilities makes it superior to alternatives, especially in challenging environments.

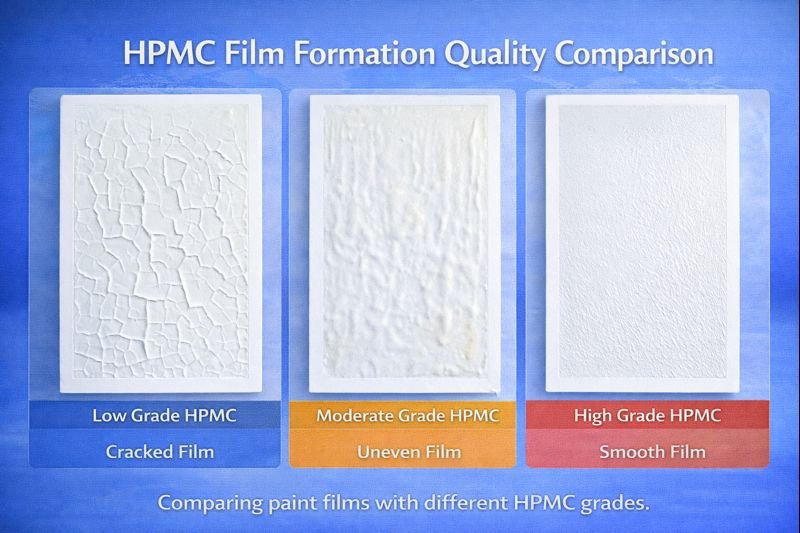

Film formation is perhaps the most critical function of HPMC in paint systems. Unlike many other additives, HPMC doesn't just thicken the formula—it actively participates in creating the film structure. During drying, HPMC forms a temporary scaffold that holds pigments and binders in place, ensuring even distribution and preventing separation.

This film-forming capability becomes even more crucial in hot climates where evaporation happens rapidly. The water retention properties of HPMC slow this process, giving the paint components time to properly orient and create a defect-free film. Without sufficient water retention, rapid evaporation causes surface defects, poor adhesion, and ultimately, premature failure.

From our extensive testing at Kehao, we've identified several key advantages of high-DS HPMC for film coating in hot conditions:

- Controlled water release during film formation

- Maintenance of critical surface tension throughout drying

- Compatible interaction with acrylic, styrene-acrylic, and VAE binders

- Prevention of pigment flocculation under thermal stress

- Excellent leveling properties even at high application temperatures

These properties explain why painters consistently achieve better results with HPMC-based formulations compared to alternatives like cellulose ethers with lower substitution degrees or non-cellulosic thickeners. The film quality difference is particularly noticeable on surfaces that experience extreme temperature variations.

Conclusion

The substitution degree2 of HPMC directly determines your paint's success in hot climates. Selecting HPMCs with higher DS values ensures your coatings maintain water retention and proper film formation even when wall temperatures exceed 70°C, preventing costly failures and callbacks.

FAQ

Does substitution degree affect HPMC price?

Yes, HPMCs with higher substitution degrees typically cost 10-15% more but prevent much costlier paint failures in hot climates.

Can I blend different HPMC types?

Yes, blending can be cost-effective, but requires expert formulation to maintain performance in extreme temperatures.

How do I know if my HPMC has the right substitution degree?

Request specific DS/MS values from your supplier and perform heat-stability testing or consult with a cellulose ether specialist.