I've seen too many clients waste thousands on low-quality hydroxypropyl methylcellulose1. Poor HPMC ruins formulations, delays production, and damages reputation - a nightmare for any serious manufacturer.

To test HPMC quality2 before purchasing, perform three simple checks: the ash test (burning a sample), transparency test (dissolving in cold water), and odor test. High-quality HPMC burns to black carbon with minimal ash, dissolves clearly in water, and has almost no smell.

After 15 years supplying HPMC to construction companies worldwide, I've developed these practical tests that anyone can perform without specialized equipment. These methods have saved our clients countless times from purchasing adulterated products. Let me share these industry insider techniques with you.

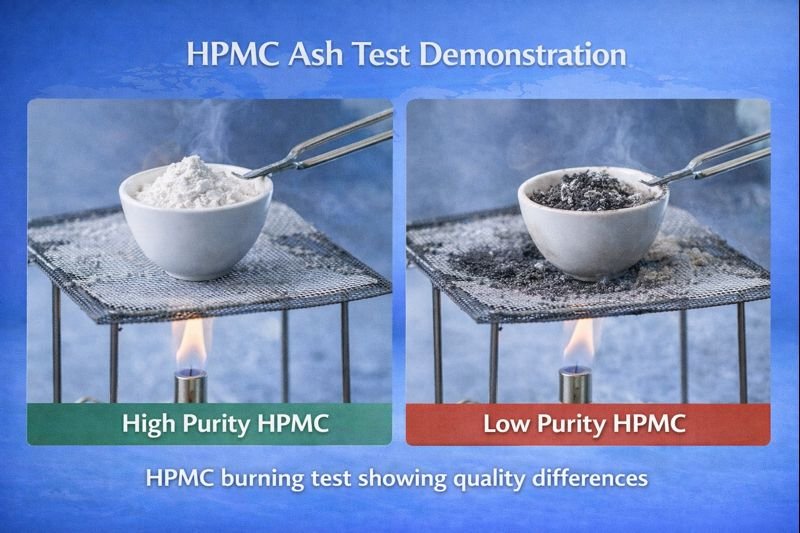

The Ash Test: How Can Burning HPMC Reveal Hidden Contaminants?

Many clients contact me after being burned by suppliers selling HPMC mixed with salt or calcium carbonate. These fillers dramatically reduce effectiveness but are invisible to the naked eye.

The ash test involves burning a small HPMC sample with a lighter. High-quality HPMC burns to black carbon powder with minimal ash residue. If significant white ash remains, the product likely contains fillers like salt or calcium carbonate, indicating adulteration.

The ash test is perhaps the most revealing quality check you can perform without laboratory equipment. I remember visiting a client in Saudi Arabia who was experiencing mysterious performance issues with their tile adhesive. When we performed this test together, the significant white ash residue immediately revealed the problem - their supplier had been selling them HPMC cut with nearly 30% calcium carbonate.

To perform this test properly, place a small amount (about 1 gram) of HPMC powder on a clean, non-flammable surface. Using a lighter, burn the sample completely until no more changes occur. Premium HPMC will burn down to a very small amount of black carbon residue. The presence of significant white or gray ash indicates inorganic fillers.

| For quantitative assessment, you can use this rough guideline: | Ash Appearance | Likely Quality Level |

|---|---|---|

| Minimal black residue (<5%) | Premium grade | |

| Small amount of grayish ash (5-15%) | Standard commercial grade | |

| Significant white/gray ash (>15%) | Likely adulterated |

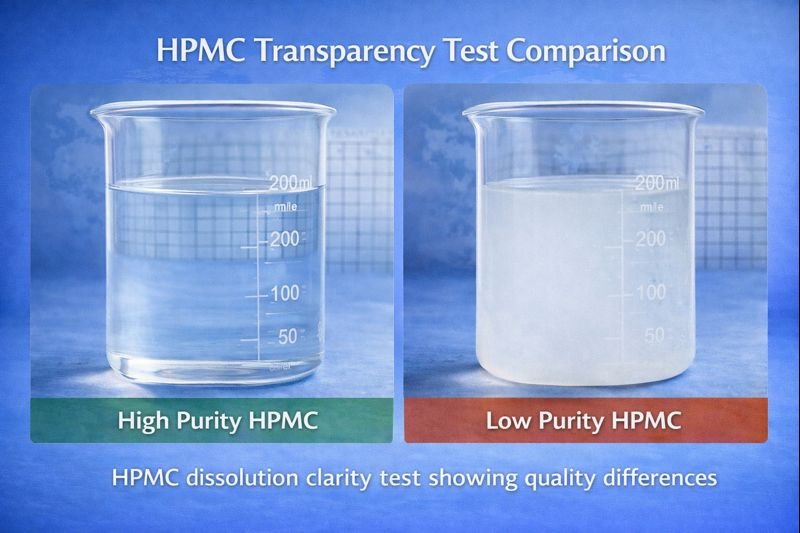

The Transparency Test: Why Does Dissolution Clarity Matter For Quality Control?

When clients complain about inconsistent performance in their products, I often discover they're using HPMC with poor dissolution properties, containing unreacted raw materials.

The transparency test involves sprinkling HPMC onto cold water and observing after dissolution. High-quality HPMC creates a clear, transparent solution with minimal cloudiness. If the solution appears milky or turbid like rice water, the HPMC contains impurities or unreacted materials.

The transparency test gives valuable insights into both purity and manufacturing quality. Last year, a paint manufacturer in Brazil was experiencing inconsistent viscosity in their products. When we performed this test, their HPMC created a cloudy solution - clear evidence of poor manufacturing quality and incomplete purification.

To conduct this test effectively, sprinkle approximately 1 gram of HPMC onto the surface of 100ml cold water (below 20°C) in a clear glass. Allow it to hydrate without stirring for 10-15 minutes, then gently mix until fully dissolved. Premium HPMC will form a clear, transparent solution with very little haziness. The presence of significant cloudiness or particles indicates impurities.

This test is particularly important for applications where clarity is critical, such as transparent coatings or certain pharmaceutical applications. Even for construction applications where clarity isn't visible in the final product, this test indicates overall purity and manufacturing consistency that directly impacts performance properties like water retention and adhesion strength.

The Odor Test: What Can Your Nose Tell You About HPMC Quality?

Many customers don't realize how revealing a simple smell test can be until I demonstrate it. Poor manufacturing processes leave chemical residues that compromise performance and stability.

The odor test involves smelling a handful of HPMC powder. High-quality HPMC is virtually odorless with perhaps a faint ether-like smell. Strong acidic, ammonia-like, or chemical odors indicate poor manufacturing processes, incomplete solvent removal, or degradation.

The odor test, while seemingly subjective, provides immediate insights into manufacturing quality. During a factory visit in Mexico, I showed a client how their supplier's HPMC had a distinct acidic smell. This indicated incomplete neutralization during production - a problem that was causing unexpected pH shifts in their final product and affecting shelf stability.

When performing this test, take a small handful of HPMC and warm it slightly with your hand. Take several short sniffs rather than one deep inhalation. Premium HPMC should have minimal odor - perhaps a very slight ether-like smell that isn't unpleasant. Any strong chemical smells, particularly acidic or ammonia-like odors, indicate manufacturing problems.

| These residual chemical odors aren't merely aesthetic concerns. They often correlate with: | Odor Type | Potential Manufacturing Issue | Possible Performance Impact |

|---|---|---|---|

| Acidic | Incomplete neutralization | pH instability in final product | |

| Ammonia/amine | Poor washing procedures | Discoloration, stability issues | |

| Strong solvent | Incomplete solvent removal | Health concerns, instability | |

| Musty/moldy | Improper storage/moisture exposure | Reduced shelf life, contamination |

Conclusion

These three simple tests - burn, dissolve, and smell - can save you from costly HPMC quality issues. By spending five minutes checking samples before ordering, you'll avoid production problems, ensure consistent quality, and protect your reputation.