Finding a trustworthy HPMC supplier can be overwhelming. With so many options claiming "top quality," how do you separate legitimate manufacturers from unreliable traders? The right certifications are your best protection against quality issues.

A reliable HPMC supplier should have ISO 9001, ISO 14001, ISO 45001 as basic qualifications, plus industry-specific certifications like REACH registration for Europe and CE certification1 for construction products. These verify both the manufacturer's operational standards and product compliance with international regulations.

When selecting an HPMC supplier for your construction materials or paint manufacturing business, certifications provide objective proof of quality and compliance. Let me walk you through what these certifications mean and why they matter to your business.

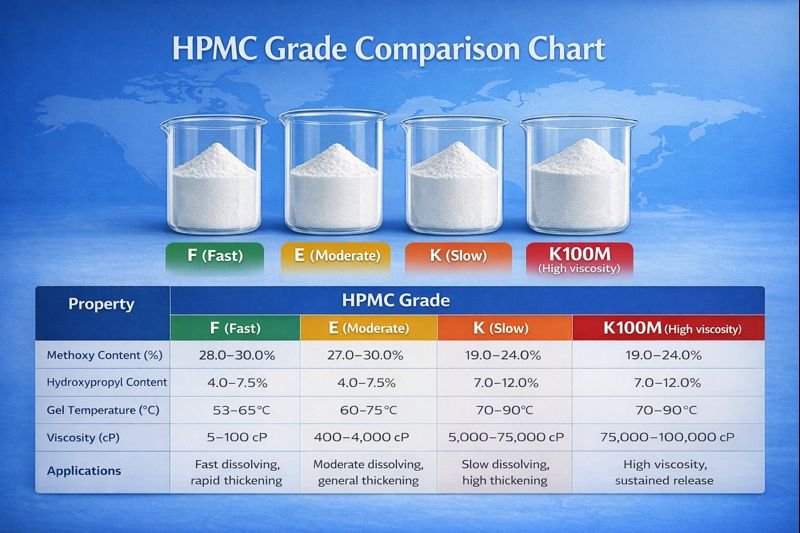

What is the Difference Between HPMC Grades?

Looking for the right HPMC grade but confused by all the technical specifications? Without understanding these differences, you might waste money on products that won't perform in your applications.

HPMC grades2 differ primarily in viscosity, methoxyl content, hydroxypropyl content, and particle size. Viscosity (ranging from 5 to 200,000 mPa·s) determines thickness and water retention properties. Higher methoxyl content improves water solubility, while hydroxypropyl content affects thermal gelation temperature.

The grade of HPMC you need depends completely on your specific application. For example, in tile adhesives, we typically use HPMC with viscosity ranges of 60,000-100,000 mPa·s for optimal water retention and workability. For wall putties, lower viscosity grades around 15,000-30,000 mPa·s provide better flowability while maintaining adequate water retention.

I've noticed many customers making the mistake of thinking higher viscosity3 always means better quality. This isn't true! Each application has its optimal viscosity range. Using too high a viscosity grade can cause mixing problems and increase costs unnecessarily.

The methoxyl and hydroxypropyl content determine the HPMC's compatibility with other ingredients in your formulation. For example:

| HPMC Type | Methoxyl Content (%) | Hydroxypropyl Content (%) | Best For |

|---|---|---|---|

| K-Type | 19-24 | 7-12 | Exterior insulation, renders |

| E-Type | 28-30 | 7-12 | Tile adhesives, self-leveling compounds4 |

| F-Type | 27-30 | 4-7.5 | Specialized applications |

Particle size also matters tremendously. Finer particles (80-120 mesh) dissolve faster but may create dust issues during production. Coarser particles (40-80 mesh) reduce dust but take longer to dissolve fully.

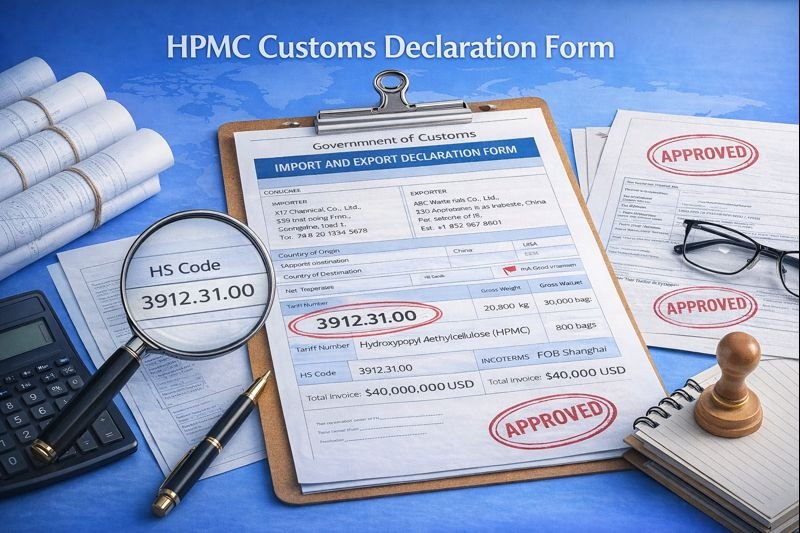

What is the HS Code for HPMC?

Dealing with import paperwork for HPMC and worried about customs delays? Wrong HS codes can lead to incorrect tariffs, rejected shipments, and painful bureaucratic headaches.

The correct HS code for Hydroxypropyl Methylcellulose (HPMC) is 3912.39.00, which covers "Cellulose and its chemical derivatives, not elsewhere specified, in primary forms - Other cellulose ethers." This classification is recognized internationally for customs declaration and duty calculation purposes.

Understanding HS codes is critical for smooth international trade of chemical products like HPMC. The Harmonized System (HS) code serves as a universal "language" for customs authorities worldwide and directly impacts import duties, trade restrictions, and documentation requirements.

I've seen many clients face unnecessary delays because their suppliers provided incorrect HS codes. Some less reputable suppliers might intentionally use incorrect codes to avoid certain regulations or taxes. This practice can backfire badly on you as the importer.

The full breakdown of the 3912.39.00 classification:

- Chapter 39: Plastics and articles thereof

- Heading 3912: Cellulose and its chemical derivatives, not elsewhere specified, in primary forms

- Subheading 3912.39: Other cellulose ethers

- 00: Further subdivision

Different countries may have additional digits for more specific local classifications. For example:

- In China: 3912.39.00.00

- In the EU: 3912.39.00.90

When importing HPMC, always verify this code with your customs broker. Some countries might classify certain specialized HPMC products under slightly different codes depending on their specific modifications or intended uses. Having proper documentation from your supplier that clearly states the correct HS code is part of what separates professional manufacturers from questionable operations.

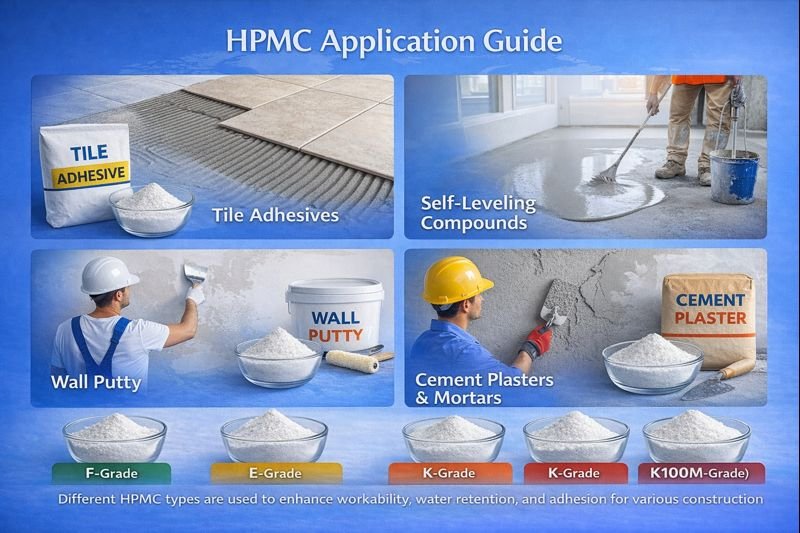

Which HPMC is Best?

Searching for the "best" HPMC for your project but overwhelmed by technical data sheets? Making the wrong choice could lead to product failures, customer complaints, and significant financial losses.

The best HPMC depends entirely on your specific application requirements. For tile adhesives, high-viscosity (60,000-100,000 mPa·s) K-type HPMC provides optimal water retention. For renders, medium-viscosity (15,000-40,000 mPa·s) works better. For self-leveling compounds4, specialized E-type HPMC with delayed dissolution properties is preferable.

There is no single "best" HPMC that works for all applications. The optimal choice varies based on several factors that I've learned through years of helping clients match their needs to the right product specifications.

Temperature stability is a major consideration often overlooked. In hot climates like Saudi Arabia or UAE, where many of our clients operate, standard HPMC might gel prematurely. For these conditions, we recommend HPMC with higher hydroxypropyl content which raises the thermal gelation temperature.

Water retention capability is another critical factor. This directly impacts open time for tile adhesives and workability time for renders. Based on our testing with clients across different climates, I've developed this reference table:

| Application | Recommended Viscosity | HPMC Type | Key Benefits |

|---|---|---|---|

| Tile Adhesives | 60,000-100,000 mPa·s | K-Type | Extended open time, excellent sag resistance |

| Wall Putty | 15,000-30,000 mPa·s | K-Type | Good workability, crack resistance |

| EIFS/ETICS | 25,000-50,000 mPa·s | K-Type | Balanced water retention and adhesion |

| Self-leveling | 20,000-40,000 mPa·s | E-Type | Controlled flow properties |

| Joint Compounds | 30,000-50,000 mPa·s | K-Type | Good workability and sanding properties |

The best HPMC should also match your production process. If you're using high-shear mixers, you might benefit from faster-dissolving grades. For bulk production with limited mixing capacity, you might need grades with anti-lump properties to ensure consistent quality.

Conclusion

Choosing the right HPMC supplier requires verifying essential certifications (ISO 9001/14001/45001, REACH, CE), understanding product grades based on your needs, knowing proper HS codes (3912.39.00), and selecting specific types for your applications. Always request COA reports to verify product consistency.

FAQ

1. How do I verify if an HPMC certificate is genuine?

Request the certificate number and contact the certification body directly to verify its authenticity.

2. Can HPMC certification requirements vary by country?

Yes, while ISO standards are international, specific regions may have additional requirements like FDA approval for food-grade HPMC in the US.

3. How often should HPMC suppliers renew their certifications?

Most certifications require renewal every 1-3 years, with regular audits in between.

4. Is food-grade HPMC the same as construction-grade HPMC?

No, food-grade HPMC has stricter purity requirements and different certifications like FDA approval or kosher certification.

5. What's more important: viscosity or methoxyl content?

Both matter for different reasons. Viscosity affects workability and water retention, while methoxyl content affects solubility and compatibility with other ingredients.

-

Understand the importance of CE certification for ensuring product safety in construction. ↩

-

Explore the various HPMC grades to find the best fit for your specific applications. ↩

-

Learn how viscosity impacts the effectiveness of HPMC in different formulations. ↩

-

Discover how HPMC enhances the properties of self-leveling compounds in construction. ↩ ↩