Ordering hydroxypropyl methylcellulose (HPMC)1 from an unverified supplier can lead to production failures, wasted money, and delayed projects. I've seen customers struggle after choosing the wrong factory.

To verify a high-quality HPMC factory before ordering, examine their production lines for automated German-style reactors, check their laboratory capabilities for application-specific testing equipment, and request batch COA documentation with full traceability from raw cotton materials to finished products.

When I first started sourcing HPMC for my projects, I made costly mistakes by focusing solely on price. Now I know better and want to share what I've learned about identifying reliable manufacturers who deliver consistent quality.

How to Test HPMC Quality Before Purchasing?

The wrong HPMC can ruin your entire production batch, costing thousands in wasted materials and missed deadlines. Many buyers skip proper testing and regret it later.

Testing HPMC quality requires checking viscosity (using Brookfield viscometer), particle size distribution, moisture content, ash content, hydroxypropyl content, methoxyl content, gel temperature, and application-specific performance like water retention and sag resistance in mortars.

Proper HPMC testing goes far beyond basic specifications on a data sheet. When I visit potential suppliers, I first examine their laboratory capabilities. A high-quality HPMC manufacturer will have a fully equipped lab with specialized testing equipment that can simulate your specific application scenarios.

For construction applications, they should have equipment to test anti-sagging properties in mortars, water retention capabilities, and workability time. For pharmaceutical applications, dissolution testing equipment and content uniformity testing capabilities are essential.

I once visited a factory that claimed to be a professional HPMC manufacturer but had only a few beakers in their "laboratory." This immediately signaled they were merely a trading company or small-scale operation incapable of ensuring consistent quality. In contrast, our factory at Kehao has invested in comprehensive testing equipment that allows us to test HPMC performance in various application scenarios, helping customers optimize formulations before full-scale production.

Key Testing Parameters for Different HPMC Applications

| Application | Critical Test Parameters | Recommended Equipment |

|---|---|---|

| Construction Mortars | Water retention, anti-sag, open time | Water retention meter, sag testing apparatus |

| Wall Putty | Thickening effect, workability | Rheometer, application simulation |

| Tile Adhesives | Bond strength, slip resistance | Bond strength tester, slip testing device |

| Pharmaceuticals | Dissolution profile, viscosity | Dissolution tester, Brookfield viscometer |

| Cosmetics | Clarity, sensory properties | Clarity meter, application testing |

Which HPMC is Best for My Application?

Many customers waste money on unnecessarily expensive HPMC or compromise quality by choosing the wrong grade. The confusion stems from unclear specifications and manufacturer claims.

The best HPMC depends on your specific application. For construction, HPMC with 100,000-150,000 mPa·s viscosity and 28-30% methoxyl content works well for mortars, while pharmaceuticals require lower viscosity (3,000-5,000 mPa·s) with higher purity standards.

Selecting the optimal HPMC grade requires understanding both your application requirements and how manufacturing processes affect HPMC performance. During my years at Kehao Factory, I've worked with customers across various industries and learned that HPMC selection isn't one-size-fits-all.

The production process significantly impacts HPMC quality and consistency. The first thing I check when evaluating a factory is whether they use fully automated "German-style" reactor technology or traditional batch processing methods. The automated systems maintain precise control over reaction conditions, ensuring batch-to-batch consistency that's impossible with manual methods.

When I visit potential suppliers, I ask to see their production lines in operation. Modern automated reactors will have sophisticated control systems, temperature monitoring, and precise etherification control. These systems create a higher quality ceiling that simpler production methods cannot match.

For construction applications, HPMC with the right balance of methoxyl and hydroxypropyl substitution delivers optimal water retention and workability. For pharmaceutical applications, the purity and dissolution profile become more critical than high viscosity. The best manufacturers customize their HPMC to your specific needs rather than offering generic products.

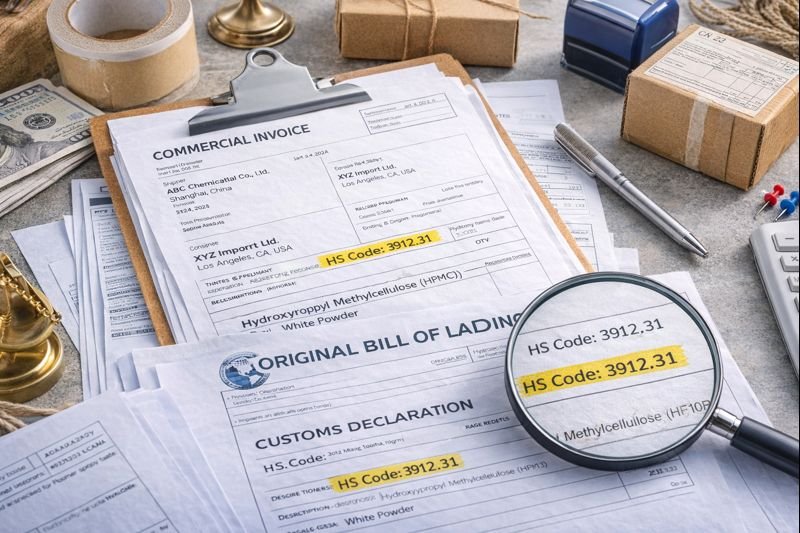

What is the HS Code for HPMC for International Orders?

Importing HPMC often leads to customs delays and unexpected duties because buyers use incorrect HS codes. These costly mistakes can disrupt your production schedule.

The correct HS code for HPMC (hydroxypropyl methylcellulose) is 3912.39, which covers "Cellulose and its chemical derivatives, not elsewhere specified, in primary forms." This classification ensures proper customs handling and appropriate duty calculations.

Understanding proper customs classification for HPMC is crucial for international trade. Beyond just knowing the basic HS code, you need to work with suppliers who have experience with international shipping documentation and compliance requirements for your specific country.

In my experience managing exports from China to over 20 countries, I've found that documentation issues can cause more delays than actual production time. A quality HPMC manufacturer will have experience with exports to your region and understand the requirements for proper classification, documentation, and shipping.

For countries like Saudi Arabia, UAE, and India, which have specific import requirements for chemicals, working with an experienced exporter can prevent weeks of customs delays. When evaluating HPMC factories, I always ask about their export experience to my target market and request examples of their shipping documentation.

The HS code 3912.39 applies to most HPMC products, but specific grades might have variations depending on their applications and modifications. Pharmaceutical grades might be classified differently than construction grades. A reputable supplier will provide proper documentation for your specific import requirements.

What Are the Different Grades of HPMC Available?

Many buyers choose the wrong HPMC grade for their application, leading to poor performance or excessive costs. The market has dozens of grades with confusing naming systems.

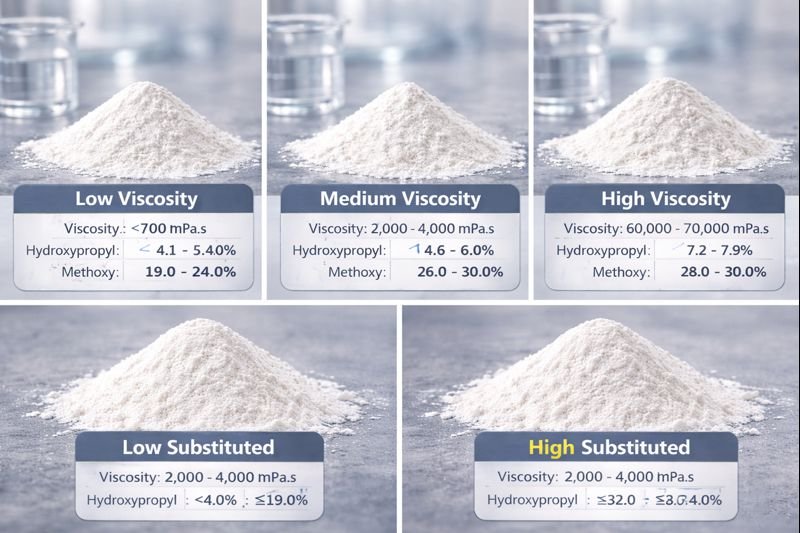

HPMC grades vary by viscosity (from 3-150,000 mPa·s), methoxyl content (19-30%), hydroxypropyl content (4-12%), and particle size. Construction grades focus on water retention and workability, pharmaceutical grades on dissolution profile and purity, and food grades on clarity and safety.

Understanding the nuances between HPMC grades is essential for optimizing your formulation. During my visits to customers' production facilities across countries like Saudi Arabia, UAE, and India, I've observed how slight variations in HPMC specifications can significantly impact final product performance.

The main parameters that differentiate HPMC grades include:

- Viscosity Range: From very low (3-15 mPa·s) used in pharmaceutical coatings to extremely high (100,000-150,000 mPa·s) used in specialty construction applications

- Methoxyl Content: Affects water solubility and gel temperature2

- Hydroxypropyl Content: Impacts organic solvent solubility and surface activity

- Particle Size Distribution: Influences dissolution speed and application method

- Gel Temperature: Critical for hot-process applications

- Modification: Some grades feature special modifications for improved performance in specific applications

For example, in construction applications:

- Tile adhesives typically use HPMC with 100,000-150,000 mPa·s viscosity and higher hydroxypropyl content

- Renders and plasters perform best with 40,000-70,000 mPa·s grades

- Self-leveling compounds need lower viscosity grades (15,000-30,000 mPa·s)

A high-quality HPMC factory will offer specialized grades for different applications rather than trying to sell you a "universal" product. When I evaluate suppliers, I check if they understand the specific requirements of my application and can recommend the optimal grade based on technical merit, not just what they have in stock.

What is the Method of Polymer Testing for HPMC Quality Control?

Inadequate quality control leads to inconsistent HPMC performance in your products. Many suppliers skip critical tests, delivering batches that vary widely in performance.

Professional HPMC polymer testing includes viscosity measurement using Brookfield viscometers, substitution degree analysis via gas chromatography, gel temperature testing, moisture content analysis using loss on drying method, and application-specific performance testing like water retention and workability time.

Quality control testing is where truly professional HPMC manufacturers distinguish themselves from basic suppliers. During my factory audits across China, I've developed a systematic approach to evaluating a manufacturer's quality control capabilities.

First, I request a complete Certificate of Analysis (COA) for a recent production batch. A professional manufacturer will provide detailed documentation showing all test parameters, results, and methods. Then, I ask them to walk me through their quality control process from raw cotton material to finished product, explaining their traceability system.

A proper polymer testing protocol for HPMC should include:

- Raw Material Testing: Verification of cellulose source purity and consistency

- In-Process Testing: Monitoring reaction parameters during production

- Finished Product Testing:

- Physical properties (particle size, bulk density)

- Chemical properties (methoxyl content, hydroxypropyl content)

- Performance properties (viscosity, gel temperature)

- Application-specific properties (water retention, anti-sag performance)

- Stability Testing: Ensuring properties remain stable throughout the shelf life

When I visit the quality control laboratory, I look for modern equipment like gas chromatography for substitution analysis, Brookfield viscometers for accurate viscosity measurement, and application-specific testing equipment that simulates real-world use conditions.

The best manufacturers maintain complete production records that allow traceability from raw materials to finished products. If a supplier cannot explain their quality control process clearly or lacks proper documentation, it's a red flag indicating potential quality inconsistencies.

Conclusion

To verify a high-quality HPMC factory, check their automated production lines, examine their application testing capabilities, and request detailed batch traceability documentation. These steps will help you find a reliable supplier who delivers consistent quality for your specific needs.

Frequently Asked Questions

1. What is the minimum order quantity for quality HPMC?

Most professional manufacturers require at least 1 ton for standard grades and 3-5 tons for customized specifications.

2. How long does HPMC remain stable in storage?

When properly stored in dry conditions, HPMC maintains its properties for 2-3 years.

3. Can HPMC quality vary between batches?

Yes, especially with manufacturers using non-automated production methods. Professional factories with German-style reactors deliver more consistent quality.

4. What certifications should a quality HPMC manufacturer have?

Look for ISO 9001, ISO 14001, and application-specific certifications like food-grade (FDA/REACH) or pharmaceutical (GMP) if needed for your application.

5. How does HPMC price relate to quality?

While higher-quality HPMC typically costs more due to better raw materials and production processes, price alone isn't a reliable quality indicator. Always verify through testing.