When I first stepped into the construction industry, I faced constant cracking and adhesion failures with traditional mortar. These problems cost me time, money, and client trust. Polymer modified mortar1 changed everything.

Polymer modified mortar1 offers superior durability, flexibility, and adhesion compared to traditional mortar. It reduces cracking by 60%+, extends service life up to 10 years (versus 5-8 years for traditional), and performs better in challenging environments like heated floors and exterior walls.

As a manufacturer with six production lines serving markets across Saudi Arabia, UAE, India, and many developing countries, I've seen firsthand how the right mortar choice impacts project success. Let me explain why polymer modified mortar might be worth your investment, even with its 15-20% higher initial cost.

What Are the Advantages of Polymer Modified Mortar Over Traditional Options?

Pain point: Traditional mortar often fails prematurely in demanding environments, causing expensive repairs and project delays. Contractors need a reliable solution that performs consistently.

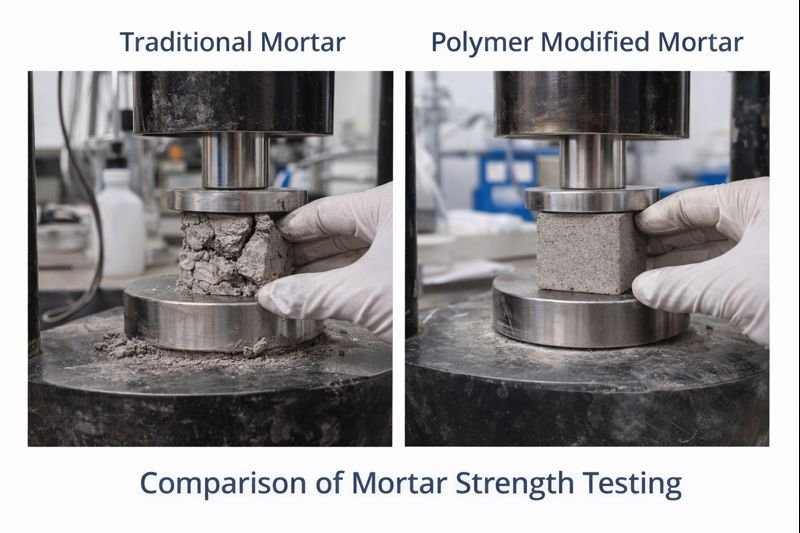

Polymer modified mortar1 provides 30-50% higher flexural strength, 60%+ reduced cracking, and superior bonding to difficult substrates. The polymer additives create a more flexible matrix that absorbs movement and vibration while maintaining structural integrity under temperature fluctuations.

Durability Improvements That Save Money Long-Term

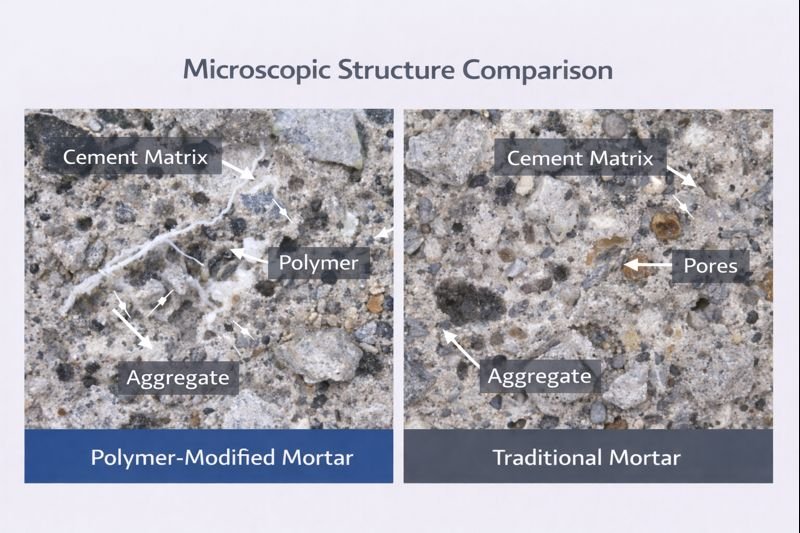

Polymer modified mortars represent a significant advancement in construction materials technology. The addition of polymers—typically latex, acrylic, or vinyl acetate-ethylene (VAE)—fundamentally transforms the mortar's microstructure. These polymers form flexible bridges between cement particles, creating a more cohesive matrix.

| When examining performance data from the China Building Materials Research Institute's 2023 White Paper, the numbers are compelling: | Property | Traditional Mortar | Polymer Modified Mortar | Improvement |

|---|---|---|---|---|

| Flexural Strength | 3-5 MPa | 5-7.5 MPa | 30-50% | |

| Bond Strength | 0.5-0.8 MPa | 1.0-1.5 MPa | Up to 100% | |

| Crack Reduction | Baseline | >60% fewer cracks | Significant | |

| Service Life | 5-8 years | 8-12 years | Nearly doubled |

I recently visited a residential complex in Shanghai where polymer modified mortar had been used for the exterior façade five years ago. Despite extreme seasonal temperature variations, the walls remained crack-free and watertight. The neighboring building, constructed with traditional mortar during the same period, was already undergoing expensive repairs for widespread cracking and water infiltration.

When Should You Use Polymer Modified Mortar?

Every project has unique requirements, and I've learned through trial and error when polymer modified solutions deliver the most value. Choosing the wrong mortar type can lead to wasted resources and potential failures.

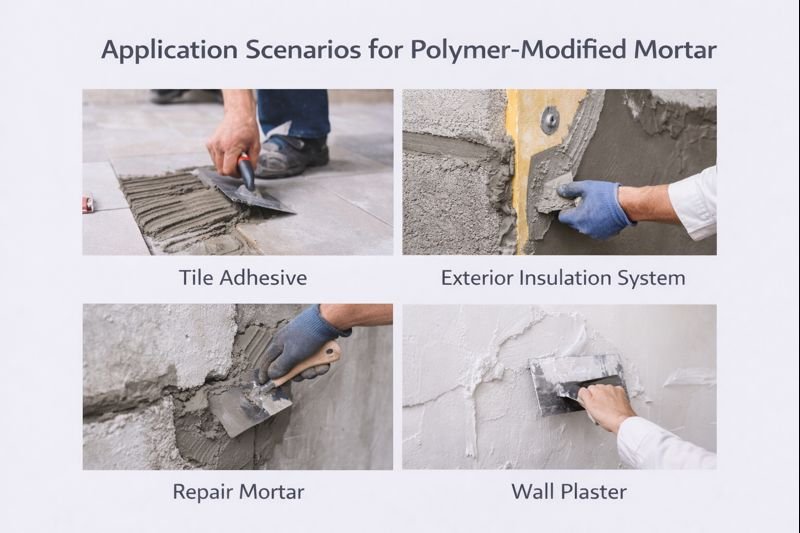

Polymer modified mortar1 is essential for applications requiring high flexibility and adhesion: exterior cladding, heated floors, wet areas, thin-set tile installation2, and repair work. It excels when bonding to difficult substrates like existing ceramic tiles, concrete, or metals.

Critical Applications Where Performance Justifies Cost

Making the right material choice depends on understanding both the immediate application needs and long-term performance requirements. Polymer modified mortars shine in several critical scenarios that conventional mortars simply cannot handle effectively.

For thin-set applications, polymer modified mortars allow for installations as thin as 3mm while maintaining structural integrity. This becomes crucial in renovation projects where floor height constraints exist. The high water retention (>98%) prevents premature drying, giving applicators more working time and ensuring proper hydration even on porous substrates.

Self-leveling compounds and specialized tile adhesives with polymer modification have revolutionized installation processes:

| Application | Traditional Approach | Polymer Modified Solution | Benefit |

|---|---|---|---|

| Bathroom Floors | Multiple leveling layers | Single self-leveling pour | 40% faster installation |

| Large Format Tiles | Thick bed method (20mm+) | Thin-set application (3-5mm) | Material savings of 75% |

| Exterior Cladding | Mechanical fastening required | Direct adhesion possible | Simplified system, fewer failure points |

| Heated Floor Systems | Prone to cracking | Accommodates thermal expansion | Extended system longevity |

A metro station project I consulted on in Guangzhou demonstrated this efficiency gain clearly. The construction schedule was compressed by 20% by using self-leveling polymer modified compounds, as reported in "Construction Technology" (December 2022). The rapid curing and single-layer application eliminated waiting periods between multiple traditional leveling coats.

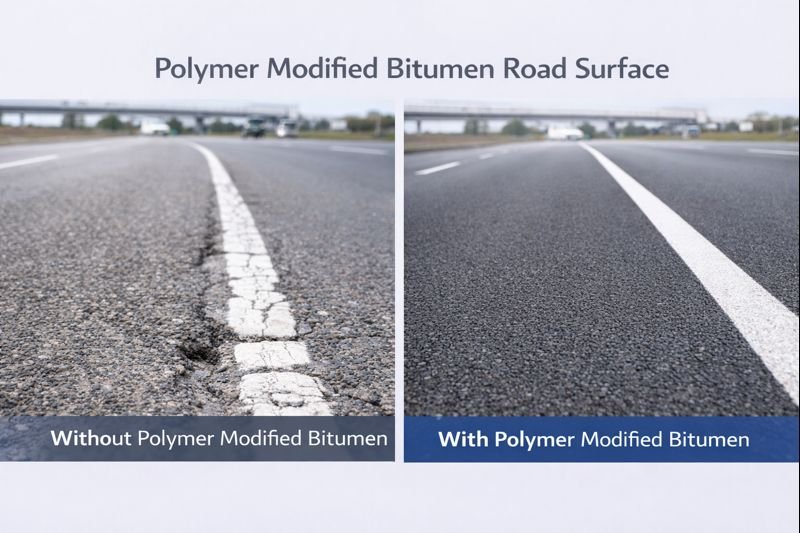

What Are the Advantages of Polymer Modified Bitumen?

Technical challenges with standard bitumen systems often frustrate contractors—poor temperature resistance leads to rutting in summer and cracking in winter. These issues create unsafe conditions and maintenance headaches.

Polymer modified bitumen demonstrates superior temperature stability, extending performance range from -30°C to 80°C. It provides 40% greater fatigue resistance, doubles the service life of pavements, and significantly reduces maintenance frequency in extreme climate regions.

Engineering Better Infrastructure with Advanced Materials

While our main focus is construction mortars, many clients also inquire about polymer modified bitumen for infrastructure projects. The principles behind polymer modification are similar, though the specific polymers differ—typically SBS (Styrene-Butadiene-Styrene) or APP (Atactic Polypropylene) for bituminous applications.

Polymer modified bitumen addresses the fundamental limitations of conventional asphalt. Standard bitumen becomes brittle at low temperatures and softens excessively at high temperatures. By introducing elastomeric or plastomeric polymers, we create a material with expanded performance parameters:

| Property | Conventional Bitumen | Polymer Modified Bitumen | Improvement |

|---|---|---|---|

| Service Temperature Range | -10°C to 60°C | -30°C to 80°C | 67% wider range |

| Fatigue Resistance | Baseline | +40% cycles to failure | Significantly extended |

| Rutting Resistance | Moderate | High | Reduced permanent deformation |

| Water Resistance | Good | Excellent | Enhanced durability |

I recently visited a highway project in Saudi Arabia where conventional asphalt had failed after just three years of exposure to the extreme desert conditions. The replacement using polymer modified bitumen has now performed flawlessly for over seven years, despite temperature swings from near-freezing nights to 50°C+ daytime temperatures.

The initial cost premium of 15-20% for polymer modified bitumen is consistently offset by the reduced maintenance frequency and extended service life—typically doubling the pavement lifespan before major rehabilitation is required.

What Is the Difference Between Polymer Modified and Unmodified Mortar?

Many construction professionals struggle to justify premium materials to project owners focused solely on initial costs. Understanding the fundamental differences helps make the case for appropriate material selection.

Polymer modified mortars incorporate specialized polymers (latex, acrylic, or VAE) that create flexible polymer bridges between cement particles. This microstructure delivers enhanced adhesion, flexibility, water resistance, and freeze-thaw durability that unmodified mortars physically cannot achieve.

The Science Behind Superior Performance

The distinction between polymer modified and unmodified mortars goes beyond simple additive inclusion—it represents a fundamental transformation of material properties at the microstructural level.

Traditional cementitious mortars rely solely on the hydraulic bonding of cement particles, creating a rigid crystalline structure. While this provides good compressive strength, it lacks flexibility and adhesive properties. The addition of polymers creates a co-matrix system where two complementary binding mechanisms operate simultaneously:

- The hydraulic cement bonding provides compressive strength and structural integrity

- The polymer film network provides flexibility, adhesion, and improved tensile properties

This synergistic combination results in measurable performance differences:

| Property | Unmodified Mortar | Polymer Modified Mortar | Key Benefit |

|---|---|---|---|

| Moisture Movement | 0.10-0.15% | 0.03-0.07% | 60% reduction in shrinkage stress |

| Impact Resistance | Low | Moderate to High | Better durability in high-traffic areas |

| Water Absorption | 8-12% | 1-4% | Significantly improved water resistance |

| Chemical Resistance | Poor | Good | Extended durability in industrial settings |

| VOC Emissions | Very Low | Low to Very Low | Environmentally responsible choice |

According to the Shanghai Construction Commission's 2021 maintenance cost analysis report, buildings using polymer modified mortars showed a remarkable 70% reduction in repair frequency over a ten-year service period compared to those using traditional mortars. The lifecycle cost analysis revealed that despite the 15-20% higher initial investment, the total ownership cost was approximately 25% lower when considering maintenance, repair, and replacement expenses.

Conclusion

Polymer modified mortar delivers superior durability, flexibility and long-term cost savings despite higher initial costs. It's the right choice for demanding applications where performance matters more than short-term savings.

FAQ

Q: Can polymer modified mortar be used in freezing conditions?

A: Yes, it exhibits superior freeze-thaw resistance compared to traditional mortars, making it ideal for cold climates.

Q: How much more does polymer modified mortar cost?

A: Typically 15-20% more initially, but total lifecycle costs are often 25% lower due to extended service life and fewer repairs.

Q: Is special equipment needed to mix polymer modified mortar?

A: No, it uses standard mixing equipment, though some pre-mixed varieties require only water addition on site.