Cracked tiles, peeling finishes, and mortar failure can turn your construction project into a costly nightmare. Traditional mortar simply can't handle thermal cycles and structural movement in modern buildings, leading to expensive repairs and unhappy clients.

Polymer modified mortar1 improves adhesion and flexibility by forming a co-matrix structure where polymers create flexible bridges between cement particles. This combination enhances bond strength to difficult substrates, increases deformation capacity, and provides better resistance to water, chemicals, and temperature changes.

As a manufacturer with six production lines, I've seen how polymer-modified mortars have revolutionized construction projects worldwide. The science behind this technology is fascinating, and I'd like to share why these advanced formulations have become essential for modern building requirements.

What Are the Advantages of Polymer Modified Mortar?

Traditional mortars frequently fail under the stresses of today's construction demands. Their rigid nature and limited bonding capability lead to cracks, delamination, and water penetration problems that compromise structural integrity.

Polymer modified mortar1s offer superior adhesion (50-300% stronger bonds), greater flexibility (accommodating 2-5% movement without cracking), enhanced water resistance, improved freeze-thaw durability, and better chemical resistance compared to conventional cement mortars.

Dive deeper into the advantages, and you'll find polymer-modified mortars deliver benefits across multiple performance categories. From my experience supplying HPMC to mortar manufacturers across Saudi Arabia and the UAE, I've observed these key advantages:

Mechanical Performance Improvements

- Tensile Strength: Polymers like EVA and SBR can increase tensile strength by 30-80%, allowing mortars to resist cracking under strain.

- Flexural Strength: Our testing shows a typical increase of 40-60% in flexural strength, critical for areas subject to vibration or movement.

- Impact Resistance: Polymer-modified mortars absorb shock better, with some formulations showing 3-5 times better impact resistance.

Application Benefits

One major advantage I've heard repeatedly from customers is workability. The addition of our HPMC and redispersible latex powder creates mortars that are:

- Easier to mix with less water

- Smoother to apply with better "slip resistance" on vertical surfaces

- Longer open time (15-30 minutes more than conventional mortars)

- Self-curing properties that reduce the need for wet curing in hot climates like the Middle East

During my visit to a major project in Dubai, the contractor specifically mentioned how polymer-modified mortars allowed them to complete tiling work 25% faster while achieving better end results.

What Makes Mortar Flexible?

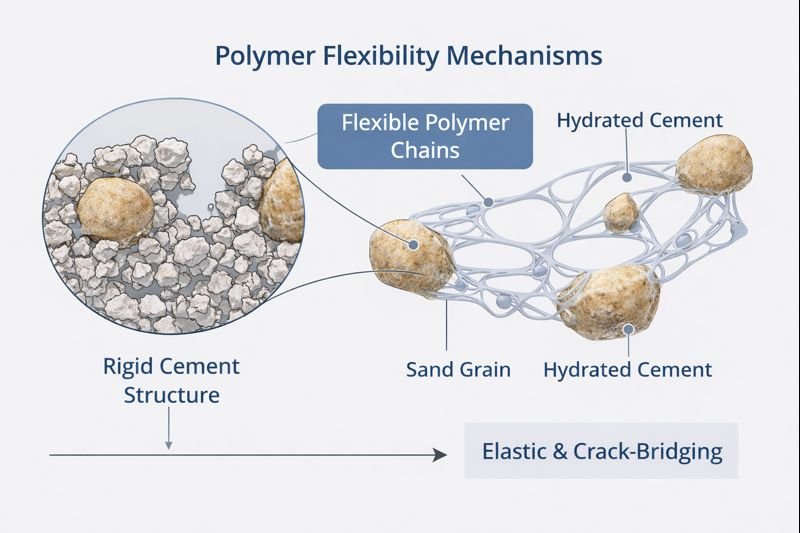

Regular cement mortars form rigid crystal structures that crack under stress. Without additives, these mortars cannot accommodate movement from thermal expansion, vibration, or substrate deformation.

Mortar becomes flexible when polymers create an interpenetrating network throughout the cement matrix. These polymer chains stretch under stress and return to their original shape, allowing the mortar to absorb movement without cracking while maintaining its bond strength.

Diving deeper into flexibility mechanisms reveals fascinating material science at work. The interplay between cement hydration and polymer film formation creates a composite material with unique properties:

Microstructural Changes

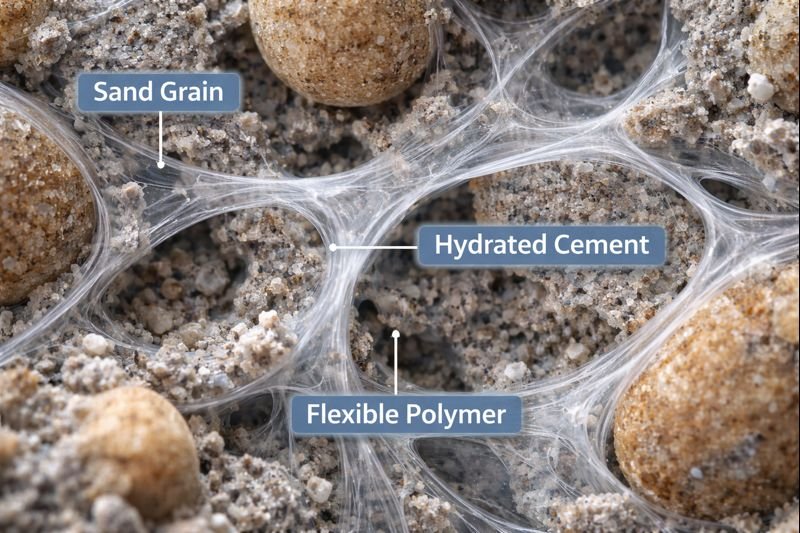

At the microscopic level, polymers in modified mortars create several important changes:

-

Interstitial Film Formation: As water evaporates during curing, polymer particles coalesce to form continuous elastic films throughout the mortar. These films bridge across cement particles and into pores.

-

Crack Bridging: When microcracks begin to form under stress, polymer strands stretch across them, preventing propagation. I've examined scanning electron microscope images of our polymer-modified mortars after stress testing, and the difference is remarkable - conventional mortars show clean fractures, while polymer-modified versions show stretched polymer bridges still connecting across crack faces.

-

Pore Structure Modification: Polymers reduce capillary porosity while creating a network of disconnected micropores that accommodate movement. This structure allows deformation without catastrophic failure.

Our laboratory tests show that mortars modified with our redispersible latex powder can accommodate movement up to 5mm per meter without cracking - approximately 3-4 times the flexibility of standard mortar.

What Is Polymer-Modified Mortar Used For?

Standard mortars often fail in demanding applications involving temperature swings, vibration, or bonding to difficult substrates. These limitations restrict their use in modern construction and renovation projects.

Polymer-modified mortars are primarily used for tile adhesives, external wall insulation systems, waterproofing membranes, concrete repair, floor screeds, and decorative renders. They excel in applications requiring adhesion to difficult substrates, flexibility, water resistance, and durability in extreme conditions.

Diving deeper into specific applications reveals why polymer-modified mortars have become indispensable in modern construction. From my experience working with clients across different regions, I've seen these materials solve numerous construction challenges:

High-Performance Tile Adhesives

Particularly in large-format tiles (now exceeding 1.2m × 3m in some projects), polymer modification is essential. Without sufficient flexibility and bond strength:

- Tiles can debond during normal building movement

- Cracking occurs at corners and edges

- Water penetration leads to freeze-thaw damage in colder climates

One of our clients in Pakistan switched to our HPMC and redispersible powder for their premium tile adhesive line after experiencing failure rates above 15% with traditional formulations. Their warranty claims dropped by 85% within one year.

External Thermal Insulation Composite Systems (ETICS)2

These systems are increasingly important for energy efficiency but create special demands:

- Adhesive mortars must bond insulation boards securely to various substrates

- Base coats need flexibility to prevent cracking while protecting insulation

- The entire system undergoes significant thermal cycling

During my visit to a large project in Georgia, I witnessed how polymer-modified mortars allowed ETICS installation on a structure with significant concrete carbonation issues that would have prevented adequate bonding with conventional mortars.

Waterproofing Membranes

Polymer content in these specialized mortars can reach 30-40% to create essentially crack-free barriers that:

- Bridge existing cracks up to 2mm

- Maintain waterproofing despite substrate movement

- Bond to challenging surfaces including PVC pipes and metal flashings

Which Polymer Additives Are Added to Improve Flexibility?

Rigid mortars crack under thermal and mechanical stress, leading to water infiltration and system failure. Without the right polymer additives, achieving both flexibility and strength remains impossible.

The main polymer additives used to improve mortar flexibility include: redispersible polymer powders3 (especially vinyl acetate-ethylene copolymer), liquid latex modifiers (SBR, acrylic), cellulose ethers4 (HPMC, HEMC), and polyvinyl alcohol. These work synergistically to enhance elasticity while maintaining cohesive strength.

Diving deeper into polymer additives reveals a fascinating world of chemical engineering that enables modern construction techniques. At our factory, we produce several key additives that transform ordinary mortars into high-performance building materials:

Redispersible Polymer Powders

These are perhaps the most important flexibility-enhancing additives. Through spray drying of polymer emulsions, we create powders that reactivate when mixed with water. The most common types include:

-

Vinyl Acetate-Ethylene (VAE): Our most widely used polymer powder, offering excellent balance between flexibility and cost. VAE copolymers typically provide:

- Good elongation (120-300%)

- Excellent adhesion to most building materials

- Hydrolysis resistance in alkaline environments

-

Styrene-Acrylic: Preferred for exterior applications due to superior:

- UV resistance

- Weathering properties

- Alkaline stability

-

Pure Acrylic: Premium option for the highest performance requirements:

- Maximum flexibility

- Excellent aging characteristics

- Superior water resistance

During development work with a major Saudi Arabian customer, we demonstrated how adjusting the VAE content from 3% to 7% increased mortar flexibility by 85% while maintaining over 90% of its compressive strength.

Cellulose Ethers

While primarily used as water retention agents and workability enhancers, our HPMC and HEMC products also contribute to flexibility:

| Property | HPMC | HEMC | Effect on Flexibility |

|---|---|---|---|

| Water retention | Very high | High | Ensures proper polymer film formation |

| Viscosity | 15,000-150,000 mPa·s | 10,000-100,000 mPa·s | Controls sag resistance and workability |

| Surface activity | Moderate | Moderate to high | Improves polymer dispersion |

| Delayed cement hydration | Yes | Yes | Allows more complete polymer film formation |

Through controlled hydroxypropyl substitution in our manufacturing process, we can fine-tune these properties for specific application requirements.

How to Make a Polymer More Flexible?

Poor polymer selection and incorrect dosage lead to mortars that are either too rigid or lack sufficient strength. Balancing flexibility with mechanical performance requires precise polymer engineering.

To make polymers more flexible in mortar, manufacturers use copolymerization with soft monomers, adjust the glass transition temperature (Tg), optimize molecular weight distribution, incorporate plasticizers, and use external flexibilizers. The polymer-to-cement ratio5 typically ranges from 5% to 20% depending on flexibility requirements.

Diving deeper into polymer flexibility reveals sophisticated material science principles that guide our product development. In our R&D center, we focus on several approaches to enhance mortar flexibility:

Polymer Architecture Engineering

The molecular structure of polymers dramatically affects their flexibility. Key approaches include:

-

Copolymerization Strategy: By incorporating "soft" monomers like ethylene, butyl acrylate, or 2-ethylhexyl acrylate alongside "hard" monomers like vinyl acetate or methyl methacrylate, we create polymers with balanced properties. The ratio of these components directly affects flexibility - increasing soft monomer content from 10% to 30% can double elongation capacity.

-

Glass Transition Temperature (Tg) Adjustment: This critical temperature determines when a polymer transitions from glassy (rigid) to rubbery (flexible) state. For construction applications in variable climates:

- Exterior mortars typically need Tg between -10°C and +10°C

- Interior applications can use polymers with Tg up to +20°C

- Specialized cold-weather formulations may require Tg as low as -25°C

-

Molecular Weight Engineering: Higher molecular weight generally improves cohesive strength but reduces elongation. Our polymerization processes carefully control:

- Average molecular weight

- Molecular weight distribution (polydispersity)

- Crosslinking density

During a collaborative project with a major university in China, we demonstrated how controlling these parameters allowed us to develop a polymer with 45% greater elongation while maintaining 90% of the tensile strength of standard formulations.

Formulation Approaches

Beyond the polymer itself, formulation techniques enhance flexibility:

- Optimized Polymer-to-Cement Ratio (P/C): Higher P/C ratios increase flexibility but must be balanced against cost and strength requirements. Typical guidelines from our application testing:

| Application | P/C Ratio | Flexibility Benefit |

|---|---|---|

| Tile adhesives | 3-8% | Moderate - accommodates substrate movement |

| Repair mortars | 7-15% | High - prevents edge cracking and debonding |

| Waterproofing | 15-40% | Very high - maintains integrity during building movement |

- Film Formation Enhancers: Additives like glycols and coalescent agents ensure complete polymer film formation, especially in challenging environments. We've measured up to 60% improvement in low-temperature flexibility when these are properly incorporated.

What Is the Role of Polymer Additives?

Traditional mortars suffer from brittleness, poor adhesion, and water sensitivity. Without polymer modification, they cannot meet the demands of modern construction systems, especially in extreme environments.

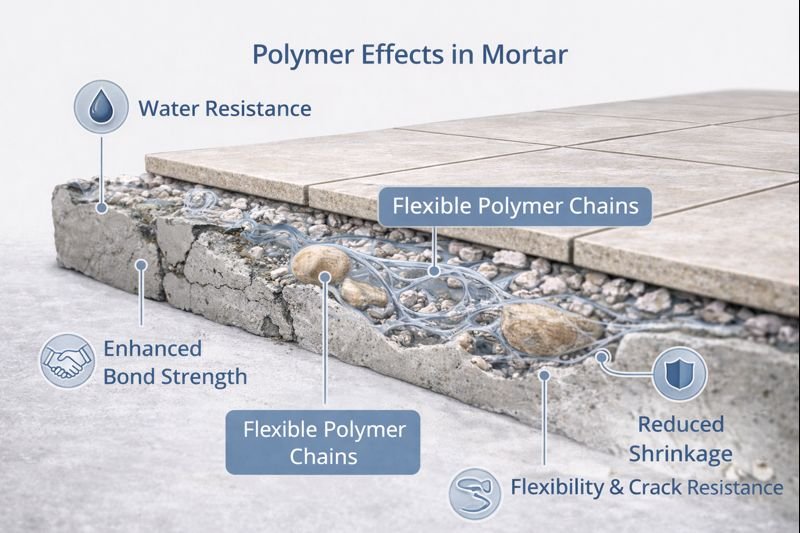

Polymer additives in mortar serve multiple crucial roles: they improve adhesion through chemical bonding and mechanical interlocking, enhance flexibility by forming elastic films, reduce water penetration through pore blocking, increase freeze-thaw resistance, and improve chemical resistance against acids and salts.

Diving deeper into polymer functionality reveals how these materials transform basic cement systems into high-performance building materials. Based on our extensive laboratory testing and field experience:

Microstructural Effects

At the microstructural level, polymers create several important changes that enhance mortar performance:

-

Interfacial Transition Zone (ITZ) Modification: The ITZ is typically the weakest area in cementitious materials. Polymers strengthen this zone by:

- Reducing calcium hydroxide crystal formation

- Creating polymer bridges across potential crack paths

- Enhancing the bond between cement paste and aggregates

-

Porosity Modification: Our mercury intrusion porosimetry tests show that polymer-modified mortars typically have:

- 15-30% lower total porosity

- Disrupted capillary networks that reduce water absorption

- Modified pore size distribution with fewer large capillary pores

-

Cement Hydration Interaction: Polymers influence cement hydration through:

- Formation of organo-mineral phases

- Modification of crystal growth patterns

- Creation of interpenetrating networks with hydration products

During a recent product development cycle, we used X-ray diffraction analysis to confirm how our redispersible polymer powder altered calcium silicate hydrate formation, resulting in a more ductile microstructure.

Performance Impact Across Properties

Our comprehensive testing program demonstrates how polymers affect multiple mortar properties simultaneously:

| Property | Mechanism | Typical Improvement |

|---|---|---|

| Adhesion | Chemical bonding & mechanical interlocking | 100-300% increase |

| Flexibility | Elastic film formation & stress distribution | 200-500% greater elongation |

| Water resistance | Pore blocking & hydrophobic effects | 50-80% reduction in water absorption |

| Freeze-thaw durability | Air entrainment & crack prevention | 3-5× more freeze-thaw cycles |

| Chemical resistance | Reduced permeability & protective films | Improved resistance to pH 4-10 |

One particularly interesting case involved our work with a Mexican customer whose projects faced both seismic concerns and coastal exposure. By optimizing the polymer system with our redispersible powder and HPMC, we developed a formulation that provided both the flexibility needed for seismic resistance and the water/salt resistance required for marine environments.

Conclusion

Polymer-modified mortars transform construction possibilities by creating flexible, strongly bonded systems that resist cracking, water penetration, and environmental damage. By choosing the right polymers and proper dosages, modern mortars can meet demanding performance requirements across numerous applications.

FAQ

1. Can polymer-modified mortars be used in wet areas?

Yes, they're excellent for wet areas due to their reduced water absorption and better waterproofing capabilities. They're commonly used in bathrooms, kitchens, and swimming pools.

2. Do polymer-modified mortars cost more than traditional mortars?

While material costs are 15-40% higher, the total installation cost may be lower due to faster application, reduced callbacks, and longer service life.

3. How long do polymer-modified mortars last?

Properly formulated systems typically last 20-30 years, compared to 10-15 years for conventional mortars, especially in demanding environments.

4. Are polymer-modified mortars environmentally friendly?

Modern formulations are increasingly eco-friendly, with low VOC emissions, reduced cement content (lowering carbon footprint), and some bio-based polymer options now available.

5. Can polymer-modified mortars be used in cold weather?

Yes, many formulations are specifically designed for application down to 5°C, with some specialty products workable at even lower temperatures.

-

Explore how polymer modified mortar enhances adhesion and flexibility, revolutionizing construction projects. ↩ ↩

-

Discover the importance of ETICS in improving energy efficiency in buildings. ↩

-

Learn how redispersible polymer powders enhance the performance of construction materials. ↩

-

Explore the role of cellulose ethers in enhancing the properties of construction materials. ↩

-

Learn about the significance of the polymer-to-cement ratio in achieving desired material properties. ↩