Winter brings unique challenges to construction sites. Freezing temperatures can ruin fresh concrete, causing cracking, scaling, and reduced strength, potentially leading to expensive repairs or complete replacement.

To properly cure concrete in cold weather, you need specialized additives that lower the freezing point, accelerate setting time, and maintain hydration processes. Quality winter concrete additives ensure strength development even when temperatures drop below 40°F (4°C), preventing costly failures.

At our factory in China, we've helped countless customers overcome winter construction challenges1. I remember one client from Saudi Arabia who was expanding operations into colder regions and struggled with concrete setting times. Let me share what I've learned about optimizing concrete performance2 in freezing conditions.

What Cold Weather Concrete Additives Are Essential for Winter Construction?

Winter construction deadlines wait for no one. Without proper additives, concrete can freeze before it sets, creating a permanently weakened structure that may need complete demolition and replacement.

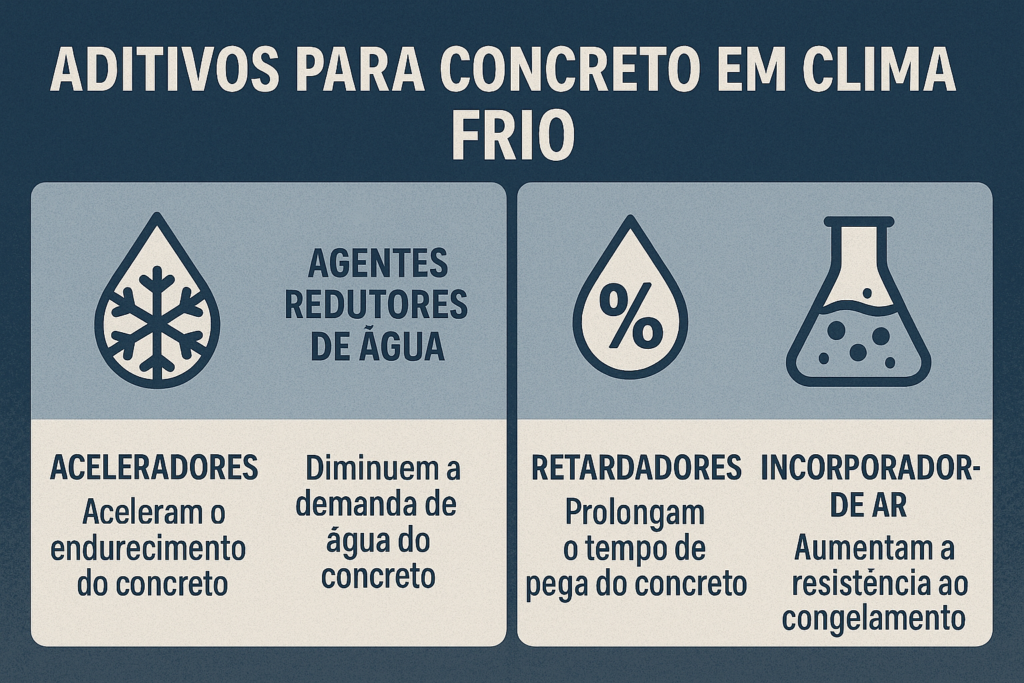

Cold weather concrete additives typically include accelerators (like calcium chloride or non-chloride accelerators), water reducers, and anti-freezing compounds. These specially formulated chemicals allow concrete to continue hydrating and gaining strength even when temperatures fall below freezing.

"Various concrete additives for winter use")

"Various concrete additives for winter use")

At WANHONG, our hydroxypropyl methylcellulose (HPMC3) serves as an excellent water-retention agent for cold weather concreting. When temperatures drop, proper water retention becomes critical for complete cement hydration. Our HPMC helps maintain the necessary water content throughout the curing process.

Types of Cold Weather Concrete Additives

| Additive Type | Function | Best Application |

|---|---|---|

| Accelerators | Speed up setting time | When rapid set is needed |

| Anti-freezing compounds | Lower freezing point of mixing water | Very cold conditions |

| Water reducers | Decrease water content while maintaining workability | Improve strength development |

| HPMC | Water retention and improved workability | General cold weather applications |

| Redispersible latex powder | Flexibility and adhesion | Repair mortars in cold conditions |

I've seen many clients struggle with choosing the right additive combination. Last winter, a customer from Georgia called me in a panic because their concrete wasn't setting properly in -5°C weather. We recommended adding our specialized HPMC along with an accelerator, which solved their problem within days.

What Are the Existing Issues with Cold Weather Concrete Curing?

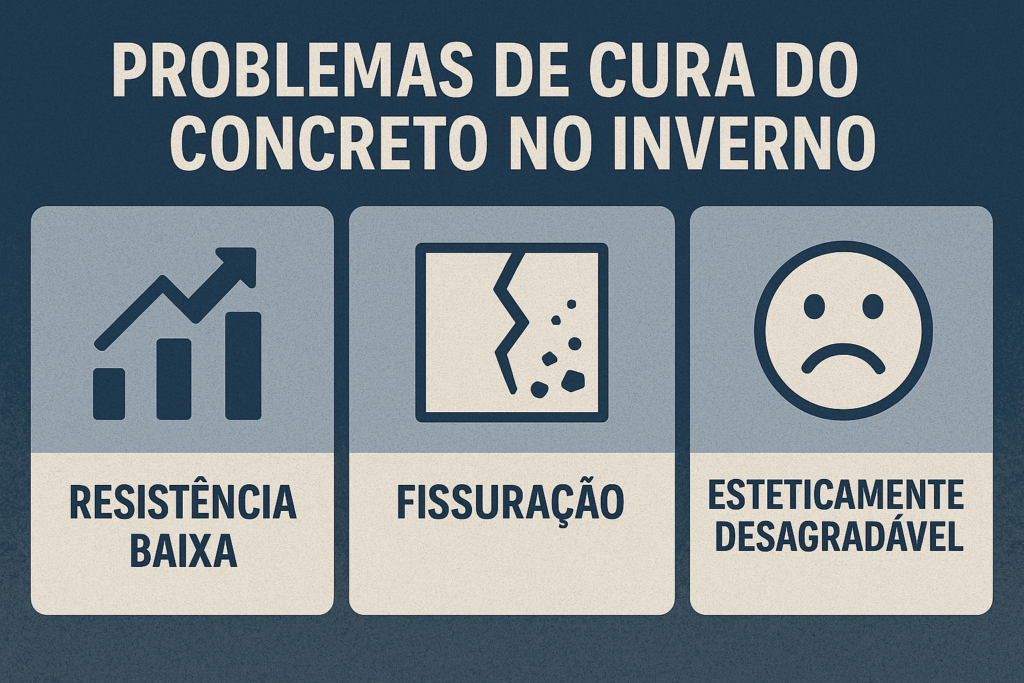

Cold weather brings serious threats to concrete quality. Water freezing within fresh concrete creates tiny ice crystals that expand and form permanent voids, resulting in weakened structures that may fail inspection or collapse under load.

Common cold weather concrete curing issues include delayed setting, reduced early strength development, freeze damage, improper finishing, and inadequate protection measures. These problems can reduce concrete strength by up to 50% and significantly impact long-term durability.

The challenges of winter concreting extend beyond just the initial pour. Temperature fluctuations between day and night create additional stress on curing concrete. Our technical team has developed specialized additive formulations to address these specific concerns.

Critical Cold Weather Concrete Challenges

| Challenge | Consequence | Solution |

|---|---|---|

| Slow setting | Extended vulnerability to freezing | Accelerating additives |

| Reduced early strength | Delayed construction schedule | High-performance water reducers |

| Freeze damage | Permanent weakening | Anti-freeze compounds + proper insulation |

| Inconsistent temperature | Variable strength throughout structure | Temperature monitoring + adjusted mix design |

| Excessive bleeding | Surface scaling and dusting | HPMC water retention agent |

I recently visited a project site in Iran where the contractor was experiencing excessive bleeding in their concrete during cold weather pours. By incorporating our HPMC at 0.2% by weight of cement, they eliminated this issue and achieved consistent surface quality despite the challenging conditions. The water retention properties prevented the rapid surface drying that occurs when warm concrete meets cold air.

Why Choose WANHONG Concrete Additives to Optimize Your Concrete Performance in Winter?

Winter construction delays cost money and stress project timelines. Without reliable concrete additives, your project risks failure, requiring expensive demolition and rebuilding when temperatures warm up.

WANHONG concrete additives are specially formulated for cold weather performance, with precise dosing recommendations for different temperature ranges. Our products undergo rigorous testing in temperature-controlled environments to ensure they perform consistently even in extreme conditions.

Our six production lines allow us to maintain consistent quality across all our products. This consistency is particularly important for winter concreting, where small variations in additive performance can have major consequences. We understand that our customers rely on us for predictable results in unpredictable weather.

WANHONG Cold Weather Performance Advantages

| Feature | Benefit | Customer Impact |

|---|---|---|

| Temperature-specific formulations | Optimal performance at various cold temperatures | Consistent results regardless of weather fluctuations |

| Quality control system | Batch-to-batch consistency | Reliable job site performance |

| Technical support | Expert advice on mix design adjustments | Avoid costly mistakes and project delays |

| Custom packaging | Right-sized for your project needs | Reduce waste and storage requirements |

| Compatibility testing | Works with your specific cement and aggregates | No unexpected reactions or performance issues |

One of our distributors in Pakistan told me how our technical support4 team helped them adjust their mix design when temperatures unexpectedly dropped to near freezing. By increasing the dosage of our specialized HPMC and adding our recommended accelerator, they maintained their construction schedule despite the challenging conditions.

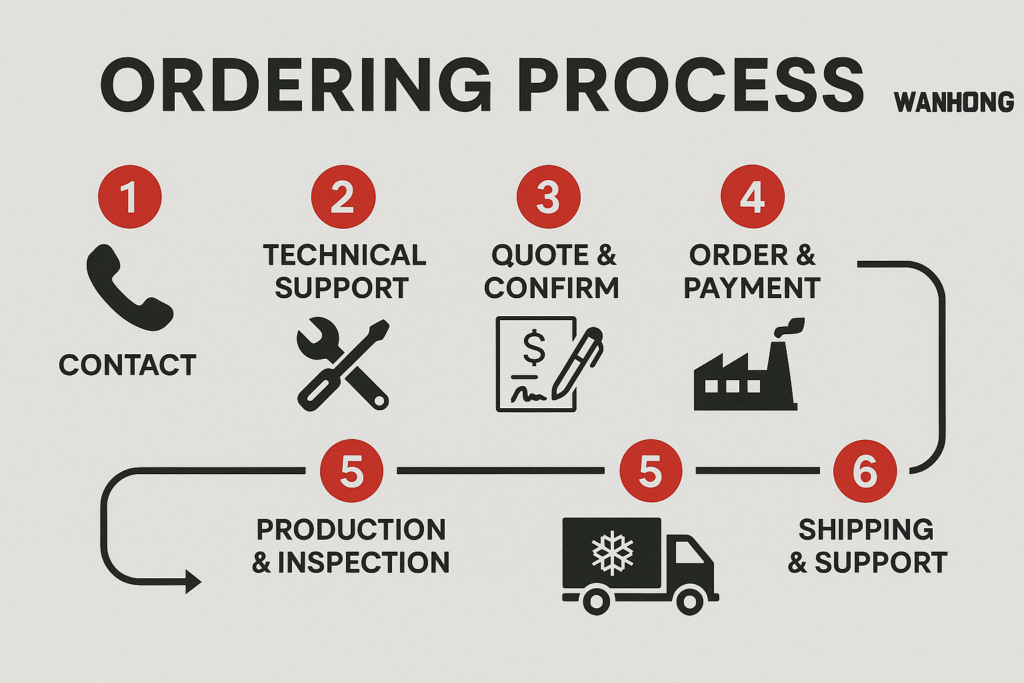

How to Place Order Now For Cold Weather Concrete Additives?

Winter construction schedules are tight, and delays in receiving critical additives can halt your entire project. Missing the opportunity to order early means risking stock shortages when everyone suddenly needs winter construction products.

To order cold weather concrete additives5, contact us at ada@xhhpmc.com or visit www.xhhpmc.com. We provide customized recommendations based on your specific project conditions, temperature range, and concrete mix design. Orders typically ship within 7-10 days with express options available.

In my 15 years working with construction chemicals, I've learned that preparation is everything for winter concreting. Many customers wait until they experience problems before ordering specialized additives, but the most successful projects have materials on hand before the first cold snap.

Ordering Process Simplified

| Step | Action | Timeline |

|---|---|---|

| Initial Consultation | Contact us with project specifications | Same business day response |

| Technical Recommendation | Receive customized product recommendation | 1-2 business days |

| Sample Testing | Optional sample testing for your specific mix | 3-5 business days |

| Order Placement | Finalize quantity and packaging requirements | Immediate |

| Production & QC | Manufacturing and quality control testing | 5-7 days |

| Shipping | Door-to-door logistics management | Varies by destination |

Last month, a customer from Saudi Arabia called with an urgent need for cold weather additives for a project in a mountainous region. We expedited production and arranged air freight, delivering the materials in just 6 days from order to job site.

What Makes Concrete Curing Additives with Outstanding Performance?

Poor-quality additives can give inconsistent results, potentially wasting time and materials during critical winter construction periods. The difference between success and failure often comes down to additive quality and proper application.

Outstanding concrete curing additives demonstrate consistent performance across temperature ranges, compatibility with various cement types, and predictable dosing responses. They maintain concrete workability without excessive retardation and protect against freezing without compromising long-term durability6.

https://placehold.co/600x400 "High-performance concrete additive testing")

https://placehold.co/600x400 "High-performance concrete additive testing")

At WANHONG, we invest heavily in research and development to enhance our products' performance in extreme conditions. Our laboratory conducts freeze-thaw testing to ensure our additives provide reliable protection in real-world scenarios.

Performance Metrics for Quality Cold Weather Additives

| Performance Metric | Industry Standard | WANHONG Performance |

|---|---|---|

| Set time acceleration | 30-50% reduction | Up to 60% reduction |

| Early strength development | 10-20% increase at 24 hours | 25-35% increase at 24 hours |

| Freeze protection | Effective to -5°C | Effective to -10°C with proper dosing |

| Water reduction capability | 5-12% | 10-15% |

| Long-term strength impact | No negative impact | 5-10% strength increase at 28 days |

I remember testing our HPMC against competing products in our laboratory last year. We subjected concrete samples to alternating freeze-thaw cycles and measured strength development. Our product consistently outperformed competitors, maintaining higher strength throughout the testing period.

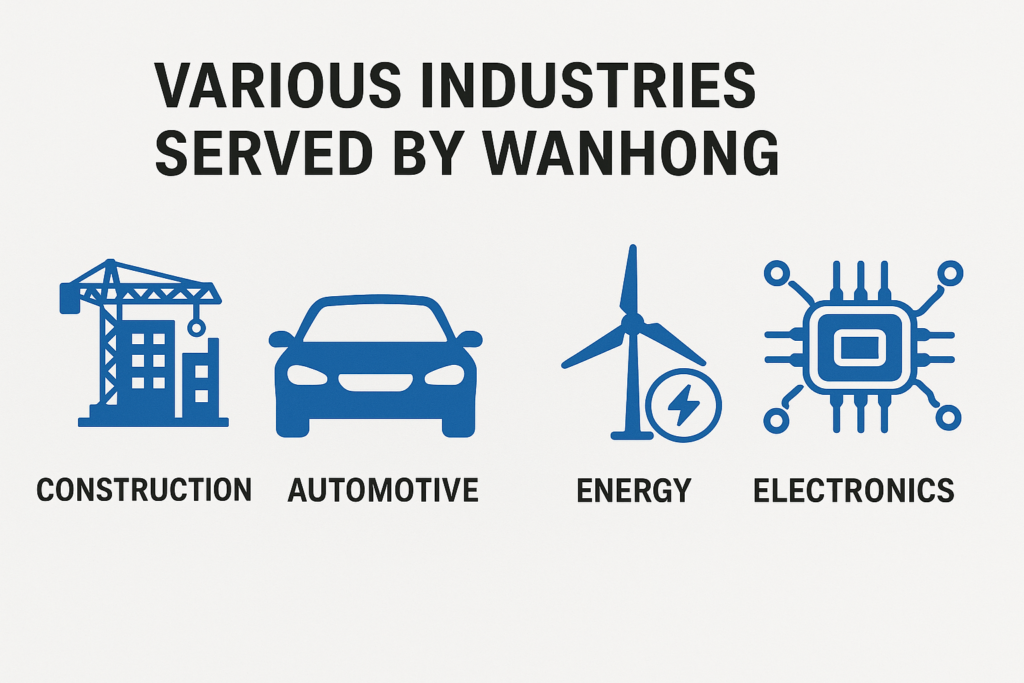

Which Industries Does WANHONG Serve?

Construction challenges vary across industries, and without specialized knowledge of specific applications, additive suppliers may provide one-size-fits-all solutions that don't address unique requirements.

WANHONG serves diverse industries including commercial construction, infrastructure development, residential building, precast concrete manufacturing, and specialty concrete applications. Our technical team has experience developing additive solutions for projects ranging from high-rise buildings to bridge construction in extreme environments.

https://placehold.co/600x400 "Various industries served by WANHONG")

https://placehold.co/600x400 "Various industries served by WANHONG")

Having worked with clients across multiple sectors, I've gained valuable insights into the specific needs of different applications. This experience allows us to provide targeted recommendations rather than generic solutions.

Industry-Specific Solutions

| Industry | Specific Challenges | WANHONG Solution |

|---|---|---|

| Commercial Construction | Fast-track schedules, large pour volumes | High-performance accelerators, consistent quality at scale |

| Infrastructure | Durability requirements, variable exposure | Enhanced freeze-thaw protection, corrosion inhibition |

| Residential | Cost considerations, contractor variability | User-friendly additives with forgiving dosage ranges |

| Precast | High early strength, aesthetic requirements | Specialized accelerator systems, consistent color performance |

| Specialty Concrete | Unique performance requirements | Custom formulations for specific applications |

Last year, I worked closely with a precast manufacturer in Vietnam who needed to maintain production through their winter season. By incorporating our specialized HPMC and accelerator package, they reduced curing time by 40% while maintaining the high early strength required for their process.

Conclusion

Cold weather concrete curing demands specialized additives that protect against freezing while ensuring proper strength development. By choosing quality products from WANHONG, you can maintain construction schedules year-round and deliver durable concrete structures regardless of temperature challenges.

-

Understand the unique challenges faced during winter construction and how to overcome them. ↩

-

Find effective strategies to enhance concrete performance even in freezing conditions. ↩

-

Learn about HPMC's role in enhancing water retention and workability for cold weather concreting. ↩

-

Explore the technical support options that can help you avoid costly mistakes in concrete mixing. ↩

-

Explore this link to discover essential additives that ensure concrete strength in freezing temperatures. ↩

-

Discover best practices for maintaining the long-term durability of concrete in various conditions. ↩