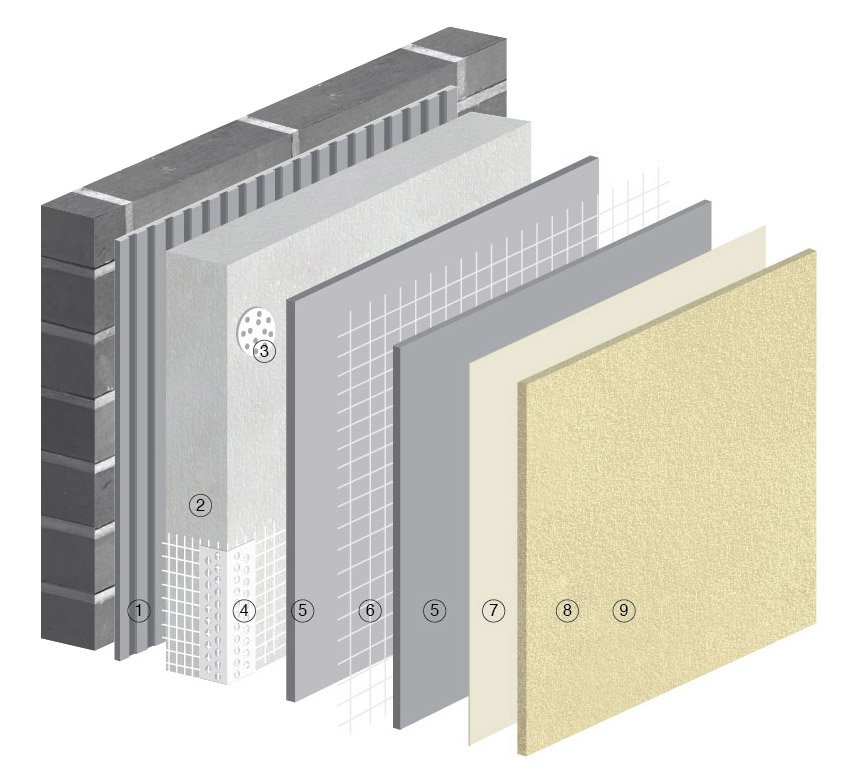

EIFS/ETICS

Exterior Insulated Finish Systems (EIFS), also known as Exterior Insulated Composite Systems (ETICS), are cladding systems used to provide exterior insulation to buildings.

Advantages of incorporating cellulose into EIFS/ETICS

Water Retention

Cellulose ethers significantly increase the water retention capacity of the mortar used in EIFS and ETICS. This is particularly important for curing; it ensures that the mortar dries slowly and evenly, reducing the risk of cracking and shrinkage. Enhanced water retention is critical in hot or windy conditions where rapid water loss could compromise the integrity of the system.

Workability and Application

Adding cellulose ethers to the adhesive and base coat layers of EIFS and ETICS improves the ease of application. These additives enhance the rheological properties of the mortar, making it easier to spread and apply, ensuring a smooth, consistent finish. Workability is crucial for efficient application, reducing labor effort and time.

Adhesion

The addition of cellulose ethers improves the adhesive properties of the mortar to various substrates, including insulation boards, reinforcing meshes, and the existing wall surfaces. This ensures a durable bond that is resistant to mechanical stress and environmental factors, contributing to the longevity and stability of the cladding system.

Thermal Efficiency

While cellulose ethers themselves are not insulating materials, their role in ensuring the integrity and performance of EIFS and ETICS directly impacts the system’s thermal efficiency. By preventing cracks and facilitating a durable, tight bond, they help maintain the continuous insulation layer’s effectiveness, minimizing thermal bridges and energy loss.

Weather Resistance

Cellulose ethers contribute to the weather resistance of EIFS and ETICS. By improving water retention and adhesion, they help protect the insulation layer from moisture ingress and damage due to freeze-thaw cycles, thereby extending the life of the insulation system under varying environmental conditions.

Sag Resistance

In EIFS and ETICS, the base coat must remain stable and in place during application and curing. Cellulose ethers provide sag resistance, ensuring the mortar stays put without dripping or sagging, which is crucial for applying on vertical surfaces and achieving a uniform thickness across the system.

Reduce shrinkage

Cellulose ether help reduce the shrinkage of the mortar, minimizing the risk of cracking and ensuring the EIFS/ETICS system is more stable and durable.

Compatibility with insulation materials

Cellulose ether are generally compatible with a variety of insulation materials, including expanded polystyrene (EPS) or mineral wool. This versatility makes them suitable for EIFS/ETICS formulations with different insulation types.

Incorporating Cellulose Ether T into EIFS and ETICS formulations brings about technical advantages that enhance the application properties, performance, and durability of these systems, directly contributing to energy-efficient and long-lasting building envelopes.

Related Products

Request an Instant Quote for Your Projects!

If you have specific questions about EIFS/ETICS

Our industry experts are here to help, and we’re happy to answer any questions you may have.