Are your EIFS projects failing because of poor-quality additives? Many contractors face cracking, delamination, and moisture problems when using substandard HPMC in their EIFS systems.

HPMC (Hydroxypropyl Methylcellulose)1 is the essential binding agent in EIFS/ETICS systems that provides water retention, adhesion2, and workability. Quality HPMC from a reliable manufacturer like WANHONG ensures proper application, extended working time, and long-lasting EIFS installations.

At WANHONG, we've been manufacturing premium HPMC specifically engineered for EIFS/ETICS applications for over 15 years. I've personally seen how the right grade of HPMC transforms challenging exterior insulation projects into successful, durable installations. Let me share what makes our HPMC the preferred choice for EIFS manufacturers worldwide.

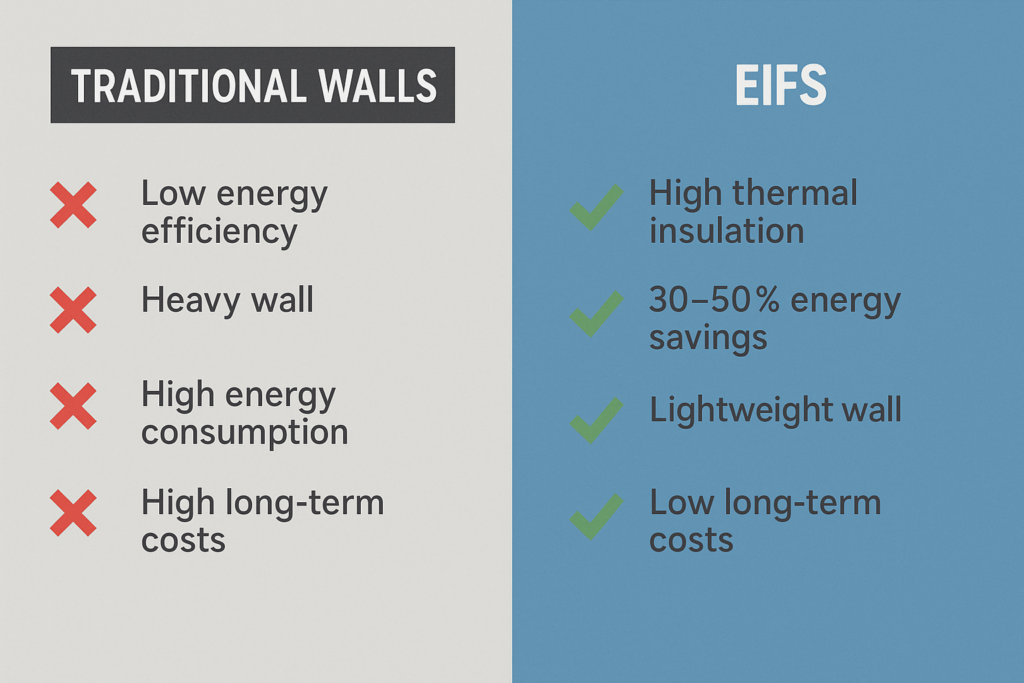

What Are the Amazing Benefits of EIFS/ETICS?

Does your building suffer from poor energy efficiency and high maintenance costs? Traditional cladding systems often fail to provide adequate insulation and require frequent repairs, draining your resources.

EIFS (Exterior Insulation and Finish Systems)3 or ETICS (External Thermal Insulation Composite Systems)4 provide continuous insulation, energy efficiency, design flexibility, and moisture control. These systems can reduce heating and cooling costs by up to 40% while offering almost unlimited aesthetic options.

EIFS systems have revolutionized exterior cladding options for both residential and commercial buildings. I've visited projects across Saudi Arabia and the UAE where clients have reduced their cooling costs dramatically after switching to EIFS. The system's multilayer approach creates a thermal envelope that shields buildings from extreme temperatures.

The versatility of EIFS is another significant advantage. You can achieve virtually any architectural style - from classical to ultra-modern. The system allows for decorative shapes, reveals, and a wide range of textures and colors that would be impossible or prohibitively expensive with other cladding materials.

EIFS Cost-Benefit Analysis

| Benefit | EIFS Performance | Traditional Systems |

|---|---|---|

| Energy Savings | 20-40% reduction | Minimal improvement |

| Installation Cost | Moderate initial investment | Often lower upfront cost |

| Maintenance Cost | Low (every 15-20 years) | High (every 3-5 years) |

| Design Options | Unlimited colors/textures | Limited options |

| Weather Resistance | Superior | Variable |

When you factor in the long-term energy savings and reduced maintenance requirements, EIFS systems typically pay for themselves within 5-7 years, making them an economically sound choice for building owners concerned with operational costs.

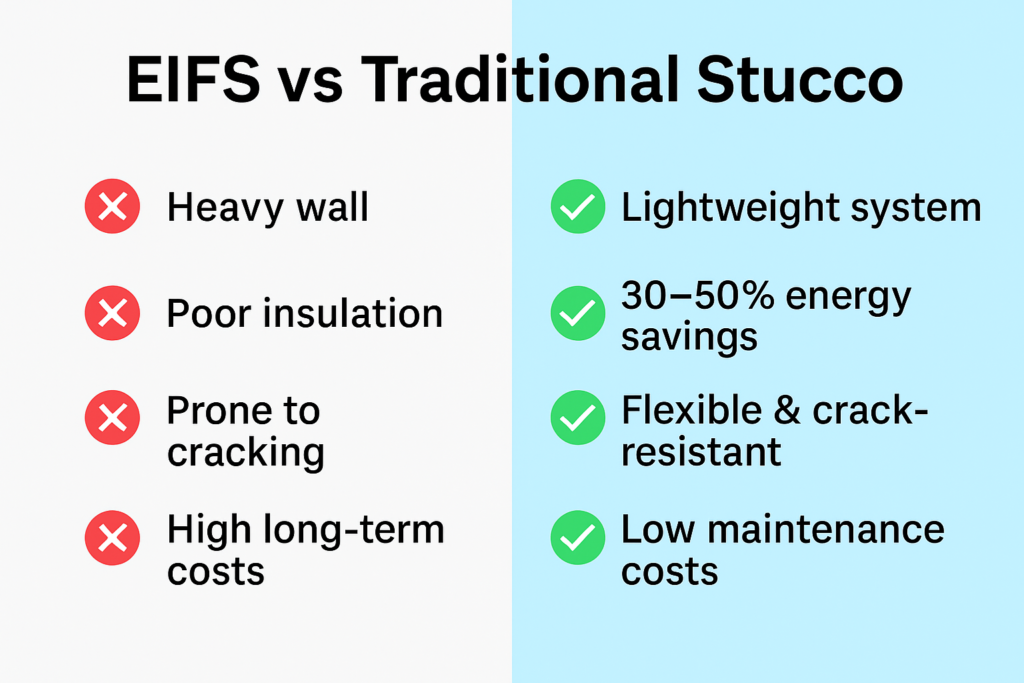

What Are the Major Differences of EIFS VS Stucco?

Are you confused about whether to choose EIFS or traditional stucco for your project? Many builders and property owners struggle with this decision, potentially sacrificing energy efficiency or durability by making the wrong choice.

EIFS differs from stucco primarily in its layered system approach. EIFS includes continuous insulation (typically EPS foam) and flexible finishes, while traditional stucco is cement-based without insulation. EIFS offers superior energy efficiency, lighter weight, and fewer cracks, while stucco provides better impact resistance.

The distinction between these two systems goes beyond surface appearance. Having worked with clients across different climate zones, I've seen how important this choice can be for building performance. EIFS creates a comprehensive thermal barrier that stucco simply cannot match.

One crucial difference lies in the physical structure. Traditional stucco is essentially a cement-based coating applied directly to the building substrate, with metal lath for reinforcement. It forms a rigid, monolithic surface that, while durable, is prone to cracking from building movement or thermal expansion.

EIFS, in contrast, employs multiple layers working together: a base coat with embedded reinforcing mesh, insulation board, adhesive, and a finish coat. This creates a more flexible system that can accommodate building movement. The reinforcing mesh in EIFS significantly reduces the risk of cracking that plagues traditional stucco installations.

EIFS vs Stucco Comparative Analysis

| Feature | EIFS | Traditional Stucco |

|---|---|---|

| R-Value | R-4 to R-16+ | R-0.2 to R-0.8 |

| Weight | 1-2 lbs/sq ft | 7-9 lbs/sq ft |

| Crack Resistance | High (flexible system) | Low (rigid system) |

| Impact Resistance | Moderate | High |

| Installation Complexity | Moderate to High | Moderate |

| Water Management | Built-in drainage plane | Requires separate systems |

| Cost | $9-15 per sq ft | $7-12 per sq ft |

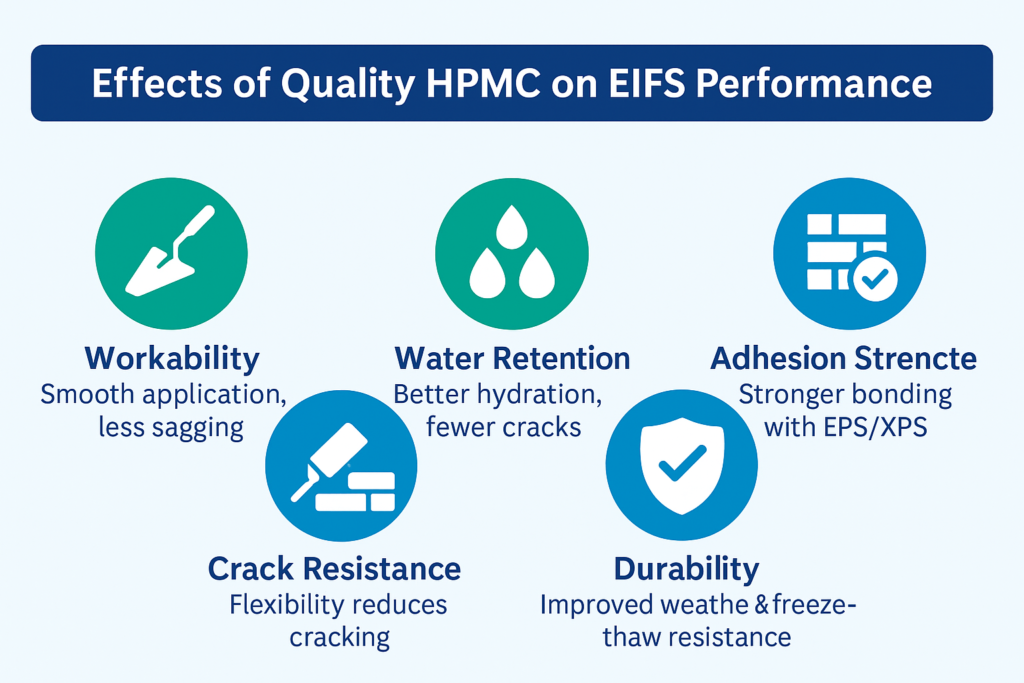

Why is Good Quality HPMC Important in EIFS Construction?

Have you noticed your EIFS mixtures drying too quickly or lacking proper adhesion? Poor quality HPMC can lead to application failures, reduced working time, and compromised system performance.

High-quality HPMC is crucial in EIFS construction because it controls water retention, improves adhesion, enhances workability, and ensures proper curing time. Premium HPMC grades prevent sagging, extend open time, and create stronger bonds between system components, resulting in more durable EIFS installations.

I've seen firsthand the dramatic difference that quality HPMC makes in EIFS applications. During summer construction in Dubai, where temperatures regularly exceed 40°C, contractors using our premium HPMC maintained workable mixtures for hours longer than those using generic products. This extended open time allowed for proper application and finishing, preventing costly rework.

The molecular structure and purity of HPMC significantly impact its performance. At WANHONG, we carefully control the manufacturing process to ensure consistent viscosity, particle size, and substitution degree. These parameters might seem technical, but they translate directly to real-world benefits on the construction site.

Water retention is perhaps the most critical function of HPMC in EIFS systems. When mortar loses water too quickly—either to the atmosphere or to the substrate—it doesn't develop proper strength. Our laboratory tests show that WANHONG HPMC5 retains optimal moisture levels for up to 300% longer than inferior products, ensuring that cement hydration occurs completely.

HPMC Properties and Their Impact on EIFS Performance

| HPMC Property | Function | Impact on EIFS |

|---|---|---|

| Viscosity | Controls mixture consistency | Prevents sagging, improves workability |

| Water Retention | Slows water evaporation | Ensures proper curing, stronger bonds |

| Particle Size | Affects dissolution rate | Consistent mixing, fewer lumps |

| Substitution Degree | Controls water solubility | Balanced water retention/release |

| Purity | Limits contaminants | Consistent performance, better adhesion |

What Makes WANHONG HPMC5 Stand Out?

Are you tired of inconsistent HPMC quality affecting your EIFS production? Many manufacturers face batch-to-batch variations that disrupt formulations and compromise end-product performance.

WANHONG HPMC5 stands out through consistent quality control, customized viscosity options (from 15,000 to 200,000 mPa·s), specialized grades for different climate conditions, and reliable technical support. Our products undergo rigorous testing for water retention, thickening efficiency, and workability to ensure optimal EIFS performance.

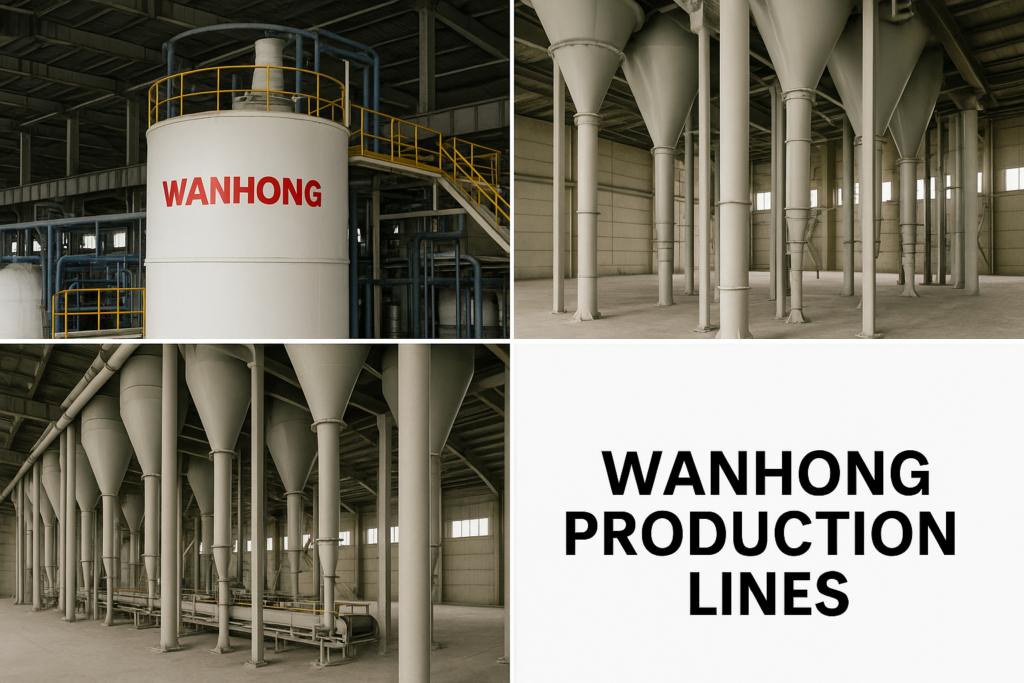

Since establishing our factory in China with six production lines, we've focused on creating HPMC formulations specifically designed for construction applications. Unlike general-purpose HPMC suppliers, we understand the unique demands of EIFS systems and have engineered our products to address these specific challenges.

One area where I take particular pride is our climate-adapted formulations. When I visited customers in Saudi Arabia last year, they described how mortars were setting too quickly in their extreme heat. We developed a special high water retention grade that extended working time by 45 minutes, solving their application problems. Similarly, for customers in colder regions like Georgia, we offer fast-dissolving grades that perform well even in low temperatures.

Our quality control process is another distinguishing factor. Each production batch undergoes 12 different tests before packaging, including viscosity stability, fineness, moisture content, and gel temperature. This meticulous testing ensures that every bag of WANHONG HPMC delivers consistent performance.

WANHONG HPMC5 Specifications for EIFS Applications

| Parameter | WANHONG Standard | Industry Average |

|---|---|---|

| Viscosity Tolerance | ±5% | ±10-15% |

| Moisture Content | ≤5% | ≤7% |

| Particle Retention (80 mesh) | ≤1% | ≤3% |

| Gel Temperature | ±2°C precision | ±5°C variation |

| Water Retention | ≥95% | 70-90% |

| Heavy Metal Content | <10ppm | <20ppm |

| Dissolution Time | Customized (3-8 min) | Variable |

What Are the Construction Plus Points of EIFS?

Is your construction project falling behind schedule and over budget? Traditional building methods often involve multiple trades, complex coordination, and lengthy installation times.

EIFS construction6 offers significant advantages including faster installation (20-30% quicker than traditional methods), reduced structural requirements due to lighter weight, lower skilled labor needs, and fewer specialized tools. The system also facilitates easier repairs and accommodates irregular building shapes.

Having visited numerous construction sites across developing markets, I've observed how EIFS simplifies the building process. A traditional brick-and-mortar façade requires masons, supports, multiple material deliveries, and lengthy curing times. By contrast, EIFS installation follows a streamlined process that a single skilled team can execute from start to finish.

The lightweight nature of EIFS7 provides both construction and structural benefits. A square meter of complete EIFS typically weighs 4-5kg, compared to 25-30kg for brick veneer. This reduced load means less structural support is required, potentially lowering overall building costs. During my visit to a high-rise project in Pakistan, the engineer explained how switching to EIFS saved nearly 8% on structural steel costs due to the reduced dead load on the building frame.

Weather vulnerabilities are also reduced with EIFS construction. While many cladding systems require ideal conditions, EIFS components can be stored on-site and installation can proceed in a wider range of temperatures and conditions. I remember a project in Brazil where work continued during light rain conditions that would have halted traditional stucco application.

EIFS Installation Efficiency Factors

| Construction Factor | EIFS Advantage | Impact on Project |

|---|---|---|

| Installation Speed | 100-150 sq ft/day/worker | Faster project completion |

| Material Handling | Lightweight components | Reduced equipment needs |

| Skill Requirements | Specialized but trainable | Easier workforce management |

| Weather Constraints | Moderate flexibility | Fewer weather delays |

| Scaffolding Time | Reduced | Lower equipment costs |

| Waste Generation | 5-7% typical | Less disposal expense |

Why Choose WANHONG as Your One-Stop HPMC Manufacturer and Supplier?

Are you frustrated with suppliers who don't understand your specific EIFS formulation needs? Many HPMC providers offer generic products that require extensive reformulation and testing before use.

WANHONG serves as your one-stop HPMC manufacturer by providing custom viscosity grades8 (15,000-200,000 mPa·s), dedicated technical support, consistent quality from our six production lines, flexible packaging options (25kg/50lb paper bags or 500-1000kg jumbo bags), and reliable logistics with on-time delivery to over 30 countries.

As a factory-direct supplier, we've eliminated intermediaries to provide both better pricing and more responsive service. When I speak with customers at exhibitions or during factory visits, they often mention how refreshing it is to work directly with the manufacturer who understands the technical aspects of their formulations.

Our dedicated R&D team continually works to improve our HPMC products based on market feedback. Last year, we developed a new grade with enhanced sag resistance specifically for EIFS basecoat applications after receiving feedback from several customers in the Middle East. This customer-driven innovation cycle helps us stay ahead of market needs.

Supply chain reliability has become increasingly important in recent years. With our six production lines operating at 90% capacity, we maintain sufficient inventory to fulfill orders promptly even during peak demand periods. During the global shipping crisis of 2021-2022, we implemented flexible logistics solutions including alternative shipping routes and consolidated containers to ensure our customers received their materials with minimal delays.

WANHONG HPMC9 Supply Advantages

| Service Aspect | WANHONG Offering | Customer Benefit |

|---|---|---|

| Technical Support | Formulation assistance, on-site visits | Optimized recipes, faster problem-solving |

| Order Flexibility | MOQ from 1 ton, emergency orders | Inventory management flexibility |

| Quality Certification | ISO 900110, CE Certified | Regulatory compliance assurance |

| Sample Service | Free by air express | Pre-purchase evaluation |

| Production Capacity | 15,000 tons annually | Consistent supply capability |

| Lead Time | 2-3 weeks typical | Reliable planning |

| Payment Terms | L/C, T/T, flexible options | Financial convenience |

How to Find Your Perfect HPMC Product Match?

Are you overwhelmed by the numerous HPMC options and unsure which is right for your EIFS formulation? Selecting the wrong viscosity or modification can lead to application issues and product failures.

To find your perfect HPMC match for EIFS applications, consider your climate conditions, required open time, machine or hand application methods, and other additives in your formulation. WANHONG offers free consultation and sample matching to help you select the ideal grade based on your specific requirements.

I've guided hundreds of customers through the HPMC selection process, and I understand it can seem complex at first. The key is to approach it systematically based on your specific application requirements rather than simply ordering based on viscosity alone.

For EIFS basecoat adhesives, we typically recommend our WHHPMC-150K or WHHPMC-200K grades, which provide excellent sag resistance and strong adhesion to EPS/XPS boards. For finish coats where workability and extended open time are critical, our modified WHHPMC-75K with enhanced water retention is often the optimal choice.

Your manufacturing process also influences the ideal HPMC grade. For fully automated production lines, we offer fast-dissolving grades that incorporate rapidly into the dry mix. For smaller operations with ribbon blenders, our standard dissolution products may be more appropriate and cost-effective.

The testing process is crucial for finding your perfect match. We recommend evaluating at least 2-3 different samples in your actual formulation under real working conditions. Our technical team can provide a testing protocol that evaluates key parameters such as open time, sag resistance, and adhesion strength to ensure you select the optimal product.

HPMC Selection Matrix for EIFS Applications

| EIFS Component | Recommended Viscosity | Key Properties Needed | WANHONG Recommendation |

|---|---|---|---|

| Adhesive Layer | 100,000-200,000 mPa·s | High adhesion, sag resistance | WHHPMC-150K, WHHPMC-200K |

| Basecoat | 75,000-150,000 mPa·s | Workability, mesh embedding | WHHPMC-100K, WHHPMC-150K |

| Finish Coat | 15,000-50,000 mPa·s | Texture, extended open time | WHHPMC-30K, WHHPMC-50K |

| One-component System | 75,000-100,000 mPa·s | Balanced properties | WHHPMC-100K Modified |

| Hot Climate Application | Varies | Enhanced water retention | Climate-Adapted Series |

| Machine Application | 15,000-50,000 mPa·s | Pumpability | |

| Machine Application | 15,000-50,000 mPa·s | Pumpability, consistent flow | WHHPMC-30K Spray Grade |

| Cold Climate Application | Varies | Faster dissolution, earlier strength | Fast-Dissolving Series |

Conclusion

WANHONG offers premium HPMC specifically engineered for EIFS/ETICS applications with consistent quality, customized solutions, and reliable support. Our six production lines deliver products to over 30 countries, helping contractors and manufacturers achieve superior EIFS installations worldwide.

-

Understanding HPMC's role can enhance your EIFS projects, ensuring better performance and durability. ↩

-

Understanding adhesion can help you choose the right materials for successful EIFS installations. ↩

-

Explore the benefits of EIFS to improve energy efficiency and reduce maintenance costs in your building. ↩

-

Learn how ETICS can provide superior insulation and energy savings for your construction projects. ↩

-

Discover the unique qualities of WANHONG HPMC that can enhance your EIFS projects. ↩ ↩ ↩ ↩

-

Explore the advantages of EIFS construction, including speed and cost savings, to enhance your building projects. ↩

-

Learn how the lightweight properties of EIFS can reduce structural loads and costs. ↩

-

Learn how custom viscosity grades can optimize your EIFS formulations for better performance. ↩

-

Explore WANHONG's commitment to quality and customer service in HPMC manufacturing. ↩

-

Understand the importance of ISO 9001 certification in ensuring product quality and compliance. ↩