Tile failures during seasonal changes cost contractors thousands in repairs. I've seen beautiful installations crack and detach after just one harsh winter, leaving customers frustrated and contractors liable for expensive rework.

The ideal tile adhesive1 that withstands both water immersion and freeze-thaw cycles requires a balanced formulation of cement (40-50%), fine silica sand (30-40%), HPMC cellulose ethers (0.2-0.4%), redispersible polymer powder2 (2-5%), and specialized additives like frost resistance agents and water repellents (1-3%).

Creating a durable tile adhesive isn't just about mixing ingredients—it's about understanding the chemistry behind what makes adhesives fail in challenging conditions. Let's explore the science and practical formulation tips that ensure your tile installations remain intact through seasonal extremes.

What is the Formulation of Tile Adhesive?

Every time I visit a failed tile installation, the same question arises: was it poor workmanship or inferior adhesive formulation? Most failures trace back to inadequate chemical composition that couldn't handle environmental stresses.

A professional-grade tile adhesive formulation typically contains Portland cement (40-50%), graded silica sand (30-40%), hydroxypropyl methylcellulose3 (HPMC) at 0.2-0.4%, redispersible polymer powder2 (2-5%), and performance additives (3-5%) including water repellents, defoamers, and setting accelerators.

The science behind a successful tile adhesive relies on the synergistic relationship between these components. Portland cement provides the base structural strength, while silica sand contributes to dimensional stability and reduces shrinkage. HPMC, one of our specialty products at Kehao, plays a crucial role in water retention, improving open time and preventing premature drying.

This cellulose ether also enhances workability and sagging resistance, critical for wall applications. The redispersible polymer powder2 (RDP) forms a flexible polymer network throughout the cement matrix when hydrated, significantly increasing bond strength and flexibility.

For water and freeze-thaw resistance specifically, the type and amount of RDP becomes especially important. We recommend using VAE (vinyl acetate-ethylene) copolymers with a higher ethylene content, typically around 15-18%, which improves water resistance dramatically. Additionally, incorporating hydrophobic additives like calcium stearate (0.3-0.5%) creates water-repellent properties without compromising breathability.

Key Component Proportions for Different Applications:

| Component | Standard Tile Adhesive | Water-Resistant Adhesive | Freeze-Thaw Resistant |

|---|---|---|---|

| Cement | 45-50% | 45-50% | 40-45% |

| Silica Sand | 35-40% | 30-35% | 30-35% |

| HPMC | 0.2-0.3% | 0.25-0.35% | 0.3-0.4% |

| RDP | 2-3% | 3-5% | 5-8% |

| Additives | 1-2% | 2-3% | 3-5% |

Can Tile Adhesive Freeze?

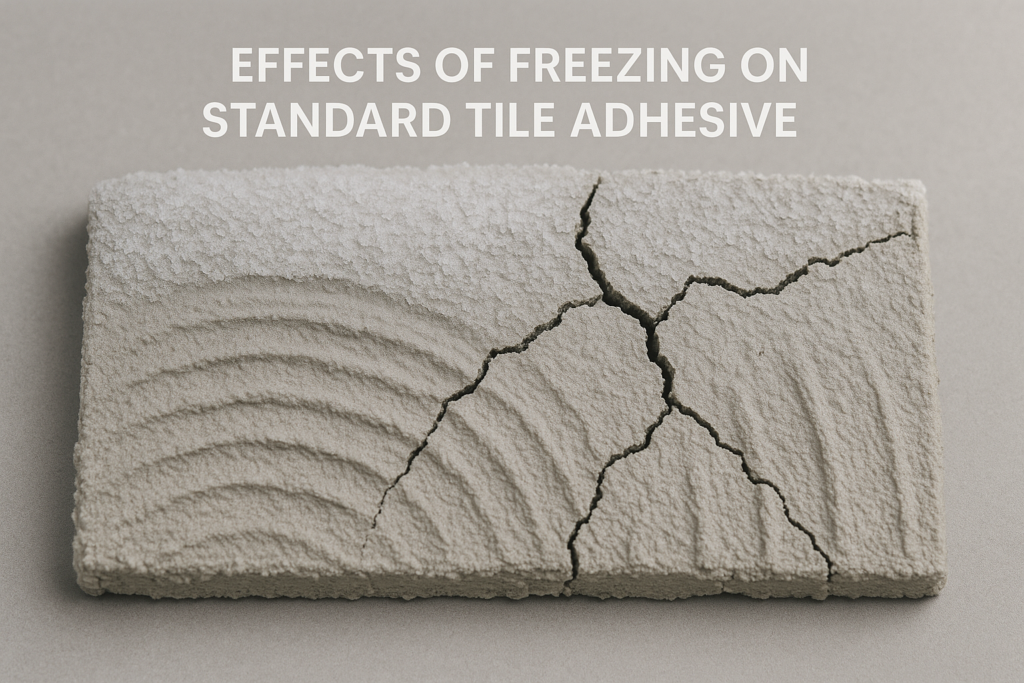

Many contractors I've worked with wonder why their perfectly installed tiles fail after winter. The harsh truth is that standard adhesives often lack the molecular structure to withstand the expansion forces of freezing water.

Yes, conventional tile adhesives can freeze when temperatures drop below 0°C (32°F), causing water within the adhesive matrix to expand by approximately 9% in volume. This expansion creates internal pressure that can rupture the cement matrix, leading to cracking, bond failure, and eventual tile detachment.

The freeze-thaw resistance of tile adhesive depends largely on its porosity and ability to accommodate the volumetric expansion of frozen water. When water freezes inside conventional adhesives, it expands and pushes against the surrounding cement matrix. Without sufficient flexibility or pressure relief mechanisms, this expansion causes microfractures that worsen with each freeze-thaw cycle.

To create a truly freeze-resistant adhesive, we need to modify the microstructure in several ways. First, incorporating air-entraining agents (0.01-0.02%) creates microscopic air voids that serve as expansion chambers for freezing water. These tiny air pockets, typically 50-200μm in diameter, provide space for ice formation without damaging the surrounding matrix.

Second, higher concentrations of flexible polymers are essential. Our laboratory testing demonstrates that increasing redispersible polymer powder2 content to 5-8% (compared to the standard 2-3%) significantly enhances freeze-thaw durability. These polymers create elasticity within the cement matrix, allowing it to flex slightly during freezing rather than cracking.

Third, reducing the water-to-cement ratio improves freeze resistance by minimizing capillary pores. This is where the quality of your HPMC becomes crucial—premium grades like our Kehao HPMC-150000 allow for good workability even with lower water content. I've found that reducing the water-cement ratio from the typical 0.55-0.6 down to 0.45-0.5 significantly improves freeze-thaw resistance without compromising workability when properly formulated.

How to Make Water-Based Adhesive?

Whenever I consult with manufacturers struggling with water resistance, they're often overlooking the critical balance between water workability and water resistance. Most attempt to solve the problem with hydrophobic additives alone.

To create an effective water-based tile adhesive, blend Portland cement (45%), fine silica sand (35%), high-viscosity HPMC (0.3%), hydrophobic-modified RDP (5%), silane coupling agents (0.5%), and water repellents like calcium stearate (0.5%). Mix dry ingredients thoroughly before adding water at a controlled 0.45-0.5 water-cement ratio.

Water resistance in cement-based adhesives represents a fundamental paradox: the formulation must resist water penetration after curing while remaining workable with water during application. This challenge requires sophisticated chemistry rather than simple waterproofing additives.

The process begins with material selection. For water-resistant formulations, I recommend using Type I Portland cement with lower C3A (tricalcium aluminate) content, which reduces susceptibility to chemical degradation4 in wet environments. The silica sand should be thoroughly dried before mixing (moisture content below 0.5%) to ensure consistent water ratios.

The polymer selection becomes particularly critical for water resistance. We've seen excellent results using specialized hydrophobic-modified polymers like VAE with silane functionalization. These polymers create water-repelling barriers around cement particles while maintaining strong adhesion properties. The silane coupling agents create chemical bridges between the inorganic cement components and the organic polymers, significantly enhancing the water resistance of these interfaces—often the weakest point in conventional formulations.

When manufacturing water-resistant adhesives, the mixing sequence matters significantly. Our technical testing shows that pre-blending the dry polymers and cement before introducing precisely controlled water amounts results in more uniform distribution and better performance. For industrial production, high-shear mixers with proper dust collection systems ensure both quality and worker safety.

Field testing is essential—laboratory water resistance doesn't always translate to real-world performance. I recommend standardized testing under ANSI A118.11 protocols, which include 7-day water immersion testing followed by shear bond evaluations.

How to Avoid Poor Adhesion in Tile Adhesive Applications?

I recently inspected a luxury hotel bathroom where nearly 30% of the tiles had detached within a year of installation. The contractor had used quality materials, but critical application errors had undermined the adhesive's performance.

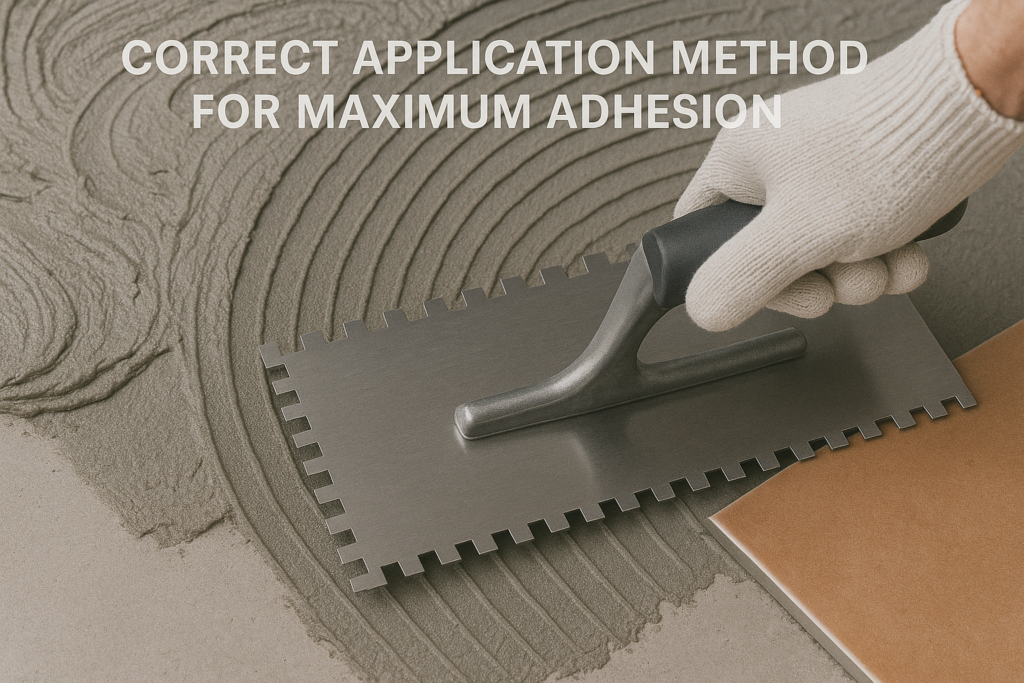

To avoid poor adhesion in tile applications, first ensure substrate preparation by removing debris and priming porous surfaces. Use the correct adhesive type for specific tiles and environments. Apply with proper notched trowels at recommended thicknesses (2-6mm), maintain optimal temperature (10-35°C) during installation, and allow full curing time (24-72 hours) before grouting.

Even the most perfectly formulated adhesive will fail if application protocols aren't followed. The adhesion problems I most commonly encounter stem from a combination of formulation inadequacies and application errors that compound each other.

Substrate preparation forms the foundation of successful tile installations. Beyond basic cleaning, understanding substrate porosity is essential. Highly absorbent substrates like gypsum board or old concrete require priming with acrylic-based primers to prevent premature water absorption from the adhesive. For non-porous substrates like existing tiles or metal, specialized high-polymer adhesives with enhanced mechanical adhesion properties are necessary.

The adhesive should be matched precisely to both the tile type and installation environment. Porcelain tiles, with their extremely low porosity, require higher polymer content adhesives (minimum 3-5% RDP) compared to ceramic tiles. For exterior applications or wet environments, polymer content should increase further to 5-8%. Natural stone installations often require white adhesives with low alkali content to prevent staining and efflorescence.

Application technique significantly impacts performance. Adhesive beds should maintain a consistent thickness between 2-6mm depending on tile size and substrate levelness. The notched trowel selection should match the tile dimensions—larger tiles require deeper notches to ensure adequate coverage. Double-spreading (applying adhesive to both substrate and tile back) becomes essential for tiles larger than 30x30cm to prevent hollow spots that can lead to cracks.

Environmental conditions during installation often go overlooked. The adhesive's chemical hydration reactions proceed optimally between 15-25°C (59-77°F). Installation during extreme temperatures requires modified working practices—hot conditions demand smaller working areas and possibly retarding agents, while cold conditions require accelerators and protection from freezing during the critical first 48 hours of curing.

Finally, proper curing time must be respected. The temptation to grout immediately should be resisted, as premature loading of the adhesive before full strength development leads to long-term adhesion problems. Light traffic should be avoided for at least 24 hours, and wet area usage should be delayed for 7-14 days to allow complete hydraulic curing and polymer film formation.

Conclusion

Formulating freeze-thaw and water-resistant tile adhesive requires balancing cement, sand, HPMC, polymers, and specialized additives. Success depends on both proper formulation and correct application techniques for long-lasting installations in challenging environments.

-

Understanding the best practices for tile adhesive selection can help ensure durable installations and prevent costly repairs. ↩

-

Understanding RDP's benefits can enhance your adhesive formulations for better performance. ↩ ↩ ↩ ↩

-

Discovering the role of HPMC in adhesives can help you choose the right products for your projects. ↩

-

Exploring the causes of chemical degradation can help you choose more durable materials for your projects. ↩