Choosing the wrong wall putty1 can lead to cracking, peeling, and costly repairs. Many homeowners waste money and time by using interior products outdoors or vice versa.

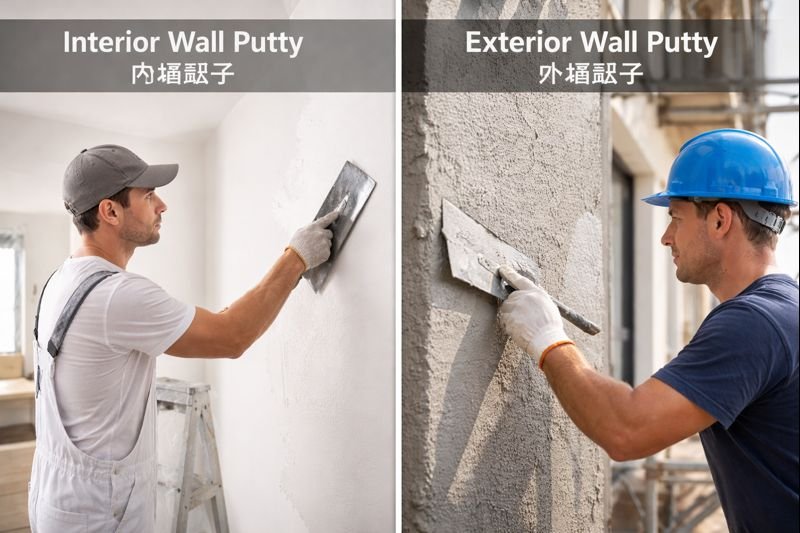

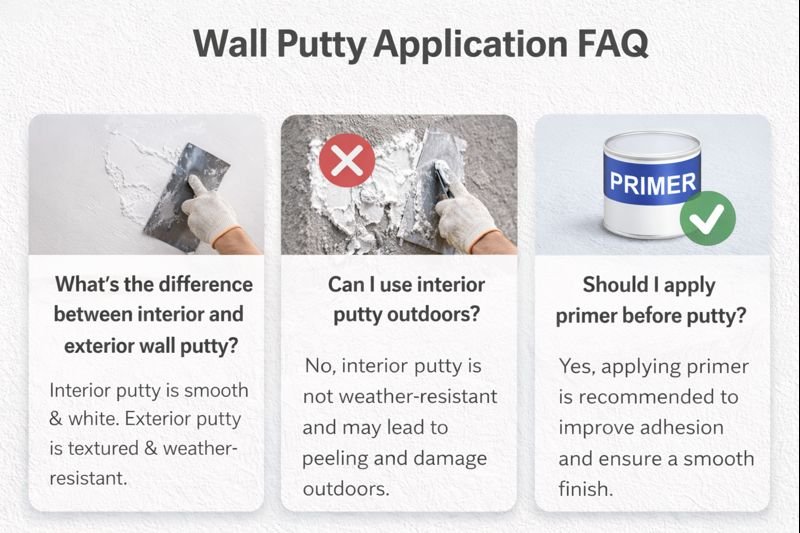

Wall putty comes in two main types: interior and exterior. Interior putty focuses on smoothness and aesthetics for indoor environments, while exterior putty prioritizes durability and weather resistance with cement-based formulations to withstand harsh outdoor conditions.

I've seen many construction projects fail simply because someone used the wrong type of wall putty. The difference might seem minor, but it's actually crucial to your wall's longevity. Let me walk you through everything you need to know about choosing between interior and exterior wall putty.

What is the difference between interior and exterior putty2?

Pain point: Using the wrong putty type can lead to wall damage, wasted materials, and expensive repairs. I've seen entire façades fail because of this simple mistake.

The main difference between interior and exterior wall putty is water resistance. Interior putty focuses on smoothness and aesthetics but deteriorates when wet. Exterior putty contains cement and polymers to withstand rain, temperature changes, and UV exposure, making it more durable but harder to work with.

The formulation fundamentally determines their performance. I remember visiting a client who had used interior putty on his exterior walls in a rainy region. Within six months, large sections were peeling off, requiring complete reworking.

Exterior wall putty always uses cement as its base component with significant polymer powder (HPMC and RDP) content. This creates a hard yet flexible finish that can handle weather extremes. It's specifically engineered to repel water while allowing the wall to "breathe" – essential for preventing moisture buildup.

In contrast, interior putty prioritizes environmental friendliness and fine texture. It creates ultra-smooth surfaces that are easy to sand and paint, but will quickly deteriorate when exposed to water. Some interior formulations use acrylic bases or POP (Plaster of Paris), focusing on aesthetic finishes rather than durability.

The application process differs too. Exterior putty typically requires professional application with proper curing time between coats, while interior varieties are generally more DIY-friendly. The price difference is also notable – exterior formulations containing weather-resistant polymers typically cost 30-50% more than interior equivalents.

Interior Wall Putty: What makes it perfect for indoor spaces?

Indoor walls face stains, minor impacts, and occasional humidity. Without proper putty, your beautiful paint job will show every imperfection underneath.

Interior wall putty creates smooth, paintable surfaces for indoor walls. It's typically made from gypsum or acrylic compounds, dries quickly, is easy to sand, and provides excellent finish quality. However, it lacks water resistance and UV protection, making it unsuitable for outdoor applications.

I've applied countless coats of interior putty, and its primary purpose is creating that perfect canvas for paint. Good interior putty makes all the difference between amateur-looking and professional wall finishes.

Interior putty comes in several varieties, each with specific advantages. Acrylic putties offer good flexibility and adhere well to various surfaces. They're ideal for areas with minor movement or vibration, like walls near doors. White cement-based putties provide better water resistance for bathrooms and kitchens, though they're still not suitable for exterior use.

POP-based (Plaster of Paris) putties are highly economical and create ultra-smooth finishes, but they're the most vulnerable to water damage. I recommend these only for completely dry indoor areas. Some premium interior putties contain additives for anti-fungal properties, especially valuable in humid climates.

When applying interior putty, the base preparation is crucial. The wall must be clean, dry, and primed properly. Most interior putties require at least two coats, with drying time between applications. The final coat must be thoroughly sanded for that glass-smooth finish that makes paint look its best.

For cost considerations, basic interior putties are quite affordable, but specialty formulations with additives like crack-filling capabilities or enhanced whiteness can cost significantly more. I generally advise clients to invest in quality interior putty for spaces where appearance matters most.

Exterior Wall Putty: Why is it essential for outdoor durability?

Exterior walls face brutal conditions: driving rain, freezing temperatures, scorching sun, and pollution. Using interior putty3 outside is like sending someone in pajamas to climb a mountain.

Exterior wall putty contains cement, polymers (like redispersible powder), and waterproofing compounds to create a highly durable surface that resists water penetration, UV damage, and temperature fluctuations. It has higher tensile strength, excellent adhesion, and vital weather resistance for outdoor walls.

I once visited a project where the contractor tried saving money by using interior putty on exterior walls. After just one monsoon season, the walls were stained, cracked, and peeling. The repair costs far exceeded what they'd "saved."

Exterior putty formulations contain significantly higher amounts of specialty additives like hydroxypropyl methylcellulose (HPMC) and redispersible polymer powder (RDP). These create a strong polymer network within the cement matrix, providing both strength and flexibility. This combination is crucial for handling thermal expansion and contraction that occurs with temperature changes.

The application process for exterior putty is more demanding. Proper surface preparation requires thorough cleaning and often a special primer. Application often requires skilled labor, as achieving the right thickness and coverage is critical for performance. Most premium exterior putties require 2-3 coats with appropriate curing time, especially important in hot climates where premature drying can reduce strength.

High-quality exterior putty contains additives for UV resistance, preventing color degradation from sunlight exposure. Some advanced formulations also include hydrophobic compounds that actively repel water while maintaining breathability – essential for preventing mold and deterioration within the wall structure.

For buildings in coastal areas, specialized exterior putties with enhanced salt resistance are available, though at premium prices. These prevent the salt crystallization that can otherwise destroy standard finishes. Similarly, industrialized areas might benefit from putties with resistance to acidic pollution.

What are the different types of wall putty?

Without understanding putty types, you risk choosing products that won't perform as needed. I've seen countless projects where this misunderstanding led to premature failure.

Wall putties come in several varieties: cement-based (durable, water-resistant, for exteriors), acrylic-based (flexible, good adhesion, for both interiors and high-end exteriors), POP-based (smooth finish, quick-drying, for dry interiors only), and specialty putties4 (with additives for specific conditions like extreme humidity or temperature).

The market offers numerous putty formulations, but understanding the base material is key. I always advise my clients to focus on matching the putty type to the specific environment rather than just looking at price.

Cement-based putties form the backbone of exterior applications. They contain Portland cement, fine aggregates, and crucial additives like cellulose ethers and redispersible powders. The quality difference between economy and premium versions usually lies in the polymer content – higher polymer content (especially RDP) creates more flexibility and adhesion but increases cost substantially. Premium versions might contain 3-5% polymer by weight, while economy versions might have less than 1%.

Acrylic-based putties offer excellent workability and flexibility. They're water-based emulsions that form a polymer film when dried. High-quality acrylic putties can work for both interior and premium exterior applications, especially where flexibility is essential. However, they typically cost 40-60% more than standard cement-based options.

POP-based putties create the smoothest finishes and are extremely easy to sand. However, their moisture resistance is minimal, making them suitable only for consistently dry indoor environments. They're often the most economical option upfront but require ideal conditions to perform well long-term.

Specialty putties include those with enhanced properties for specific conditions – mold-resistant formulations for bathrooms, elastic putties for areas with structural movement, and textured putties that can create decorative finishes. These typically command premium prices but solve specific problems effectively.

When selecting between putty types, it's also worth considering environmental factors. Some modern formulations offer low-VOC options for better indoor air quality, while others focus on recycled content or reduced carbon footprint in manufacturing. These eco-friendly options usually come at a 15-25% price premium.

What happens if you accidentally use exterior paint inside?

Using products in the wrong application can waste money and create health hazards. I've consulted on projects where this mistake led to unnecessary costs and remediation.

Using exterior putty indoors results in unnecessary expenses, difficult application and sanding, and potentially higher VOC levels. However, it won't cause structural issues. Exterior putties are harder, less workable, and typically require more sanding to achieve the smooth finish expected for interior walls.

While using exterior putty indoors isn't as catastrophic as using interior putty outdoors, it still creates significant problems. I once worked with a client who used leftover exterior putty for interior touch-ups, and the difference in workability and finish quality was immediately obvious.

The primary issue with using exterior putty indoors is its hardness and difficult workability. Exterior formulations contain higher cement content and coarser particles, making them significantly harder to sand to the smooth finish expected for interior walls. This often results in visible texture differences after painting, especially under direct or angled lighting.

Cost inefficiency is another major factor. Premium exterior putties can cost 50-100% more than quality interior options due to their weather-resistant additives. These additives serve no purpose indoors and essentially waste money. Additionally, exterior putties typically require stronger tools and more labor for sanding, further increasing the project cost.

Some exterior putties may contain higher levels of VOCs (Volatile Organic Compounds) or other chemicals designed for outdoor use where ventilation isn't a concern. When used indoors, these can potentially affect indoor air quality, especially in poorly ventilated spaces. While modern formulations are improving in this regard, it remains a consideration for sensitive individuals.

Application characteristics also differ significantly. Exterior putties generally have shorter working times and different water requirements, making them less forgiving for DIY applications. They may also have different drying and curing profiles, potentially extending project timelines unnecessarily when used indoors.

How to Choose the Right Wall Putty for Your Project?

Selecting the wrong putty type wastes your money and compromises your wall's durability. I've helped many clients avoid this costly mistake through a systematic approach.

Choose wall putty by assessing the application environment first: use weather-resistant, cement-based putty for exteriors or wet interiors (bathrooms/kitchens), and smooth, workable acrylic or POP-based putty5 for standard interiors. Consider climate conditions, surface type, budget constraints, and required durability when making your selection.

My approach to putty selection always starts with environment assessment. Beyond the simple interior/exterior division, you need to consider specific conditions. I remember advising a client in a tropical climate to use exterior-grade putty even for their bathroom interiors due to the extreme humidity levels.

For exterior applications, climate severity should guide your choice. Moderate climates might allow standard exterior putties, while extreme conditions (coastal areas, freeze-thaw zones, or areas with driving rain) demand premium formulations with enhanced polymer content. Look for products specifically mentioning freeze-thaw resistance, salt resistance, or enhanced UV protection depending on your specific challenges.

Surface compatibility is crucial for proper adhesion. New concrete surfaces, old painted walls, and brick all require different putty formulations for optimal results. Some surfaces may need specialized primers before any putty application. I recommend patch testing on inconspicuous areas, especially when working with unusual or old surfaces.

Budget constraints naturally affect choices, but I advise considering lifecycle costs rather than just purchase price. Premium putties might cost 30-50% more upfront but can last twice as long, making them more economical over time. For rental properties or temporary structures, standard formulations may make more financial sense.

Application method also influences selection. DIY projects benefit from more forgiving putties with longer working times and easier sanding properties. Professional applications can handle more demanding products that might deliver better long-term performance but require skilled application.

For special requirements like enhanced crack resistance or thermal insulation properties, specialized putties are available. These solve specific problems but come at premium prices. Assess whether these enhanced properties justify the additional cost for your particular project.

FAQ: Common Questions About Wall Putty

People often ask me these questions about wall putty, and making mistakes here can lead to wasted materials and poor results.

Wall putty typically requires 2-3 coats for best results, with 4-6 hours drying time between coats. For exterior putty, curing takes 5-7 days before painting. Quality putty should resist water (exterior) or provide smooth finishes (interior). Putty isn't waterproof alone; proper paints must be applied for complete protection.

After years of working with different wall putties, I find many clients confused about proper application techniques. Proper wall preparation determines at least 70% of your final result quality. All surfaces must be clean, structurally sound, and primed appropriately before putty application.

Drying times vary significantly between products and environmental conditions. While interior acrylic putties might be ready for sanding within 2-4 hours in dry conditions, cement-based exterior putties often require 24 hours between coats and full 5-7 day curing periods before painting. Rushing this process is one of the most common mistakes I see, resulting in premature failure.

The shelf life of unopened putty products typically ranges from 6-12 months, depending on formulation and storage conditions. Once opened or mixed with water, most putties must be used within hours. I've seen projects delayed when contractors tried using putty that had been mixed the previous day – it simply won't perform properly.

Coverage rates vary by product and surface condition. Rough surfaces require significantly more product than smooth ones. As a general guideline, expect 15-20 square feet per kilogram for a two-coat application on moderately textured surfaces. Budgeting for 10-15% extra material is always wise to avoid mid-project shortages.

Putty thickness is critical for performance. Too thin, and it won't provide adequate coverage; too thick, and it may crack during drying. Most putties perform best at 1-2mm total thickness across all coats. Professional applicators often achieve this through multiple thin coats rather than fewer thick ones.

For storage, keep unopened putty in cool, dry places away from direct sunlight. Extreme temperatures can degrade even unopened products. Once water is added, most putties cannot be effectively stored for future use, though some premium acrylic putties can be kept in airtight containers for 1-2 days with some quality loss.

Conclusion

Choose your wall putty based on its intended environment: exterior putties need cement-base with polymers for weather resistance, while interior putties prioritize smooth finishes and workability. Using the wrong type will lead to costly failures and repairs.

-

Explore this resource to understand the various applications and benefits of wall putty in construction. ↩

-

Discover why exterior putty is essential for protecting outdoor walls from harsh weather conditions. ↩

-

Learn about the advantages of using interior putty for achieving smooth and aesthetic indoor finishes. ↩

-

Explore the different types of specialty putties designed for specific conditions and their benefits. ↩

-

Explore the advantages of using acrylic or POP-based putty for achieving smooth finishes in interior projects. ↩