Your mortar fails too soon because your substrate steals water from the mix. Without proper water retention, cement can't fully hydrate, leading to weak bonds and premature cracking.

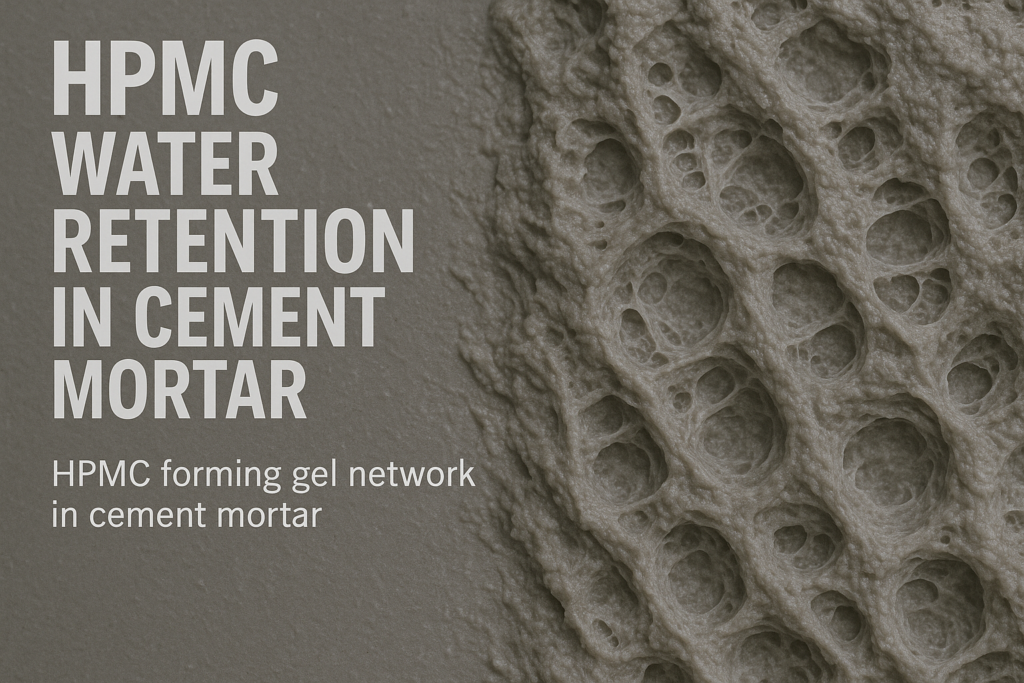

HPMC (Hydroxypropyl Methylcellulose)1 solves this problem by forming a protective gel network that temporarily holds water within the mortar. This controlled release mechanism ensures cement particles have enough time to fully hydrate, creating stronger bonds even on highly absorbent substrates.

At our Wanhong factory, we've spent years perfecting HPMC formulations specifically for construction applications. I've watched countless customers transform their problematic mortars into reliable products simply by understanding how water retention works. Let me explain how this miracle additive can revolutionize your construction materials.

What is the water retention2 mechanism of HPMC in cement mortar?

Your mortar failures might stem from water loss to porous substrates like brick or concrete. Without sufficient water, cement particles can't complete their critical hydration reactions.

HPMC creates a three-dimensional molecular network within the mortar that temporarily binds water molecules through hydrogen bonding. This gel structure slows water migration to the substrate while maintaining workability and ensuring gradual water release for optimal cement hydration.

The water retention2 mechanism of HPMC is fascinating when examined at the molecular level. When HPMC dissolves in the water phase of mortar, its long polymer chains unfold and create a complex matrix throughout the mixture. This network acts as a physical barrier that regulates water movement.

I've conducted numerous tests in our lab showing that HPMC can retain over 98% of mix water even after extended contact with absorbent surfaces. This retention isn't permanent - it's a controlled delay that gives cement the perfect hydration window. The mechanism works through two main actions:

- Viscosity modification: HPMC increases the mix's viscosity, physically slowing water migration

- Hydrogen bonding: The hydroxyl groups on HPMC form temporary hydrogen bonds with water molecules

This dual approach creates what we call "smart water management" - water remains available to cement particles but resists absorption by the substrate. The retention capacity varies by HPMC viscosity3 and substitution degree. For example:

| HPMC Type | Viscosity (mPa·s) | Water Retention (%) | Recommended Applications |

|---|---|---|---|

| Low viscosity | 5,000-15,000 | 85-90% | Self-leveling compounds |

| Medium viscosity | 15,000-60,000 | 90-95% | Tile adhesives, render |

| High viscosity | 60,000+ | 95-98%+ | Exterior insulation systems |

Is HPMC water soluble or not?

You might wonder if HPMC dissolves completely or swells in your mortar mix. This property directly impacts how effectively it will control water movement in your application.

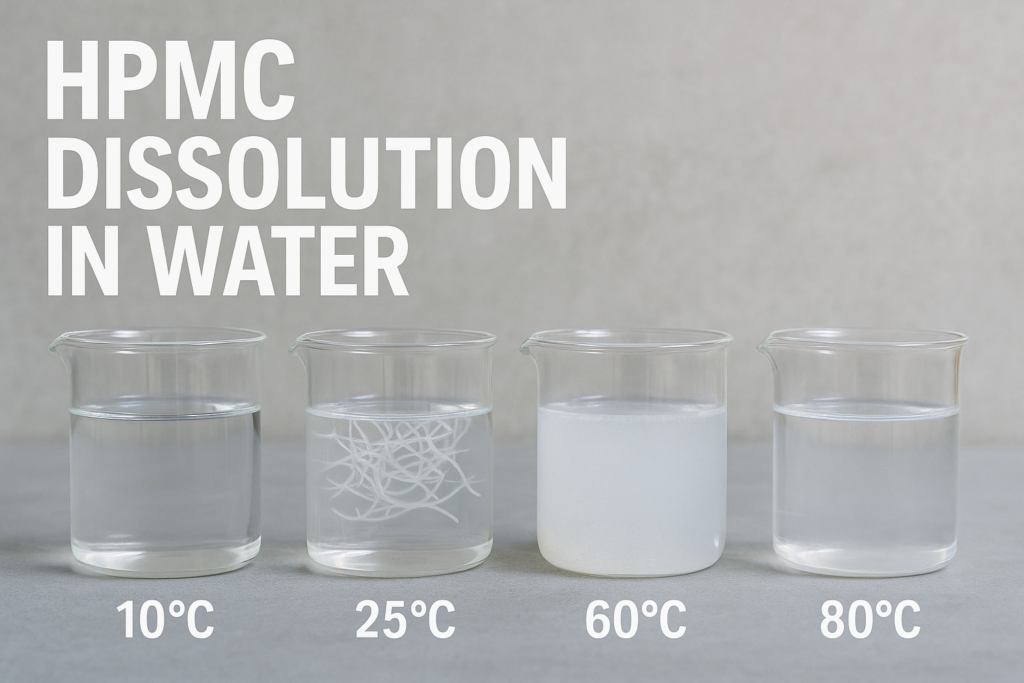

HPMC is water-soluble but exhibits unique temperature-dependent behavior. At cold temperatures (below 30°C), it dissolves completely to form a clear solution. However, at higher temperatures, it becomes temporarily insoluble - a property called "thermal gelation" that enhances its effectiveness in hot weather applications.

The solubility characteristics of HPMC make it particularly versatile for construction applications across different climates. I remember visiting a customer in Saudi Arabia who struggled with extreme heat affecting their exterior renders. Understanding HPMC's solubility behavior was key to solving their problem.

HPMC dissolves through a multi-stage process when added to water. First, the particles absorb water and swell. Then, as water penetrates deeper, the polymer chains gradually untangle and dissolve into solution. This process is influenced by several factors:

-

Temperature: As mentioned, HPMC shows inverse solubility at higher temperatures. This thermal gelation point typically ranges between 65-90°C depending on the specific HPMC grade.

-

Degree of substitution: More heavily substituted HPMC grades (higher methoxyl content) dissolve more readily in cold water but gel more quickly at elevated temperatures.

-

Particle size: Finer HPMC particles dissolve faster than coarser grades.

-

Water pH: Extreme pH values can affect dissolution rate and final solution properties.

This controlled solubility provides significant advantages in construction applications. For example, in hot climates, as surface temperatures rise, HPMC near the mortar surface forms a gel layer that further slows water evaporation - essentially providing additional protection exactly when it's most needed. This is what we call "responsive water management" and represents a significant advantage over older cellulose technologies.

Does methylcellulose absorb water?

Your building materials may fail if additives swell too much or too little. Understanding how HPMC interacts with water will help you formulate better products.

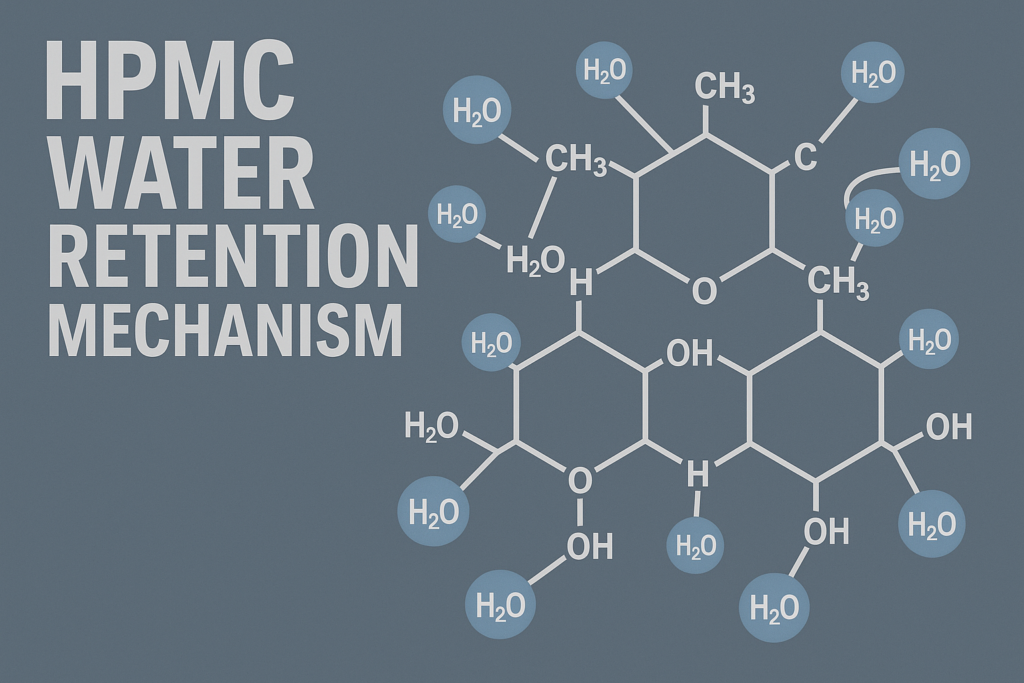

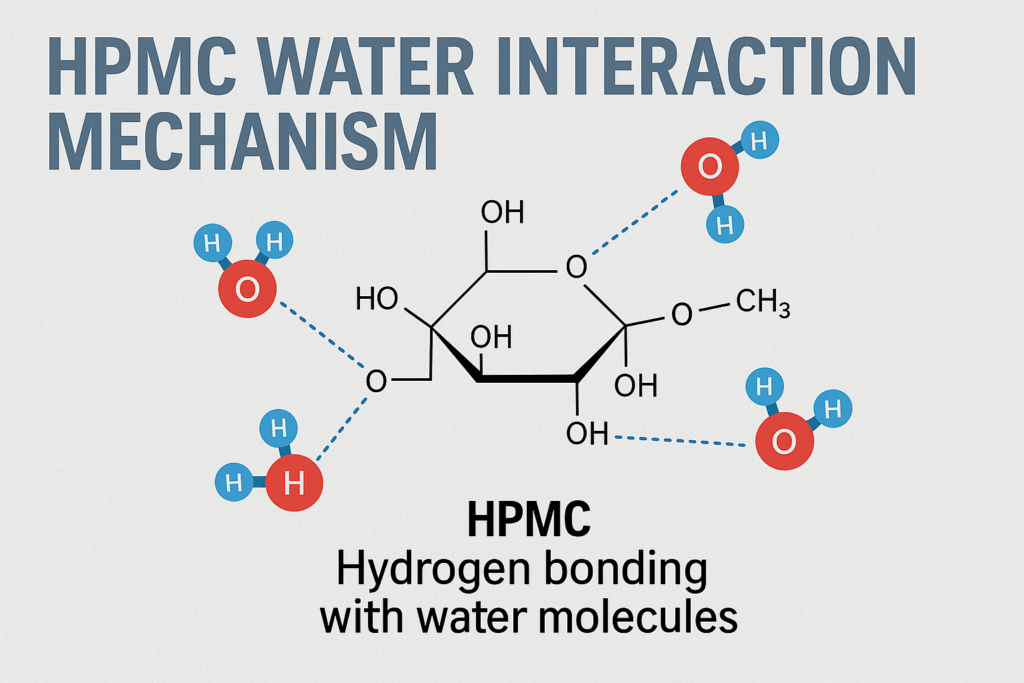

Unlike sponge-like absorbents that physically trap water, HPMC doesn't permanently absorb water. Instead, it forms hydrogen bonds with water molecules, temporarily holding them in a gel structure. This dynamic interaction maintains water in a bioavailable state for cement hydration while preventing rapid migration.

The water interaction behavior of HPMC represents one of its most valuable characteristics for construction materials. Having tested hundreds of cellulose ether samples in our laboratory, I can confirm that the mechanism differs fundamentally from conventional absorbents.

When HPMC comes into contact with water, it undergoes hydration rather than absorption. The hydroxypropyl and methyl substituent groups along the cellulose backbone create regions of varying hydrophilicity. This molecular structure allows HPMC to form extensive hydrogen bonding networks with water molecules without permanently capturing them.

In practical terms, this means several important benefits for your mortar formulations4:

-

Controlled swelling: Unlike some additives that expand significantly and create internal pressure, HPMC exhibits limited dimensional change when hydrated.

-

Reversible water binding: The water-HPMC interaction is dynamic, allowing water to participate in cement hydration reactions when needed.

-

Consistent performance across humidity conditions: HPMC won't prematurely absorb atmospheric moisture during storage like some hygroscopic materials.

We've quantified this behavior through differential scanning calorimetry tests that measure the states of water in HPMC-modified mortars. Results show approximately:

- 15-20% of water forms direct hydrogen bonds with HPMC

- 30-40% exists in the hydration shell around polymer chains

- 40-55% remains as bulk water available for cement reactions

This balanced distribution ensures that water remains available for proper cement hydration while still being protected from rapid loss to the substrate or atmosphere.

How to mix HPMC with water?

You've experienced lumping and poor dispersion when adding HPMC directly to your mix. This common mistake wastes material and results in inconsistent performance across your batch.

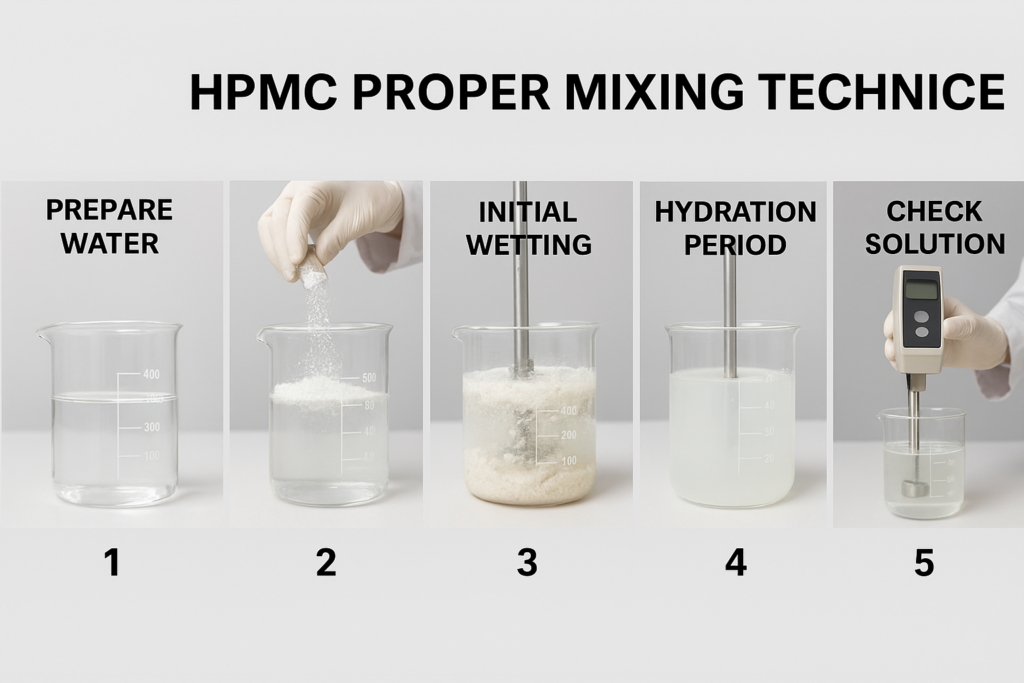

For optimal dispersion, first blend dry HPMC powder with other dry ingredients before adding water. Alternatively, prepare a concentrated solution by sprinkling HPMC onto cold water's surface (never pour water onto powder), allowing it to wet for 30-60 minutes, then mix thoroughly to ensure complete dissolution.

Proper HPMC dissolution is critical for achieving maximum benefit from this remarkable additive. In my 15+ years working with cellulose ethers, I've seen countless formulation problems traced back to improper mixing techniques.

The challenge with HPMC lies in its rapid surface hydration. When HPMC particles contact water, the outer layer quickly forms a gel that can trap dry powder inside - creating what we call "fish-eyes" or lumps. These undissolved particles won't provide their intended function and can create weak spots in your finished application.

For construction applications, we recommend two primary mixing approaches:

Dry-blending method:

- Thoroughly mix HPMC with dry components (cement, sand, fillers) at a ratio of at least 1:5 (HPMC:dry materials)

- Add this premix to the remaining dry ingredients

- Introduce water gradually while mixing continuously

- Mix for at least 3-5 minutes to ensure complete hydration

Pre-solution method:

- Use cold water (under 20°C) in a clean container with gentle agitation

- Sprinkle HPMC powder evenly across the water surface

- Allow 30-60 minutes for initial hydration (particles will sink as they become wetted)

- Mix vigorously until completely dissolved

- Add this solution to your dry mortar components

For industrial production, we recommend installing high-shear mixers5 specifically designed for cellulose ethers. These systems can reduce dissolution time to minutes rather than hours, significantly improving production efficiency.

Temperature control is especially important - if water temperature exceeds 30°C, HPMC may form thermal gel lumps that are extremely difficult to dissolve. In hot climates, consider using ice water for the initial dissolution step.

Conclusion

HPMC transforms ordinary mortars into high-performance systems by controlling water movement through its unique gel network. By selecting the right grade and mixing properly, you'll achieve superior bonding, extended working time, and dramatically reduced failures.

-

Explore how HPMC enhances water retention in mortars, ensuring stronger bonds and durability. ↩

-

Understanding water retention is crucial for improving cement performance and preventing failures. ↩ ↩

-

Explore the relationship between HPMC viscosity and its effectiveness in construction applications. ↩

-

Learn best practices for formulating mortars that leverage HPMC's unique properties. ↩

-

Learn how high-shear mixers improve the efficiency of mixing cellulose ethers in construction. ↩