Are you struggling with mortar that cracks, lacks water retention, or simply doesn't stick well? Poor mortar quality can destroy your construction timeline and budget, creating headaches that last for years.

Masonry mortar additives are chemical compounds added to mortar mixtures to improve specific properties like adhesion, workability, water retention, and strength. The right additives can transform standard mortar into a high-performance building material1 tailored to specific construction needs.

As a factory owner with six production lines and years of experience supplying construction materials to developing markets across Saudi Arabia, UAE, Iran, and beyond, I've seen firsthand how the right additives can make or break a project. Let me take you through what you need to know about these essential construction components.

Your Trusted Source of Masonry Mortar Additives: Why Choose WANHONG?

Pain point: finding reliable suppliers with consistent quality can waste time and money. Many distributors promise quality but deliver disappointment instead.

WANHONG (Kehao) is a leading manufacturer of construction additives2 with six production lines specializing in hydroxypropyl methylcellulose3, redispersible polymer powder4, and other cellulose derivatives that enhance mortar performance. Our products meet international quality standards with customizable packaging options.

Our Commitment to Quality

When I founded WANHONG, I made one promise: never compromise on quality. This commitment has made us trusted partners for major construction material distributors across developing markets. Our stringent quality control system includes:

| Quality Control Measure | Benefit to You |

|---|---|

| Batch-by-batch testing | Consistent performance across all shipments |

| ISO certified processes5 | Internationally recognized quality standards |

| In-house R&D department | Continuous product improvement and customization |

| Technical support team | Expert advice on optimal product selection |

I remember visiting a client's factory in Saudi Arabia where they were struggling with mortar adhesion in their high-heat environment. Our technical team worked with them to formulate a custom HPMC solution that increased water retention by 35% without compromising strength. This kind of personalized approach defines our business model.

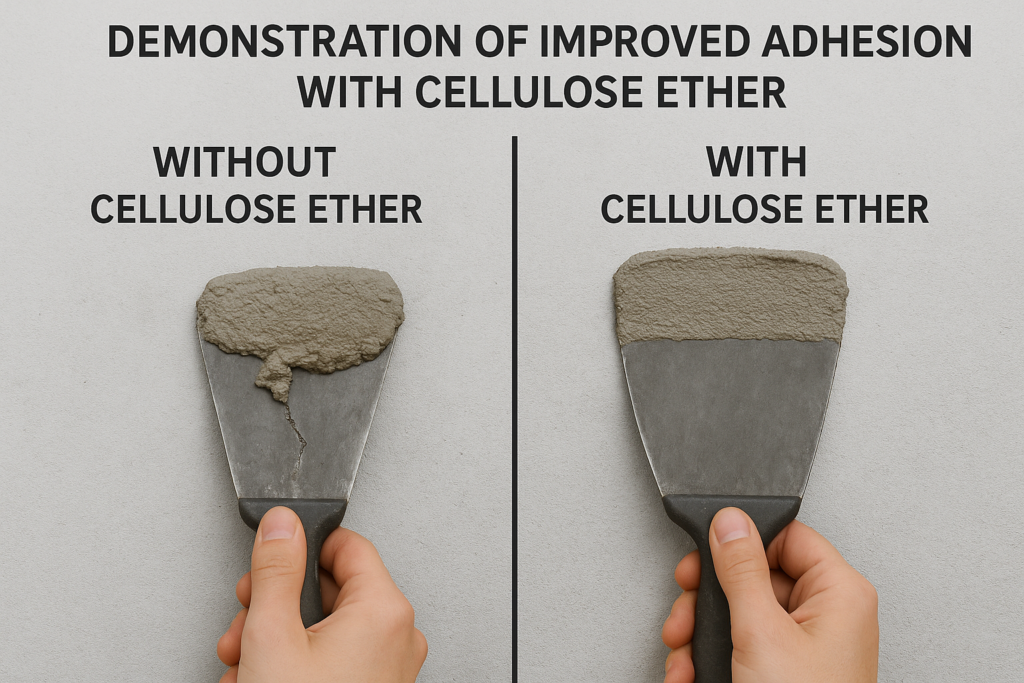

Masonry Mortar Additives for Adhesion: Cellulose Ether - How Does It Transform Your Mortar?

Poor adhesion can lead to tiles falling off walls and mortar that crumbles under stress. These failures create expensive callbacks and damage your reputation.

Cellulose ethers like HPMC (hydroxypropyl methylcellulose3) and HEMC (hydroxyethyl methylcellulose) improve adhesion by enhancing water retention, increasing open time, and creating stronger bonds between mortar and substrates. They're essential for vertical applications where slip resistance is crucial.

Understanding Cellulose Ether Types and Applications

In my 15+ years working with construction material manufacturers, I've found that many builders don't fully understand the differences between cellulose ether types. This knowledge gap often leads to poor additive selection and suboptimal results.

Cellulose ethers come in several categories, each with specific benefits for masonry applications:

| Cellulose Type | Primary Benefits | Best Applications |

|---|---|---|

| HPMC | Excellent water retention, good workability | Tile adhesives, renders, EIFS systems |

| HEMC | Enhanced adhesion, good sagging resistance | Wall putties, skim coats, repair mortars |

| CMC | Cost-effective viscosity control | Masonry mortars, grouts, joint fillers |

| HEC | Fast dissolution, good consistency | Self-leveling compounds, spray plasters |

The viscosity of these products matters tremendously. At WANHONG, we offer multiple viscosity grades (from 5,000 to 200,000 mPa·s) because we understand that different applications require different flow characteristics. For instance, a tile adhesive typically needs higher viscosity HPMC compared to a self-leveling compound. Our technical team can help you select the optimal grade for your specific application.

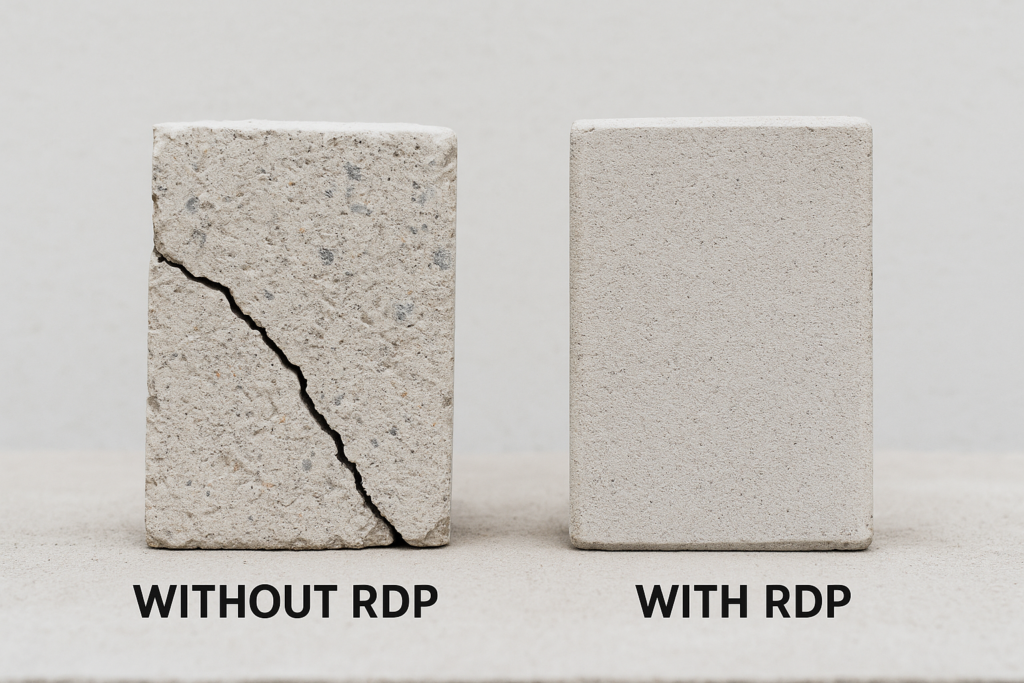

Masonry Mortar Additives for Strength: Redispersible Polymer Powder - Why Is It Revolutionary?

Traditional mortars without polymer modification often fail under flexural stress, leading to cracks, reduced durability, and increased maintenance costs.

Redispersible polymer powder (RDP) transforms ordinary mortar into a high-performance composite by forming polymer films within the cement matrix. This enhances flexural strength, adhesion to difficult substrates, and provides critical properties like crack resistance and flexibility.

The Science Behind Redispersible Polymer Powder

The first time I witnessed the dramatic difference RDP makes was during a product demonstration for a major mortar producer from Pakistan. We created two identical mortar samples, one with and one without our VAE-based RDP. After curing, the polymer-modified mortar showed 65% higher flexural strength and 300% better adhesion to glass substrates.

Redispersible polymer powders work through a fascinating mechanism:

- When mixed with water, the powder redisperses into a stable polymer emulsion

- As the mortar dries, the polymer particles form continuous films

- These films create bridges between cement particles and the substrate

- The result is a composite material with both rigid (cement) and flexible (polymer) components

The type of polymer base significantly impacts performance:

| Polymer Base | Key Properties | Ideal Applications |

|---|---|---|

| VAE/EVA | Good balance of properties, cost-effective | General purpose mortars, tile adhesives |

| Acrylic | Superior weather resistance, UV stability | Exterior renders, facade systems |

| Styrene-Acrylic | Enhanced water resistance, durability | Waterproofing mortars, pool applications |

| VeoVa | Excellent alkali and hydrolysis resistance | High-pH environments, long-term durability |

At WANHONG, our RDP line includes all these polymer types, with our most popular being our VAE-based RDP-100 series. We can customize the glass transition temperature (Tg) to match your climate conditions—lower Tg for colder regions and higher Tg for warmer areas.

What Makes WANHONG Different: How Do We Ensure Your Success?

Finding reliable suppliers who understand both chemistry and construction is nearly impossible. Most manufacturers focus on selling products without providing crucial application knowledge.

WANHONG differentiates itself through technical expertise, quality consistency, flexible payment terms, and sustainable manufacturing practices. We function as partners rather than mere suppliers, offering formula customization and ongoing technical support.

Our Value-Added Services

What truly sets us apart isn't just our products—it's our approach to partnership. When you work with WANHONG, you gain:

Technical Support Beyond Sales

Our technical team includes former mortar manufacturers who understand your challenges from both chemical and practical perspectives. Recently, when a Brazilian customer struggled with mortar that was setting too quickly in their tropical environment, our team reformulated their HPMC with modified viscosity and substituted our RDP-110 for their current polymer. The result was an extended open time of 25 minutes—perfect for their application needs.

Formula Customization

No two construction markets are identical. That's why we offer:

| Customization Service | Benefit to You |

|---|---|

| Viscosity adjustment | Optimized workability for specific applications |

| Particle size control | Better dispersion and reduced dust |

| Modified chemical substitution | Enhanced performance in extreme environments |

| Packaging customization | Your branding, your specifications |

Flexible Payment Options

We understand cash flow challenges for growing businesses. That's why we offer multiple payment terms including L/C, T/T, and D/P options. For established customers, we can arrange favorable credit terms to help manage your inventory and cash flow.

Masonry vs. Concrete: Why Do They Require Different Additives?

Using concrete additives in masonry applications often leads to disappointing results: decreased workability, poor adhesion, and premature hardening.

Masonry mortar requires specific additives optimized for adhesion, water retention, and workability, unlike concrete additives that prioritize strength and flow. Masonry additives must create bonds between dissimilar materials and maintain consistency during application.

Key Differences in Additive Requirements

During my visit to a construction site in Dubai last year, I noticed contractors using concrete superplasticizers in their masonry mortar. The result was a disaster—the mortar slid off the vertical surfaces and failed to bond properly with the bricks. This common mistake highlights the fundamental differences between these materials.

Masonry and concrete serve different structural purposes:

| Property | Masonry Requirements | Concrete Requirements |

|---|---|---|

| Application | Thin layers, often vertical | Poured into forms, often horizontal |

| Primary function | Bond dissimilar materials | Create monolithic structure |

| Working time | Longer open time needed | Quicker setting often preferred |

| Water retention | Critical for proper curing | Less critical with formwork |

| Flexibility | Some flexibility beneficial | Rigid strength prioritized |

This is why WANHONG offers separate product lines specifically engineered for masonry applications. Our HPMC products are available with different methoxyl content and hydroxypropyl substitution levels to optimize water retention and workability for masonry, while our RDP products are formulated with the right particle size and redispersion characteristics for thin-layer applications.

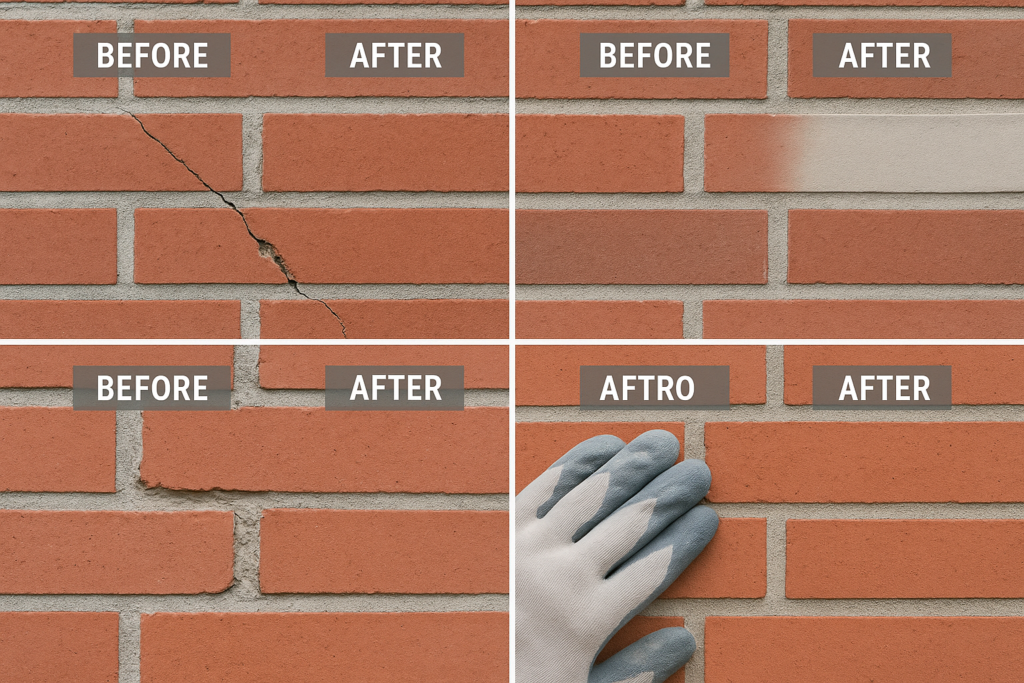

Resolving Common Masonry Mortar Issues with WANHONG Additives: What Problems Can We Solve?

Cracking mortar, poor freeze-thaw resistance, and inadequate bonding create ongoing headaches for contractors and end-users alike. These issues lead to costly repairs and damaged reputations.

WANHONG additives address common masonry mortar failures by enhancing water retention (preventing premature drying), improving flexural strength (reducing cracking), increasing adhesion (preventing delamination), and boosting freeze-thaw resistance through proper air entrainment.

Targeted Solutions for Specific Problems

In my years of consulting with mortar manufacturers, I've encountered virtually every possible masonry failure. Here's how our products address the most common issues:

Preventing Cracking and Enhancing Durability

Mortar cracking typically stems from rapid water loss or insufficient flexibility. Our approach combines multiple additives for comprehensive solutions:

| Problem | WANHONG Solution | How It Works |

|---|---|---|

| Shrinkage cracking | HPMC (15,000-30,000 mPa·s) + RDP-120 | Water retention prevents rapid drying; polymer adds flexibility |

| Thermal expansion cracking | RDP-150 with higher Tg | Creates microstructure that accommodates thermal movement |

| Impact cracking | Polypropylene fiber + RDP | Fiber provides reinforcement; polymer adds ductility |

| Freeze-thaw damage | Air-entraining RDP + hydrophobic HPMC | Creates microair voids; reduces water absorption |

One of our UAE customers was experiencing severe cracking in exterior renders until we formulated a custom solution combining our HPMC-30000 with RDP-150 and polypropylene fiber6s. The new formulation reduced cracking incidents by over 90% even in their extreme desert climate with high temperature differentials.

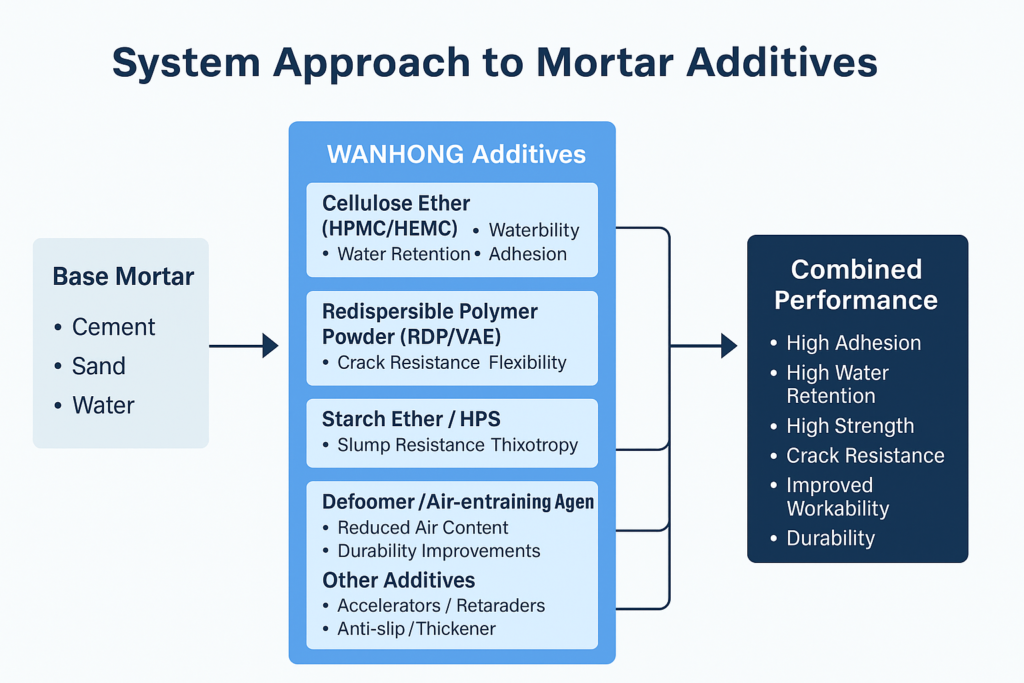

The Secret to Stronger Structures: WANHONG - How Do Our Products Work Together?

Using individual additives without understanding their interactions can lead to disappointing performance or even chemical incompatibility. This trial-and-error approach wastes time and materials.

WANHONG products are designed to work synergistically, with cellulose ethers7 providing water retention and workability while redispersible polymers enhance strength and adhesion. This complementary approach creates stronger, more durable masonry structures than either additive could achieve alone.

Creating Synergistic Formulations

When I conduct technical workshops for our customers, I emphasize that the real magic happens when additives work together in properly balanced formulations. This systems approach is central to WANHONG's philosophy.

Consider our recommended starting point for a high-performance tile adhesive:

| Component | Percentage | Function | Interaction Effect |

|---|---|---|---|

| Cement | 35-40% | Binding agent | Base material |

| Aggregates | 55-60% | Structure, economy | Skeleton structure |

| HPMC-20000 | 0.25-0.30% | Water retention, workability | Prevents polymer migration |

| RDP-100 | 2.5-3.0% | Adhesion, flexibility | Forms films utilizing retained water |

| Optional additives | 0.5-1.0% | Specific properties | Enhanced performance |

The key is that the HPMC retains water, which gives the RDP sufficient time to properly form polymer films. Without adequate water retention, the polymer particles can't coalesce properly, dramatically reducing effectiveness. This is why we test our products together, not just individually.

I recently worked with a Mexican tile adhesive manufacturer who was using an RDP from a different supplier with our HPMC. They were experiencing inconsistent results. Our laboratory testing revealed that their RDP required a different hydration profile than our HPMC was providing. By switching to our matching RDP-120 product, their adhesion strength improved by 40%.

Other Types of Additives: What Else Might You Need?

Focusing solely on cellulose ethers and polymers leaves mortar vulnerable to other performance issues like efflorescence, slow setting, and inadequate waterproofing.

Beyond cellulose ethers7 and redispersible polymers, professional masonry mortars often incorporate accelerators, retarders, water repellents, lightweight fillers, and reinforcing fibers. These specialized additives address specific performance requirements for different applications and environments.

Complementary Additives in the WANHONG Portfolio

While cellulose ethers and RDPs form the foundation of most quality mortars, certain applications require additional performance characteristics. At WANHONG, we offer a comprehensive range of additives:

| Additive Type | Function | Key Benefits |

|---|---|---|

| Polypropylene fiber | Reinforcement | Crack resistance, impact strength improvement |

| Hydrophobic agents | Water repellency | Reduced water absorption, efflorescence prevention |

| Set modifiers | Control setting time | Adaptation to climate conditions, extended workability |

| Lightweight fillers | Weight reduction | Improved thermal insulation, reduced material weight |

| Air entrainers | Freeze-thaw resistance | Microair void creation, durability enhancement |

During my visit to our Georgia customer's facilities last winter, I noticed they were struggling with mortar durability in freezing conditions. We introduced them to our air-entraining admixture and hydrophobic HPMC, which created the microscopic air voids necessary to accommodate freezing water expansion. Their callback rate for frost damage dropped by 85% the following season.

The key is understanding how these additives interact. For instance, excessive air entrainment can reduce strength, while certain water repellents can interfere with polymer film formation. Our technical team can help you find the right balance for your specific requirements.

Masonry Mortar Additives! FAQ: What Do You Need to Know?

Choosing the wrong additives wastes money and compromises construction quality. Many buyers make decisions based on price alone, missing critical performance factors.

Selecting optimal masonry additives requires considering application method, environmental conditions, substrate type, and performance requirements. Quality additives may cost slightly more initially but deliver superior long-term performance and reduced callback rates.

Expert Answers to Your Most Pressing Questions

As a technical consultant to major mortar manufacturers, these are the questions I'm asked most frequently:

How do I choose between HPMC8 and HEMC?

While both are cellulose ethers, HPMC generally offers better water retention while HEMC provides enhanced adhesion. For hot, dry climates, HPMC is usually preferable. For applications requiring exceptional bond strength, HEMC often performs betterI'll continue the blog post from where it left off.

How much RDP do I need in my formulation?

This depends on performance requirements. For basic tile adhesives, 2-3% is typical. For highly flexible waterproofing mortars, you might need 5-7%. Environmental exposure also matters—exterior applications generally require higher polymer content than interior ones.

I worked with a Vietnamese manufacturer who was using 5% RDP in an interior tile adhesive—essentially wasting money. By reducing to 2.5% and optimizing the cellulose ether content, we achieved the same performance at lower cost.

Will these additives work in all weather conditions?

Different climates require different formulations. For hot weather, we recommend higher viscosity HPMC (25,000-30,000 mPa·s) for better water retention. In cold weather, lower viscosity grades (10,000-15,000 mPa·s) combined with set accelerators work better. Our RDP grades are also available with different glass transition temperatures (Tg) for different climates.

How do additives affect setting time?

Most cellulose ethers have a retarding effect on cement hydration—the higher the dosage, the greater the retardation. RDPs typically have minimal impact on setting time. If faster setting is required, we can recommend compatible accelerators that won't interfere with other additives.

Are these additives environmentally friendly?

At WANHONG, we've invested heavily in sustainable manufacturing processes. Our cellulose ethers are derived from renewable resources, and our production methods minimize waste and energy consumption. We offer low-VOC formulations and were among the first in China to achieve ISO 14001 environmental management certification.

Conclusion

Masonry mortar additives transform ordinary mixtures into high-performance building materials. With WANHONG's premium cellulose ethers, redispersible polymers, and specialized additives, you can create mortars with superior adhesion, flexibility, and durability. Contact us today to discover how our products and technical expertise can elevate your construction projects.

-

Discover the characteristics that make a building material high-performance and suitable for modern construction. ↩

-

Explore the various types of construction additives and their impact on material performance. ↩

-

Learn about the versatile applications of hydroxypropyl methylcellulose in improving mortar performance. ↩ ↩

-

Discover the revolutionary effects of redispersible polymer powder on mortar strength and flexibility. ↩

-

Learn about the importance of ISO certification in ensuring quality and reliability in construction materials. ↩

-

Discover how polypropylene fiber can reinforce mortar and enhance its durability. ↩

-

Explore the role of cellulose ethers in enhancing water retention and workability in construction materials. ↩ ↩

-

Explore the differences between HPMC and HEMC and their specific applications in construction. ↩