Struggling with mortar that cracks too easily, doesn't stick well, or sets too quickly? Poor mortar quality can jeopardize entire construction projects and lead to expensive repairs down the line.

Masonry mortar additives are special ingredients added to mortar mixtures to improve specific properties like adhesion, strength, workability, and durability. The right additives can transform standard mortar into high-performance material tailored to your exact construction requirements.

At Kehao, I've spent years helping construction professionals1 solve their mortar challenges. The difference between regular mortar and one with properly selected additives is like night and day. Let me walk you through everything you need to know about choosing and using these performance-enhancing materials.

Your Trusted Source of Masonry Mortar Additives: What Makes Us Different?

Pain: Finding reliable masonry additive suppliers who understand your specific needs can be frustrating and time-consuming. Many suppliers offer generic products without technical support2.

As a manufacturer with six production lines, Wanhong specializes in high-quality masonry mortar additives3 including HPMC4, redispersible powder5, HEMC6, CMC, HEC, and polypropylene fiber7. Our products feature consistent performance, customizable packaging, and comprehensive technical support tailored to your regional conditions.

I established our factory in China specifically to serve developing markets like Saudi Arabia, UAE, Iran, and others where construction is booming but access to quality additives can be challenging. Unlike many suppliers who simply trade products, we control the entire manufacturing process from raw materials to finished products.

Our team includes chemical engineers who understand not just our products, but how they perform in different climatic conditions. For example, when working with customers in Saudi Arabia, we regularly adjust our HPMC formulations to account for the extreme heat and low humidity that affects water retention.

We've invested heavily in quality control facilities that test every batch before shipment, ensuring consistency that large mortar and paint factories depend on. This commitment to quality has helped us build lasting relationships with major distributors and manufacturers across developing regions.

What truly sets us apart is our willingness to customize. We don't just sell standard products - we work with you to understand your specific application and recommend the right combination of additives for optimal performance. Many of our longest-standing customers started with small trial orders before becoming regular buyers of container-load quantities.

Masonry Mortar Additives for Adhesion: Cellulose Ether, Why Is It Essential?

Pain: Poor adhesion causes tiles to fall off walls, creates weak joints between bricks, and leads to structural failures. Traditional mortar often lacks sufficient bonding ability.

Cellulose ethers like HPMC4 (Hydroxypropyl Methylcellulose) dramatically improve mortar's adhesion by creating polymer networks within the mixture. They enhance water retention, extend open time, and form flexible bonds that resist shrinkage and thermal movement.

Cellulose ethers represent the backbone of modern mortar technology, and I've seen their transformative effects firsthand across thousands of construction projects. These powerful additives work at a molecular level to create stronger, more reliable bonds between mortar and substrate.

The science behind cellulose ether8's effectiveness lies in its unique molecular structure. When added to mortar, these polymers form a three-dimensional network throughout the mixture. This network serves multiple critical functions simultaneously:

-

Water retention - Perhaps the most important property, cellulose ethers hold water in the mix, preventing rapid absorption by porous substrates. This allows cement particles to fully hydrate, creating stronger bonds.

-

Extended workability - By controlling water movement, these additives extend the "open time" of mortar, giving workers more time to place and adjust materials.

-

Improved sag resistance - They increase the viscosity of fresh mortar, preventing heavy tiles from sliding down vertical surfaces.

The type and dosage of cellulose ether significantly impacts performance. At Kehao, we manufacture several varieties:

| Type | Viscosity Range | Best Applications |

|---|---|---|

| HPMC | 100,000-200,000 mPa·s | General tiling, renders |

| HEMC | 40,000-70,000 mPa·s | Self-leveling compounds |

| HEC | 10,000-30,000 mPa·s | Specialty mortars |

I recommend starting with HPMC for most mortar applications, with dosages between 0.2-0.5% of the dry mix weight. In extremely hot climates like those faced by our Middle Eastern customers, slightly higher dosages may be necessary to compensate for accelerated evaporation.

Masonry Mortar Additives for Strength: Redispersible Polymer Powder, How Does It Work?

Pain: Traditional cement-based mortars are brittle and prone to cracking when subjected to movement, vibration, or temperature changes. This leads to water penetration and structural damage.

Redispersible polymer powder (RDP) consists of specialty polymers that re-emulsify when mixed with water, forming flexible films within mortar as it cures. These polymers create bridges between cement particles, dramatically improving tensile strength, flexibility, and adhesion to difficult surfaces.

I've witnessed remarkable improvements in mortar performance when properly formulated RDP is added to the mix. These sophisticated additives transform rigid, brittle mortar into a resilient material that can accommodate movement and resist cracking.

Redispersible polymer powders represent one of the most significant advancements in mortar technology over the past few decades. Unlike liquid polymers, RDP comes in powder form that can be pre-blended with dry mortar components, creating stable mixtures with long shelf lives. The magic happens during mixing with water, when these polymers spring back to life.

The transformation process occurs in several phases:

- Dispersion - When water is added to the mortar mix, the RDP particles disperse throughout the mixture

- Film formation - As water evaporates during curing, the polymer particles coalesce to form continuous films

- Network creation - These films create flexible bridges between the rigid cement structures

- Composite behavior - The finished mortar becomes a true composite material, combining cement's compressive strength with polymer's flexibility

At Kehao, we manufacture several types of RDP with different polymer compositions:

| RDP Type | Base Polymer | Key Properties | Best Applications |

|---|---|---|---|

| VAE | Vinyl Acetate-Ethylene | Good flexibility, water resistance | Tile adhesives, external renders |

| VA/VeoVa | Vinyl Acetate-Versatate | Excellent water/alkali resistance | External applications, wet areas |

| Acrylic | Pure acrylic | Superior UV stability, flexibility | Premium applications, extreme conditions |

The dosage of RDP significantly impacts mortar performance and cost. For basic applications, I typically recommend starting with 1-3% RDP content. For demanding applications like exterior tile installation or areas subject to vibration, 3-5% provides optimal performance. Premium applications might require up to 10% RDP for maximum flexibility and durability.

Many of our customers in regions with extreme temperature variations (like Saudi Arabia's hot days and cool nights) find that mortars with 3-5% RDP significantly reduce callback rates for cracked installations.

Masonry Mortar Additives for Fluidity: Superplasticizer, When Do You Need It?

Pain: Achieving the right mortar consistency often means adding excess water, which weakens the final product. Traditional mortars can be stiff and difficult to work with, slowing down application.

Superplasticizers are high-performance water-reducing agents that dramatically improve mortar flow while maintaining or reducing water content. These additives disperse cement particles through electrostatic repulsion, allowing the same workability with up to 25% less water, resulting in stronger, more durable mortar.

I've seen superplasticizers revolutionize mortar applications, particularly in self-leveling compounds and pump-applied mortars. These powerful additives solve the age-old problem of having to choose between workability and strength.

Superplasticizers function through a sophisticated mechanism that addresses cement's natural tendency to clump together in water. Cement particles carry slight positive and negative charges in different areas, causing them to attract each other and form agglomerations that trap water. Superplasticizers neutralize these charges and create uniform repulsion between particles.

The benefits of incorporating superplasticizers extend far beyond simply making mortar easier to work with:

- Increased strength - By reducing the water requirement by up to 25%, superplasticizers significantly increase compressive and flexural strength

- Reduced shrinkage - Less water means less evaporation and shrinkage during curing, minimizing crack formation

- Enhanced durability - Lower porosity resulting from reduced water content improves resistance to freeze-thaw cycles and chemical attack

- Extended working time - Some formulations provide controlled setting times, giving applicators more flexibility

At Wanhong, we produce several types of superplasticizers based on different chemical structures:

| Type | Chemical Base | Special Properties | Best Applications |

|---|---|---|---|

| PCE | Polycarboxylate ether | High efficiency, low dosage | Self-leveling compounds, premium mortars |

| SMF | Sulfonated melamine formaldehyde | Good early strength | Fast-setting mortars |

| SNF | Sulfonated naphthalene formaldehyde | Cost-effective, heat resistant | General purpose mortar, hot weather applications |

The correct dosage depends on both the specific superplasticizer and the desired performance characteristics. Generally, PCE-based products are effective at 0.1-0.3% of cement weight, while SMF and SNF types require 0.5-1.5% dosages. I always recommend starting with manufacturer guidelines and conducting field tests to determine optimal levels.

For our customers operating in hot climates, we often suggest combining superplasticizers with set retarders to maintain workability despite accelerated evaporation. This combination has proven particularly effective for large-scale mortar applications in countries like Saudi Arabia and the UAE.

Masonry vs. Concrete: Why Do They Need Different Additives?

Pain: Using concrete additives in masonry mortar often leads to poor performance. Construction professionals frequently confuse these distinct materials, leading to costly errors.

Masonry mortar requires specific additives optimized for its higher water content, smaller aggregate size, and application methods. While concrete focuses on compressive strength, masonry demands adhesion, workability, and water retention. Using purpose-designed masonry additives ensures proper bonding, reduced shrinkage, and long-term durability.

I frequently encounter confusion between masonry and concrete additives, even among experienced construction professionals. Understanding the fundamental differences is crucial for selecting the right products for your specific application.

Masonry mortar and concrete serve distinctly different purposes in construction, and this necessitates different additive formulations. Concrete primarily functions as a structural material designed to bear loads, while masonry mortar binds building units together and serves as a bedding material.

These functional differences create several key distinctions that influence additive selection:

-

Aggregate composition - Concrete contains large aggregates (up to 1-2 inches) while mortar uses only fine sand. This affects the type of water reducers and plasticizers needed.

-

Water content - Mortar typically requires significantly higher water-to-cement ratios than concrete, necessitating different water retention agents.

-

Installation method - Mortar is often applied in thin layers with trowels, requiring excellent workability and adhesion, while concrete is frequently poured into forms.

-

Curing environment - Masonry mortar is usually applied in thin, exposed layers, making it more vulnerable to rapid drying than mass concrete pours.

This table highlights some key differences in additive requirements:

| Property | Masonry Mortar Needs | Concrete Needs |

|---|---|---|

| Water Retention | Critical (uses HPMC, HEMC) | Less critical (uses AEA) |

| Adhesion | Primary requirement (uses RDP) | Secondary concern |

| Flexural Strength | Highly important (uses RDP, fibers) | Less crucial than compressive strength |

| Workability | Extended open time needed | Initial flow more important than extended work time |

| Air Entrainment | Minor role | Major role in freeze-thaw resistance |

At Kehao, we've developed specific product lines for masonry applications. For example, our HPMC products are available in viscosity ranges specifically optimized for different masonry applications, from thin-set mortars to renders and grouts. Similarly, our RDP products are formulated to provide the ideal balance of adhesion and flexibility that masonry connections require.

I always recommend consulting with additive specialists before selecting products for your specific masonry application, as regional building practices, climate conditions, and substrate properties all influence the optimal additive formulation.

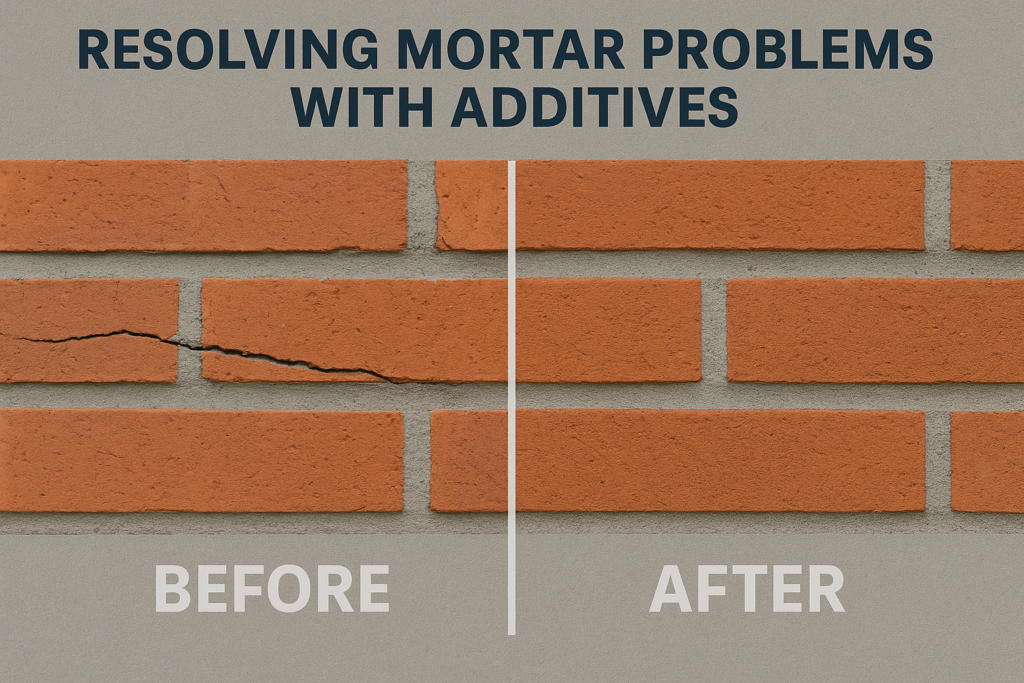

Resolving Common Masonry Mortar Issues: How Can Wanhong Additives Help?

Pain: Masonry projects often suffer from recurring problems like cracking, poor adhesion, efflorescence, and inconsistent setting times that lead to expensive repairs and unhappy clients.

Wanhong additives address specific masonry problems through precisely engineered solutions. Our HPMC prevents quick drying and improves adhesion, RDP eliminates cracking and enhances flexibility, while our specialized additives prevent efflorescence and control setting time even in extreme weather conditions.

Throughout my years working with construction companies across developing markets, I've encountered nearly every possible masonry mortar challenge. Our additive solutions have consistently helped resolve these issues through targeted intervention.

Let me walk through some of the most common problems and their solutions:

Problem 1: Mortar Cracking and Debonding

Cracking often stems from excessive shrinkage during drying, poor flexibility, or inadequate bond strength. Our comprehensive solution involves:

-

RDP (Redispersible Polymer Powder)9: At 3-5% dosage, our VAE-based RDP dramatically improves flexibility and adhesion. The polymer film that forms during curing accommodates substrate movement without cracking.

-

Polypropylene Fibers10: These microfibers (6mm or 12mm length) reinforce the mortar matrix and prevent microscopic cracks from propagating. A typical dosage of 0.1-0.3% by weight creates a three-dimensional reinforcement network.

-

HPMC (Hydroxypropyl Methylcellulose)11: By improving water retention (0.2-0.4% dosage), HPMC ensures proper cement hydration and reduces drying shrinkage.

Problem 2: Poor Workability and Early Stiffening

These issues typically occur in hot weather or with highly absorbent substrates:

-

HEMC/HPMC: Our cellulose ethers dramatically extend open time by forming a protective layer that prevents water loss. For extreme conditions, we recommend our high-viscosity grades (150,000+ mPa·s).

-

Set Retarders: For applications in temperatures exceeding 35°C (common in countries like Saudi Arabia), we offer specialized set retarders that prevent premature hardening.

Problem 3: Efflorescence and White Staining

This unsightly issue occurs when soluble salts migrate to the mortar surface:

-

Water-Repellent Additives: Our hydrophobic agents (typically silicone-based) reduce capillary water movement that transports salts.

-

Pozzolanic Additives: These react with free lime in cement, reducing the source of efflorescence.

The most effective approach often combines multiple additives in precisely calibrated dosages. For example, for exterior renders in hot climates, we typically recommend:

| Additive | Dosage (% of dry mix) | Primary Function |

|---|---|---|

| HPMC | 0.3% | Water retention, workability |

| RDP (VA/VeoVa based) | 3.0% | Flexibility, adhesion, water resistance |

| Polypropylene fibers | 0.1% | Crack prevention |

| Water-repellent additive | 0.2% | Efflorescence prevention |

This formulation has proven particularly successful for our customers inI'll continue from where the previous response was cut off:

This formulation has proven particularly successful for our customers in the Middle East, where extreme temperatures and highly porous substrates create challenging conditions for masonry mortars.

Our approach goes beyond simply selling additives - we provide comprehensive solution packages that include formulation advice, testing protocols, and on-site support when needed. Many of our long-term clients initially approached us with specific mortar problems, which we helped solve through properly selected and dosed additives.

Other Types of Additives: What Else Can Improve Your Masonry Mortar?

Pain: Standard mortar additives may not address specialized needs like fast setting, extreme weather performance, or specific aesthetic requirements. Finding specialized solutions can be difficult.

Beyond the core additives, specialized masonry mortar enhancers include air-entraining agents for freeze-thaw resistance, water repellents for moisture protection, accelerators for cold weather, retarders for hot conditions, and pigments for decorative applications. These additives can be combined to meet virtually any project requirement.

I've worked with countless specialized projects that required going beyond standard additive packages. These specialty additives can transform ordinary mortar into highly specialized materials suitable for unique applications.

Air-entraining agents introduce controlled microscopic air bubbles into the mortar. These bubbles provide expansion chambers for freezing water, preventing damage in cold climates. Typically dosed at 0.02-0.1%, these additives are essential for masonry exposed to freeze-thaw cycles. I've found them particularly valuable for our customers in northern regions of China and high-altitude applications where temperature fluctuations are extreme.

Water repellents come in several forms, with silicone-based additives being the most common for masonry applications. These create a hydrophobic barrier that dramatically reduces water absorption while maintaining vapor permeability. When working with customers in monsoon-prone regions like India and Sri Lanka, I often recommend dosages of 0.2-0.5% to provide long-term protection against moisture damage.

Set-time controllers are essential for extreme weather applications:

- Accelerators (calcium chloride, calcium formate) speed up setting and strength development in cold weather

- Retarders (sucrose, citric acid) delay setting in hot conditions to extend working time

For colored masonry, high-quality pigments can be incorporated directly into the mortar mix. Iron oxide pigments offer excellent UV resistance and color stability, while more specialized pigments can produce vibrant colors or special effects. Proper dispersion is critical - we recommend using pigments pre-blended with dispersing agents.

This table summarizes specialty additives and their applications:

| Additive Type | Typical Dosage | Primary Benefits | Best Applications |

|---|---|---|---|

| Air-entraining agents | 0.02-0.1% | Freeze-thaw resistance | Cold climate masonry |

| Hydrophobic agents | 0.2-0.5% | Water repellency | Exterior applications, wet areas |

| Accelerators | 0.5-2.0% | Faster setting, early strength | Cold weather application, rapid repairs |

| Retarders | 0.05-0.2% | Extended working time | Hot weather, complex applications |

| Pigments | 0.5-5.0% | Color | Decorative masonry, architectural features |

| Rheology modifiers | 0.1-0.3% | Enhanced sprayability | Machine-applied mortars, decorative finishes |

The real art is in combining these specialty additives with core products like HPMC and RDP to create comprehensive solutions. Our laboratory technicians regularly develop custom formulations that integrate multiple additives in balanced proportions for specific applications.

For example, for a customer creating a colored exterior render for a luxury resort in Dubai, we developed a custom package that included:

- HPMC (water retention, workability)

- VA/VeoVa RDP (adhesion, flexibility, durability)

- Iron oxide pigment (UV-stable color)

- Hydrophobic agent (water resistance)

- Set retarder (extended working time in hot conditions)

This holistic approach to additive selection ensures all performance criteria are met without compromise.

FAQ: Your Most Common Questions About Masonry Mortar Additives Answered

Pain: Finding clear, practical information about mortar additives is challenging. Product information is often technical and doesn't address real-world application concerns.

The most important facts about masonry mortar additives include: correct dosages depend on specific project conditions; additives should be thoroughly mixed in dry form before adding water; compatibility between different additives must be verified; and quality differences between manufacturers significantly impact performance despite similar specifications.

In my years of supporting customers across developing markets, certain questions come up repeatedly. Here are straightforward answers to the most common inquiries:

How do I determine the correct dosage for my project?

While manufacturers provide recommended dosage ranges, optimal levels depend on your specific conditions. I recommend first considering your climate conditions (temperature and humidity), substrate properties (porosity and roughness), and performance requirements (flexibility, setting time, etc.).

Start with the middle of the recommended range and prepare test batches. For example, with HPMC, begin with 0.3% for general applications. Evaluate workability, adhesion, and setting time, then adjust accordingly. Remember that higher dosages aren't always better - excessive HPMC can lead to sticky mortar and slower strength development.

Can I mix different types of additives together?

Most common masonry additives are compatible, but interactions can occur. As a general rule:

- Always add cellulose ethers (HPMC, HEMC) to dry ingredients first

- RDP works well with most other additives

- Some accelerators can interfere with superplasticizers

- Air-entraining agents may require dosage adjustments when used with superplasticizers

At Kehao, we test all our products for compatibility and can provide specific guidance for your formulation. When in doubt, laboratory testing is the safest approach.

How do additives affect working time and curing time?

Cellulose ethers extend working time by retaining water in the mix, while redispersible polymers generally have minimal impact on setting time. Specific set controllers (accelerators/retarders) directly modify setting behavior.

Working time is primarily influenced by:

- HPMC/HEMC content (higher = longer working time)

- Temperature (higher = shorter working time)

- Substrate porosity (more porous = shorter working time)

For example, in Saudi Arabia's summer conditions (45°C+), a standard mortar might remain workable for just 15 minutes, while the same mix with 0.3% HPMC could provide 45+ minutes of working time.

How do I store additives properly?

Most powder additives are moisture-sensitive and should be stored in cool, dry conditions in their original sealed packaging. Typical shelf life ranges from:

- HPMC/HEMC: 2 years when properly stored

- RDP: 1 year when properly stored

- Specialty additives: 6 months to 2 years (check product documentation)

Once a package is opened, use the contents promptly or reseal carefully. I've seen numerous cases where improper storage led to performance issues - particularly with RDP, which can lose its redispersibility if exposed to moisture.

Why should I pay more for premium additives when cheaper options are available?

Quality differences between additives with similar specifications can be dramatic in real-world performance. Premium products often offer:

- More consistent particle size distribution

- Higher purity with fewer contaminants

- More precise modification (degree of substitution in cellulose ethers)

- Better technical support

In my experience, the cost difference between standard and premium additives typically represents just 1-2% of total mortar cost but can eliminate expensive callbacks and failures. The peace of mind from consistent performance makes the investment worthwhile for professional applications.

Conclusion

Selecting the right masonry mortar additives is crucial for creating durable, high-performance mortar. With Kehao's range of quality HPMC, RDP, and specialty additives, you can solve common mortar problems and achieve superior results tailored to your specific conditions and requirements.

-

Discover the common challenges faced by construction professionals and how to overcome them. ↩

-

Discover how technical support can help you select the right additives for your specific needs. ↩

-

Explore how masonry mortar additives can enhance your construction projects by improving adhesion, strength, and durability. ↩

-

Learn about HPMC's role in enhancing mortar adhesion and water retention for better construction outcomes. ↩ ↩

-

Discover the advantages of redispersible powder in creating flexible and strong mortar for various applications. ↩

-

Find out how HEMC can enhance the performance of self-leveling compounds and specialty mortars. ↩

-

Understand how polypropylene fiber can improve the durability and crack resistance of your mortar. ↩

-

Discover the transformative effects of cellulose ethers on mortar adhesion and workability. ↩

-

Learn how RDP can improve flexibility and adhesion in masonry applications. ↩

-

Discover how these fibers can prevent cracking and improve the overall strength of mortar. ↩

-

Explore the advantages of HPMC in improving water retention and workability. ↩