Are your construction projects plagued by cracking, poor adhesion, and water damage? Traditional mortars often fail in demanding environments, costing you time and money on repairs. Polymer mortar1 offers a proven solution to these persistent problems.

Polymer mortar1 is a specialized construction material that combines traditional cement with polymer additives like redispersible polymer powder2, creating a high-performance binding agent with superior flexibility, adhesion strength, water resistance, and durability compared to conventional mortars.

I've been in the construction materials industry for over 15 years, and I've witnessed firsthand the dramatic improvement polymer mortars bring to building projects. Let me share what makes this material so revolutionary and why it might be the perfect solution for your next construction challenge.

What Is Polymer Mortar?

Have you struggled with mortar that cracks too easily or fails to bond properly? Traditional cement-based mortars often disappoint in challenging conditions, leading to costly repairs and maintenance headaches.

Polymer mortar is a specialized construction material combining traditional cement components with polymer additives. These polymers, typically in the form of redispersible polymer powder2, significantly improve the mortar's performance by enhancing flexibility, adhesion strength, and durability.

Polymer mortars represent a significant advancement in construction technology. The addition of polymers fundamentally changes how the material behaves both during application and after curing. Unlike conventional mortars that rely solely on hydraulic binding, polymer mortars create two complementary binding systems: the traditional cement matrix and a polymer film network that forms throughout the material.

This dual-binding mechanism explains why polymer mortars exhibit such improved performance characteristics. When the mortar cures, the polymer particles coalesce to form continuous films and membranes that interpenetrate the cement hydrate phase. This creates a more cohesive microstructure with fewer microcracks and voids.

The most common polymers used include:

- Redispersible polymer powder (RDP)

- Styrene-butadiene rubber (SBR)

- Ethylene-vinyl acetate (EVA)

- Acrylic polymers

Each polymer type imparts specific properties, allowing manufacturers to tailor polymer mortars for particular applications. For instance, EVA-modified mortars typically offer excellent workability and water resistance, while acrylic-modified versions provide superior UV resistance for exterior applications.

Benefits of Polymer Mortars

Are you tired of dealing with mortar failures that lead to expensive repairs? Standard mortars often crack, debond, and deteriorate when exposed to harsh environments, creating ongoing maintenance nightmares.

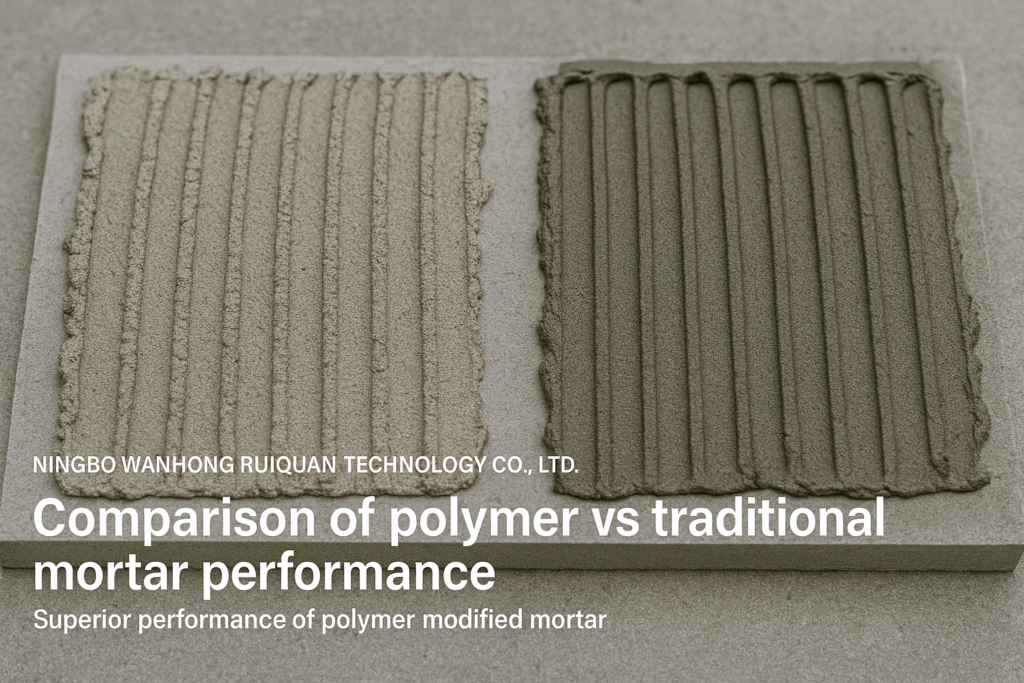

Polymer mortars dramatically outperform traditional mortars with 3-5 times better adhesion strength, enhanced flexibility preventing cracks, 60-80% reduced water absorption, and chemical resistance against acids and salts. These properties extend structural lifespans and reduce maintenance costs significantly.

The benefits of polymer mortars extend far beyond the obvious improvements in physical properties. From my experience working with construction projects across diverse climates, I've observed how these advanced materials change the entire construction process and long-term building performance.

One of the most significant advantages is the remarkable improvement in workability. Polymer additives act as plasticizers, making the mortar more cohesive and easier to apply. This translates to faster application times, reduced labor costs, and better overall quality of finished work. Our clients consistently report 20-30% increases in productivity when switching to polymer-modified systems.

The enhanced durability manifests in multiple ways:

| Property | Improvement | Practical Impact |

|---|---|---|

| Flexural Strength | 30-50% increase | Reduces cracking in areas subject to movement |

| Tensile Strength | 40-60% increase | Better performance in seismic zones |

| Impact Resistance | 2-3x improvement | Lower maintenance in high-traffic areas |

| Freeze-Thaw Durability | 3-4x more cycles | Extended lifespan in cold climates |

These property enhancements make polymer mortars particularly valuable in challenging applications like exterior facades, swimming pools, water treatment facilities, and industrial flooring. The initial cost premium (typically 15-25% higher than traditional mortars) is quickly offset by reduced maintenance and extended service life.

Types Breakdown of Polymer Additive For Mortar

Have you wondered which polymer additive is right for your specific construction needs? Choosing the wrong type can lead to wasted materials, project delays, and potential structural issues down the line.

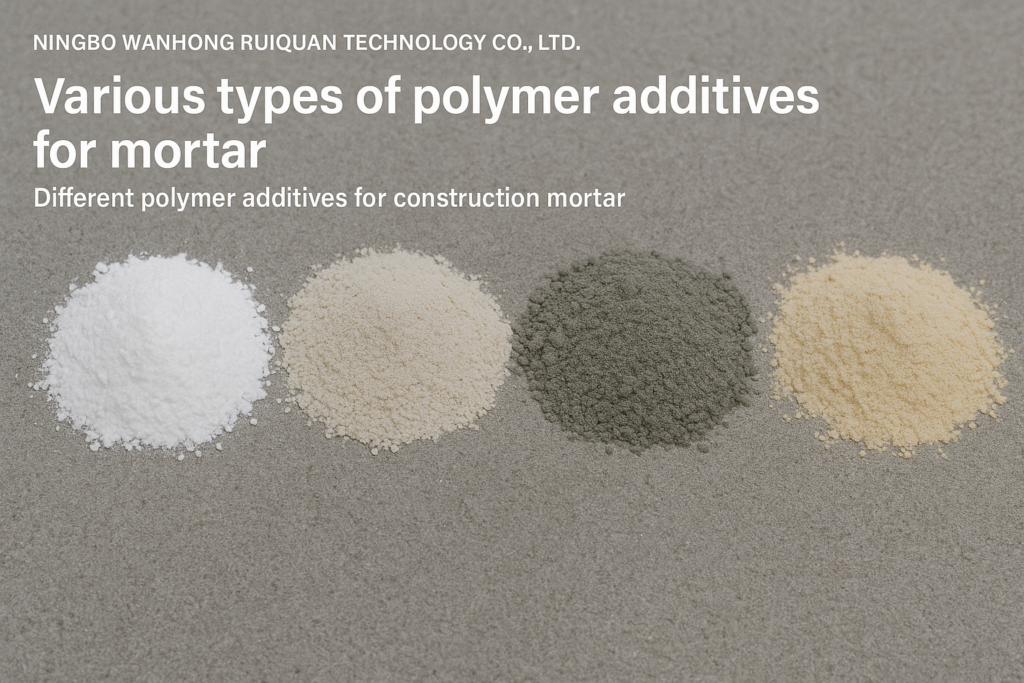

The main polymer additives for mortar include redispersible polymer powder2 (RDP), styrene-butadiene rubber (SBR), ethylene-vinyl acetate (EVA), and acrylic polymers. Each type serves specific functions - RDP provides flexibility and adhesion, SBR offers waterproofing, EVA enhances workability, and acrylics deliver superior weather resistance.

Understanding the nuanced differences between polymer additive types can significantly impact your project outcomes. Through my work consulting with construction firms across various climate zones, I've developed a comprehensive understanding of how these additives perform in real-world applications.

Redispersible Polymer Powder (RDP) has become the industry standard for many applications due to its versatility and ease of use. As a dry powder, it can be pre-mixed with other dry ingredients, creating convenient one-component systems that only require water addition on-site. The redispersion technology allows the polymer particles to uniformly distribute throughout the mix when water is added, forming a three-dimensional network within the cement matrix. This technology is particularly valuable for tile adhesives3 and external thermal insulation composite systems (ETICS).

The chemical composition of these polymers significantly affects their performance properties:

| Polymer Type | Chemical Base | Ideal Applications | Special Considerations |

|---|---|---|---|

| EVA-based RDP | Ethylene-Vinyl Acetate | General-purpose tile adhesives, ETICS | Excellent balance of properties |

| VAc-E-VeoVa based RDP | Vinyl Acetate-Ethylene-Versatate | Exterior renders, repair mortars | Enhanced hydrophobicity |

| Acrylic RDP | Acrylic esters | Pool plasters, exterior facades | Superior UV and alkaline resistance |

| SBR Latex | Styrene-Butadiene | Industrial flooring, bridge deck repairs | Must be added on-site as liquid |

The concentration of polymer also plays a crucial role. For general applications like tile adhesives, 2-5% polymer content (by weight of cement) often provides optimal performance. However, specialized applications may require higher dosages:

- High-flexibility systems: 5-8%

- Waterproofing membranes: 10-15%

- Repair mortars for critical infrastructure: 7-12%

Proper selection requires consideration of not just the immediate performance requirements but also long-term durability factors like UV exposure, chemical environments, and temperature cycling conditions.

How Much Polymer Additive for Mortar?

Are you uncertain about the correct dosage of polymer additives for your mortar mix? Using too little fails to deliver the benefits, while excessive amounts waste money and can actually harm performance.

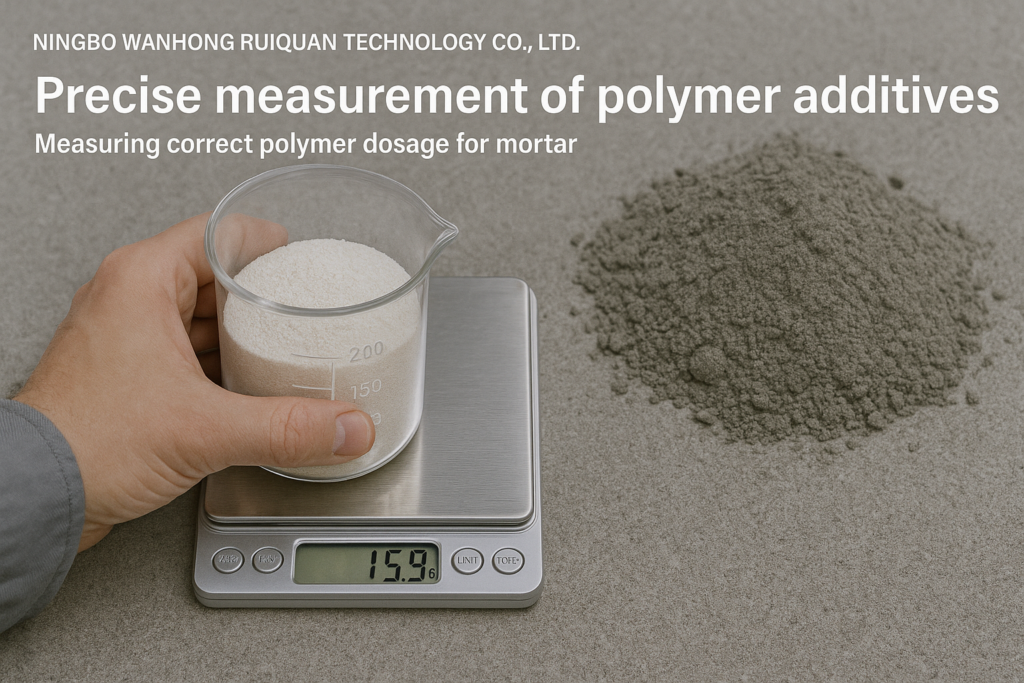

Polymer additive dosages typically range from 2-15% by weight of cement, depending on application requirements. General-purpose mortars need 3-5%, tile adhesives 5-8%, waterproofing applications 8-10%, and repair mortars for extreme conditions 10-15%. Always start with manufacturer recommendations and adjust based on field testing.

The science behind polymer dosage optimization is fascinating and essential for achieving the optimal balance between performance and cost. Through my laboratory work and field testing with various polymer systems, I've discovered that the relationship between polymer content and performance improvement isn't always linear - there are important thresholds to understand.

The minimum effective dosage (MED) represents the polymer content below which you won't see significant property improvements. This threshold varies depending on the specific polymer type and the cement components, but generally falls around 2-3% for most applications. Below this level, the polymer particles are too dispersed to form an effective interconnected network.

At the other end of the spectrum, there's a point of diminishing returns, typically around 15-20% for most applications, beyond which additional polymer doesn't provide proportional performance improvements and can actually create problems like excessive air entrainment or delayed cement hydration.

Different performance properties also optimize at different polymer contents:

| Performance Property | Optimal Polymer Range | Critical Factors |

|---|---|---|

| Adhesion Strength | 5-8% | Surface preparation, polymer type |

| Flexibility | 7-12% | Polymer Tg value, particle size |

| Waterproofing | 8-15% | Hydrophobic polymer content |

| Workability | 3-6% | Polymer particle size, cement compatibility |

Environmental conditions during application and curing also affect optimal dosage:

- Hot, dry conditions: Increase dosage by 1-2% to prevent rapid water evaporation

- Cold conditions: Consider using polymers with lower film formation temperatures

- High humidity: May require adjustments to air-entraining additives

Laboratory testing with specific material combinations from your region provides the most reliable dosage recommendations. I always recommend pilot applications before proceeding with large-scale projects, especially when working with new material combinations or extreme environmental conditions.

Polymer Fortified Mortar: A Multifunctional Solution for Modern Construction

Do you face multiple construction challenges that seem to require different specialized mortars? Traditional building approaches often involve using several products, creating inventory complexity, application inconsistencies, and potential compatibility issues.

Polymer fortified mortars serve as versatile all-in-one solutions, functioning effectively as adhesives, repair compounds, waterproofing agents, and decorative finishes. With a single properly formulated polymer mortar system4, contractors can reduce inventory, simplify training, ensure material compatibility, and maintain consistent quality across projects.

The multifunctionality of polymer mortars represents a paradigm shift in construction methodology. On numerous projects I've supervised, switching to integrated polymer systems has streamlined the entire construction process. One particularly challenging restoration project required structural repair, waterproofing, and aesthetic finishing of a 100-year-old concrete structure. Using a coordinated polymer mortar system allowed us to ensure perfect compatibility between layers while reducing the project timeline by nearly 30%.

This versatility stems from the formulation flexibility that polymers provide. By adjusting polymer type, content, and complementary additives, manufacturers can fine-tune performance characteristics for specific applications while maintaining a consistent base technology. This allows for the development of coordinated "systems" rather than isolated products.

The practical applications of polymer mortars span virtually every segment of construction:

| Construction Segment | Application Examples | Key Performance Requirements |

|---|---|---|

| Residential | Tile installation, basement waterproofing, façade renovation | Ease of use, aesthetic finish, durability |

| Commercial | Flooring systems, exterior cladding, swimming pools | Rapid installation, wear resistance, chemical resistance |

| Infrastructure | Bridge deck overlays, parking structures, water management | Extreme durability, crack resistance, minimal maintenance |

| Industrial | Chemical processing areas, food production, pharmaceutical | Chemical resistance, hygienic properties, easy decontamination |

The cost-benefit analysis increasingly favors polymer systems when considering the total lifecycle costs. While initial material costs may be 15-30% higher than traditional systems, the savings emerge through:

- Reduced labor costs (faster application, fewer layers)

- Lower maintenance requirements (2-3 times longer service intervals)

- Extended renovation cycles (typically 10-15 years vs 5-7 for conventional systems)

- Improved energy efficiency (better interface with insulation systems)

- Reduced waste and environmental impact

For contractors and project managers, the simplified logistics and reduced training requirements translate directly to more efficient project execution and more predictable outcomes.

WANHONG – Unlock the Outstanding Quality of Polymer Mortar!

Are you frustrated with inconsistent polymer additives that produce unpredictable results? Unreliable suppliers can undermine your reputation and cost you repeat business through product failures and customer complaints.

WANHONG produces premium redispersible polymer powders and cellulose ethers specifically engineered for high-performance construction mortars. With six dedicated production lines, strict quality control measures, and customized technical support, we ensure consistent performance that meets international standards while maintaining competitive pricing.

At WANHONG, our commitment to polymer technology excellence stems from years of focused research and development in construction-specific applications. Unlike general chemical suppliers, our entire manufacturing process is optimized for the unique demands of construction polymers, where particle size distribution, redispersion properties, and cement compatibility are critical.

My personal involvement with our quality control protocols ensures that every batch meets our exacting standards. We've implemented a comprehensive testing regime that goes beyond standard industry practices:

- Advanced rheological testing to predict field workability

- Accelerated weathering simulations for long-term performance prediction

- Application-specific testing that replicates actual usage conditions

- Compatibility testing with regional cement types and aggregates

This attention to detail has earned us the trust of major construction material manufacturers across Saudi Arabia, UAE, India, Pakistan, and throughout Asia and Latin America. Our technical collaboration approach means we don't just supply products – we help optimize your entire formulation.

Our primary polymer offerings include:

| Product Line | Key Features | Recommended Applications |

|---|---|---|

| KERAD™ RDP Series | Enhanced adhesion, flexible film formation | Tile adhesives, EIFS systems, repair mortars |

| KEHEC™ Cellulose Ethers | Water retention, improved workability | Self-leveling compounds, renders, grouts |

| KECMC™ Specialty Grades | Delayed solubility for extended working time | Complex applications, pumped mortars |

We understand the challenges facing mortar manufacturers in developing markets – from raw material variability to extreme climate conditions. Our technical team provides on-site support, helping clients troubleshoot issues and optimize formulations for local conditions.

With WANHONG as your polymer supplier, you gain more than just premium materials – you gain a partner committed to your success. Our flexible production capabilities allow for customized products to meet your specific requirements, while our consistent quality ensures your finished mortars perform reliably batch after batch.

Conclusion

Polymer mortars transform construction outcomes through superior adhesion, flexibility, and durability. By selecting the right polymer type and dosage for your specific application, you'll create stronger, longer-lasting structures that outperform traditional materials in every measure that matters.

-

Explore how polymer mortar can enhance your construction projects with superior performance and durability. ↩ ↩

-

Learn about RDP and how it improves mortar performance in various construction applications. ↩ ↩ ↩

-

Discover the benefits of using polymer-modified tile adhesives for better bonding and durability. ↩

-

Understand how polymer mortar systems streamline construction processes and enhance performance. ↩