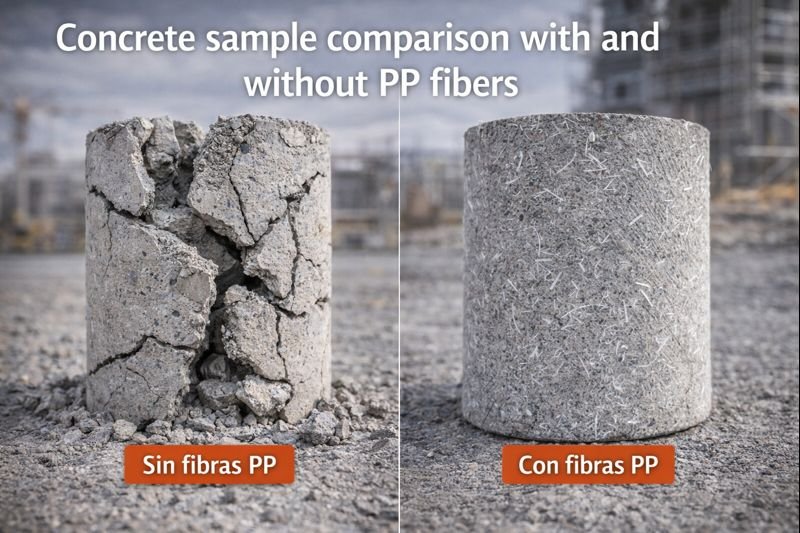

Are you struggling with concrete cracking and durability issues? Conventional concrete often fails prematurely, leading to costly repairs and compromised structural integrity. Polypropylene fiber reinforcement1 offers a simple yet effective solution.

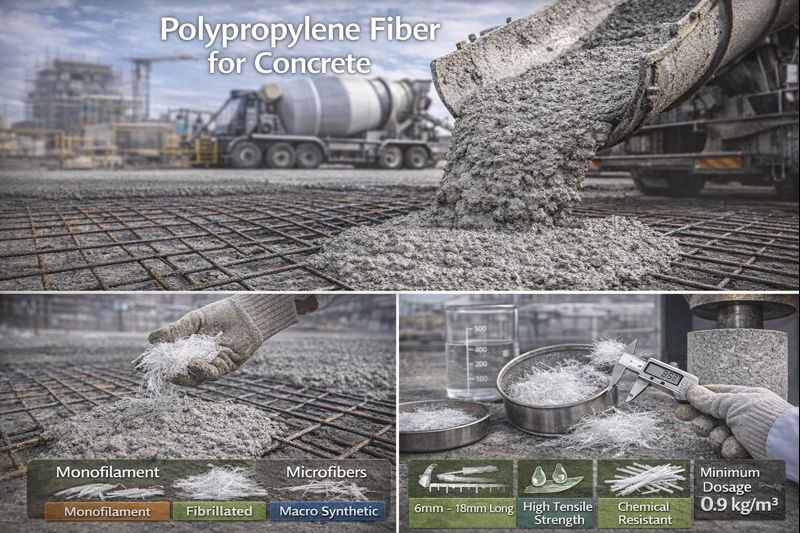

Polypropylene fiber for concrete is a synthetic reinforcement material that reduces shrinkage cracking, increases impact resistance, and improves long-term durability. When evenly distributed throughout the concrete mix, these fibers create a three-dimensional reinforcement system that enhances concrete performance significantly.

As a leading manufacturer of construction additives2 with over 15 years of experience, I've seen firsthand how polypropylene fibers transform ordinary concrete into exceptional building material. Our clients consistently report improved project outcomes when incorporating these innovative fibers. Let me share everything you need to know about this game-changing concrete reinforcement solution.

What Is PP Fiber for Concrete and How Does It Work?

Cracking concrete threatens structural integrity and creates costly repair bills. Traditional reinforcement methods often fall short, especially in controlling microscopic cracking that leads to major failures.

Polypropylene (PP) fiber consists of synthetic monofilament or fibrillated strands that disperse evenly throughout concrete mixtures. These fibers create millions of reinforcement points that bridge micro-cracks, absorb energy, and enhance tensile strength while remaining chemically inert and alkali-resistant in the concrete matrix.

Types of Polypropylene Fibers

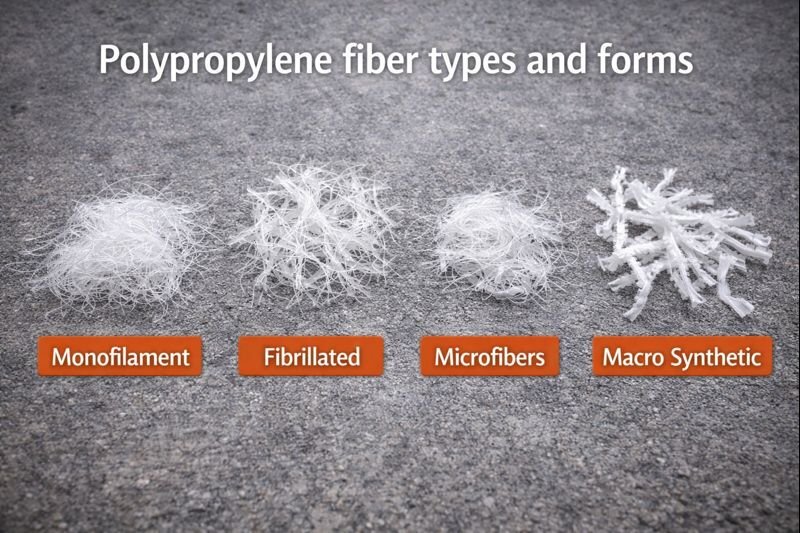

Understanding the different types of polypropylene fibers available can help you make better decisions for your specific applications:

| Type | Characteristics | Best Applications |

|---|---|---|

| Monofilament | Individual smooth strands, excellent finishing | Decorative concrete, surfaces with high aesthetic requirements |

| Fibrillated | Interconnected net-like structure, higher tensile strength | Industrial floors, pavements, precast elements |

| Micro-fibers | Very thin (< 0.3mm diameter), high count per kg | Shotcrete, thin overlays, fire resistance |

| Macro-fibers | Thicker (> 0.3mm diameter), structural reinforcement | Partial replacement of steel reinforcement, industrial floors |

The length of PP fibers significantly impacts performance. At Kehao, we produce PP fibers in standard lengths of 3mm, 6mm, 9mm, and 12mm, with custom sizes available upon request. Shorter fibers (3-6mm) work best for finer mixes and surface crack control, while longer fibers (9-12mm) provide better structural reinforcement for larger aggregate concrete.

How Can Polypropylene Fiber Concrete Improve Your Project Performance?

Construction projects often suffer from durability issues despite following standard practices. Traditional concrete's inherent brittleness leads to premature failure, especially in challenging environments.

Polypropylene fiber concrete offers multidimensional performance improvements including up to 80% reduction in plastic shrinkage cracking, 20-40% increased impact resistance, and enhanced freeze-thaw durability. These benefits extend concrete service life while reducing maintenance costs and improving safety factors in critical applications.

Performance Advantages of Fiber-Reinforced Concrete

I've worked with countless construction companies across Saudi Arabia, UAE, India, and other regions where extreme temperature variations place enormous stress on concrete structures. Our clients consistently report these key performance improvements when using our polypropylene fibers:

-

Enhanced Crack Resistance: The three-dimensional fiber matrix intercepts microcracks before they propagate into structural issues. This is particularly valuable in large concrete pours where differential setting rates create internal stresses.

-

Improved Impact and Abrasion Resistance: The fibers absorb energy from impacts and distribute it throughout the concrete matrix. Tests show up to 40% improvement in impact resistance, making it ideal for industrial floors and high-traffic areas.

-

Reduced Permeability: By controlling microcracking, PP fibers reduce water and chemical penetration pathways. This fundamentally improves concrete durability in aggressive environments like coastal areas or chemical processing facilities.

-

Enhanced Freeze-Thaw Durability: The fiber network provides space for water expansion during freezing cycles, reducing internal pressure that would otherwise cause spalling and deterioration.

What Are the PP Fiber for Concrete Specifications You Need to Know?

Choosing the wrong fiber type or dosage can lead to mixing problems, finishing difficulties, or inadequate performance. Many contractors struggle to understand the technical specifications that actually matter for their specific applications.

Standard polypropylene fibers for concrete should have a specific gravity of 0.91, tensile strength between 300-700 MPa, melting point around 160-170°C, and acid/alkali resistance >99.9%. Typical dosage rates range from 0.6-0.9 kg/m³ for plastic shrinkage control and up to 2-5 kg/m³ for structural applications.

Critical Technical Parameters for Project Success

In my experience supplying fibers to major construction projects across developing countries, I've found these specifications to be most critical for project success:

| Specification | Standard Range | Impact on Performance |

|---|---|---|

| Material | 100% virgin polypropylene | Ensures consistent quality and fiber properties |

| Length | 3mm, 6mm, 9mm, 12mm | Determines dispersion and reinforcement effectiveness |

| Diameter | 15-40 microns (microfiber) 0.3-1.0mm (macrofiber) |

Affects fiber count per kg and reinforcement mechanism |

| Tensile Strength | 300-700 MPa | Determines load capacity before fiber failure |

| Elastic Modulus | 3500-5000 MPa | Affects fiber's ability to absorb energy |

| Alkali Resistance | >99.9% | Ensures durability in high-pH concrete environment |

| Absorption | Nil | Prevents water content issues in the mix |

At Wanhong, we rigorously test each production batch to ensure consistency across all these parameters. We've found that maintaining tight quality control on fiber dimensions and mechanical properties directly translates to predictable performance improvements in the field. For specialized applications, we can customize fiber length, tensile strength, and other parameters to meet specific project requirements.

Why Should You Choose Our PP Fiber for Concrete?

Finding reliable construction additive suppliers can be challenging. Many manufacturers offer inconsistent quality, limited customization options, or poor technical support, leaving you with underperforming concrete and project delays.

Wanhong produces premium polypropylene fibers with six advanced production lines, ensuring consistent quality and reliable supply chains. Our manufacturing facilities meet international standards with ISO certifications, while our technical team provides expert dosage recommendations and mixing guidance for optimal performance in your specific applications.

Our Competitive Advantages

Having supplied construction additives to major projects across Saudi Arabia, UAE, Iran, India, Pakistan, Brazil, Mexico and other developing countries, I understand the challenges contractors face in these regions. Here's why our global clients choose Kehao's polypropylene fibers:

-

Manufacturing Excellence: Our six specialized production lines dedicated to construction additives ensure consistent fiber quality and reliable supply capacity. Unlike smaller manufacturers, we can guarantee product consistency across large projects requiring multiple shipments.

-

Customization Capabilities: We understand that different applications require different fiber specifications. Whether you need special fiber lengths beyond our standard 3mm, 6mm, 9mm, and 12mm options, or custom packaging solutions, our flexible manufacturing process accommodates your specific requirements.

-

Technical Support: Our engineering team provides comprehensive mixing recommendations, dosage calculations, and field support to ensure optimal fiber performance in your specific applications. This level of support is particularly valuable for first-time fiber users or challenging project conditions.

-

Quality Assurance: Every batch undergoes rigorous testing against international standards. We provide detailed technical documentation and test certificates with each shipment, giving you confidence in the material's performance and helping you meet project specifications.

-

Logistics Expertise: With extensive experience shipping to over 20 countries, we understand the complexities of international logistics, customs requirements, and documentation needed for smooth importation of construction additives.

What Other Synthetic Fibers Does Wanhong Offer?

Construction projects often require multiple performance-enhancing additives, but sourcing from different suppliers creates coordination headaches, inconsistent quality, and logistics complications.

Beyond polypropylene fibers, Wanhong produces complementary construction additives including hydroxypropyl methylcellulose (HPMC), redispersible latex powder, hydroxyethyl methylcellulose, carboxymethyl cellulose, and hydroxyethyl cellulose—all manufactured in our ISO-certified facilities to ensure chemical compatibility and performance synergy.

Comprehensive Concrete Enhancement Solutions

As a full-spectrum manufacturer of construction additives, we offer significant advantages for clients seeking complete concrete enhancement solutions:

-

Chemical Compatibility: When using multiple additives in concrete, chemical compatibility is critical. Our R&D department thoroughly tests all our products together to ensure they work synergistically without adverse interactions.

-

Simplified Supply Chain: By sourcing multiple additives from a single supplier, you simplify procurement, reduce documentation, and minimize coordination efforts. Many of our clients appreciate receiving consolidated shipments that reduce logistics costs and administrative overhead.

-

Consistent Quality Control: All our products undergo the same rigorous quality control processes in our ISO-certified facilities. This ensures uniform quality standards across your entire additive package.

-

Customized Solutions: Rather than offering one-size-fits-all products, we analyze your specific project requirements and recommend the optimal combination of fibers and chemical additives to achieve your performance goals within budget constraints.

Our technical team can help you determine the ideal combination of polypropylene fibers and other additives based on your specific application, environmental conditions, and performance requirements.

How Can You Get a Free Sample of PP Fiber for Concrete?

Testing new construction additives usually involves lengthy procurement processes, minimum order quantities, and difficult approval procedures. This often prevents contractors from evaluating innovative materials that could improve project outcomes.

Request your free polypropylene fiber sample today by emailing ada@whhpmc.com or visiting www.whhpmc.com. Include your project specifications and performance requirements so we can recommend the optimal fiber type and provide relevant technical documentation tailored to your application.

Our Sampling Process

I personally oversee our sampling program to ensure clients receive the most appropriate materials for evaluation. Our process includes:

-

Initial Consultation: We'll discuss your specific application, performance challenges, and technical requirements to determine the optimal fiber type and dosage for your project.

-

Customized Sample: Based on your requirements, we'll prepare a tailored sample package with the recommended fiber type and length, along with comprehensive technical documentation.

-

Application Guidance: Our technical team provides detailed mixing, placement, and finishing recommendations to ensure optimal results during your evaluation.

-

Performance Assessment: After you've conducted initial tests, we'll review the results together and make any necessary adjustments to fiber type or dosage rates to optimize performance for your specific conditions.

-

Scaling Up: Once you're satisfied with the sample performance, we'll help transition to full-scale implementation with comprehensive support throughout the procurement and application process.

This systematic approach has helped hundreds of clients successfully integrate polypropylene fibers into their construction practices, resulting in improved concrete performance and reduced long-term maintenance costs.

Frequently Asked Questions About PP Fiber for Concrete

What dosage of polypropylene fibers should I use?

For plastic shrinkage crack control in standard applications, use 0.6-0.9 kg/m³ of concrete. For improved impact resistance and structural enhancement, increase to 1.5-5 kg/m³ depending on your specific requirements. Our technical team can provide precise dosage recommendations based on your project specifications.

Will polypropylene fibers3 affect concrete workability?

At recommended dosage rates, the impact on workability is minimal. However, fiber addition typically reduces slump by approximately 25mm. This can be easily compensated for with minor mix adjustments or appropriate superplasticizers. Our technical team can provide specific recommendations for your mix design.

How do polypropylene fibers compare to steel fibers?

Polypropylene fibers excel at controlling plastic shrinkage cracking and enhancing durability, while steel fibers provide greater structural reinforcement and load-carrying capacity. Many projects benefit from combining both types. The optimal choice depends on your specific performance requirements and economic considerations.

Are polypropylene fibers visible in the finished concrete surface?

When properly mixed and finished, microfibers (like our 3mm and 6mm options) are virtually invisible in the final concrete surface. For decorative or exposed aggregate concrete, we recommend specific fiber types and application techniques to maintain aesthetic quality.

Conclusion

Polypropylene fibers transform ordinary concrete into a more durable, crack-resistant building material. With Kehao's premium PP fibers, comprehensive technical support, and customization options, you can significantly improve your concrete performance and project outcomes. Request your sample today!