Are you struggling with adhesives that don't perform well in humid conditions? Many construction professionals face project delays and failures due to adhesive products that simply can't hold up when needed most.

Starch ether1 improves adhesive performance by enhancing water retention, increasing viscosity, and providing better bonding strength. It's an eco-friendly, cost-effective alternative to synthetic additives that works especially well in cement-based adhesives used in construction applications.

I remember visiting a construction site in Dubai where the foreman was showing me how their tile adhesive kept failing in the humid conditions. After switching to our starch ether-enhanced formula, their adhesion problems disappeared. Let me show you why this ingredient is transforming the adhesive industry.

Why Use Starch Ether in Adhesives?

Have you noticed how traditional adhesives often fail in challenging environmental conditions? Many construction companies waste thousands on rework because their adhesive products simply can't handle moisture variations or temperature fluctuations.

Starch ether provides excellent water retention ability in adhesives2, preventing premature drying and ensuring proper cement hydration. It also increases viscosity for better workability, reduces slippage on vertical surfaces, and enhances bonding strength while being more environmentally friendly than many synthetic alternatives.

When I first started supplying starch ether to adhesive manufacturers, I was surprised by how much it improved their products. The science behind this is fascinating. Starch ether works by modifying natural starch through an etherification process, which introduces hydroxypropyl groups into the starch molecules.

This modification creates a product that maintains its viscosity under varying pH and temperature conditions.

The modified starch provides several key benefits that make it ideal for adhesives:

Improved Adhesion Performance Factors

| Feature | Benefit to Adhesives | Practical Impact |

|---|---|---|

| Water Retention | Prevents premature drying | Longer working time for contractors |

| Viscosity Enhancement | Better consistency control | Easier application, less dripping |

| Temperature Stability | Performs in hot/cold conditions | Year-round usability |

| Eco-friendly | Biodegradable, renewable resource | Meets green building standards |

I've seen customers switch from synthetic additives to our starch ether products and achieve not just better performance but also cost savings of 15-20%. This is because starch ether is derived from renewable resources and requires less processing than many petroleum-based alternatives.

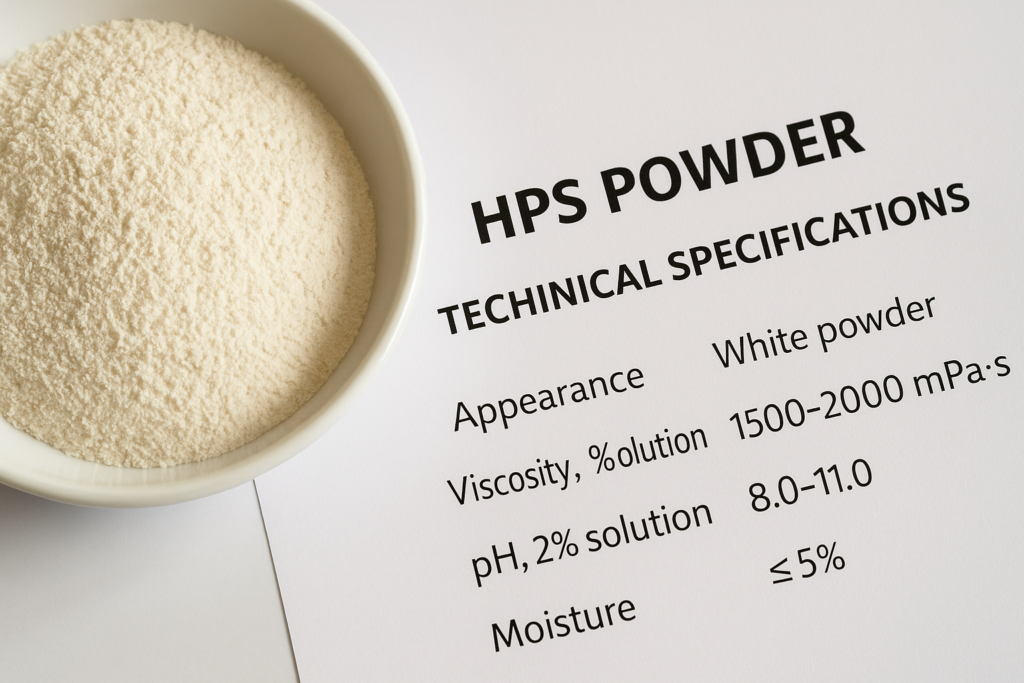

HPS Powder Specifications: What Should You Look For?

Are you confused by the various grades of hydroxypropyl starch (HPS)3 available in the market? Many buyers make costly mistakes by selecting the wrong specification for their specific adhesive application.

Quality HPS powder for adhesives should have molar substitution between 0.05-0.2, viscosity of 4,000-10,000 mPa·s (2% solution), pH value of 6.0-9.0, moisture content below 10%, and ash content less than 0.5%. The particle size should be fine enough to pass through a 100-mesh sieve for optimal dissolution.

When selecting HPS powder4 for adhesive applications, I always advise my customers to consider their specific formulation needs. The specifications of HPS powder directly impact how it will perform in the final product.

From my experience working with various adhesive manufacturers across the Middle East and Asia, I've found that getting these specifications right is crucial for product success.

The most important specifications to consider include:

Key HPS Powder Technical Parameters

| Parameter | Optimal Range | Impact on Adhesives |

|---|---|---|

| Molar Substitution (MS) | 0.05-0.2 | Controls water retention and stability |

| Viscosity (2% solution) | 4,000-10,000 mPa·s | Determines thickening power |

| pH Value | 6.0-9.0 | Affects compatibility with cement |

| Moisture Content | <10% | Influences shelf life and handling |

| Ash Content | <0.5% | Indicates purity level |

| Particle Size | 100 mesh pass rate >95% | Affects dissolution speed |

Different adhesive applications require specific HPS characteristics. For example, I worked with a tile adhesive manufacturer in Saudi Arabia who needed exceptional water retention in their product due to the hot climate.

We supplied an HPS powder with higher molar substitution (0.18) which solved their problem by extending the open time of the adhesive by nearly 30 minutes – crucial for large-scale tiling projects in high temperatures.

Top 4 Starch Ether Uses in The Construction Industry

Have you wondered why some construction products perform better than others in challenging conditions? The secret often lies in the additives used, with starch ether becoming increasingly popular among leading manufacturers.

The top four uses of starch ether5 in construction are: 1) tile adhesives for improved slip resistance and extended open time, 2) gypsum-based products for better workability, 3) exterior insulation finishing systems for enhanced adhesion, and 4) self-leveling compounds for improved flow characteristics.

I've witnessed the transformation starch ether brings to various construction materials firsthand. During my visits to construction sites across developing markets, I've seen how this simple additive solves complex problems that have plagued builders for years.

Versatile Applications of Starch Ether in Construction

-

Tile Adhesives

Starch ether in tile adhesives6 prevents slippage of tiles during installation, especially on vertical surfaces. It extends the open time, giving installers more flexibility when working on large areas. One of our customers in Pakistan reported that using our starch ether allowed their workers to cover 30% more area per day because they didn't need to constantly remix dried-out adhesive. -

Gypsum-Based Products

In gypsum plasters and joint compounds, starch ether improves water retention and workability. This results in smoother finishes and reduced cracking. The thixotropic properties it adds are particularly valuable for ceiling applications where sag resistance is essential. -

Exterior Insulation Finishing Systems (EIFS)

EIFS adhesives benefit from starch ether's bonding strength enhancement. In regions with extreme temperature variations like the Middle East, this added strength prevents delamination and failure of insulation panels. I've seen buildings in Dubai where EIFS systems made with standard adhesives failed within two years, while those using starch ether-enhanced adhesives remained intact after five years. -

Self-Leveling Compounds

Starch ether provides critical flow control in self-leveling underlayments. It helps maintain the delicate balance between fluidity for self-leveling properties and stability to prevent material separation. The result is smoother floors with fewer defects.

What is the use of starch ether7?

Have you tried formulating construction products without proper rheology modifiers? Many manufacturers struggle with inconsistent quality and performance issues when they cut corners on these essential ingredients.

Starch ether functions as a thickener, binder, film-former, and water retention agent in various industrial applications. Beyond construction, it's used in food processing, textile sizing, paper manufacturing, and pharmaceutical products, offering biodegradable and sustainable alternatives to petroleum-based additives.

My experience with starch ether spans beyond construction applications. I've consulted with manufacturers across various industries and seen its versatility firsthand. This modified starch product brings unique properties that solve specific problems across different sectors.

The versatility of starch ether comes from its ability to be customized through different degrees of substitution and molecular weights. These modifications allow us to tailor the product for specific end uses.

For example, when I worked with a paint manufacturer in Vietnam, we developed a custom starch ether that improved their water-based paint's spatter resistance and brush feel significantly.

Starch Ether Applications Across Industries

| Industry | Application | Benefit Provided |

|---|---|---|

| Construction | Mortars, renders, adhesives | Water retention, workability, adhesion |

| Food | Sauces, dairy products | Thickening, stabilizing |

| Textiles | Sizing agents, printing pastes | Film formation, binding |

| Paper | Surface sizing, coating | Improved printability, strength |

| Pharmaceuticals | Tablet binding, controlled release | Binding, film-forming |

| Oil Drilling | Drilling fluids | Viscosity control, fluid loss prevention |

I've found that manufacturers who understand the specific type of starch ether needed for their application gain significant advantages in product performance.

For instance, a mortar producer in Brazil switched from generic starch ether to our specially formulated construction-grade product and reported a 40% improvement in water retention – crucial for proper cement hydration in their hot climate.

What are the uses of cellulose ether?

Are you confused about when to use cellulose ether8 versus starch ether in your formulations? Many manufacturers waste money using expensive cellulose ethers when starch ethers would perform better for their specific applications.

Cellulose ethers are primarily used as thickeners, binders, film formers, and water retention agents in construction (concrete, mortars, tile adhesives), pharmaceuticals (tablet coatings, controlled release), personal care (shampoos, lotions), food products (ice cream, sauces), and paints (water-based). They provide viscosity, stability, and improved application properties.

When discussing additives with customers, I often get asked about the differences between cellulose ethers and starch ethers. While they share some functional similarities, their performance characteristics and cost profiles differ significantly. Understanding these differences has helped many of my customers optimize their formulations for both performance and cost.

Cellulose ethers include several types like HPMC (hydroxypropyl methylcellulose), MC (methylcellulose), CMC (carboxymethyl cellulose), and HEC (hydroxyethyl cellulose). Each type offers specific benefits that make them suitable for different applications.

In my work with construction material manufacturers across developing markets, I've seen how choosing the right cellulose ether can dramatically improve product performance.

Comparison Between Cellulose Ethers and Starch Ethers

| Property | Cellulose Ethers | Starch Ethers | Best Application Scenario |

|---|---|---|---|

| Cost | Higher ($2-5/kg) | Lower ($0.8-2/kg) | Starch ethers for cost-sensitive formulations |

| Water Retention | Excellent | Good | Cellulose ethers for premium tile adhesives |

| Temperature Stability | Very High | Moderate | Cellulose ethers for extreme conditions |

| Workability | Excellent | Good | Cellulose ethers for high-end rendering systems |

| Biodegradability | Moderate | Higher | Starch ethers for eco-friendly products |

| Compatibility | Wide range | More limited | Cellulose ethers for complex formulations |

I've helped many customers create hybrid systems that use both cellulose and starch ethers to optimize performance and cost. For example, one of our customers in Mexico reduced their production costs by 18% by replacing half of their HPMC with our starch ether in their economy-grade tile adhesive, with no reduction in performance.

For their premium product line, they maintained the higher cellulose ether content to justify the price difference.

What is HPS material?

Wondering if HPS is just another industry acronym or something that could actually improve your products? Many manufacturers miss out on significant formulation improvements because they don't fully understand specialized ingredients like HPS.

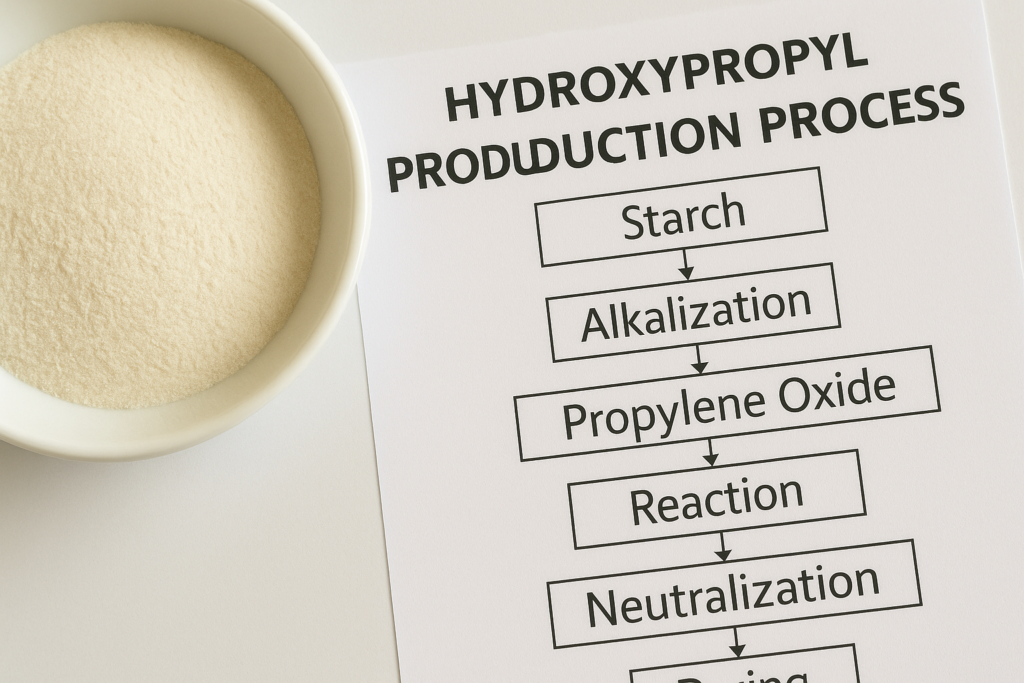

HPS (Hydroxypropyl Starch)9 is a modified starch produced by reacting starch with propylene oxide under alkaline conditions. This chemical modification enhances water solubility, viscosity stability, and freeze-thaw resistance compared to native starch, making it valuable in adhesives, paper coating, textile sizing, and construction products.

In my years supplying raw materials to adhesive manufacturers, I've seen HPS transform product performance. HPS is created through an etherification process that fundamentally changes how starch behaves in water and under varying conditions.

These changes make it much more suitable for industrial applications than natural starch.

The manufacturing process of HPS is fascinating and directly impacts its performance characteristics. Starch molecules (typically from corn, potato, or tapioca) are reacted with propylene oxide in the presence of sodium hydroxide.

This reaction substitutes hydroxyl groups in the starch with hydroxypropyl groups, creating a modified starch with enhanced properties.

HPS Material Properties and Benefits

| Property | Native Starch | Hydroxypropyl Starch (HPS) | Benefit in Applications |

|---|---|---|---|

| Water Solubility | Poor (forms paste) | Excellent (true solution) | Better mixing, no lumps |

| Viscosity Stability | Poor, breaks down | Excellent, stable | Consistent performance |

| pH Stability | Narrows range | Wide range (3-12) | Works in various formulations |

| Freeze-Thaw Stability | Poor | Excellent | Better product stability |

| Clarity in Solution | Cloudy | Clear to slightly cloudy | Improved aesthetics |

| Film Forming | Brittle films | Flexible films | Better end product quality |

I once visited a customer in India who was having problems with their adhesive breaking down during storage. After analyzing their formula, I recommended replacing their native starch with our HPS powder.

The results were immediate – their product maintained consistent viscosity throughout its shelf life, eliminating customer complaints and reducing waste by nearly 25%.

The level of hydroxypropyl substitution (measured as MS or molar substitution) is critical to HPS performance. I typically recommend different MS levels based on the specific application.

For general adhesive use, an MS of 0.05-0.1 provides a good balance of properties, while applications requiring more stability in extreme conditions benefit from higher MS levels of 0.15-0.2.

Conclusion

Starch ether offers a powerful, cost-effective solution for adhesives in construction applications. By enhancing water retention, workability, and adhesion while remaining environmentally friendly, it's becoming essential for manufacturers looking to improve both performance and sustainability.

-

Explore how starch ether can enhance adhesive performance, especially in humid conditions, making it a game-changer for construction projects. ↩

-

Discover the critical role of water retention in adhesives and how it can prevent premature drying and improve project outcomes. ↩

-

Learn about the key specifications of HPS powder to avoid costly mistakes in adhesive applications and ensure optimal performance. ↩

-

Explore this link to understand the properties and applications of HPS powder in adhesives, enhancing your formulation knowledge. ↩

-

Discover the advantages of starch ether in construction, which can improve your product's performance in various applications. ↩

-

Learn about the advantages of using starch ether in tile adhesives for better installation and reduced labor costs. ↩

-

Explore how starch ether enhances construction materials, improving performance and sustainability in various applications. ↩

-

Learn about the diverse applications of cellulose ether and how it compares to starch ether for optimal formulation choices. ↩

-

Discover the advantages of HPS in various applications and how it can improve your product formulations. ↩