Are you struggling with construction materials1 that crack, have poor adhesion, or lack durability? Traditional mortar and cement solutions often fall short, leaving builders frustrated and projects compromised.

Redispersible Polymer Powder2 (RDP) is a specialized additive that transforms ordinary construction materials1 into high-performance building solutions by improving flexibility, adhesion, and water resistance while reducing cracking and enhancing overall durability in various construction applications.

I've been in the construction materials industry for over 15 years, and I've seen firsthand how RDP has revolutionized building practices. The difference between projects using standard materials and those incorporating RDP is night and day. Let me walk you through everything you need to know about this game-changing construction additive.

What Is RDP And Why Is It Essential For Modern Construction?

Pain point: Traditional cement-based materials are brittle, crack easily, and have poor adhesion3 to surfaces, leading to costly repairs and maintenance.

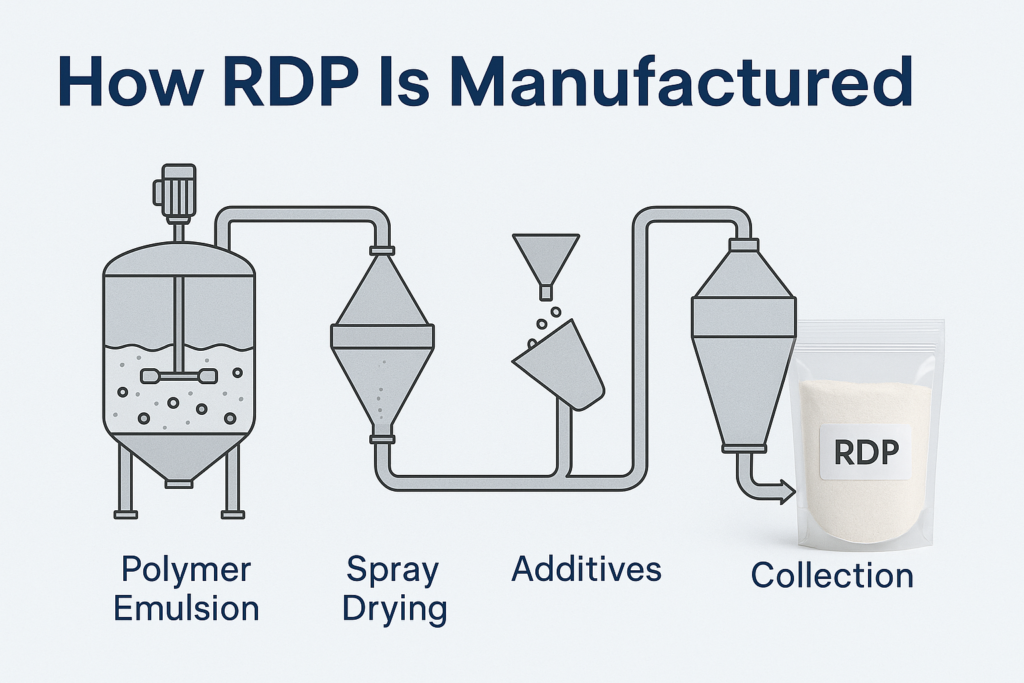

RDP (Redispersible Polymer Powder2) is a water-soluble powder created by spray-drying polymer emulsions4 that reactivates when mixed with water, forming a flexible polymer film that significantly enhances cement-based materials' performance, flexibility, and adhesion properties.

RDP works through a fascinating process. When added to mortar or cement mixtures and combined with water, these polymer particles disperse throughout the mixture. As water evaporates during the curing process, the polymers form a continuous film that interlocks with cement particles, creating a matrix with both flexibility and strength.

The chemistry behind RDP involves primarily vinyl acetate-ethylene5 (VAE) copolymers, though other formulations like styrene-acrylic and pure acrylics exist for specific applications. Each type offers unique properties that can be matched to different construction needs.

Types of RDP Available for Construction Projects

RDP comes in several varieties, each designed for specific applications:

| RDP Type | Main Components | Best For | Special Properties |

|---|---|---|---|

| VAE-based | Vinyl acetate-ethylene | General mortars, tile adhesives | Good balance of flexibility and strength |

| Acrylic-based | Acrylic polymers | Exterior applications | Excellent UV and weather resistance |

| Styrene-acrylic | Styrene and acrylic | Waterproofing applications | Superior water resistance |

| Specialized blends | Custom formulations | Specific performance needs | Tailored properties for unique requirements |

The development of RDP represents one of the most significant advancements in modern construction materials technology, allowing builders to overcome many limitations of traditional cement-based products.

What Are The Top Benefits of Using RDP In Your Construction Projects?

Pain point: Construction projects frequently suffer from poor material performance, leading to early deterioration, water damage, and structural failures.

RDP powder provides ten key benefits: improved adhesion, flexibility, reduced cracking, water resistance, freeze-thaw stability, workability enhancement, extended open time, better impact resistance, reduced material shrinkage, and increased durability in various environmental conditions.

The benefits of RDP go far beyond what most contractors initially understand. Let me expand on these advantages based on both technical research and my experience with countless construction projects across diverse climates and conditions.

Improved Adhesion & Bonding Strength

RDP dramatically improves the adhesion capabilities of mortars and cements. This enhanced bonding occurs because the polymer forms bridges between the substrate and the mortar, creating mechanical interlocking and chemical bonding simultaneously.

In practical terms, this means tile installations that previously might have failed within months or years now remain firmly attached for decades. For external wall insulation systems, improved adhesion prevents delamination even under extreme weather conditions.

Testing data from our labs shows adhesion strength improvements of 30-150% compared to non-modified mortars, depending on the substrate and RDP concentration. This translates directly to fewer callbacks and warranty claims for contractors.

Flexibility & Crack Resistance

One of the most valuable properties RDP imparts is flexibility. Standard cement-based materials are notoriously brittle, but RDP-modified materials can accommodate structural movements, thermal expansion, and contraction without cracking6.

This is particularly important for:

- Facades and external surfaces exposed to temperature fluctuations

- Flooring applications subject to foot traffic and vibration

- Waterproofing membranes that must remain intact despite substrate movement

The polymer film's ability to elongate under stress before returning to its original position gives modified mortars and cements a cushioning effect that prevents the micro-cracks that eventually lead to structural failures.

How to Use RDP In Construction Projects For Maximum Benefit?

Pain point: Improper use of construction additives can waste money and actually decrease material performance, leaving builders confused about correct application methods.

To use RDP effectively, add it to dry mortar ingredients before mixing with water, typically at 1-5% by weight for general applications and 3-8% for specialized uses like tile adhesives7 or waterproofing mortars, following manufacturer-recommended proportions.

The successful application of RDP in construction projects depends heavily on proper integration into mortar or cement formulations. I've seen many projects fall short of their potential because of improper mixing procedures or incorrect dosage levels. Here's what you need to know to get it right:

Mixing Procedures for Different Applications

The mixing sequence significantly impacts RDP performance. For best results, always add RDP to the dry components first, ensuring thorough distribution before introducing water. This prevents the formation of polymer lumps that can compromise performance.

For tile adhesives7, the recommended procedure includes a two-stage mixing process:

- Mix the dry components (cement, sand, RDP, and other additives) thoroughly

- Add approximately 70% of the required water and mix for 2-3 minutes

- Add the remaining water gradually while continuing to mix until achieving the desired consistency

- Allow the mixture to stand for 3-5 minutes (called "slaking time")

- Briefly remix before application

For self-leveling compounds8, higher shear mixing equipment is often necessary to fully activate the RDP and other additives. The water temperature also matters – using water between 15-25°C (59-77°F) generally produces optimal results.

Dosage Recommendations by Application Type

The amount of RDP needed varies significantly based on the application:

| Application | Recommended RDP Dosage (% by weight) | Critical Performance Factors |

|---|---|---|

| Tile adhesives | 3-6% | Adhesion strength, slip resistance, open time |

| Repair mortars | 2-5% | Crack resistance, adhesion to old substrates |

| Waterproofing membranes | 5-10% | Water resistance, flexibility, crack-bridging ability |

| Self-leveling compounds | 1-3% | Flow properties, surface smoothness |

| External wall insulation | 2-4% | Adhesion, weather resistance, durability |

| Joint fillers | 3-7% | Flexibility, water resistance, color stability |

It's important to note that higher dosages aren't always better. Excessive RDP can lead to decreased compressive strength, extended setting times, or unnecessarily high costs. Starting with the manufacturer's recommended dosage and adjusting based on site-specific testing is the best approach.

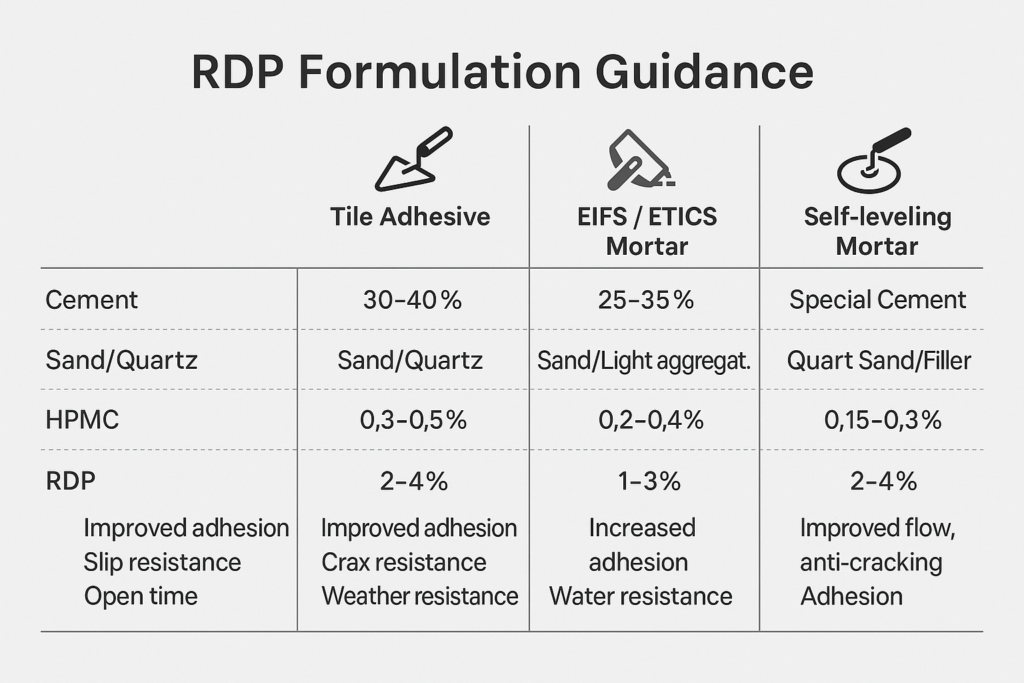

What's The Best RDP Formulation Guidance for Different Projects?

Pain point: Selecting the wrong RDP formulation for a specific application can lead to material failure, wasted resources, and project delays.

Choose RDP formulations based on your application: VAE types for interior work, acrylic-based for exterior weatherproofing, styrene-acrylic for wet areas, anti-sagging variants for vertical applications, and specialized grades for extreme conditions like freeze-thaw environments.

Creating the optimal RDP formulation for a specific construction project involves understanding both the performance requirements and the environmental conditions the material will face. At Kehao, we've developed extensive expertise in tailoring RDP formulations for diverse applications around the world.

Matching RDP Type to Environmental Conditions

The environment where the construction material will be used significantly impacts RDP selection. Through years of field testing across different climates, I've observed these patterns of performance:

For hot, dry climates like those in Saudi Arabia or UAE, RDP formulations with higher glass transition temperatures and improved water retention properties are essential. These prevent premature drying and ensure proper polymer film formation despite rapid water evaporation.

In humid tropical environments like Vietnam or the Philippines, mold-resistant RDP formulations with enhanced wet adhesion properties perform best. These prevent biological growth while maintaining adhesion even when applied to damp substrates.

For areas with freeze-thaw cycles, specialized RDP formulations with elongation properties that remain stable at low temperatures are critical. Standard RDPs can become brittle in cold conditions, negating their crack-resistance benefits precisely when they're most needed.

Compatibility with Other Additives

Modern construction materials rarely contain just one additive. Understanding the interaction between RDP and other common additives is crucial for optimal performance:

| Additive Type | Compatibility with RDP | Optimization Notes |

|---|---|---|

| Cellulose ethers (HPMC) | Highly compatible | Enhances water retention, improves workability |

| Air entrainers | Generally compatible | May require dosage adjustments to maintain proper air content |

| Superplasticizers | Compatibility varies | Test specific combinations; some can destabilize RDP |

| Accelerators | Compatible with limitations | May affect polymer film formation if setting is too rapid |

| Hydrophobic agents | Compatibility depends on type | Silicone-based agents may interfere with RDP film formation |

At Kehao, our technical team regularly conducts compatibility testing to ensure our RDP products work effectively with the full range of additives used in modern construction materials.

Conclusion

RDP powder transforms ordinary construction materials1 into high-performance building solutions, offering improved flexibility, adhesion, water resistance and durability. By selecting the right formulation and following proper application techniques, you'll achieve superior results that stand the test of time.

-

Learn about materials that withstand the test of time and environmental challenges. ↩ ↩ ↩

-

Explore how RDP enhances construction materials, improving performance and durability. ↩ ↩

-

Understand the role of adhesion in ensuring long-lasting construction. ↩

-

Understand how polymer emulsions enhance the properties of construction materials. ↩

-

Discover the applications and benefits of VAE in modern construction. ↩

-

Learn effective strategies to minimize cracking in your projects. ↩

-

Get insights on effective tile adhesive applications for lasting results. ↩ ↩

-

Find guidance on selecting the best self-leveling compounds for various applications. ↩