Are cold walls driving up your heating bills? Touching your walls in winter shouldn't feel like touching ice. Insulating mortar offers an effective solution for those seeking comfort without extensive renovations.

Insulating mortar1 is a specialized building material designed to improve thermal efficiency by creating a barrier that reduces heat transfer through walls. It combines traditional mortar components with lightweight thermal insulators like perlite, vermiculite, or EPS beads to maintain comfortable indoor temperatures.

Many homeowners struggle with energy inefficiency without realizing the walls themselves might be the culprit. Let's explore how insulating mortar works and why it might be the solution you've been looking for.

What Is Insulating Mortar and What Is It Used For?

I've seen many clients puzzled by persistently cold homes despite running heaters continuously. Their walls were literally sucking heat away, creating uncomfortable living spaces and inflated energy bills.

Insulating mortar1 is a specialized cement-based compound containing thermal insulation additives that significantly reduce heat transfer through walls. It's primarily used for interior and exterior wall applications where thermal efficiency is needed without sacrificing structural integrity or significantly altering wall dimensions.

Insulating mortar serves multiple purposes in modern construction. As a factory owner with extensive experience in building materials, I've witnessed its growing popularity across various climates and building types.

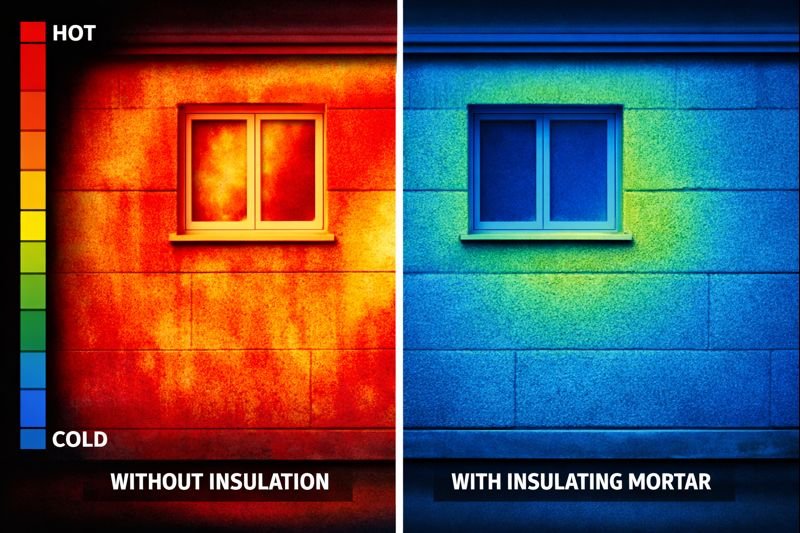

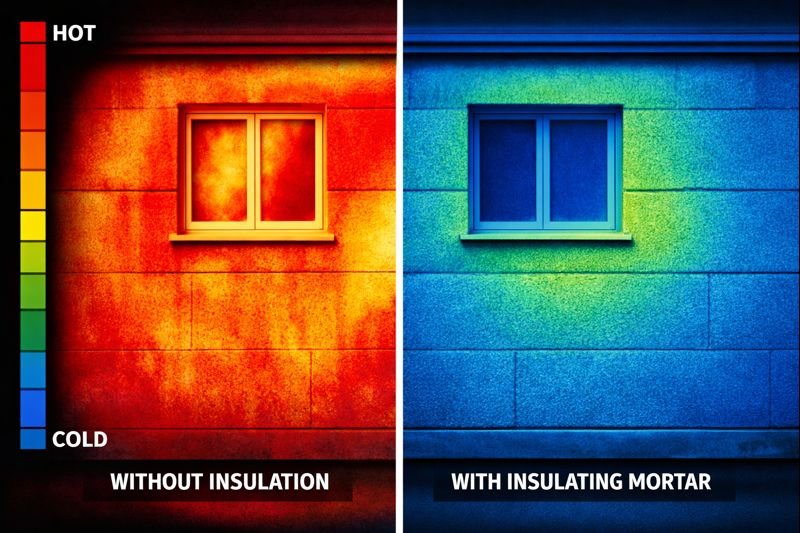

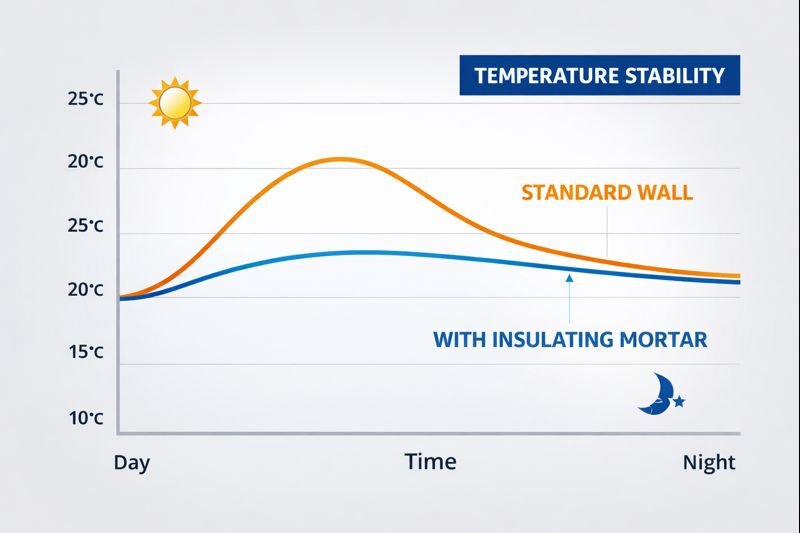

The most obvious benefit is improved thermal insulation. When applied to either internal or external walls, insulating mortar creates a thermal barrier that keeps warm air inside during winter and outside during summer. This translates to noticeable energy savings—typically 15-30% on heating costs, depending on the building's construction and climate zone.

Unlike conventional insulation methods that may require major renovations, insulating mortar can be applied directly to existing surfaces. This makes it ideal for retrofitting older buildings where installing traditional insulation would be impractical or too expensive. It's particularly valuable in historical buildings where preserving architectural features is essential.

Beyond thermal benefits, quality insulating mortar also contributes to:

- Sound dampening between rooms

- Prevention of thermal bridges

- Reduction in condensation and mold growth

- Improved overall comfort without sacrificing living space

Application Methods:

| Method | Thickness | Best For |

|---|---|---|

| Trowel application | 10-25mm | Small areas, detailed work |

| Spray application | 15-50mm | Large surface areas, faster application |

| Pre-mixed panels | 30-100mm | Modular construction, uniform results |

What Is Insulating Mortar?

I remember walking into a century-old brick home in January—outside was freezing, inside wasn't much better despite the heating running full blast. The walls felt like ice to touch, becoming massive heat sinks.

Insulating mortar1 is a specialized building material that combines traditional mortar components with thermally insulating aggregates like expanded polystyrene beads, perlite, or vermiculite. These materials create millions of tiny air pockets that significantly reduce thermal conductivity while maintaining workability and adhesion.

Insulating mortar differs fundamentally from regular mortar in both composition and purpose. Standard mortar primarily provides structural bonding between building elements, while insulating mortar adds the critical function of thermal regulation.

The science behind this material is fascinating. Thermal conductivity is measured using a value called lambda (λ), expressed in W/mK (watts per meter-kelvin). Lower values indicate better insulation properties. While standard cement mortar has a λ-value around 1.0-1.8 W/mK, quality insulating mortars achieve values between 0.045-0.09 W/mK—up to 20 times more effective at preventing heat transfer.

During my factory visits across Europe, I've seen considerable innovation in this field. The most effective insulating mortars combine multiple insulating materials to create a synergistic effect. For instance, some premium products incorporate both expanded perlite for structural stability and aerogel particles for superior thermal performance.

These materials can be applied in varying thicknesses depending on the insulation requirements, though most applications range from 10mm to 50mm. Thicker applications provide better insulation but require more specialized application techniques to prevent cracking or sagging during the curing process.

The key technical advantage of quality insulating mortar is its ability to create a continuous thermal envelope without the cold bridges often found with panel insulation systems where gaps might exist between panels.

What Does It Do?

I visited a client's newly renovated home last summer where insulating mortar had been applied just months earlier. Inside was pleasantly cool despite the scorching heat outdoors, and their energy bills had dropped dramatically.

Insulating mortar creates a thermal barrier that prevents heat transfer through walls, maintaining comfortable indoor temperatures year-round. It works by trapping air in millions of microscopic pockets, greatly reducing thermal conductivity and minimizing energy loss while preventing condensation and mold growth.

The functionality of insulating mortar extends far beyond basic temperature regulation. Through my experience working with various construction projects across different climate zones, I've observed multiple performance advantages that make this material increasingly popular among architects and builders.

Insulating mortar addresses a fundamental building physics challenge: thermal bridging. In conventional construction, even small gaps in insulation can create pathways for significant heat loss. By applying insulating mortar as a continuous layer, these thermal bridges are effectively eliminated. This continuous thermal envelope is particularly valuable in complex architectural designs with numerous corners, joints, and penetrations that would be difficult to insulate using traditional methods.

Moreover, insulating mortar helps regulate humidity within wall structures. By maintaining warmer interior wall surfaces, the dew point (temperature at which condensation occurs) is pushed outward, reducing the risk of interstitial condensation within the wall. This moisture management capability significantly extends the lifespan of the building structure by preventing the growth of mold and decay of building materials.

| In quantifiable terms: | Benefit | Typical Performance |

|---|---|---|

| Thermal conductivity reduction | 70-90% compared to standard mortar | |

| Energy savings | 15-30% on heating/cooling costs | |

| Surface temperature increase | 4-8°C warmer wall surface in winter | |

| Sound reduction | 3-6 dB improvement in transmission loss |

What Is Insulated Mortar Made Of?

I remember touring a materials research facility where scientists were testing different insulating mortar formulations. The variety of ingredients surprised me, each chosen for specific performance characteristics rather than simply cost.

Insulating mortar consists of Portland cement or lime binders mixed with thermal insulating aggregates such as expanded polystyrene beads, perlite, vermiculite, or aerogel. These are supplemented with cellulose ethers2 like HPMC for workability, resins for adhesion, and fibers for strength.

The composition of insulating mortar represents a carefully engineered balance between thermal efficiency, structural integrity, and application properties. After examining countless formulations in our laboratory and production facilities, I've gained deep insights into how these materials work together.

The foundation of any insulating mortar is its binder system. Portland cement remains the most common option, though hydraulic lime is gaining popularity for its breathability and compatibility with historic structures. These binders provide the structural strength and adhesion necessary for wall applications.

What transforms ordinary mortar into an insulating material are the specialized aggregates, which typically make up 50-80% of the volume:

-

Expanded Polystyrene (EPS) beads: These lightweight spheres contain 98% trapped air, creating excellent insulation properties. We typically use beads sized between 1-4mm with densities of 15-30 kg/m³.

-

Expanded perlite: This volcanic glass expanded through heat treatment creates porous, lightweight particles with excellent fire resistance and thermal properties.

-

Vermiculite: Heat-expanded mineral that forms accordion-like particles, trapping air while providing some structural strength.

-

Aerogel: The premium option, these silicon-based materials offer the lowest thermal conductivity of any solid (as low as 0.013 W/mK).

Additionally, high-quality insulating mortars incorporate essential additives:

| Additive Type | Purpose | Key Example |

|---|---|---|

| Cellulose ethers | Water retention, workability | Hydroxypropyl methylcellulose (HPMC) |

| Redispersible polymers | Flexibility, adhesion | Vinyl acetate-ethylene (VAE) powders |

| Fibers | Crack resistance | Polypropylene microfibers |

| Water repellents | Moisture resistance | Silicone-based hydrophobing agents |

What Affects the Performance of Insulated Mortar?

I once conducted a side-by-side test of two seemingly identical insulating mortar mixes in different conditions. The results shocked my client—one outperformed the other by nearly 40% simply due to differences in application thickness and ambient humidity.

The performance of insulating mortar is primarily affected by its formulation, application thickness, installation quality, moisture exposure, and aging. The type and proportion of insulating aggregates, proper mixing techniques, and appropriate curing conditions are crucial for achieving optimal thermal efficiency.

Understanding the variables that affect insulating mortar performance has been crucial in helping our clients achieve optimal results. Through extensive testing and field experience, I've identified several critical factors that building professionals must consider.

Formulation balance is perhaps the most fundamental consideration. While increasing the proportion of lightweight insulating aggregates improves thermal performance, it simultaneously decreases mechanical strength. Premium insulating mortars achieve an optimal balance, typically containing 60-70% insulating aggregates by volume without compromising structural integrity.

Application thickness follows a non-linear relationship with thermal resistance. For example, doubling the thickness from 20mm to 40mm doesn't simply double the insulating effect—due to the physics of heat transfer, the improvement may only be 70-80% better. This diminishing return must be weighed against increased material costs and potential application challenges.

Environmental conditions during application significantly impact long-term performance. I've observed projects where mortar applied in high humidity conditions (>75% RH) exhibited up to 25% higher thermal conductivity than identical material applied under optimal conditions. This occurs because excess moisture trapped during curing disrupts the micrometric air pocket structure critical for insulation.

Aging and weathering effects must also be considered:

- UV exposure can degrade certain polymeric components

- Repeated freeze-thaw cycles can cause microcracking

- Moisture infiltration can gradually reduce insulating properties

To mitigate these effects, quality insulating mortars incorporate:

- UV-resistant additives for exterior applications

- Hydrophobic agents to repel water while maintaining vapor permeability

- Microfibers to prevent crack propagation during thermal cycling

The application technique itself is equally important. Spray application generally achieves more consistent results than manual troweling, particularly over large areas, by ensuring uniform density and minimizing compression of insulating particles.

Wanhong – Your Trusted Supplier of Insulating Mortar Additives

In my early days of running the factory, we supplied basic HPMC to a mortar manufacturer who complained about inconsistent performance in their insulating products. After analyzing their formulation, we developed a specialized grade that transformed their product's stability.

At Wanhong, we've specialized in producing high-quality cellulose ethers and other key additives essential for premium insulating mortars. Our hydroxypropyl methylcellulose (HPMC) provides optimal water retention and workability, while our redispersible powder enhances adhesion and flexibility in thermal insulation systems.

With six state-of-the-art production lines and over 15 years of experience serving global markets, Kehao has established itself as a leading supplier of critical chemical additives for the construction industry. Our specialized focus on thermal efficiency materials has made us a preferred partner for insulating mortar manufacturers across developing markets.

Our technical expertise extends beyond simply manufacturing chemicals. We maintain a dedicated R&D department that works directly with customers to optimize formulations for specific climate conditions and application requirements. This collaborative approach has proven particularly valuable in challenging environments like the extreme heat of Saudi Arabia or the monsoon conditions of Southeast Asia.

The cornerstone of our offering for insulating mortar applications is our premium HPMC product line, specifically engineered to provide:

- Extended open time for larger application areas

- Balanced water retention that prevents premature drying while allowing proper curing

- Compatibility with lightweight thermal aggregates including EPS and perlite

- Stable viscosity across varying temperature conditions

We complement this with specially formulated redispersible powders that enhance adhesion to difficult substrates and improve the mortar's resistance to thermal cycling. Our technical experts routinely help customers determine the optimal combination of:

| Product | Function in Insulating Mortar | Recommended Dosage |

|---|---|---|

| HPMC K-series | Water retention, workability | 0.2-0.4% |

| RDP K-series | Flexibility, adhesion | 1-3% |

| Cellulose Fibers | Crack resistance | 0.1-0.2% |

We understand the challenges facing building material manufacturers in developing markets, from raw material consistency to technical support. That's why we offer not just quality products but comprehensive support including formulation assistance, quality control guidance, and ongoing technical service.

Conclusion

Insulating mortar offers an impressive solution to cold walls and energy inefficiency, combining ease of application with significant thermal benefits. With the right additives from a reliable supplier like Wanhong, you can create comfortable spaces while reducing energy costs.