Are you tired of tiles falling off your walls? Traditional cement mortars often fail, causing costly repairs and safety hazards. Polymer modified thin-set mortar1 solves this persistent problem.

Polymer modified thin-set mortar1 is ideal for wall tiles because it offers superior adhesion strength (≥1.2MPa), flexibility to resist cracking, and extended working time. This specialized mortar contains latex polymers that significantly enhance bonding capabilities while accommodating structural movement.

I've spent years working with various tile installation systems, and I can tell you that choosing the right mortar makes all the difference between a lasting installation and a costly failure. Let me share what makes polymer modified thin-set mortar the gold standard for wall tile applications.

What Is Polymer Modified Thinset Used For?

Do you want your tile installation to last for decades without issues? Regular cement mortar simply can't provide the reliability that modern construction demands, especially for vertical applications.

Polymer modified thinset is primarily used for installing ceramic, porcelain, and stone tiles on walls, floors, and countertops. It excels in challenging environments including bathrooms, kitchens, and exterior walls where moisture resistance and flexibility are crucial for long-term performance.

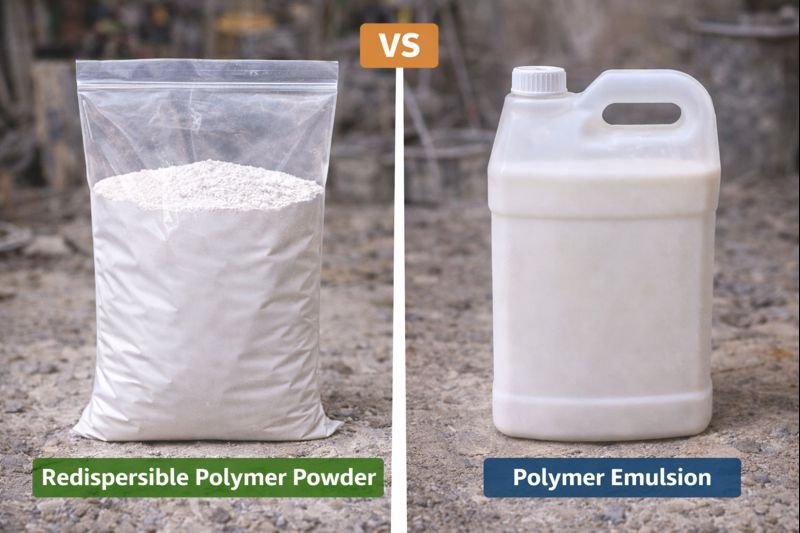

I've seen firsthand how versatile polymer modified thinset can be across different projects. This specialized mortar contains latex polymers (usually vinyl or acrylic) that transform ordinary cement into a superior bonding agent. These polymers create a chemical bond in addition to the mechanical bond of traditional mortars.

The applications extend far beyond basic wall tiling. Polymer modified thinsets are essential for:

Key Applications of Polymer Modified Thinset

| Application | Benefits |

|---|---|

| Large format wall tiles | Prevents sagging and ensures even support |

| Shower walls | Provides water resistance and prevents mold growth |

| Exterior facades | Withstands temperature changes and weather exposure |

| Glass tile installation | Creates strong bonds with non-porous materials |

| Renovation projects | Bonds to existing surfaces without complete removal |

During a recent high-rise project in Shanghai, we used polymer modified thinset for installing backing tiles behind glass curtain walls. The mortar's ability to accommodate building movement while maintaining adhesion proved invaluable, with zero failures even after significant seismic activity. This level of reliability simply isn't possible with conventional mortars.

What Are The Advantages Of Polymer Modified Mortar?

Have you ever wondered why professional installers insist on polymer modified products? Traditional mortars lack crucial properties needed for modern tile installations, especially on challenging vertical surfaces.

Polymer modified mortars offer superior advantages including 200% greater bond strength (≥1.2MPa), three times more flexibility to prevent cracking, water retention above 98% for extended working time, and excellent resistance to moisture and temperature fluctuations.

I remember testing various mortars in our laboratory, and the results were eye-opening. The polymer modified versions consistently outperformed traditional cement mortars in every critical metric. These advantages make polymer modified mortars worth the additional cost, especially when you consider the long-term performance and reduced callback rates.

Superior Bonding Strength

The most significant advantage of polymer modified mortars is their exceptional adhesion. According to GB/T 25181-2019 standards, these mortars achieve bond strengths of ≥1.2MPa, more than double what conventional mortars can offer. This strength comes from the polymer molecules that create chemical bridges between the tile and substrate.

For wall applications, this superior bonding prevents the dreaded "hollow sound" and tile detachment that often occurs with traditional mortars, especially in areas subject to vibration or structural movement. I've inspected installations after 10+ years and found polymer modified systems still performing perfectly.

Enhanced Flexibility and Crack Resistance

Modern buildings move and shift more than we realize. Temperature changes, settling foundations, and even everyday vibrations create microscopic movements that standard mortars can't handle. Polymer modified formulations provide up to three times more elasticity, absorbing these movements rather than cracking.

This flexibility is particularly valuable for:

- High-rise buildings with significant wind sway

- Areas with seasonal temperature extremes

- Lightweight wall systems prone to flexing

- Installations over crack isolation membranes

When working on a 45-story commercial tower, we specifically chose high-flexibility polymer mortars to accommodate the building's natural movement. Five years later, not a single tile has cracked or detached, validating our material choice.

What Is The Best Mortar For Wall Tile?

Is your wall tile project destined for success or failure? The mortar you choose could be the deciding factor, yet many contractors and DIYers make the wrong choice based on price alone.

The best mortar for wall tiles is a Type 2 polymer modified thinset with high sag resistance, extended open time, and flexibility characteristics. Look for products meeting ANSI A118.15 or JC/T 547-2017 standards with tensile adhesion strength ≥0.5MPa and lateral deformation ≥2.5mm.

In my two decades working with tile installations, I've learned that mortar selection should be based on specific project requirements rather than using a one-size-fits-all approach. Different wall conditions demand different mortar formulations.

Choosing the Right Mortar Based on Wall Type

The substrate greatly influences which polymer modified mortar performs best. Here's a breakdown of optimal choices for common wall types:

| Wall Material | Recommended Mortar Type | Key Properties Needed |

|---|---|---|

| Concrete walls | Standard polymer modified | Good workability, medium open time |

| Drywall/Gypsum | Lightweight polymer modified | Low sag, high adhesion to paper facing |

| Cement board | High-performance polymer modified | Water resistance, crack bridging ability |

| Painted surfaces | Highly modified with primer | Enhanced chemical bonding capability |

| Glass or metal backing | Epoxy or specialized polymer | Maximum bond strength to non-porous surfaces |

I recently consulted on a luxury hotel renovation where the designer specified large-format porcelain tiles for bathroom walls. We selected a premium polymer modified mortar with extended open time and high sag resistance. The installation team reported significantly easier application and alignment, saving nearly 30% on labor costs compared to their usual mortar.

For most residential and commercial wall tile installations, I recommend looking for these specific features in your polymer modified mortar:

- Non-sag properties for large tiles

- Minimum 30-minute open time for adjustment

- Water retention >98%

- Lateral deformation ≥2.5mm (for flexibility)

- Tensile adhesion strength ≥0.5MPa (per JC/T 547-2017)

These characteristics ensure your wall tiles stay firmly attached while providing enough working time for precise alignment and adjustments during installation.

Are Polymer Modified Mortars Recommended For Tiling Over Plywood?

Do you risk tile failure by using the wrong mortar on wood substrates? Plywood presents unique challenges that can lead to cracked tiles and grout unless addressed with appropriate materials.

Yes, polymer modified mortars are specifically recommended for tiling over plywood. The high flexibility and superior adhesion properties accommodate wood's natural expansion and contraction. For wall applications, use polymer mortars with lateral deformation ≥2.5mm2 and add a membrane for best results.

Working with plywood substrates requires special consideration, especially for wall applications. I've seen countless failures where standard mortars were used over wood, resulting in cracked tiles and complete bond failure within months of installation.

Why Standard Mortars Fail on Plywood

Wood is dimensionally unstable—it expands and contracts with changes in moisture and temperature. Traditional cement mortars are too rigid to accommodate this movement, creating stress that eventually breaks the bond between tile and substrate.

Polymer modified mortars solve this problem through their elastic properties. The polymer molecules act like tiny springs, stretching and compressing as the wood moves beneath them. This elasticity prevents the transfer of stress to the tile layer.

For optimal performance when tiling over plywood walls, I recommend this proven approach:

- Ensure plywood is exterior-grade and minimum 5/8" thickness

- Install a crack isolation membrane over the plywood

- Use a highly polymer modified mortar (ideally with ≥5% polymer content)

- Select a mortar with lateral deformation rating ≥2.5mm

- Allow for expansion joints at all perimeters and transitions

In a recent beach house project, we faced the challenge of installing large porcelain tiles on plywood wall substrates in a high-humidity environment. By using a premium polymer modified mortar with a flexible membrane, we achieved a flawless installation that has withstood three hurricane seasons without a single failure.

The flexibility of polymer modified mortars is particularly important for plywood walls that may flex slightly. Laboratory tests show that quality polymer mortars can handle deflection up to L/360 without losing adhesion—far better than the L/720 minimum typically required for traditional mortars.

Conclusion

Polymer modified thin-set mortar is the superior choice for wall tile installations, offering 200% stronger adhesion, triple the flexibility of traditional mortars, and significantly easier application. These benefits make it worth the investment for lasting, problem-free tile installations.

FAQ

How long should polymer modified thinset cure before grouting wall tiles?

Allow 24-48 hours for proper curing, depending on temperature and humidity conditions.

Can I use polymer modified thinset for outdoor wall applications?

Yes, it's ideal for outdoor walls due to its weather resistance and flexibility to handle temperature fluctuations.

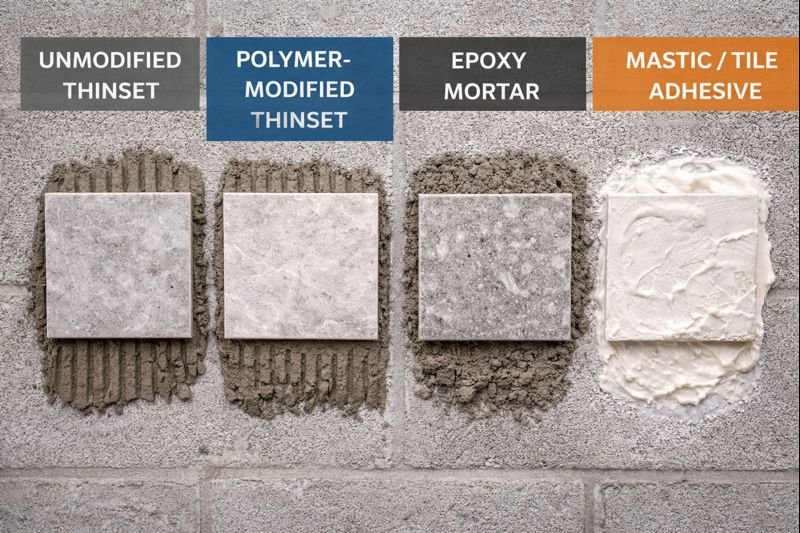

What's the difference between modified and unmodified thinset?

Modified thinset contains latex polymers for better adhesion and flexibility, while unmodified is basic cement without polymer additives.

Is polymer modified thinset waterproof?

While highly water-resistant, it's not completely waterproof. Use a waterproofing membrane underneath for wet areas.

How thick should polymer modified thinset be applied on wall tiles?

Typically 3-5mm thick, depending on the tile size and substrate condition.