Construction delays cost money and damage reputations. When cold weather threatens to slow down cement setting times, you need a reliable accelerator that won't compromise quality or durability.

Calcium formate1 is the optimal cement accelerator2 for construction projects because it speeds up setting time without the corrosive drawbacks of calcium chloride alternatives. It increases early strength development while maintaining long-term durability and works effectively across various temperature conditions.

As a manufacturer with six production lines, I've seen countless projects succeed or fail based on their cement additive choices. Let me share what makes calcium formate the superior choice for your construction needs and why our factory consistently delivers the quality your projects demand.

Why Is Calcium Formate Increasingly Used In Modern Construction?

Project timelines get tighter every year, while quality standards keep rising. Traditional accelerators often create more problems than they solve with their corrosive properties.

Calcium formate1 has emerged as the preferred cement accelerator because it provides effective setting time reduction without the damaging side effects of chloride-based alternatives. It accelerates cement hydration by promoting rapid formation of calcium silicate hydrates while maintaining structural integrity.

The construction industry's shift toward calcium formate represents a critical development in cement technology. Unlike traditional accelerators, calcium formate works through a different chemical mechanism. When added to cement mixtures, it reacts with tricalcium silicate (C3S) and tricalcium aluminate (C3A), which are key compounds in cement. This reaction accelerates the hydration process, causing faster setting and hardening.

What makes calcium formate particularly valuable is its non-corrosive nature. While calcium chloride has been widely used historically, its chloride ions cause reinforcement corrosion in steel-reinforced concrete. This corrosion risk is especially problematic in infrastructure projects where durability is paramount. Calcium formate contains no chloride ions, eliminating this risk entirely.

Additionally, calcium formate offers better compatibility with modern cement formulations. As cement manufacturing evolves with various supplementary cementitious materials like fly ash and slag, calcium formate has shown superior performance across these diverse mixtures. This versatility means contractors can standardize on calcium formate regardless of the specific cement type being used on a project.

What Makes Calcium Formate The Best Accelerator For Concrete Projects?

Cold weather construction deadlines loom while your concrete won't set. The wrong accelerator can lead to weakened structures and costly repairs down the line.

Calcium formate1 excels as a concrete accelerator because it significantly reduces setting time while enhancing early compressive strength development. Unlike alternatives, it maintains long-term durability without introducing harmful elements that can compromise structural integrity.

Calcium formate's superiority extends beyond its non-corrosive properties. One of its most remarkable advantages is its effect on concrete microstructure. When calcium formate accelerates the hydration process, it creates a denser cement paste matrix with refined pore structure. This improved microstructure directly translates to better mechanical properties and enhanced durability.

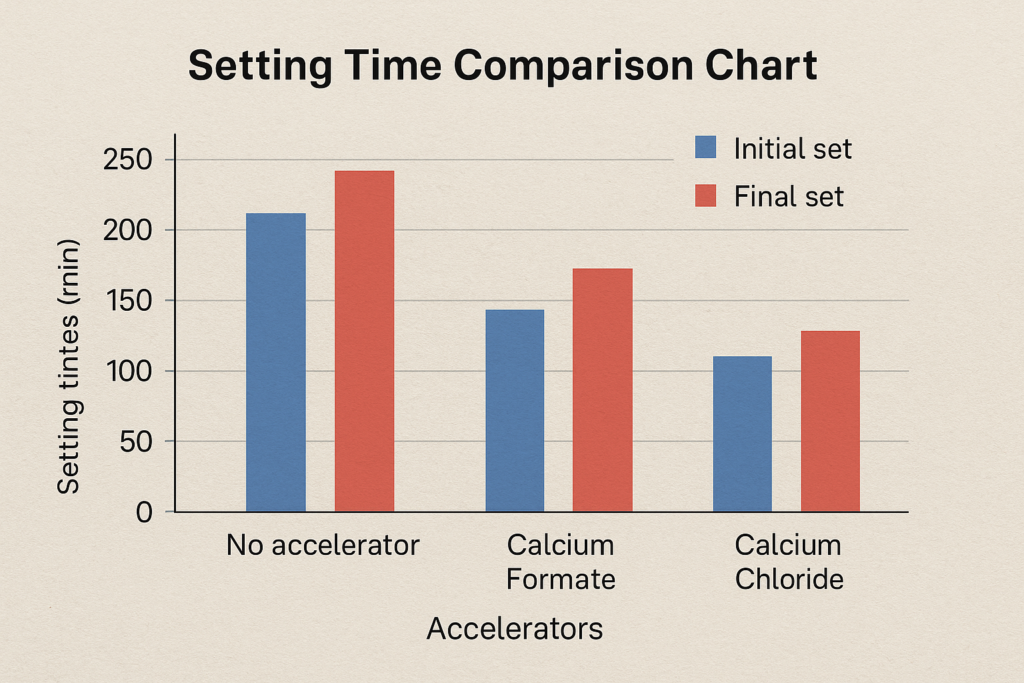

Technical performance data consistently shows calcium formate outperforming other options across critical parameters. In standardized tests, concrete containing calcium formate typically shows 15-25% higher early strength (1-3 days) compared to untreated concrete. This early strength gain is crucial for construction scheduling, allowing for faster formwork removal and shorter project timelines.

Another significant advantage is calcium formate's temperature versatility. While many accelerators lose effectiveness at lower temperatures, calcium formate maintains consistent performance across a wide temperature range (-5°C to 30°C). This makes it exceptionally valuable for projects in variable climate conditions or cold-weather construction where reliable setting time is essential.

Environmental considerations also favor calcium formate. It has a substantially lower carbon footprint compared to traditional accelerators like calcium chloride, which require energy-intensive manufacturing processes. As construction regulations increasingly focus on sustainability metrics, calcium formate offers compliance advantages that benefit both contractors and project owners.

What Are The Top 5 Calcium Formate Highlights Every Constructor Should Know?

Choosing the wrong cement additives leads to project failures, structural defects, and wasted resources. Many constructors remain unaware of calcium formate's full potential.

The five most important benefits of calcium formate are: non-corrosive formula safe for reinforced concrete, significant acceleration of setting time (30-50%), enhanced early strength development, compatibility with various cement types, and excellent performance in cold weather conditions.

Let's examine each of these key benefits in greater technical detail to understand why calcium formate has become indispensable in modern construction:

Non-Corrosive Properties

The non-corrosive nature of calcium formate represents perhaps its most critical advantage. Unlike chloride-based accelerators that initiate and accelerate steel corrosion, calcium formate is completely chloride-free. In laboratory testing, reinforced concrete specimens containing calcium formate show virtually identical corrosion resistance to control samples without accelerators, even after accelerated aging tests. This makes it suitable for use in critical infrastructure like bridges, marine structures, and high-rise buildings where structural longevity is non-negotiable.

Setting Time Acceleration

Calcium formate typically reduces setting times by 30-50% depending on dosage and ambient conditions. This acceleration occurs through enhanced dissolution of cement minerals and accelerated formation of ettringite and calcium silicate hydrate gel. The practical benefit is that concrete can achieve final set in 2-3 hours rather than 4-6 hours under normal conditions, allowing construction teams to finish concrete surfaces earlier and proceed with subsequent construction activities faster.

Early Strength Development

The early strength enhancement provided by calcium formate is particularly valuable for precast concrete manufacturing, where rapid turnover of forms is economically important. At recommended dosages (1-3% by weight of cement), calcium formate typically delivers 20-30% higher compressive strength at 24 hours compared to untreated mixes. This early strength gain comes without sacrificing ultimate strength at 28 days, which distinguishes calcium formate from some other accelerators that boost early strength at the expense of long-term performance.

Wide Compatibility

Calcium formate demonstrates excellent compatibility with diverse cement types including Portland cement, Portland limestone cement, and cements containing supplementary cementitious materials like fly ash and slag. It also works harmoniously with other concrete admixtures like water reducers, superplasticizers, and air-entraining agents, making it easy to incorporate into existing mix designs without causing unexpected interactions or performance issues.

Cold Weather Performance

When temperatures drop below 10°C, normal concrete setting and strength development slow dramatically. Calcium formate1 maintains its accelerating effectiveness even at temperatures approaching freezing, allowing construction to proceed during cold seasons. This cold-weather resilience extends the construction season in many regions, providing significant economic benefits to contractors and project owners alike.

How Does Wanhong Support Your Cement Success With Premium Calcium Formate?

Finding reliable suppliers who deliver consistent quality can be challenging. Many manufacturers cut corners, leading to unpredictable performance and project delays.

Wanhong provides superior calcium formate with 98% minimum purity, consistent particle size distribution, and rigorous quality control. Our six production lines ensure reliable supply chain stability, while our technical support team helps optimize your specific applications.

At Wanhong, our commitment to calcium formate excellence goes beyond simply manufacturing a chemical product. Our production process incorporates several proprietary refinements that yield a product with significantly fewer impurities than industry standards. This heightened purity directly translates to more predictable performance in your cement applications.

Our production capacity across six specialized lines allows us to maintain strict segregation between product types, eliminating cross-contamination concerns that plague many multi-product chemical factories. Each production batch undergoes comprehensive testing including XRF spectroscopy, particle size distribution analysis, and application-specific performance testing3 in concrete samples.

What truly distinguishes Wanhong is our technical partnership approach. Rather than simply supplying a commodity, our technical service team works directly with customers to optimize dosage rates based on your specific cement chemistry, ambient conditions, and performance requirements. This collaborative approach has helped customers reduce their effective calcium formate usage by up to 15% while maintaining or improving performance outcomes.

Our global supply chain expertise ensures timely delivery to over 30 countries, with specialized packaging options designed for different climate conditions during transport. For customers in hot, humid regions like Saudi Arabia or UAE, our moisture-resistant packaging prevents clumping and maintains product efficacy even after extended storage periods. For cold-weather destinations, we offer specialized packaging that prevents freezing and agglomeration during transportation.

What Are The Amazing Highlights That Make Wanhong Calcium Formate Superior?

Inferior calcium formate leads to inconsistent results and wasted material. Many suppliers lack the technical expertise to help you optimize usage for your specific applications.

Wanhong calcium formate delivers superior performance through our 98.5%+ purity levels, specialized particle size control for optimal dissolution, technical application support4, comprehensive quality certifications, and cost-effective bulk purchasing options with reliable global logistics.

The exceptional quality of Wanhong calcium formate stems from several technical and operational advantages we've developed over decades of specialization:

Our proprietary purification process removes trace contaminants that can interfere with cement hydration kinetics. While standard industrial calcium formate typically contains 96-97% purity, Wanhong consistently achieves 98.5%+ purity. This higher purity directly translates to more predictable performance and allows for more precise dosage calculations.

Particle size distribution significantly impacts dissolution rate and ultimately affects setting time consistency. Wanhong employs advanced micronization and classification technology to achieve a controlled particle size profile optimized specifically for cement applications. Our standard grade maintains 95% of particles between 75-150 μm, while our premium grade offers an even tighter distribution for the most demanding applications.

Our in-house R&D laboratory continuously tests calcium formate performance across various cement formulations. This research has led to application-specific grades tailored for particular challenges – such as our "ColdSet" formula with enhanced nucleation promoters for extreme cold weather conditions and our "PreCast" grade optimized for maximum early strength development in precast applications.

Wanhong's quality management system integrates full traceability from raw material to finished product. Each production batch receives a unique identifier linked to comprehensive test data, and customers can access this information through our digital certificate system. This transparency provides assurance that every shipment meets the exact specifications your project requires.

Finally, our integrated production ecosystem creates significant sustainability advantages. By recovering heat energy and byproducts from our main production processes, we've reduced the carbon footprint of our calcium formate by approximately 22% compared to industry averages, helping our customers meet increasingly important environmental performance targets.

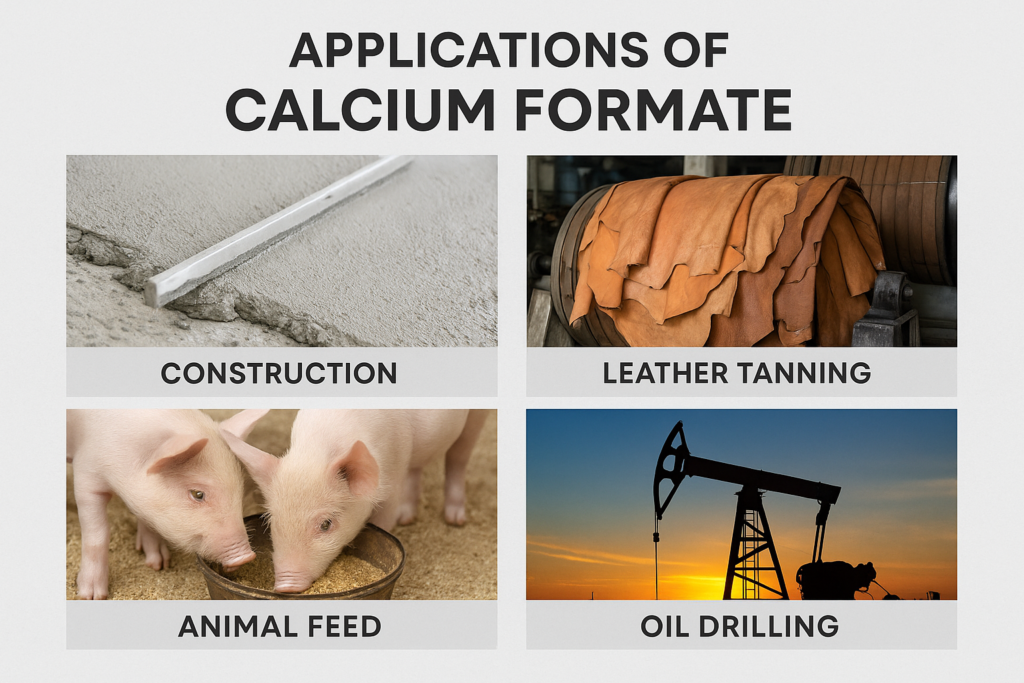

What Other Applications Can Benefit From High-Quality Calcium Formate?

Limiting calcium formate to just cement acceleration means missing valuable opportunities in other applications. Many potential uses go unexplored due to lack of awareness.

Beyond cement, calcium formate serves as an effective snow-melting agent, leather tanning auxiliary, feed preservative, silage additive, and scale inhibitor in water treatment. Its versatility makes it valuable across multiple industries requiring calcium supplementation or formate functionality.

The versatility of calcium formate[^5] extends far beyond construction applications, with each alternative use leveraging different aspects of its chemical properties:

In snow and ice melting applications, calcium formate offers significant advantages over traditional chloride-based deicers. It operates effectively at temperatures as low as -15°C while causing substantially less corrosion damage to vehicles, infrastructure, and vegetation. Municipal authorities in environmentally sensitive areas increasingly specify calcium formate for bridge decks and protected zones where minimizing environmental impact is crucial. Our specially formulated deicer grade features enhanced hygroscopicity and optimized crystal structure for faster ice penetration.

The leather industry utilizes calcium formate in several processing stages. During tanning, it serves as a basification agent that helps control pH progression while promoting chromium fixation in the leather fibers. This results in improved leather quality with enhanced fullness and better dye uptake. Our ultra-pure grade for leather applications contains minimal iron content (<10ppm) to prevent unwanted leather discoloration.

In animal nutrition, calcium formate serves dual purposes as both a calcium supplement and a preservative. Its antimicrobial properties inhibit the growth of harmful bacteria in feed and silage, extending shelf life while simultaneously providing bioavailable calcium. Studies have demonstrated improved feed conversion ratios when calcium formate is incorporated into poultry and swine diets at appropriate levels. Our feed-grade product meets stringent regulatory requirements for feed additives in all major markets.

Water treatment systems benefit from calcium formate's ability to prevent scale formation in pipes and equipment. When used in cooling water systems, it helps maintain heat transfer efficiency by inhibiting calcium carbonate precipitation. Unlike phosphate-based scale inhibitors, calcium formate is biodegradable and contributes minimal nutrient loading to waterways, making it environmentally preferable in many jurisdictions.

The pharmaceutical and food industries utilize pharmaceutical-grade calcium formate1 as a mineral supplement and food preservative. Its excellent solubility and bioavailability make it an effective calcium source in nutritional formulations, while its preservative properties help extend shelf life in certain food products where formic acid derivatives are permitted preservatives.

Conclusion

Calcium formate stands as the superior choice for cement acceleration, offering faster setting times without the drawbacks of traditional accelerators. With Wanhong's premium product and technical support, you can achieve optimal concrete performance while expanding into diverse application opportunities.

-

Explore the diverse applications of calcium formate and discover how it can enhance performance across multiple industries. ↩ ↩ ↩ ↩ ↩

-

Learn about the role of cement accelerators in construction and their impact on project timelines. ↩

-

Understand the importance of performance testing in ensuring material quality and reliability. ↩

-

Learn how technical support can optimize the use of construction materials for better results. ↩