When temperatures drop, my construction clients panic about their concrete projects. Cold weather can stop cement hydration, leading to weak structures and costly repairs later.

Yes, concrete can cure in cold weather, but it requires special care. The hydration process slows significantly below 50°F (10°C), and nearly stops below 40°F (4°C). Special techniques like heated enclosures, insulation blankets, and chemical additives are essential to maintain proper curing temperatures.

I've learned from decades in concrete manufacturing that understanding cold weather concrete curing isn't just technical knowledge—it's essential for project success. Let's explore the science behind concrete curing and how to manage it when temperatures drop.

What Happens During The Concrete Curing Process?

I've seen countless projects fail because people don't understand that pouring concrete isn't the finish line. The chemical reaction between cement and water needs proper conditions or strength development stops.

Concrete curing1 is a chemical process where cement reacts with water (hydration) to form crystals that bind aggregate materials together. This reaction generates heat and requires time to develop optimal strength, with the first 48 hours being most critical for proper crystal formation.

The curing process is fascinating when you look closer. During hydration, calcium silicates in cement react with water to form calcium silicate hydrate (C-S-H) gel and calcium hydroxide. This reaction generates heat (exothermic) and creates the "glue" that holds concrete together.

Critical Stages of Concrete Curing

| Curing Stage | Timeframe | Strength Development | Sensitivity to Cold |

|---|---|---|---|

| Initial Set | 1-4 hours | Begins to harden | Extremely high |

| Final Set | 4-8 hours | No longer plastic | Very high |

| Early Strength | 1-3 days | 30-50% of design strength | High |

| Continued Hardening | 3-7 days | 60-80% of design strength | Moderate |

| Final Curing | 28+ days | 100% of design strength | Low |

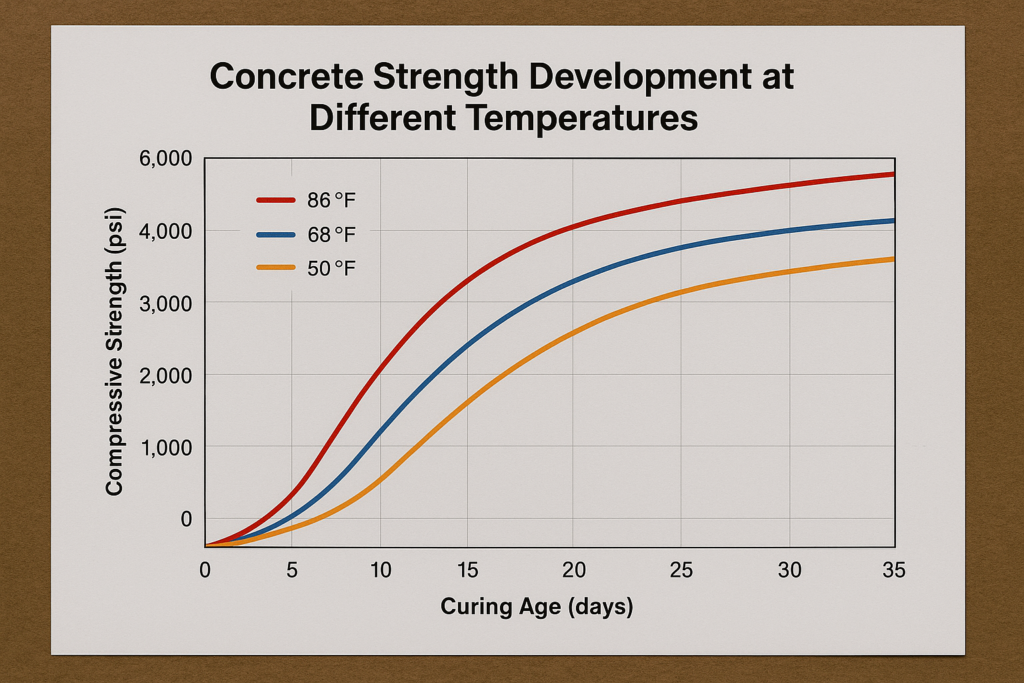

Temperature directly impacts hydration speed. At 73°F (23°C), concrete typically reaches 70% of its design strength within 7 days. When temperatures fall below 50°F (10°C), this same strength development might take 14 days or longer. Below freezing, water inside concrete can expand and create microcracks that permanently weaken the structure.

How is Cold Weather Concrete Defined by Professional Organizations?

I've sat through many heated debates about when "cold weather precautions" become necessary. Different codes have different thresholds, making it confusing for project managers who just want clear answers.

Cold weather concrete is officially defined as periods when average daily air temperature falls below 40°F (4°C) for more than three consecutive days, and air temperature doesn't rise above 50°F (10°C) for more than half of any 24-hour period, according to ACI 306.

The definition varies slightly between organizations, which can cause confusion on international projects. My clients often need guidance navigating these different standards.

Comparative Cold Weather Definitions by Major Organizations

| Organization | Temperature Threshold | Duration Requirement | Additional Criteria |

|---|---|---|---|

| ACI 306 (American) | Below 40°F (4°C) | 3+ consecutive days | Air temp stays below 50°F (10°C) for >12 hours |

| CSA A23.1 (Canadian) | Below 41°F (5°C) | During placing and curing | N/A |

| BS EN 13670 (European) | Below 41°F (5°C) | Expected during placing/curing | Special consideration below 32°F (0°C) |

| IS 7861 (Indian) | Below 41°F (5°C) | During placing and curing | N/A |

These definitions matter because they trigger specific requirements for mix design modifications, thermal protection, and curing procedures. For example, when my Saudi Arabian clients expand to colder regions, they're often surprised that concrete specifications change dramatically with the seasons.

What Are The Best Concrete Curing Methods For Cold Weather?

I've seen contractors lose entire concrete pours to freezing damage. The pain of demolishing and replacing that work could have been avoided with proper curing methods adapted for cold conditions.

The best cold weather curing methods include using insulated blankets, enclosures with heaters, hot water mixing, accelerating admixtures, and increasing cement content. These techniques maintain the concrete temperature above 50°F (10°C) during the critical first days of curing.

Cold weather doesn't mean construction must stop, but it demands different approaches. Having supplied concrete admixtures for decades, I've learned what works reliably in challenging conditions.

Effectiveness of Cold Weather Curing Methods

| Method | Temperature Increase | Cost Impact | Practical Duration | Best Application |

|---|---|---|---|---|

| Insulated Blankets | +10-20°F (+5-11°C) | Low-Medium | 1-7 days | Horizontal slabs |

| Heated Enclosures | +20-50°F (+11-28°C) | High | 1-14 days | Critical structural elements |

| Concrete Additives | N/A (accelerates at existing temp) | Medium | Permanent | All applications |

| Heated Mixing Water | +10-15°F (+5-8°C) | Low | First 24 hours | Emergency situations |

| Increasing Cement Content | +5-10°F (+2-5°C) | Medium | Permanent | Pre-planned cold weather mixes |

Using HPMC (hydroxypropyl methylcellulose)2 as a water-retention agent can also help maintain hydration in cold weather. This keeps more water available for cement hydration rather than evaporating or freezing. Our factory has developed specialized HPMC grades specifically for cold weather concreting that maintain workability without delaying set times excessively.

What Are The Required Temperature and Curing Period of Concrete as per IS Code 270 and ACI?

I've consulted on projects where contractors followed their "usual methods" in winter and faced disastrous results. Codes exist for a reason—they represent decades of research and practical experience.

According to ACI 306 and IS 456, concrete must be maintained above 50°F (10°C) for at least the first 3 days when curing in temperatures between 40-50°F (4-10°C). For high-early-strength concrete, this period can be reduced to 2 days, while structural concrete may require 7+ days of protection.

Different codes have slightly different requirements, which has led to interesting discussions with my international clients.

Temperature Requirements by Code and Application

| Code/Standard | Minimum Placement Temp | Min Curing Temp | Duration of Protection | Special Requirements |

|---|---|---|---|---|

| ACI 306 | 40°F (4°C) | 50°F (10°C) | 3-7 days based on exposure | Gradual cooling at max 5°F (2.8°C) per hour |

| IS 456 | 41°F (5°C) | 50°F (10°C) | 72 hours minimum | Surface temp must not fall below freezing |

| Eurocode/EN 13670 | 41°F (5°C) | 41°F (5°C) | Time to reach 5 MPa strength | Protection against freezing until 5 MPa |

| CSA A23.1 | 41°F (5°C) | 50°F (10°C) | 3 days (normal) 2 days (high-early) | Detailed protection for different types |

Temperature specifications vary with concrete application and exposure conditions. For instance, concrete exposed to freeze-thaw cycles or deicing chemicals requires even more stringent protection. I always advise clients to check local building codes, which may be more stringent than these general standards.

How Do You Monitor Concrete Temperature During Cold Weather Curing?

I once visited a project where the contractor assured me their concrete was "warm enough" based on touching the surface. When we placed proper sensors, we discovered the core temperature had dropped to dangerous levels overnight.

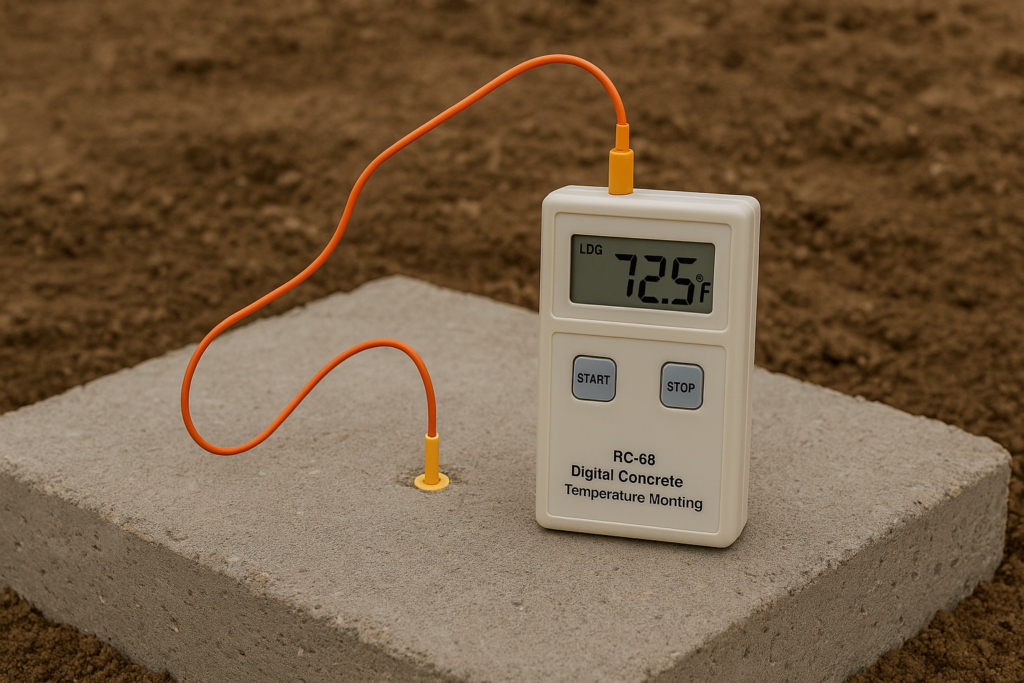

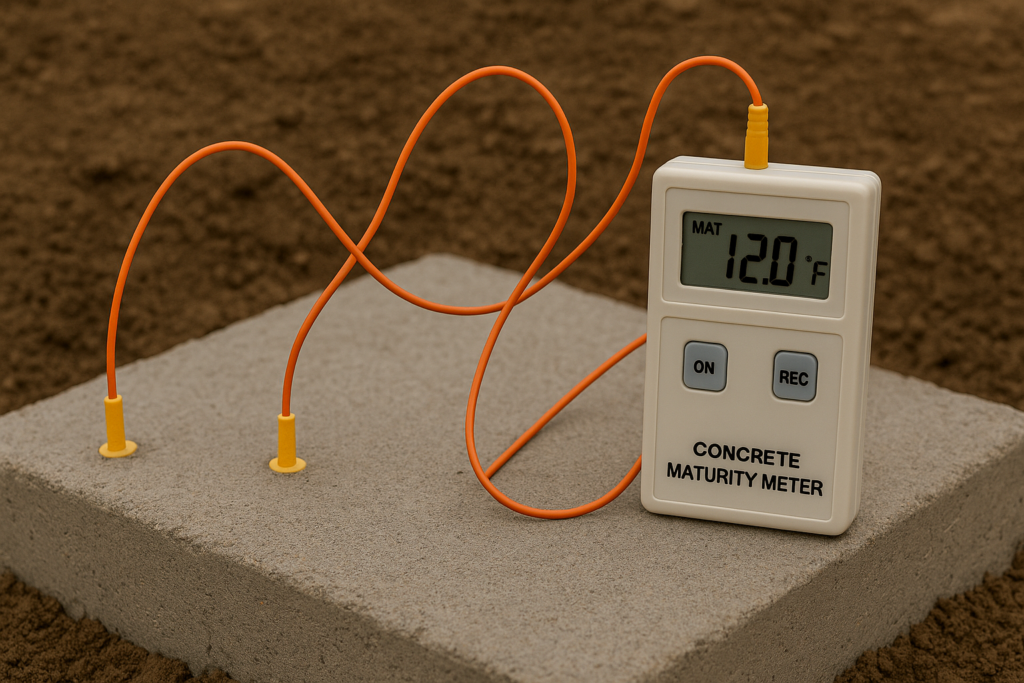

Concrete temperature monitoring during cold weather curing requires embedded sensors at the most vulnerable locations (corners, edges, thin sections) and regular documentation. Digital thermometers with data logging capabilities, infrared guns for surface readings, and maturity meters are essential tools.

Temperature monitoring isn't just checking a box—it's ensuring your investment develops proper strength. I've helped many clients implement proper monitoring protocols.

Critical Monitoring Points and Methods

| Location | Why It's Critical | Recommended Sensors | Monitoring Frequency |

|---|---|---|---|

| Concrete Surface | First point of exposure to cold | Infrared thermometer, Surface probes | Every 4-8 hours |

| Corners/Edges | Greatest heat loss areas | Embedded thermocouples | Continuous or every 2-4 hours |

| Concrete Core | Represents internal temperature | Embedded sensors with loggers | Continuous or every 4 hours |

| Ambient Air | Indicates changing conditions | Weather station or thermometer | Hourly |

| Under Insulation | Verifies protection effectiveness | Wireless sensors | Every 4-8 hours |

Modern technology has made monitoring much easier with wireless sensors that connect to smartphones and cloud-based data storage. This allows real-time alerts if temperatures approach critical thresholds. For larger projects, I recommend implementing concrete maturity monitoring, which combines time and temperature data to accurately estimate strength development regardless of weather fluctuations.

How Long Does Concrete Take To Cure In Cold Weather?

I've had clients frustrated when their cold-weather projects take "forever" to gain strength. They don't realize that curing time isn't fixed—it's temperature-dependent and follows predictable patterns.

Concrete curing time3 approximately doubles for every 20°F (10°C) drop in temperature. At 40°F (4°C), concrete might take 14 days to reach the strength it would achieve in 7 days at 70°F (21°C). Below freezing, hydration essentially stops, and strength development halts until temperatures rise.

Understanding these timeframes helps set realistic expectations for form removal, load application, and project scheduling.

Concrete Curing Times at Various Temperatures

| Temperature | Time to 25% Strength | Time to 50% Strength | Time to 70% Strength | Time to 100% Strength |

|---|---|---|---|---|

| 70°F (21°C) | 1-2 days | 3-4 days | 7 days | 28 days |

| 50°F (10°C) | 2-3 days | 5-7 days | 10-14 days | 28+ days |

| 40°F (4°C) | 3-4 days | 7-14 days | 14-21 days | 42+ days |

| 30°F (-1°C) | Essentially halted | Essentially halted | Essentially halted | Essentially halted |

These timelines assume proper protection measures are in place. Without protection, cold weather concrete may never reach its design strength. Using maturity meters can help determine actual strength development regardless of temperature fluctuations.

Our clients who implement maturity monitoring often report significantly reduced project timelines, as they can remove forms earlier based on actual strength data rather than conservative time estimates.

What Precautions Should Be Taken In Cold Weather Concreting?

I've seen crews prepare perfectly good concrete mixes, only to place them on frozen subgrades—essentially guaranteeing failure. Cold weather success requires thinking beyond just the concrete itself.

Key cold weather concreting precautions include pre-heating aggregates and water, removing ice/snow from forms, using windbreaks and enclosures, planning for sudden temperature drops, and modifying mix designs with accelerators or extra cement. Never place concrete on frozen ground.

Prevention costs far less than repair. From my experience, thorough preparation makes the difference between success and failure in cold weather.

Critical Cold Weather Concreting Checklist

| Stage | Precaution | Why It's Critical | Common Mistakes |

|---|---|---|---|

| Pre-Placement | Clear all snow/ice from forms | Prevents freezing layers under concrete | Assuming small amounts will melt |

| Subgrade | Thaw completely; never place on frozen ground | Prevents uneven settlement | Inadequate thawing time |

| Materials | Pre-heat water and aggregates | Ensures placement temperature above 50°F | Heating only water, not aggregates |

| Mix Design | Use accelerators and extra cement | Faster setting and heat generation | Using standard summer mixes |

| Placement | Windbreaks, minimal handling | Reduces heat loss during placement | Extended finishing in cold winds |

| Early Protection | Cover immediately after finishing | Critical when concrete is most vulnerable | Delays in covering fresh concrete |

| Curing Period | Maintain protection for required duration | Ensures proper strength development | Removing protection too early |

The use of advanced chemical admixtures4 can significantly improve cold weather performance. When we formulate HPMC for cold weather applications, we carefully balance water retention with set time modification. This helps maintain workability without excessively delaying setting—a critical balance in cold conditions.

What Additional Costs Come With Winter Concreting?

I've had uncomfortable conversations with clients who were shocked by winter concreting costs. Better to understand these costs upfront than face budget overruns or cut corners that compromise quality.

Winter concreting typically adds 5-20% to overall concrete costs. These expenses come from heating materials, providing enclosures, using specialized admixtures, additional labor for protection setup/monitoring, and extended project timelines due to slower curing.

Understanding these costs helps make informed decisions about winter scheduling versus postponement.

Breakdown of Winter Concreting Cost Increases

| Cost Component | Typical Increase | Variability Factors | Cost Mitigation Strategies |

|---|---|---|---|

| Heating Materials | +3-8% | Climate severity, project size | Insulated material storage |

| Specialized Admixtures | +2-5% | Required acceleration level | Optimized dosage testing |

| Protection Materials | +5-10% | Duration of protection needed | Reusable insulation systems |

| Additional Labor | +5-15% | Protection complexity | Efficient protection designs |

| Monitoring Equipment | +1-3% | Project criticality | Reusable sensor systems |

| Extended Schedule | Varies widely | Project timeline flexibility | Strength-based rather than time-based milestones |

Many of my clients find that using high-performance admixtures actually reduces overall costs despite their higher initial price. For instance, using our premium HPMC with set-accelerating properties can reduce the need for heating and protection by several days, resulting in net savings of 5-10% on winter projects.

How Can You Make Your Cold Weather Protection Plan Perfect?

I've reviewed countless cold weather protection plans that looked great on paper but failed in execution. The best plans combine technical knowledge with practical implementation details.

Perfect cold weather protection plans include clear temperature thresholds for different actions, specific responsibility assignments, detailed material quantities, equipment maintenance checks, contingency protocols for extreme weather, and verification procedures for all protection measures.

Planning might seem tedious, but it prevents costly emergencies. I've helped many clients develop protection protocols that work reliably.

Elements of an Effective Cold Weather Protection Plan

| Component | Key Considerations | Documentation Needed | Common Oversights |

|---|---|---|---|

| Weather Monitoring | Multiple reliable sources, alert thresholds | Forecast logging procedure | Relying on single forecasts |

| Material Preparation | Pre-heating requirements, storage | Temperature logs | Insufficient heating capacity |

| Equipment Readiness | Backup systems, fuel supplies | Maintenance records | No contingency for equipment failure |

| Protection Materials |

Elements of an Effective Cold Weather Protection Plan

| Component | Key Considerations | Documentation Needed | Common Oversights |

|---|---|---|---|

| Weather Monitoring | Multiple reliable sources, alert thresholds | Forecast logging procedure | Relying on single forecasts |

| Material Preparation | Pre-heating requirements, storage | Temperature logs | Insufficient heating capacity |

| Equipment Readiness | Backup systems, fuel supplies | Maintenance records | No contingency for equipment failure |

| Protection Materials | Quantity, placement method, timing | Inventory list, coverage maps | Inadequate edge protection |

| Staff Training | Cold weather procedures, emergency protocols | Training records | Assuming summer crews understand winter needs |

| Quality Control | Testing frequency, acceptance criteria | Testing schedule and procedures | Reduced testing in difficult conditions |

| Contingency Plans | Severe weather responses, power failures | Decision tree for various scenarios | No clear chain of command in emergencies |

What makes a plan "perfect" isn't just thorough technical considerations but practical implementation details. I've found that assigning specific responsibilities and creating simple checklists dramatically improves execution.

For example, one client reduced cold weather problems by 90% simply by implementing a mandatory pre-pour inspection checklist that required signatures from both quality control staff and site management.

Conclusion

Cold weather concrete curing is absolutely possible with proper planning, material selection, and protection techniques. By monitoring temperatures, adjusting mix designs, and maintaining proper thermal protection, you can achieve quality results year-round. Remember that prevention is always less expensive than repair.

-

Understanding concrete curing is essential for ensuring optimal strength and durability in construction projects. Explore this link to learn more. ↩

-

Learn how HPMC enhances hydration and workability in cold conditions, crucial for successful concrete projects. ↩

-

This link will provide insights into how temperature variations influence concrete curing, essential for project planning. ↩

-

Discover how advanced chemical admixtures can enhance the durability and performance of concrete in cold weather applications. ↩