Are you tired of cracked, stained, and weakening grout in your projects? Traditional grout formulations often fail prematurely, costing you time and reputation. Our specialized grout additives provide the solution you need.

Grout additives1 are worth the investment because they significantly enhance durability, flexibility, and water resistance of grout applications. Quality additives prevent common failures like cracking and staining while extending the lifespan of installations by up to 40% compared to standard grout.

I've spent over 15 years developing and manufacturing grout additives at our WANHONG production facilities. During this time, I've seen firsthand how the right additives transform ordinary grout into a superior building material. Let me share what makes our solutions different and how they can benefit your business.

What Makes Custom Grout Additives at WANHONG Different from Standard Options?

Is your current grout supplier offering the same generic additives to everyone? This one-size-fits-all approach is costing you performance, as each project has unique requirements that demand specialized solutions.

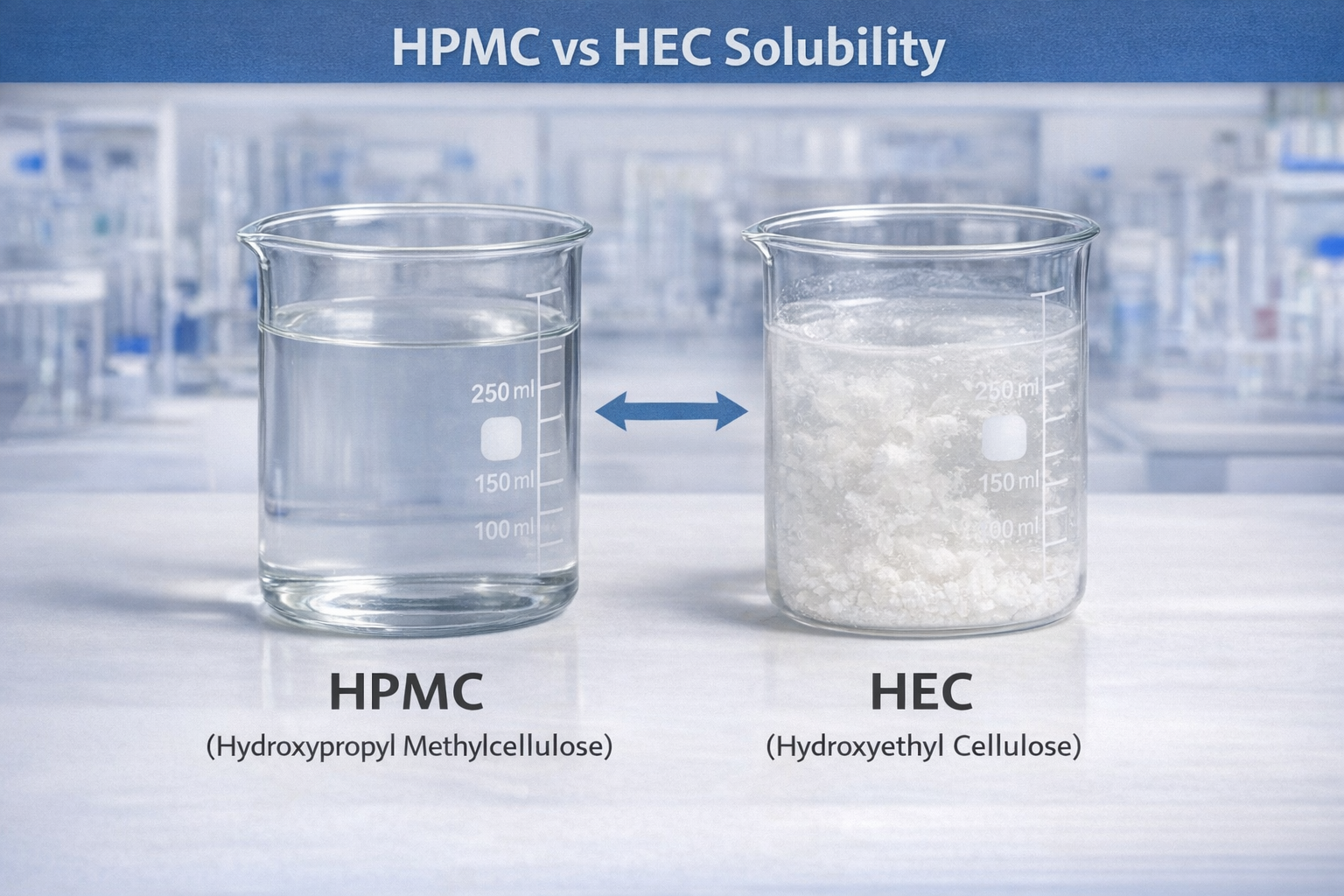

WANHONG custom grout additives are specifically formulated based on your climate conditions, application requirements, and performance needs. Unlike standard additives, our hydroxypropyl methylcellulose2 and redispersible powders3 are tailored to optimize workability, adhesion, and durability for your exact specifications.

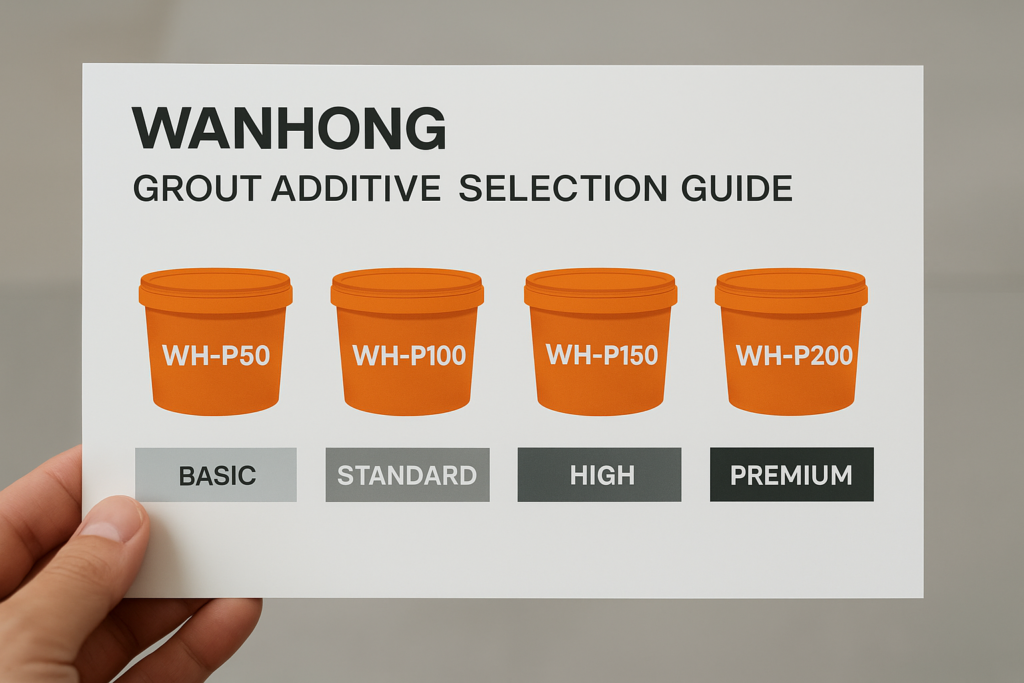

At WANHONG, customization isn't just marketing—it's our fundamental approach to product development. We start by analyzing your specific needs, including the environmental conditions where the grout will be used, the substrate materials, and the performance expectations. Our six production lines allow us to adjust formulations with precision.

For example, when working with clients in humid climates like the Philippines or Vietnam, we increase the water resistance properties of our hydroxypropyl methylcellulose (HPMC). For customers in regions with extreme temperature fluctuations like Saudi Arabia, we enhance the flexibility component through our specialized redispersible polymer powders.

This customization extends to packaging as well. Whether you need small quantities for specialty applications or bulk supplies for large projects, we can accommodate your requirements. Many of our clients appreciate our ability to provide private labeling options, allowing them to build their own brand while benefiting from our technical expertise.

How Do Eco-Friendly Grout Enhancers Benefit Your Projects and the Environment?

Are environmental regulations or eco-conscious clients creating new challenges for your construction materials? Traditional grout additives often contain harmful VOCs and chemicals that pose health risks and environmental concerns.

Eco-friendly grout enhancers from WANHONG use biodegradable cellulose derivatives and low-VOC formulations that meet international green building standards. These sustainable additives maintain superior performance while reducing environmental impact, helping you comply with regulations and meet growing market demand for green building materials.

Our commitment to sustainability goes beyond simple compliance with regulations. I personally oversee our eco-friendly product development, ensuring we balance environmental responsibility with performance requirements.

The key to our eco-friendly formulations lies in our advanced cellulose processing techniques. By refining our hydroxypropyl methylcellulose and carboxymethyl cellulose production methods, we've managed to reduce water usage by 30% compared to industry standards. Our redispersible powders are formulated with minimal use of petroleum-based ingredients, instead focusing on renewable resources when possible.

These green formulations provide tangible benefits for contractors and end-users alike. The reduced VOC content improves indoor air quality both during installation and throughout the life of the building. This is especially important for healthcare facilities, schools, and residential projects where air quality is a primary concern.

Many of our clients in the UAE and Singapore have successfully used our eco-friendly grout additives to achieve green building certifications like LEED and BREEAM. These certifications not only benefit the environment but also increase the market value of their projects.

Why Are Flexible Grout Additives Essential to Prevent Cracking?

Have you dealt with the frustration of callbacks for cracked grout? Rigid grout formulations fail to accommodate building movement, temperature changes, and substrate shifting, leading to unsightly and problematic cracks.

Flexible grout additives contain specialized polymers and fibers that allow grout to expand and contract without breaking. WANHONG's flexible additives incorporate redispersible polymer powder and polypropylene fibers that create microscopic flexibility zones within the grout, reducing crack formation by up to 75% compared to standard formulations.

Flexibility in grout is not just about preventing visible cracks—it's about the long-term structural integrity of the installation. Our research and development team has conducted extensive testing to understand the relationship between different types of movement and grout performance.

We've identified three critical types of movement that affect grout integrity:

| Movement Type | Cause | Solution Component |

|---|---|---|

| Thermal Expansion | Temperature fluctuations | Redispersible polymer powder |

| Structural Settlement | Building settling over time | Polypropylene fibers |

| Vibration | Mechanical equipment, foot traffic | Hydroxypropyl methylcellulose |

By addressing each of these movement types with specific components, our flexible additives create a comprehensive solution. The redispersible polymer powder provides elasticity, while the polypropylene fibers reinforce the matrix and prevent crack propagation. The hydroxypropyl methylcellulose improves cohesion within the mixture, enhancing overall resilience.

This multi-component approach has proven particularly effective in high-stress applications like facade claddings in high-rise buildings and floor installations in high-traffic commercial spaces. Our clients in Brazil and Mexico have reported significant reductions in maintenance costs after switching to our flexible grout additives.

How Do Grout Additives Enhance Strength for Demanding Applications?

Is your current grout failing under heavy loads or in high-traffic areas? Standard grout often lacks the compressive and tensile strength needed for commercial and industrial applications, leading to premature failure and costly repairs.

Strength-enhancing grout additives from WANHONG incorporate modified cellulose ethers and proprietary polymer blends that increase compressive strength by up to 40% and tensile strength by up to 65%. These specialized additives create stronger chemical bonds within the grout matrix, delivering superior performance in demanding environments.

The science behind our strength-enhancing additives involves a careful balance of multiple components working in synergy. Our specialized hydroxypropyl methylcellulose4 creates improved particle distribution during mixing, resulting in a more uniform and dense final product. The redispersible polymer powders5 form polymer bridges between cement particles, significantly enhancing tensile strength.

We've developed specific strength-enhancing formulations for different applications:

| Application | Key Challenge | Primary Additive Component | Strength Increase |

|---|---|---|---|

| Industrial Flooring | Abrasion resistance | Modified HPMC with silica | 45% higher abrasion resistance |

| Exterior Cladding | Wind load resistance | Polymer-fiber hybrid | 65% higher tensile strength |

| Wet Areas | Water pressure resistance | Hydrophobic polymers | 80% reduced water absorption |

These specialized formulations have been tested under extreme conditions to ensure they meet the demands of real-world applications. For instance, our industrial flooring additive undergoes accelerated wear testing equivalent to 10 years of heavy forklift traffic.

Many of our clients in India and Pakistan use these strength-enhanced grout additives for industrial projects where failure is not an option. The increased durability translates directly to extended service life and reduced maintenance costs.

Why is WANHONG a Trusted Source to Buy Additive for Grout from China?

Are quality inconsistencies and supply chain uncertainties making you hesitant about sourcing from China? Many manufacturers offer attractive prices but fail to deliver consistent quality and reliable service, putting your projects and reputation at risk.

WANHONG has established itself as a trusted grout additive supplier through rigorous quality control, ISO-certified manufacturing processes6, and consistent performance across all six production lines. With over 15 years of specialized experience and exports to over 20 countries, we combine Chinese manufacturing efficiency with international quality standards.

Trust is built on consistent actions over time, and at WANHONG, we've invested heavily in systems that ensure reliability. Our quality control process includes testing at multiple stages:

- Raw material verification using advanced spectroscopy

- In-process monitoring with automated systems

- Finished product testing for all key performance parameters

- Long-term stability studies to ensure shelf life

This comprehensive approach allows us to provide batch-to-batch consistency that many of our competitors cannot match. Our state-of-the-art laboratory is equipped with testing equipment calibrated to international standards, ensuring that what we measure aligns with global expectations.

We understand the importance of documentation and compliance in the international market. All our products come with complete technical documentation, safety data sheets in multiple languages, and relevant certifications for different markets. For customers in regulated markets, we can provide additional testing and certification as needed.

Our logistics partnerships ensure reliable delivery schedules, with tracking systems that provide real-time updates on your order status. We've developed alternative shipping routes to mitigate potential disruptions, ensuring your supply chain remains robust even in challenging times.

Why Choose WANHONG as Your Grout Enhancer Supplier?

Are you struggling to find a supplier who understands both technical requirements and business needs? Many manufacturers focus solely on product specifications without considering how their products fit into your overall business strategy.

WANHONG combines technical expertise with business acumen, offering not just superior products but comprehensive support including formulation assistance, market-specific adaptations, and business growth strategies. Our approach goes beyond supplying ingredients—we become technical partners in your success.

Partnership with WANHONG means gaining access to more than just raw materials. Our technical team includes specialists with decades of experience in construction chemistry who can help optimize your formulations for specific applications.

We regularly conduct workshops and training sessions for our customers' technical teams, sharing the latest advancements in grout technology. These knowledge-sharing initiatives help our customers stay at the forefront of industry developments.

Our business support extends to market intelligence, helping you understand trends and opportunities in different regions. This information can be invaluable when developing new products or entering new markets.

We also offer flexible commercial terms that align with your business model. Whether you need just-in-time delivery for lean manufacturing or bulk orders for cost efficiency, we can structure our supply arrangements accordingly.

Many of our long-term customers in the Middle East and Southeast Asia consider us an extension of their own R&D departments, regularly consulting with us on new product development and formulation challenges.

How Do You Choose the Right Grout Additives and Reliable Manufacturer?

Are the technical specifications and manufacturer claims leaving you confused about which grout additive is truly right for your needs? With so many options and technical jargon, making the optimal choice can seem overwhelming.

Choosing the right grout additive requires matching your specific application requirements to the appropriate cellulose type, polymer content, and additive ratio. The ideal manufacturer provides comprehensive technical guidance, consistent quality, transparent communication, and proven performance history.

The process of selecting the right grout additive should be methodical and based on clear criteria. I've guided hundreds of customers through this process, and I've developed a framework that simplifies the decision-making:

First, clearly define your performance requirements:

- What are the environmental conditions where the grout will be used?

- What level of flexibility is needed?

- What strength requirements must be met?

- Are there specific regulatory or environmental considerations?

Next, evaluate potential manufacturers using these criteria:

| Evaluation Criteria | What to Look For | Why It Matters |

|---|---|---|

| Technical Expertise | Detailed technical data sheets, application guides | Indicates understanding of product performance |

| Quality Consistency | ISO certification, quality control processes | Ensures reliable performance batch after batch |

| Supply Reliability | Production capacity, inventory management | Prevents costly project delays |

| Innovation Capability | R&D facilities, new product development | Provides access to cutting-edge solutions |

| Business Practices | Transparent pricing, ethical operations | Builds foundation for long-term partnership |

At WANHONG, we facilitate this evaluation process by providing comprehensive information upfront. We encourage potential customers to request samples for testing in their specific applications, as real-world performance is the ultimate test of any product.

We also recommend considering the total value rather than just the unit price. A slightly more expensive additive that reduces application time, improves performance, or extends service life often provides better overall value.

How Do You Properly Use WANHONG Grout Additives for Optimal Results?

Have you experienced inconsistent results with grout additives due to improper application techniques? Even the best additives will fail to perform if not used correctly, leading to wasted materials and project delays.

For optimal results with WANHONG grout additives, follow the specified mixing ratios (typically 0.2-0.5% by weight), use clean mixing equipment, control water temperature (ideally 15-25°C), and allow proper curing time. Proper preparation and application techniques maximize the performance benefits of our specialized formulations.

The science of proper grout additive use begins with understanding the chemistry involved. Our hydroxypropyl methylcellulose and other cellulose derivatives require specific conditions to properly dissolve and distribute throughout the mixture. Temperature, mixing sequence, and mixing duration all play critical roles in achieving optimal performance.

Based on our laboratory testing and field experience, here's a step-by-step guide to using our grout additives:

-

Preparation: Ensure all equipment is clean and free from contaminants. Previous batch residues can negatively impact performance.

-

Dosing: Measure the additive precisely according to the specified ratio. Even small variations can affect workability and final properties.

-

Mixing Process:

- Add dry additives to dry components first and mix thoroughly

- Gradually add water while continuing to mix

- Mix for the recommended duration (typically 3-5 minutes)

- Allow the mixture to rest for 2-3 minutes to fully activate

- Briefly remix before application

-

Environmental Considerations:

- Adjust water temperature based on ambient conditions

- In hot climates, use cooler water to extend working time

- In cold climates, slightly warmer water improves dissolution

-

Application Techniques:

- Apply within the recommended pot life

- Use appropriate tools for the specific application

- Follow specified thickness guidelines

We provide detailed application guides with all our products, tailored to specific formulations and applications. Our technical support team is also available to provide guidance on unusual or challenging applications.

Many of our customers in Brazil and Mexico have significantly improved their project outcomes simply by refining their application techniques based on our recommendations.

What Dealer Benefits Does WANHONG Offer for Grout## What Dealer Benefits Does WANHONG Offer for Grout Additive Distributors?

Are high minimum orders and rigid supplier policies limiting your growth potential? Many manufacturers focus on large clients while neglecting the needs of distributors and emerging businesses, making it difficult to establish your market position.

WANHONG offers exclusive dealer benefits including flexible minimum order quantities, customized packaging options, technical training programs, marketing support materials, and protected territories. Our dealer program is designed to build mutually beneficial long-term partnerships rather than simple supplier-customer relationships.

I've personally worked with dozens of distributors across our key markets, and I understand the challenges faced by building material dealers. Our dealer program was developed based on direct feedback from these partners, addressing their specific needs and pain points.

Our dealer benefits are structured to support you at every stage of your business development:

| Business Stage | Key Challenge | WANHONG Support |

|---|---|---|

| Market Entry | Building technical knowledge | Comprehensive training program and application guides |

| Growth Phase | Expanding customer base | Co-branded marketing materials and technical seminars |

| Maturity | Protecting market position | Exclusive formulations and territory protection |

| Expansion | Entering new segments | Joint product development for specialized applications |

Beyond these stage-specific supports, all our dealers benefit from our flexible logistics arrangements. We understand that cash flow management is critical for distributors, so we offer optimized container loads and mixed-product shipments to help you maintain ideal inventory levels without overextending financially.

Our technical support doesn't end with the initial training. We provide ongoing education about new applications and techniques, helping you position yourself as a knowledge leader in your market. Many of our dealers in Saudi Arabia and the UAE have used this expertise to transition from pure distribution to value-added service providers, significantly increasing their profit margins.

We also facilitate knowledge sharing between our dealers in different regions (while respecting territorial protections), creating a community of practice that benefits everyone involved. This collaborative approach has helped identify new applications and solve challenging problems.

Conclusion

Quality grout additives from WANHONG deliver superior performance through customization, eco-friendly formulations, and technical expertise. Partner with us to transform your construction projects with products that truly stand the test of time.

-

Discover how grout additives can enhance durability and flexibility, ensuring long-lasting results for your projects. ↩

-

Explore this link to understand how hydroxypropyl methylcellulose enhances grout performance and its specific applications in construction. ↩

-

Discover the advantages of redispersible powders in construction and how they can elevate your building projects. ↩

-

Explore this link to understand how hydroxypropyl methylcellulose enhances construction materials and improves performance. ↩

-

Learn about the benefits of redispersible polymer powders in cement applications and their impact on strength. ↩

-

Understand the significance of ISO certification in manufacturing and how it ensures quality and reliability. ↩