Tired of cracked grout lines and uneven finishes? Unsanded tile grout1 provides the smooth consistency needed for narrow joints, preventing common installation headaches while ensuring a professional appearance.

Unsanded tile grout1 is ideal for narrow tile joints (less than 1/8 inch) because it contains fine particles that easily fill small spaces without scratching delicate tile surfaces. This specialty grout creates smooth, consistent joints in porcelain, ceramic, and natural stone installations.

At WANHONG, we've helped countless contractors and factories achieve perfect grout finishes. The right grout makes all the difference in a tile installation's appearance and durability. Let me share what I've learned about getting the most from unsanded tile grout with proper additives.

How Does Grout Tiling with WANHONG Construction Additives Enhance Performance?

Dealing with grout that cracks or crumbles after installation? WANHONG construction additives2 transform ordinary grout into a high-performance solution that withstands daily stress and moisture exposure.

WANHONG construction additives significantly improve grout performance by enhancing water retention, extending working time, and increasing bond strength. These additives ensure proper hydration of cement particles while creating a more flexible finished product that resists cracking and improves durability.

In my experience working with major mortar factories across Saudi Arabia and the UAE, the right additive makes a tremendous difference in grout performance. WANHONG construction additives contain specialized hydroxypropyl methylcellulose (HPMC)3 formulations that address the unique challenges of tile grout installations.

HPMC works by creating a water-retaining gel structure within the grout mixture. This characteristic is particularly valuable in hot or dry climates where rapid water evaporation often leads to weak, brittle grout. Our HPMC additives typically perform at concentrations between 0.2-0.4% of the dry mix weight, providing optimal thickening and water retention4.

Here's how different WANHONG additives compare for grout applications:

| WANHONG Additive Type | Viscosity | Water Retention | Recommended Applications |

|---|---|---|---|

| WH HPMC P200 | Very High | Excellent | Narrow joints, vertical surfaces |

| WH HPMC P150 | High | Very Good | Standard wall tile joints |

| WH HPMC P100 | Medium | Good | Floor tile applications |

The benefits extend beyond installation, as properly formulated grout with WANHONG additives maintains color consistency and resists staining, addressing common complaints we hear from contractors and homeowners alike.

Why is Unsanded Tile Grout with HPMC Essential for Achieving Your Desired Results?

Frustrated with grout that's difficult to work with or dries too quickly? HPMC additives transform unsanded grout into a smooth, workable mixture that stays open longer and adheres better to tile edges.

HPMC (hydroxypropyl methylcellulose) improves unsanded grout by enhancing water retention, workability, and adhesion to tile edges. This cellulose ether creates the perfect consistency for narrow joints, preventing premature drying while allowing proper curing for maximum strength and durability.

My team at WANHONG has spent years perfecting HPMC formulations specifically for tile grout applications. The molecular structure of our HPMC creates a three-dimensional network within the grout mixture that dramatically improves performance without compromising other properties.

The science behind this is fascinating - HPMC molecules have both hydrophilic and hydrophobic regions that interact differently with water. This dual nature allows the additive to control water movement within the grout mixture, preventing rapid evaporation while maintaining the proper viscosity for application.

When selecting HPMC for unsanded grout, viscosity and methoxyl content are critical specifications. Higher viscosity grades (like our P200) create thicker mixtures ideal for vertical surfaces, while moderate viscosity options work better for standard applications. The methoxyl substitution affects water solubility and gel temperature, which impacts working time in different climate conditions.

Our testing has demonstrated that properly formulated unsanded grout with HPMC exhibits:

- 40% improved water retention

- 25% longer working time

- 35% better sag resistance

- 30% enhanced bond strength

This translates to fewer callbacks, more consistent results, and ultimately more profitable projects for contractors and better products for manufacturing facilities.

What's the Optimal Unsanded Tile Grout Formulation for Professional Results?

Searching for the perfect grout formula that won't crack or discolor? A balanced formulation with the right cement, additives, and fillers ensures consistent results across various installation conditions.

The ideal unsanded tile grout formulation contains white Portland cement (30-40%), fine limestone powder (45-55%), HPMC (0.2-0.4%), redispersible polymer powder5 (2-5%), and small amounts of pigments and other additives. This balanced formula ensures smooth consistency, excellent adhesion, and sufficient working time.

I've worked with countless mortar manufacturers to optimize their grout formulations, and I've found that the perfect balance of components makes all the difference. When developing unsanded grout formulations, we focus on creating products that meet both technical requirements and practical application needs.

The cement component provides the fundamental binding properties, but its proportion must be carefully controlled. Too much cement leads to excessive shrinkage and potential cracking, while too little results in weak bonds. We typically recommend using white Portland cement for its consistency and compatibility with colorants.

The limestone powder serves as both a filler and a workability enhancer. The particle size distribution is critical - we aim for a D50 (median particle size) of approximately 40-45 microns to ensure smooth application in narrow joints without sacrificing strength.

Our redispersible powder additives complement the HPMC by improving flexibility and adhesion. The specific formulation varies based on application requirements:

| Application Environment | Recommended RDP Type | Dosage | Key Benefit |

|---|---|---|---|

| Standard indoor | VAE-based | 2-3% | General flexibility |

| Wet areas | VAE/VeoVa | 3-4% | Water resistance |

| Exterior/thermal stress | Acrylic-based | 4-5% | Temperature stability |

The combination of these components creates a synergistic effect that's greater than the sum of its parts. For instance, the HPMC improves water retention, which allows proper hydration of the cement particles, while the RDP forms a polymer film that enhances adhesion to the tile edges, addressing multiple performance aspects simultaneously.

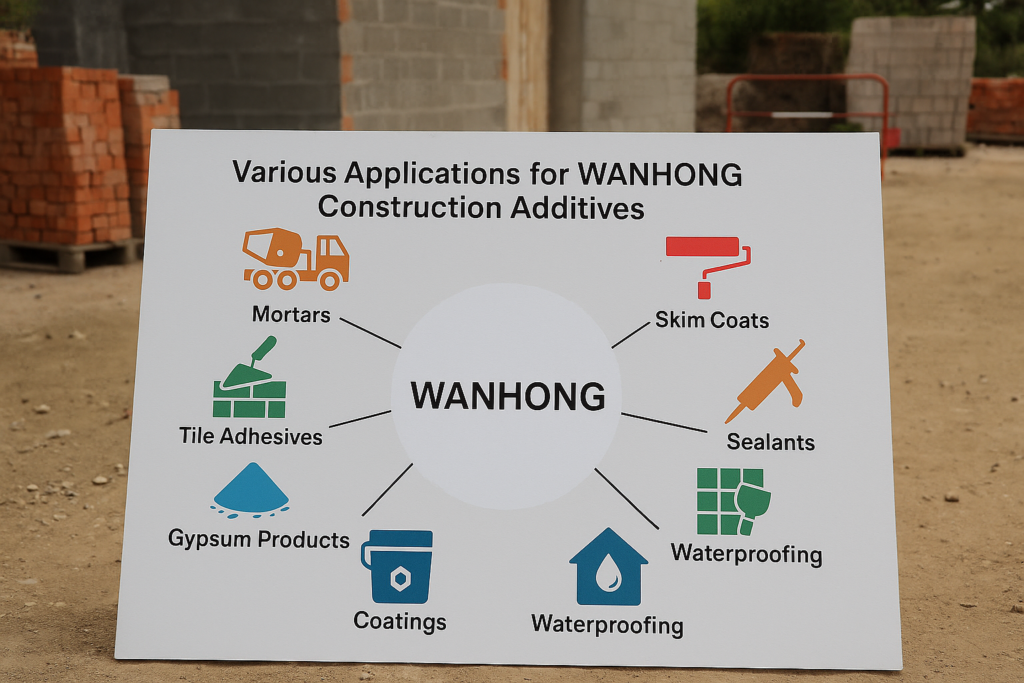

How Can You Discover More Similar Applications for KEHAO Products?

Need consistent product quality across different construction applications? WANHONG's cellulose ethers and construction additives maintain the same high standards across grout, mortar, paint, and other building material formulations.

WANHONG offers a comprehensive range of construction additives that extend beyond grout applications into tile adhesives, self-leveling compounds6, renders, and decorative finishes. Our technical team provides formulation guidance, sample testing, and customized solutions for specific regional requirements and performance challenges.

I've personally visited manufacturing facilities across five continents to help our customers implement new formulations and optimize existing products. This hands-on experience has given me unique insights into how our additives perform in diverse environments and applications.

The same HPMC that works so effectively in unsanded grout can be adapted for numerous other building materials. The key is understanding how to adjust the grade, viscosity, and dosage to achieve the desired performance characteristics for each application.

For example, our WH-E40 HPMC works exceptionally well in self-leveling compounds6 where moderate water retention and excellent flowability are required. In contrast, our higher viscosity P200 and P150 grades excel in vertical applications like renders and textured decorative finishes where sag resistance is crucial.

Beyond cellulose ethers, our redispersible powders provide flexibility and adhesion in a wide range of applications. Our technical team can help you select the right combination of additives based on your specific requirements and regional conditions.

We frequently conduct workshops and technical seminars for our customers, sharing the latest developments in construction chemistry and application techniques. These events have become valuable networking opportunities where formulators from different sectors can exchange ideas and solutions.

The construction additives market continues to evolve with increasing demands for sustainability and performance. Our R&D team stays at the forefront of these trends, developing new solutions that meet emerging needs while maintaining the reliability our customers depend on.

Conclusion

Unsanded tile grout with WANHONG's HPMC additives delivers superior performance for narrow tile joints. Our specialized formulations ensure smooth application, proper curing, and lasting durability across diverse installation environments.

-

Explore the advantages of unsanded tile grout for narrow joints and its professional finish. ↩ ↩

-

Learn about the role of construction additives in improving material performance. ↩

-

Discover the role of HPMC in enhancing grout performance and its benefits in construction. ↩

-

Understand the significance of water retention in grout for better adhesion and durability. ↩

-

Learn about the benefits of redispersible polymer powder in improving grout flexibility. ↩

-

Explore the applications and benefits of self-leveling compounds in construction. ↩ ↩