Are you struggling with water retention1 issues in your gypsum plaster2? Many manufacturers face this problem, leading to cracking, poor workability, and reduced adhesion. PVA binders might seem like a solution, but they fall short in key ways.

HPMC (Hydroxypropyl methylcellulose) binders are superior to PVA for gypsum plaster because they provide better water retention, improved workability, longer open time, and enhanced adhesion. Unlike PVA, HPMC creates a three-dimensional network that maintains consistent moisture levels throughout curing.

As a manufacturer of premium HPMC for over 15 years, I've seen countless clients switch from PVA to our HPMC binders3 and achieve remarkable improvements in their gypsum plaster formulations. The difference isn't just in the technical specifications – it's in the real-world performance that keeps customers satisfied and coming back for more.

What is an HPMC Binder and Why Does it Outperform PVA4?

Do you know what makes your plaster stick to the wall and maintain workability for the optimal amount of time? The binder you choose plays a crucial role in these properties, affecting everything from application ease to final durability.

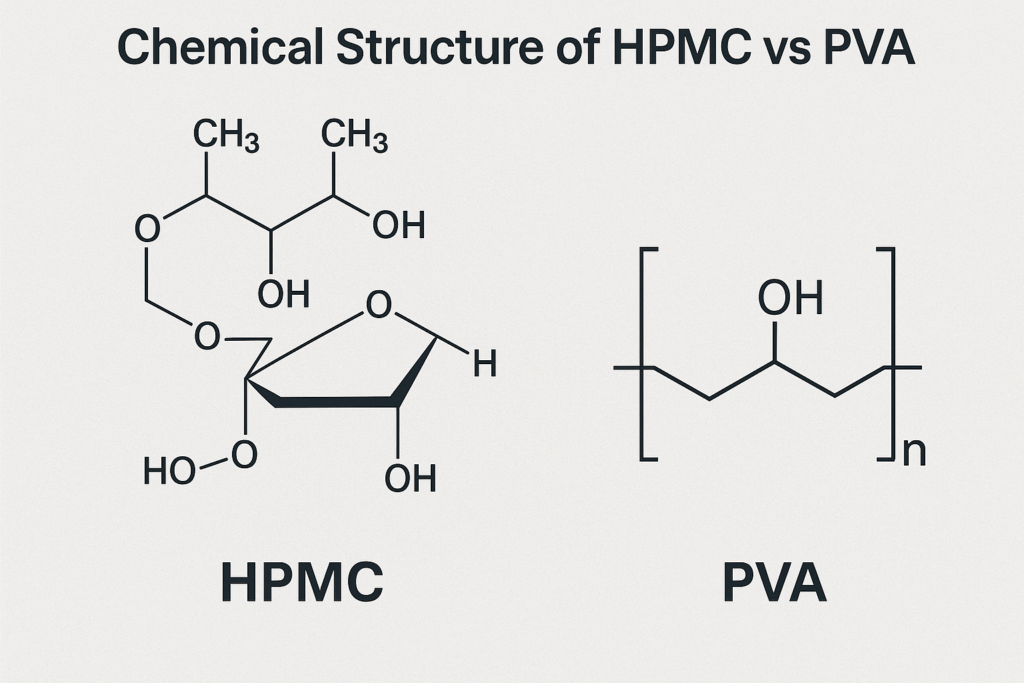

HPMC (Hydroxypropyl methylcellulose) is a cellulose-derived polymer that functions as a thickener, binder, water retention agent, and rheology modifier in gypsum plasters. Unlike PVA which forms a simple film, HPMC creates a three-dimensional network that holds water molecules while allowing controlled release during curing.

When we develop HPMC binders3 at our factory, we carefully control the degree of substitution and viscosity to optimize performance in construction applications. The hydroxypropyl groups in HPMC make it more responsive to temperature changes compared to PVA, creating a unique thermal gelation property that benefits plaster application.

The key advantage of HPMC over PVA lies in its water retention mechanism. While PVA primarily functions through surface film formation, HPMC works through:

| Property | HPMC Mechanism | PVA Mechanism | Benefit of HPMC |

|---|---|---|---|

| Water Retention | Hydrogen bonding between hydroxyl groups and water molecules | Surface film formation | More uniform drying, reduced cracking |

| Workability | Lubrication between particles + pseudoplastic flow | Simple viscosity increase | Better spreadability and less fatigue for workers |

| Open Time | Controlled water release | Faster water loss | Longer working time before setting |

| Temperature Stability | Maintains performance across wider temperature range | More sensitive to temperature extremes | Better performance in varied climates |

I remember visiting a client in Saudi Arabia who had been struggling with plaster cracking in the extreme heat. After switching from their PVA-based formula to our HPMC binder, they reported a 78% reduction in cracking defects and significantly improved worker satisfaction due to the extended open time.

What is the Purpose of Hydroxypropyl Methylcellulose in a Drug Formulation?

Have you ever wondered why the same HPMC we use in construction is also vital in pharmaceutical applications5? This versatility actually highlights the precise control and quality that HPMC brings to any formulation, whether it's building a wall or delivering medicine.

Hydroxypropyl methylcellulose in pharmaceutical applications serves as a controlled-release agent, coating material, and binding agent. It forms a gel matrix when in contact with water, allowing for predictable drug dissolution rates and improved bioavailability of active ingredients.

The pharmaceutical grade of HPMC demonstrates the exceptional purity and performance control that carries over to our construction-grade products6. Through our production processes, we create HPMC with tightly controlled specifications that ensure consistent performance across batches.

The pharmaceutical industry's demands for HPMC highlight key properties that benefit construction applications as well:

-

Precise Viscosity Control: Just as drug release rates depend on exact viscosity, plaster workability requires consistent flow properties. Our HPMC production involves multi-stage testing to ensure each batch meets strict viscosity specifications.

-

Stability Across pH Ranges: Pharmaceutical HPMC must perform in various bodily environments; similarly, our construction HPMC maintains stability across different substrate pH levels - from acidic concrete to alkaline environments.

-

Dissolution Profile: The controlled dissolution of HPMC in pharmaceuticals parallels the ideal water release pattern needed in gypsum plaster applications.

When comparing pharmaceutical and construction applications, we find that many of the same quality parameters apply:

| Property | Pharmaceutical Importance | Construction Benefit |

|---|---|---|

| Viscosity Control | Controls drug release rate | Ensures consistent workability |

| Gel Strength | Maintains tablet integrity | Prevents sagging on vertical surfaces |

| Thermal Gelation | Protects temperature-sensitive drugs | Adapts to environmental conditions during application |

| Surface Activity | Enhances mixing with active ingredients | Improves homogenization with other additives |

In my experience supplying both industries, I've found that manufacturers who understand this connection gain confidence in the technical capabilities of our HPMC products. One major client in UAE switched to our HPMC after learning about our dual pharmaceutical and construction expertise, recognizing that the precision required for drug formulations translated to superior performance in their plaster products.

What is HPMC Used For in Construction?

Have you been wondering why so many premium construction materials list HPMC as a key ingredient? From simple mortars to complex exterior insulation systems, this versatile polymer is often the hidden hero behind the best-performing products.

HPMC serves multiple functions in construction materials including water retention, improved adhesion, enhanced workability, sag resistance, and extended open time. It's used in tile adhesives, renders, EIFS systems, self-leveling compounds, and gypsum-based products to improve application properties and final performance.

In our six production lines, we manufacture HPMC specifically designed for different construction applications. The molecular weight, substitution type, and particle size all influence how the HPMC will perform in specific building materials.

HPMC's role in gypsum plaster specifically addresses several critical challenges that contractors face daily:

-

Improving Slip Resistance: HPMC's thixotropic properties prevent freshly applied plaster from sliding down vertical surfaces while maintaining spreadability during application. Our high-viscosity grades can support layers up to 25mm thick without sagging.

-

Extending Working Time: The water retention capability of HPMC gives applicators more time to achieve smooth finishes before setting begins. In hot climates like those in Saudi Arabia or UAE, this can extend working time by up to 300% compared to unmodified formulations.

-

Enhancing Mechanical Bond: HPMC creates microscopic polymer bridges between gypsum particles and the substrate, significantly increasing both wet and dry adhesion strength.

The specific benefits of HPMC in different construction applications include:

| Application | HPMC Benefit | Performance Improvement |

|---|---|---|

| Gypsum Plaster | Water retention, adhesion, workability | Reduced cracking, better bonding, easier application |

| Tile Adhesives | Open time extension, slip resistance | Larger working area, heavier tiles placement |

| EIFS Systems | Consistency control, weather resistance | Better impact resistance, improved durability |

| Self-Leveling Compounds | Flow control, bleed reduction | Smoother surfaces, fewer bubbles/defects |

| Joint Compounds | Sag resistance, crack prevention | Cleaner joints, reduced callbacks |

I recently visited a major project in Pakistan where the contractor had been experiencing significant problems with premature drying of gypsum plaster in their high-rise construction. After reformulating with our HPMC at a 0.3% dosage, they reported 40% faster application speeds and virtually eliminated the need for rework due to cracking or delamination.

Which is Better: Plaster of Paris or Gypsum?

Are you confused by the terms "plaster of Paris" and "gypsum plaster" being used interchangeably? Many professionals don't realize there are significant differences that can affect your project outcomes and the additives you should choose.

Plaster of Paris is actually a type of gypsum plaster made from calcined gypsum (calcium sulfate hemihydrate). While plaster of Paris sets quickly and has higher strength, modern gypsum plasters contain additional ingredients including retarders and polymers like HPMC that provide better workability and finishing properties.

Through our work with different plaster manufacturers, I've observed that the distinction between traditional plaster of Paris and modern gypsum plaster formulations is increasingly important when selecting appropriate additives like HPMC or PVA.

The evolution of gypsum plasters demonstrates why HPMC has become the preferred binder over PVA4 in modern formulations:

-

Historical Context: Traditional plaster of Paris sets too quickly for many contemporary applications. While PVA was an early solution to extend working time, it couldn't match the water retention properties of HPMC that later became available.

-

Compatibility Factors: HPMC shows superior compatibility with the crystalline structure of gypsum, allowing for more complete hydration without interfering with the natural strength development.

-

Performance Across Environments: Modern construction demands materials that perform consistently across different climates and application techniques. HPMC-modified gypsum plasters maintain their properties in both extremely dry and humid conditions.

The following comparison highlights why HPMC is the preferred choice for modern gypsum plaster formulations:

| Property | Plaster of Paris | Modern Gypsum Plaster with HPMC | Modern Gypsum Plaster with PVA |

|---|---|---|---|

| Setting Time | 5-15 minutes | 60-180 minutes (adjustable) | 30-90 minutes (less controllable) |

| Water Retention | Poor | Excellent | Moderate |

| Shrinkage | Higher | Minimal | Moderate |

| Adhesion to Substrates | Fair | Excellent | Good |

| Cost-Effectiveness | Low initial cost, high labor cost | Higher material cost, lower labor cost | Medium material cost, medium labor cost |

| Durability | Brittle | Flexible, crack-resistant | Moderate flexibility |

During my recent visit to a major plaster manufacturer in Brazil, they shared data from their switch from PVA to our HPMC in their premium gypsum plaster line. They documented a 65% reduction in customer callbacks due to plaster failures and a 28% increase in coverage area per bag - both directly attributable to the superior water retention and workability provided by the HPMC.

Conclusion

HPMC clearly outperforms PVA4 in gypsum plaster2 formulations by providing superior water retention, workability, and adhesion. Making this switch can transform your products, reducing failures and increasing customer satisfaction while improving overall cost-effectiveness.

-

Understanding water retention can help improve plaster formulations and reduce cracking. ↩

-

Learn about gypsum plaster's applications and benefits in modern construction. ↩ ↩

-

Explore the advantages of HPMC binders for better plaster performance and durability. ↩ ↩

-

Discover why PVA may not be the best choice for gypsum plaster compared to HPMC. ↩ ↩ ↩

-

Discover the versatility of HPMC and its benefits in both construction and pharmaceuticals. ↩

-

Learn about the specifications that make HPMC suitable for construction applications. ↩