Are you struggling with mortar that dries too quickly in hot weather? The solution might be using the right cellulose ether. Not all cellulose ethers perform equally, especially when temperatures rise.

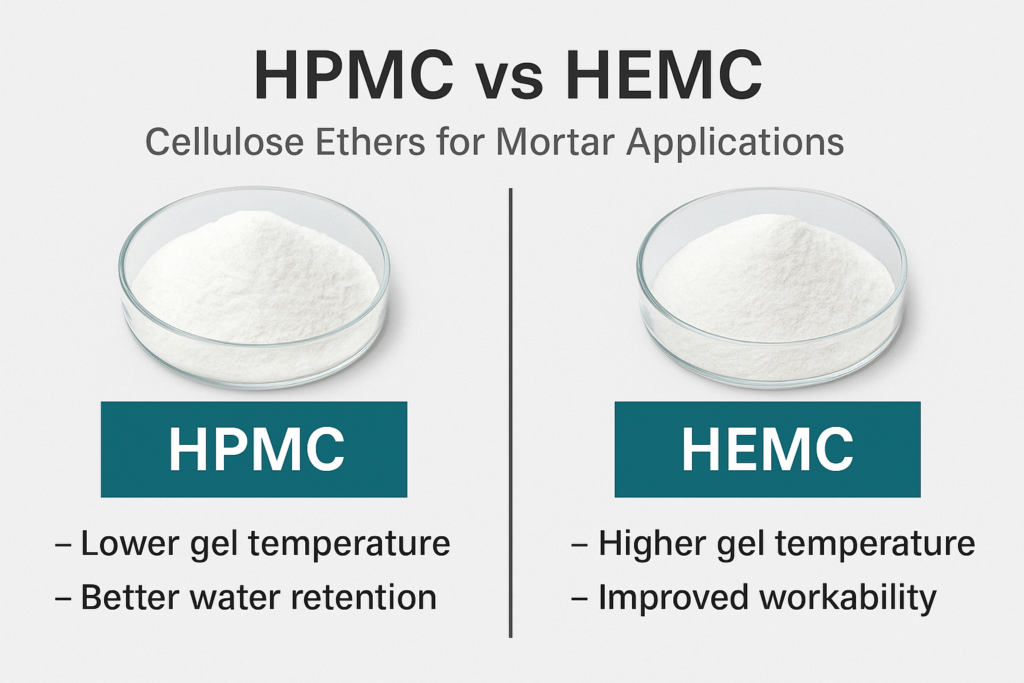

The main difference between HPMC (hydroxypropyl methylcellulose)1 and HEMC (hydroxyethyl methylcellulose)2 is their thermal gelation temperature. HPMC is a cost-effective all-rounder suitable for 90% of applications, while HEMC performs better in high-temperature conditions with superior water retention and extended open time.

I've spent years working with different cellulose ethers in our factory, helping customers find the perfect match for their specific applications. Let me share what I've learned about these two powerful additives and how to choose the right one for your projects.

What is the Difference Between HPMC and HEMC?

Do you keep hearing these acronyms but aren't sure what sets them apart? Many mortar manufacturers face this confusion when selecting the right additive for their formulations.

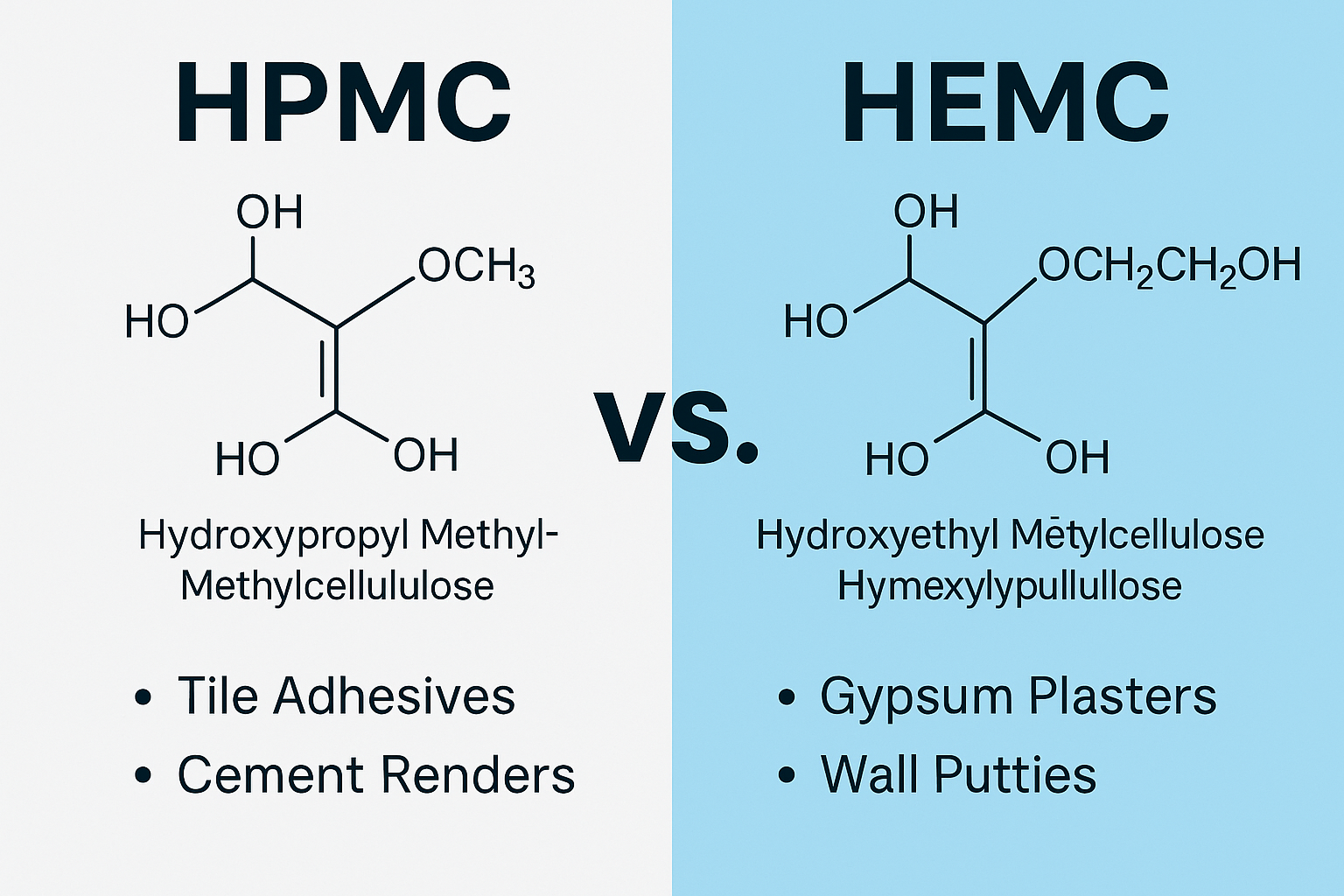

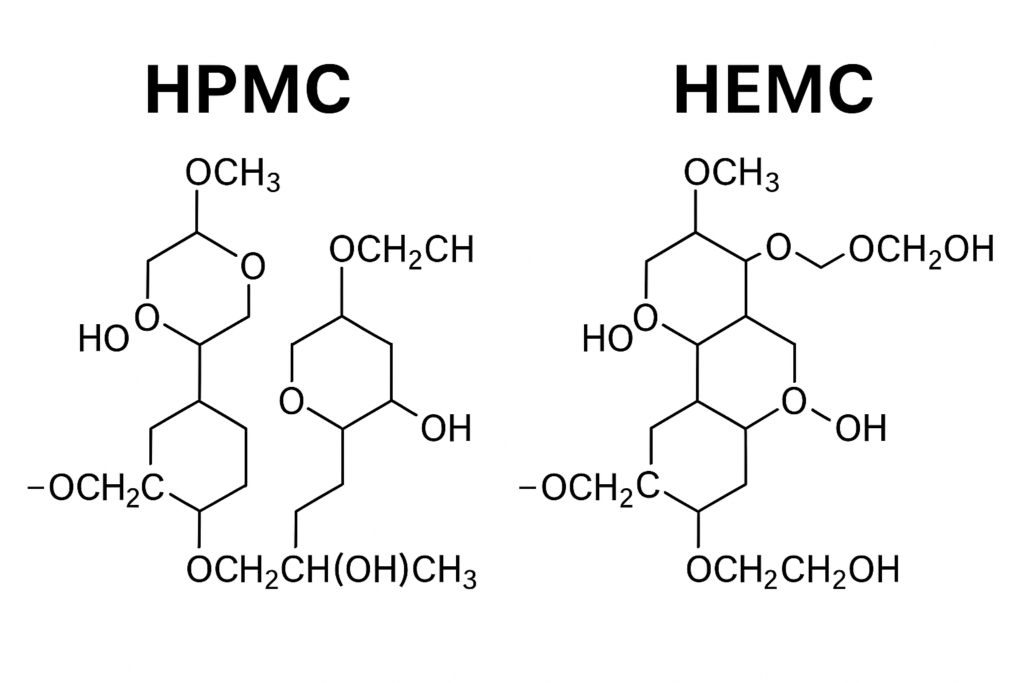

HPMC (hydroxypropyl methylcellulose)1 and HEMC (hydroxyethyl methylcellulose)2 differ in their chemical structure. HPMC contains hydroxypropyl groups, while HEMC has hydroxyethyl groups. This seemingly small difference significantly impacts performance characteristics, particularly in water retention and thermal gelation.

When I first started working with cellulose ethers, I often wondered why we needed both types. Through years of testing and customer feedback, I've gained deep insights into their practical differences.

HPMC is what I call our "all-around player" in the cellulose ether family. It offers excellent cost performance and meets about 90% of typical construction needs. That's why it dominates the market.

HEMC has a special talent - it performs better in high temperatures. Its higher gelation temperature means it maintains water retention stability even when applied on hot walls or in tropical regions. This translates to longer open time for mortar, giving workers more time to make adjustments.

Another notable difference is the feel during application. HEMC provides a smoother, more buttery consistency that many professional applicators prefer. This improved workability can be a significant advantage for premium mortar products.

Let's look at the key differences in a more structured way:

Performance Comparison: HPMC vs HEMC

| Property | HPMC | HEMC |

|---|---|---|

| Cost efficiency | Higher (more economical) | Lower |

| Thermal gelation temperature | Lower (65-70°C) | Higher (70-80°C) |

| Water retention in high temp | Good | Excellent |

| Open time in hot conditions | Standard | Extended |

| Workability | Good | Excellent (smoother) |

| Market dominance | Approximately 90% | Approximately 10% |

What is the Difference Between Hydroxyethyl Cellulose and Hydroxypropyl Methylcellulose?

When formulating mortars, are you confused about which cellulose derivative will deliver the performance your customers demand? This is a common challenge for manufacturers looking to optimize their products.

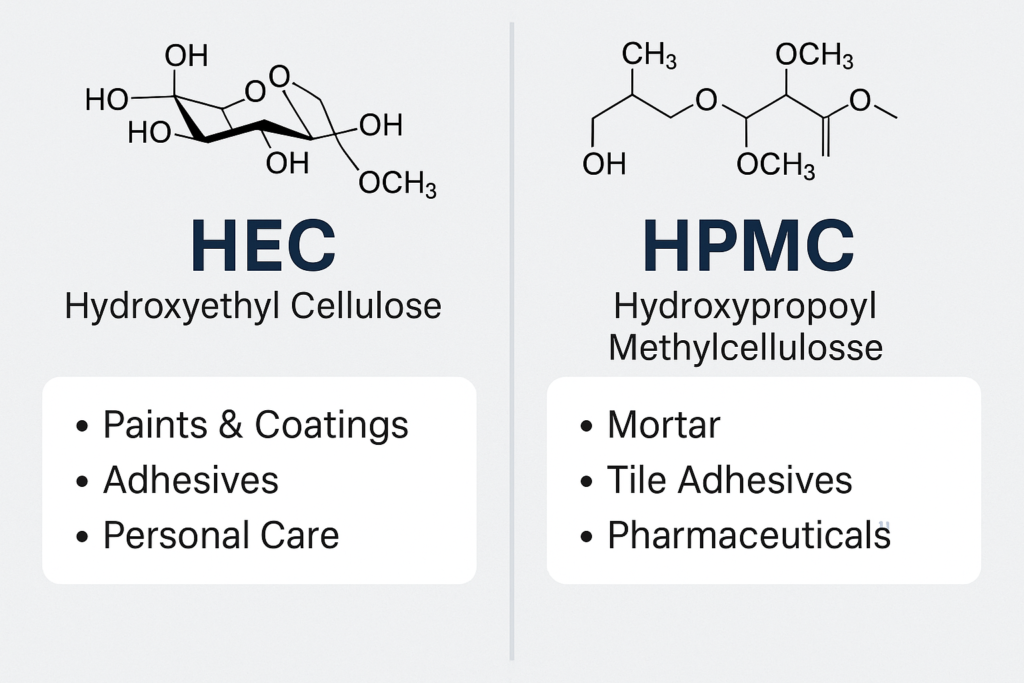

Hydroxyethyl cellulose (HEC) and hydroxypropyl methylcellulose (HPMC)3 differ fundamentally in their chemical structure and performance. HEC is a non-ionic cellulose ether with only hydroxyethyl substitution, while HPMC has both hydroxypropyl and methyl groups. This gives them different properties for mortar applications.

I remember when one of our customers from Saudi Arabia called me with an urgent problem. His mortar was failing in the extreme summer heat, drying too quickly before workers could finish application. This is where understanding the difference between these cellulose ethers became crucial.

HEC (hydroxyethyl cellulose) and HPMC (hydroxypropyl methylcellulose) might sound similar, but they perform quite differently in construction applications. HEC is typically used in paint formulations rather than mortars. It provides good thickening but doesn't offer the same level of water retention that cement-based products require.

HPMC, on the other hand, excels in mortar applications thanks to its balanced water retention, adhesion enhancement, and workability improvement. It's specifically designed for cement-based systems, making it the preferred choice for tile adhesives, renders, and self-leveling compounds.

The methyl groups in HPMC provide a hydrophobic characteristic that helps control water interaction in the mortar mix. This leads to better consistency and performance reliability across various environmental conditions.

For completeness, let me also explain where HEMC fits in this comparison. HEMC (hydroxyethyl methylcellulose)2 combines features of both HEC and HPMC. Like HPMC, it contains methyl groups that make it suitable for mortar applications, but it uses hydroxyethyl instead of hydroxypropyl groups, giving it that higher thermal gelation temperature I mentioned earlier.

Application Guide: When to Choose Each Cellulose Ether

| Application | Recommended Cellulose Ether | Reason |

|---|---|---|

| Standard mortar in moderate climate | HPMC | Cost-effective with sufficient performance |

| Mortar application in hot climate (>35°C) | HEMC | Higher thermal gelation temperature prevents premature drying |

| Premium tile adhesives requiring extended open time | HEMC | Better water retention even in challenging conditions |

| Budget-conscious projects | HPMC | Lower cost while maintaining acceptable performance |

| Paint and coating applications | HEC | Better suited for liquid systems than cement-based applications |

| Winter applications in cold climates | HPMC | Performs well in lower temperatures, more economical choice |

Conclusion

Choose HPMC for most standard mortar applications to optimize cost efficiency. Switch to HEMC when facing high-temperature conditions or when premium workability4 justifies the higher price. Both have their place in modern construction.

-

Explore this link to understand the versatile applications of HPMC in construction and why it's a popular choice. ↩ ↩

-

Discover the benefits of HEMC in hot weather applications and how it enhances mortar performance. ↩ ↩ ↩

-

Discover the advantages of HPMC in mortar formulations and why it's a preferred choice for many. ↩

-

Explore the factors that enhance workability in mortars and how they can improve application efficiency. ↩