Uneven floors create major problems for construction projects, leading to structural issues and poor aesthetics. Self-leveling compounds1 solve this, but only with the right additives like hydroxypropyl methylcellulose (HPMC)2.

HPMC acts as a critical water retention agent in self-leveling mortars, preventing premature water evaporation and ensuring proper cement hydration. This results in optimal flow properties, extended working time, and superior surface finish while preventing cracking and delamination.

As a leading HPMC manufacturer with over 15 years of experience, I've seen how the right cellulose ether transforms self-leveling projects. Our customers consistently report smoother application, better flow, and superior end results when using our specialized HPMC formulations.

What Makes HPMC Essential for Self-Leveling Mortar?

The frustration of dealing with poorly flowing self-leveling compounds wastes time and compromises quality. Without proper water retention, these products dry too quickly, creating an unworkable mess with poor strength.

HPMC in self-leveling mortar controls rheology (flow behavior), provides water retention, and stabilizes the mixture. It creates the perfect balance between flowability and stability, preventing segregation while maintaining an ideal spreading rate for professional results.

Self-leveling compounds face unique challenges that HPMC effectively addresses. Let me break down the specific benefits this remarkable additive provides:

Key Benefits of HPMC in Self-Leveling Applications

| Benefit | How HPMC Delivers | Real-World Impact |

|---|---|---|

| Controlled Flow | Modifies viscosity precisely | Even spreading without excessive fluidity |

| Extended Working Time | Retains water in the mixture | More time for application and adjustments |

| Prevents Bleeding | Stabilizes water in the mixture | No water separation on the surface |

| Sag Resistance | Provides thixotropic properties | Maintains thickness on sloped surfaces |

| Crack Resistance | Ensures proper cement hydration | Stronger final product with fewer defects |

In my experience working with major mortar manufacturers across Saudi Arabia and the UAE, the HPMC viscosity grade makes a significant difference. For self-leveling applications, we typically recommend our 100,000-150,000 mPa·s grades at 2% concentration. This provides the optimal balance between flow and stability.

The dosage is also critical - too little HPMC results in poor water retention and quick setting, while excess can reduce the final strength and extend drying time unnecessarily. Our technical team provides precise dosage recommendations based on your specific formulation needs.

Why Choose Wanhong as Your HPMC Cellulose Supplier for Self-Leveling Solutions?

Poor quality HPMC causes inconsistent batches, customer complaints, and project delays. Unreliable suppliers with fluctuating quality standards create ongoing headaches for production managers and quality control teams.

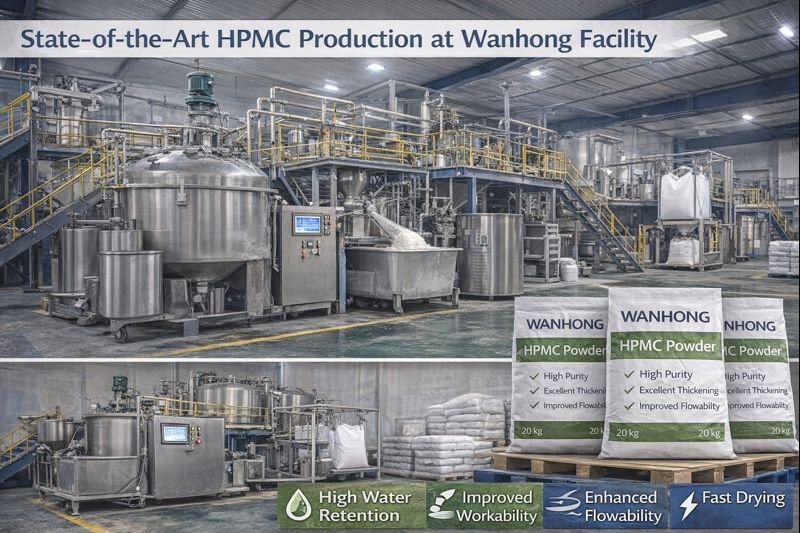

Wanhong produces specialized HPMC grades specifically engineered for self-leveling applications, with consistent viscosity, particle size distribution, and moisture content. Our ISO-certified manufacturing processes ensure batch-to-batch reliability that meets international construction standards.

When you partner with Wanhong, you gain more than just a supplier—you gain a technical partner with specialized knowledge in construction applications. Our six production lines deliver over 20,000 tons of HPMC annually, serving customers in over 50 countries.

Our Competitive Advantages for Self-Leveling HPMC

I believe transparency builds trust, so let me share what makes our HPMC stand out:

-

Customized Solutions: We adjust viscosity, substitution degree, and particle size based on your specific requirements.

-

Technical Support: Our team provides formulation assistance, troubleshooting, and on-site support.

-

Quality Control: Every batch undergoes rigorous testing for viscosity, substitution degree, moisture content, particle size, and application performance.

-

Supply Chain Reliability: With six production lines and strategic inventory management, we maintain consistent supply even during peak demand seasons.

-

Competitive Pricing: Direct manufacturer pricing without intermediaries saves you 10-15% compared to European or American suppliers.

I recently worked with a large mortar manufacturer in Saudi Arabia who was struggling with inconsistent self-leveling performance. By switching to our HPMC-SL150 grade and adjusting their formulation slightly, they eliminated customer complaints and improved their product's reputation in the market.

How to Connect with Wanhong for Your HPMC Needs?

Finding reliable chemical suppliers that understand your application needs can be frustrating. Many salespeople lack technical knowledge, leading to unsuitable product recommendations and wasted time.

Reaching out to Wanhong is simple through our website (www.xhhpmc.com), direct email (ada@xhhpmc.com), or by scheduling a virtual technical consultation. We provide free samples for testing, detailed technical data sheets, and application-specific recommendations.

I understand the importance of responsive communication in the chemical supply industry. When you contact us, you'll receive a reply within 24 hours from a technical sales representative who understands self-leveling applications.

Our customer relationship process typically follows these steps:

- Initial Consultation: We discuss your specific application requirements and performance goals

- Sample Testing: We provide free samples for your in-house testing

- Technical Support: Our team assists with formulation optimization

- Order Processing: Streamlined ordering with transparent lead times

- Ongoing Partnership: Regular check-ins and continuous improvement

We pride ourselves on building long-term partnerships rather than transactional relationships. Many of our customers have been with us for over a decade, relying on our consistent quality and technical support.

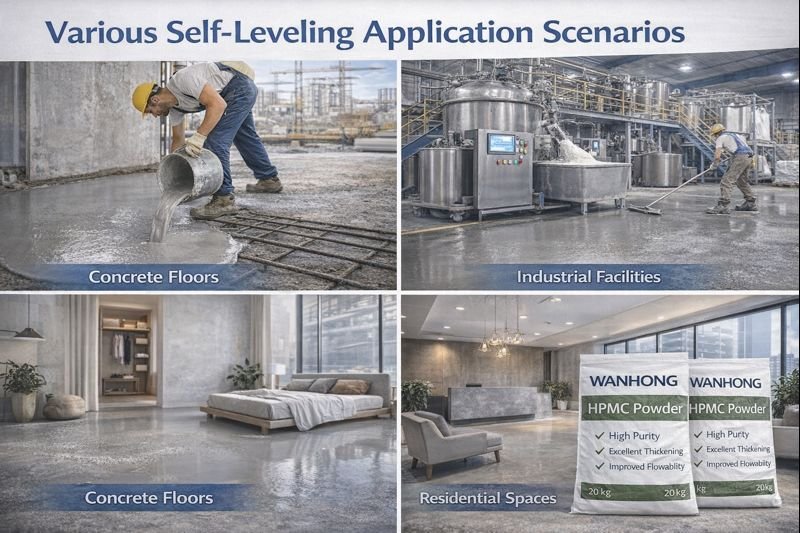

What Are the Most Common Self-Leveling Application Scenarios?

Choosing the wrong HPMC grade for specific applications leads to poor performance, customer dissatisfaction, and damaged reputation. Different scenarios require tailored solutions to meet performance requirements.

Self-leveling compounds are widely used in residential flooring, commercial spaces, underfloor heating systems, and industrial facilities. Each scenario requires specific flow characteristics, working time3, and final strength properties that HPMC helps control.

Through my years working with customers across different industries, I've gained insights into how self-leveling compounds perform in various scenarios. Let me share some application-specific recommendations:

Residential Flooring

For residential applications, smooth finish and ease of application are typically priorities. Our HPMC-SL100 grade works exceptionally well here, providing moderate water retention and excellent flow properties. This creates a user-friendly product that contractors appreciate for its forgiving working time and smooth finish.

In residential settings, self-leveling compounds often need to work with various subfloor types - from concrete to plywood. The right HPMC helps ensure good adhesion to these surfaces while maintaining proper flow characteristics. I recommend a dosage of 0.2-0.3% for most residential formulations.

Commercial Spaces

Commercial floors face higher traffic and often need faster setting times to minimize downtime. Our HPMC-SL150 grade is perfect for these applications, offering excellent water retention while allowing for faster hardening. This balance helps contractors meet tight project timelines while ensuring quality results.

The higher viscosity of this grade also helps support additional additives common in commercial formulations, such as fibers and hardening accelerators, maintaining proper suspension throughout the application process.

Industrial Facilities

Industrial self-leveling compounds require exceptional durability and chemical resistance. For these applications, our HPMC-SL200 grade provides superior water retention in thicker applications, ensuring thorough hydration throughout the entire thickness of the application.

This grade also performs well with higher cement content formulations typical in industrial settings, preventing the rapid water loss that can occur with more hydraulic mixes. The result is a stronger, more durable floor with fewer defects.

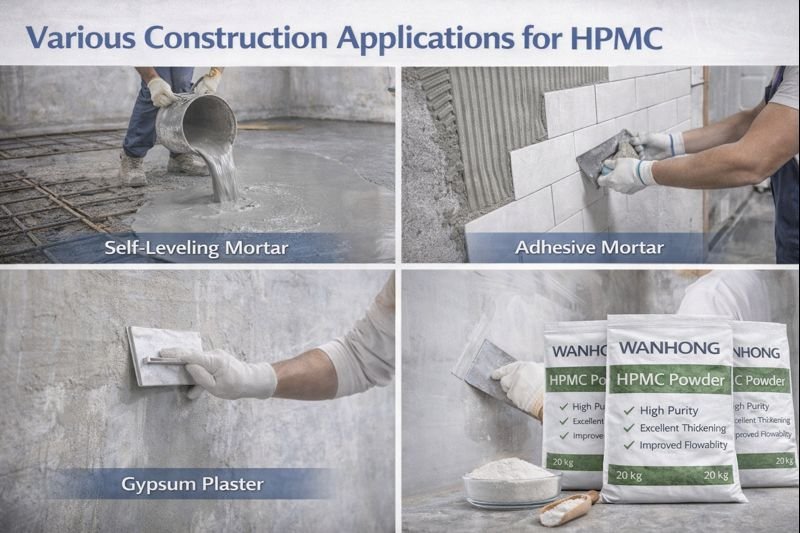

What Other Applications Benefit from HPMC Beyond Self-Leveling?

Limiting HPMC use to only self-leveling applications misses opportunities to improve other products in your portfolio. Construction chemical manufacturers often overlook the versatility of this powerful additive.

HPMC improves tile adhesives4, renders, EIFS systems, gypsum-based products, and 3D printing mortars. The same water retention, workability enhancement, and stability benefits that improve self-leveling compounds transfer to these other construction materials.

As a manufacturing partner to companies across the construction industry, I've seen firsthand how our HPMC grades perform in diverse applications. This versatility often allows our customers to streamline their raw material inventory while maintaining high performance across product lines.

Tile Adhesives

In tile adhesives, HPMC provides essential open time extension and slip resistance. Our HPMC-TA series is specifically engineered for this application, with adjusted hydroxypropyl content that balances water retention with final adhesive strength.

Modern large-format tiles present unique challenges, requiring adhesives that maintain thickness while providing extended adjustment time. Our HPMC-TA250 grade is particularly effective here, creating the perfect balance of workability and hold. Many of our customers in the UAE and Saudi Arabia have successfully reformulated their tile adhesives with this grade to meet the growing demand for large-format tile installation.

Renders and EIFS Systems

External renders and EIFS (External Insulation and Finishing Systems) benefit from HPMC's ability to resist sagging while maintaining workability in varied weather conditions. Our HPMC-EF series provides excellent water retention even in hot, dry climates, protecting these systems during the critical curing phase.

The thixotropic properties of these grades allow for easy application while preventing material waste through dripping or sagging. This is particularly important for decorative finishes where aesthetic consistency is paramount.

3D Printing Mortars

The emerging field of construction 3D printing presents unique rheological challenges that our specialized HPMC grades help solve. These materials must flow through pumping systems yet maintain shape immediately after extrusion.

Our HPMC-3D series provides the perfect balance of these seemingly contradictory properties, enabling precise control of open time and shape stability. As construction 3D printing continues to grow, we're investing in research to further optimize our offerings for this innovative application.

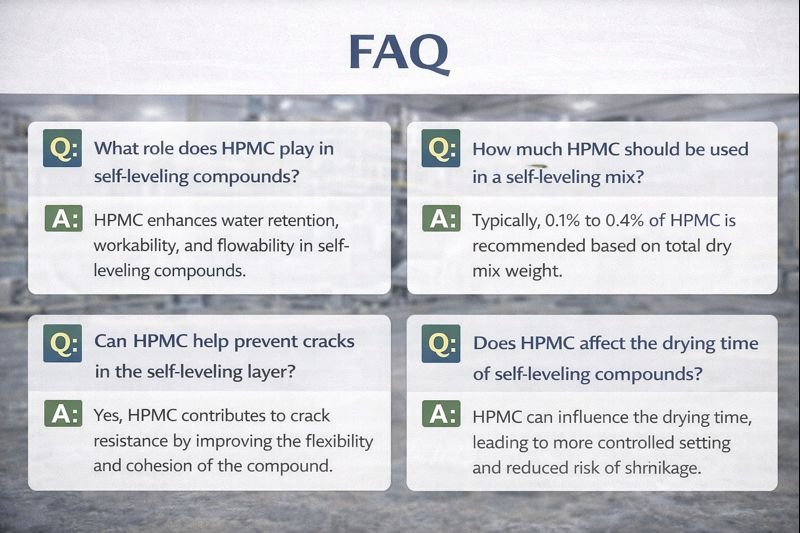

What Are the Most Frequently Asked Questions About HPMC5 for Self-Leveling?

Confusion about HPMC specifications leads to poor product selection and disappointing results. Without clear answers, formulators make costly mistakes that impact product performance and customer satisfaction.

Common questions about HPMC for self-leveling focus on dosage rates, compatibility with other additives, storage stability, and troubleshooting common issues. The right information helps optimize formulations and avoid costly mistakes.

Based on the questions I receive most frequently from customers, I've compiled these helpful answers to guide your HPMC usage in self-leveling applications:

What is the optimal HPMC dosage for self-leveling compounds?

The ideal dosage typically ranges from 0.15% to 0.3% of the dry mix weight, depending on other ingredients and performance requirements. I recommend starting at 0.2% and adjusting based on flow characteristics and water retention tests. Too little HPMC results in poor water retention and workability, while excessive amounts can delay setting time and reduce final strength.

Factors affecting optimal dosage include cement type and content, presence of other additives like superplasticizers, and application temperature conditions. Our technical team can help you determine the perfect balance for your specific formulation.

How does HPMC interact with superplasticizers in self-leveling formulations?

HPMC works synergistically with superplasticizers, with each serving distinct functions. While superplasticizers reduce water requirements and improve flow, HPMC provides water retention and stability. The key is finding the right balance between these components.

We typically recommend using polycarboxylate-based superplasticizers with our HPMC grades, as they show excellent compatibility. The dosage relationship is important - as superplasticizer content increases, you may need to slightly reduce HPMC dosage to maintain optimal setting time.

How should HPMC be added to self-leveling mixes?

The addition sequence significantly impacts performance. For best results, dry-blend HPMC with other powder components before adding water. This prevents clumping and ensures uniform distribution throughout the mixture.

Alternatively, you can create a slurry by dispersing HPMC in cold water (which prevents immediate dissolution) and then adding this to other liquid components. However, the dry-blend method typically provides more consistent results in production environments.

What shelf life can I expect for self-leveling products containing HPMC?

Properly formulated self-leveling compounds containing our HPMC typically maintain their performance characteristics for 12-18 months when stored in dry conditions. The HPMC itself is extremely stable, with our products showing consistent performance even after 24+ months of storage.

To maximize shelf life, we recommend using moisture-resistant packaging and adding appropriate anti-caking agents to your formulation. Our technical team can provide specific recommendations based on your packaging system and storage conditions.

Conclusion

HPMC is essential for high-performance self-leveling compounds, providing critical water retention, flow control, and stability. Partnering with Wanhong gives you access to specialized grades, technical expertise, and reliable supply for superior self-leveling products.

-

Explore the advantages of self-leveling compounds for construction projects and how they improve flooring quality. ↩

-

Learn about HPMC's role in enhancing construction materials and its importance in self-leveling applications. ↩

-

Explore the concept of working time and its importance for effective application in construction projects. ↩

-

Discover the essential factors to consider when selecting tile adhesives for various applications. ↩

-

Explore this link to understand HPMC's role in construction and its benefits for various applications. ↩