Are your EIFS systems failing to meet performance expectations? Inconsistent adhesion, poor workability, and reduced durability are common problems that can derail construction projects and damage reputations.

HPMC (Hydroxypropyl Methylcellulose)1 is the essential additive that transforms EIFS/ETICS systems by improving adhesion, water retention, workability, and durability. It creates the perfect consistency for both application and long-term performance, preventing costly failures in exterior insulation systems.

As a leading manufacturer of HPMC for construction materials, I've seen countless projects transformed by using the right cellulose ether. The difference between a mediocre EIFS installation and an exceptional one often comes down to the quality and proper selection of additives like HPMC. Let's explore how this crucial component can elevate your EIFS systems to new heights.

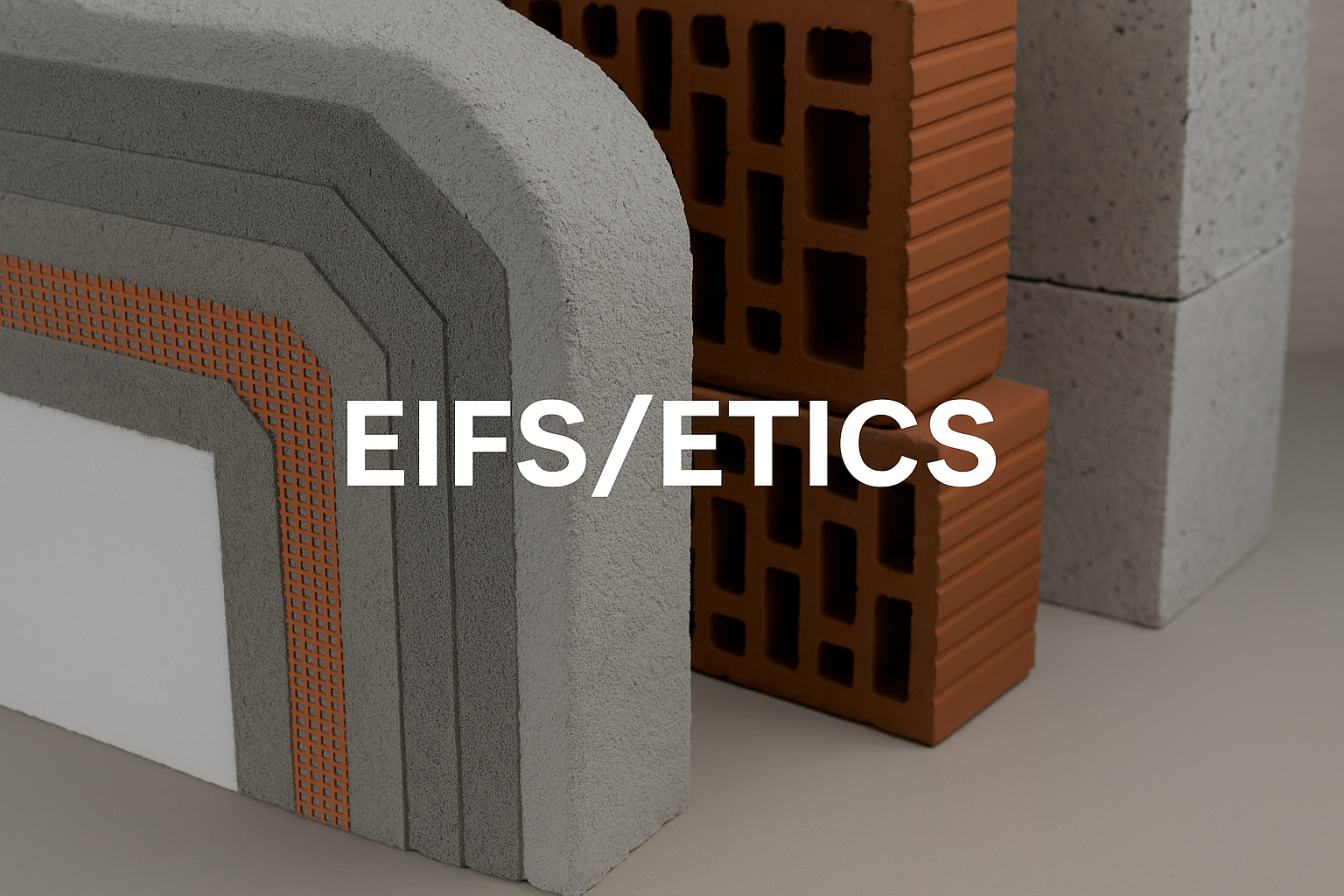

What is EIFS? What Are the Differences between EIFS and Stucco?

Have you been confusing EIFS with traditional stucco? This misunderstanding can lead to improper material selection and application failures that compromise building integrity and energy efficiency.

EIFS (Exterior Insulation and Finish System)2 is a multi-layered exterior wall system consisting of insulation board, reinforced base coat, and decorative finish coat. Unlike traditional stucco, EIFS includes an insulation component and requires specific additives like HPMC to ensure proper adhesion and performance.

EIFS represents a significant advancement in building envelope technology. When I first started working with these systems, I quickly realized their complexity compared to traditional stucco.

EIFS systems typically consist of five key components: adhesive, insulation board (usually EPS), base coat, reinforcing mesh, and finish coat. Traditional stucco, in contrast, is simply a cement-based plaster applied directly to a building substrate without the insulation layer.

The performance differences are substantial. EIFS provides superior thermal insulation with R-values ranging from R-4 to R-5.6 per inch, while traditional stucco offers minimal insulation value (around R-0.2 per inch).

This translates to significant energy savings - I've seen projects reduce heating and cooling costs by 20-30% after upgrading to properly formulated EIFS systems.

Another critical difference lies in weight and installation. EIFS typically weighs about 1 pound per square foot, while traditional stucco can weigh 7-8 pounds per square foot. This lighter weight makes EIFS easier to install and puts less structural load on buildings.

However, this is precisely why proper formulation with HPMC is essential - the adhesion requirements are different from traditional heavy stucco systems.

EIFS vs. Traditional Stucco Comparison

| Feature | EIFS | Traditional Stucco |

|---|---|---|

| Composition | Multi-layer system with insulation | Cement-based plaster |

| Insulation Value | High (R-4 to R-5.6 per inch) | Minimal (R-0.2 per inch) |

| Weight | Light (±1 lb/sq ft) | Heavy (7-8 lbs/sq ft) |

| Flexibility | More flexible, less cracking | Less flexible, more prone to cracking |

| Water Management | Requires drainage system | Relies on water shedding |

| HPMC Requirement | Higher levels for adhesion & workability | Lower levels primarily for workability |

What Are the Major Benefits of HPMC3 for EIFS4?

Are your EIFS applications showing inconsistent quality? Problems like poor adhesion, rapid drying, and difficult application might be traced back to inadequate or improper HPMC usage in your formulations.

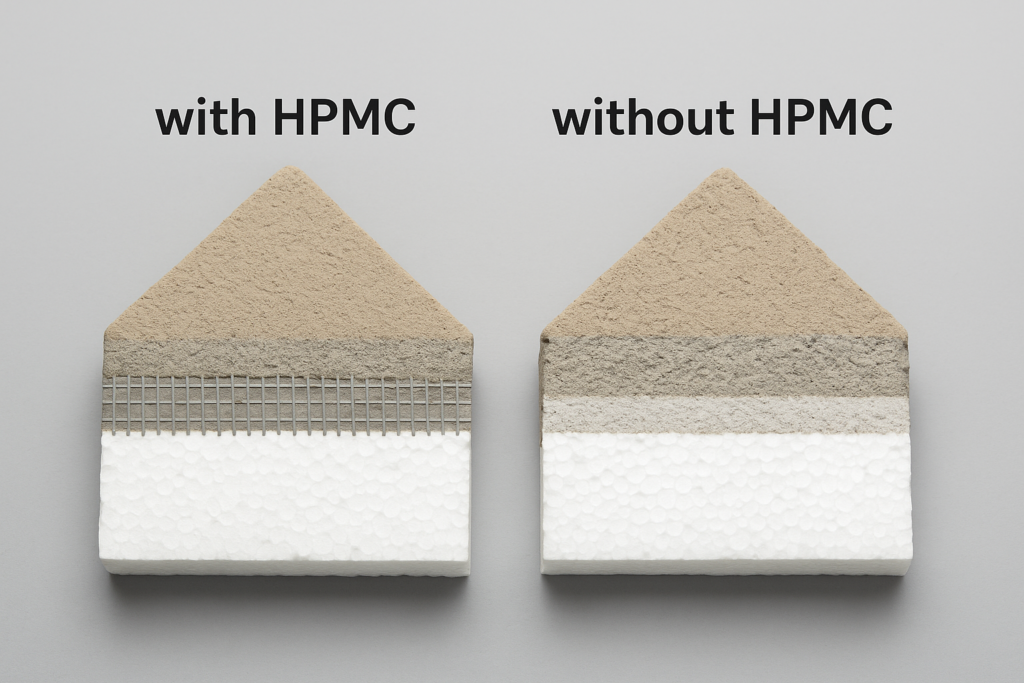

HPMC provides four essential benefits for EIFS systems: excellent water retention to prevent premature drying, enhanced adhesion between layers, improved workability for easy application, and increased open time allowing for proper installation adjustments. These properties directly impact the long-term durability and performance of the entire system.

In my years supplying HPMC to major EIFS manufacturers, I've witnessed firsthand how this additive transforms performance. Water retention is perhaps the most crucial property HPMC brings to these systems. When installing EIFS in hot or windy conditions, the mixture can dry too quickly, leading to poor adhesion and eventual system failure.

Our high-quality HPMC creates a water-retaining gel structure that keeps moisture in the mix long enough for proper cement hydration.

The adhesion improvement can't be overstated. Modern EIFS systems often face challenging installation conditions - attaching insulation boards to various substrates requires exceptional bonding strength.

HPMC creates physical and chemical bonds that significantly enhance adhesion. In our laboratory tests, properly formulated HPMC increased adhesion strength by up to 40% compared to formulations without it.

Workability improvements make a substantial difference in real-world applications. EIFS applicators face time constraints and varying environmental conditions.

HPMC adds lubrication to the mixture, making it smoother and easier to spread while reducing sagging on vertical surfaces. This translates to faster application times and more consistent coverage.

The thickening effect of HPMC also contributes to anti-sagging properties, allowing applicators to apply thicker layers when needed without risking material failure. This is particularly important for the base coat layer where reinforcing mesh must be fully embedded.

HPMC Effects on EIFS Performance

| HPMC Property | Direct Benefit | Long-term System Impact |

|---|---|---|

| Water Retention | Prevents premature drying | Ensures complete cement hydration for maximum strength |

| Adhesion Enhancement | Stronger bonds between layers | Reduces risk of delamination over time |

| Thickening/Workability | Easier application, consistent thickness | More uniform protection, fewer weak spots |

| Open Time Extension | More working time for adjustments | Better overall installation quality |

| Air Entrainment | Improved freeze-thaw resistance | Extended system lifespan in cold climates |

How Should HPMC Be Applied in Different EIFS/ETICS Scenarios?

Do you struggle with selecting the right HPMC viscosity for different EIFS applications? Using the wrong specification can lead to material wastage, application difficulties, and compromised system performance.

For EIFS adhesives, use HPMC with viscosity of 100,000-150,000 mPa·s to ensure strong bonding and sufficient open time. Base coats benefit from medium viscosity (60,000-80,000 mPa·s) for good workability and mesh embedding. Finish coats require lower viscosity HPMC (15,000-40,000 mPa·s) to balance texture control and decorative finish quality.

After supplying HPMC5 for countless EIFS projects across different climate zones, I've developed specific recommendations for each system component. For the adhesive layer, which bonds insulation boards to the substrate, higher viscosity HPMC creates stronger initial tack and better bond strength.

In hot, dry environments like Saudi Arabia or the UAE, I recommend increasing HPMC content by 0.1-0.2% compared to standard formulations to compensate for rapid water evaporation.

The base coat layer presents unique challenges as it must embed the reinforcing mesh while maintaining adequate thickness. Medium viscosity HPMC works best here, providing the right balance between spreadability and sag resistance.

Our clients in tropical regions like Singapore and the Philippines have found that adding methyl hydroxyethyl cellulose (MHEC)6 instead of standard HPMC improves resistance to high humidity conditions.

For the decorative finish coat, lower viscosity HPMC helps achieve the desired textures while still providing essential water retention. The dosage typically ranges from 0.2% to 0.4% of the dry mix weight, depending on the specific texture requirements and application conditions.

Temperature considerations cannot be overlooked. When applying EIFS in temperatures above 35°C (95°F), which is common in Middle Eastern markets, I recommend using HPMC with delayed dissolution properties.

This prevents premature thickening when mixing and extends working time. Conversely, in colder conditions below 10°C (50°F), a faster-dissolving grade helps ensure proper viscosity development during mixing.

HPMC Selection Guide by EIFS Component

| EIFS Component | Recommended HPMC Viscosity | Dosage Range | Special Considerations |

|---|---|---|---|

| Adhesive Layer | 100,000-150,000 mPa·s | 0.3%-0.5% | Higher dosage for porous substrates |

| Base Coat | 60,000-80,000 mPa·s | 0.25%-0.4% | Add methylcellulose for improved workability |

| Finish Coat | 15,000-40,000 mPa·s | 0.2%-0.4% | Lower viscosity for fine textures |

| Leveling Compounds | 40,000-60,000 mPa·s | 0.2%-0.3% | Add redispersible powder for flexibility |

| Repair Mortars | 80,000-100,000 mPa·s | 0.3%-0.5% | Higher dosage for vertical applications |

Conclusion

HPMC is the unsung hero of EIFS performance, providing essential water retention, adhesion, and workability that determine system success. By selecting the right HPMC grade for each component, you'll create EIFS installations that deliver lasting energy efficiency and durability.

-

Explore how HPMC enhances adhesion and durability in EIFS systems, ensuring long-lasting performance and reducing project failures. ↩

-

Learn about the advantages of EIFS over stucco, including energy efficiency and insulation properties, to make informed construction choices. ↩

-

Explore how HPMC enhances EIFS performance, ensuring better adhesion and durability for your projects. ↩

-

Learn about the benefits of EIFS, including insulation and flexibility, which can improve your building's energy efficiency. ↩

-

Explore this link to understand HPMC's role in construction, its benefits, and how it enhances EIFS systems. ↩

-

Learn about MHEC's advantages in construction, especially in humid environments, and how it improves material performance. ↩