Dealing with wall cracks can be a homeowner's nightmare. You patch them up, only to see them return months later, wider and longer than before. This endless cycle is not just annoying, it's expensive.

Yes, redispersible polymer powder1 (RDP) effectively reduces wall cracking by creating a flexible polymer network2 within cement-based materials. It acts like thousands of micro-shock absorbers, absorbing stress from thermal changes and substrate movement while bridging microcracks before they develop into visible cracks.

When I first heard about redispersible polymer powder, I was skeptical. How could a simple powder make such a big difference in preventing wall cracks? After seeing the results on numerous projects and understanding the science behind it, I'm now convinced it's one of the most important innovations in modern construction materials.

What is Redispersible Polymer Powder Used For?

Pain point: Traditional cement mortars are rigid and prone to cracking, causing costly repairs and unhappy clients. Without proper additives, even high-quality cement will eventually crack.

Redispersible polymer powder is used to enhance cement-based materials by improving flexibility, adhesion, water resistance, and workability. It's commonly added to tile adhesives, self-leveling compounds3, repair mortars, EIFS (exterior insulation finishing systems4), and decorative renders to prevent cracking and improve durability.

Redispersible polymer powder transforms ordinary cement-based products into high-performance building materials. I've seen this transformation first-hand in our factory production lines. When we add RDP to our formulations, the end result is dramatically improved.

The key benefit of RDP lies in its unique molecular structure. Unlike traditional cement which forms a rigid skeleton, RDP creates a flexible polymer network within the cement matrix. This network acts like a series of tiny springs, absorbing stress and preventing crack formation.

RDP works by forming polymer films within the cement as it dries. These films bridge between cement particles, sand grains, and other components, creating a cohesive yet flexible structure. The polymer content also significantly improves adhesion to various substrates, which is critical for preventing delamination - another common cause of wall cracks.

For exterior applications, RDP provides essential protection against weather extremes. When walls experience thermal cycling (heating up during the day and cooling at night), the added flexibility from RDP helps the material expand and contract without developing stress cracks.

Types of RDP and Their Specific Applications

| RDP Type | Best For | Crack Prevention Properties |

|---|---|---|

| VAc/E based | General mortars, interior applications | Good flexibility, cost-effective |

| VAc/VeoVa | Exterior applications, wet areas | Excellent water resistance, good flexibility |

| Acrylic based | High-end applications, severe conditions | Superior flexibility, best crack resistance |

| Styrene-acrylic | Decorative finishes, repair mortars | Good balance of hardness and flexibility |

What is RDP in Construction?

Problem: Many builders use outdated materials that can't withstand modern building stresses, leading to premature failures. Without understanding what RDP is, they miss out on a key solution.

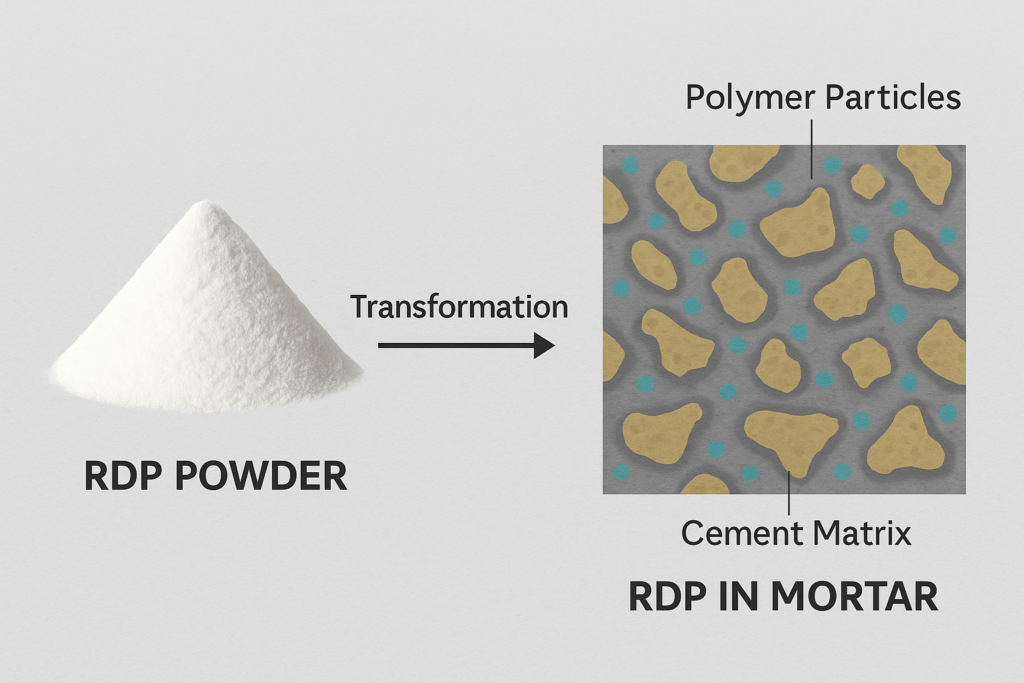

In construction, RDP (Redispersible Polymer Powder) is a spray-dried polymer emulsion that reactivates when mixed with water, creating a flexible binding agent within cement-based materials5. It fundamentally changes mortar properties from brittle to elastic, allowing it to absorb building movement without cracking.

Diving deeper into what makes RDP so valuable in construction requires understanding its transformation process. When water is added to a dry mix containing RDP, the polymer particles disperse (or redisperse, hence the name) into the mixture. As the water evaporates during curing, these polymers form continuous films and networks throughout the cement matrix.

This process fundamentally changes how the construction material behaves under stress. Traditional cement-based products without RDP are essentially ceramic in nature - hard but brittle. When force is applied, they resist until they suddenly break. There's very little elastic deformation before failure.

With RDP incorporated, the material gains viscoelastic properties. It can temporarily deform under stress and return to its original shape when the stress is removed - much like adding rubber to a ceramic. This property is crucial in construction where buildings are constantly subjected to various forces:

- Thermal expansion and contraction

- Vibration from traffic or machinery

- Slight foundation settlement

- Wind loads on exterior surfaces

- Impact forces

The effectiveness of RDP in construction varies based on dosage. Typically, applications require between 1-5% of RDP by weight of the dry mix, with specialized applications sometimes using up to 10%. I've found that even small additions of 1-2% can dramatically reduce cracking in many typical applications.

Construction professionals should also be aware that different RDP formulations offer specialized benefits beyond crack prevention, including water repellency, improved open time for application, and enhanced resistance to alkaline conditions found in cement.

What is the Full Form of RDP in Construction?

Problem: Confusing technical terms and acronyms make it hard to specify the right materials. Many contractors don't know what RDP actually stands for or how to request it properly.

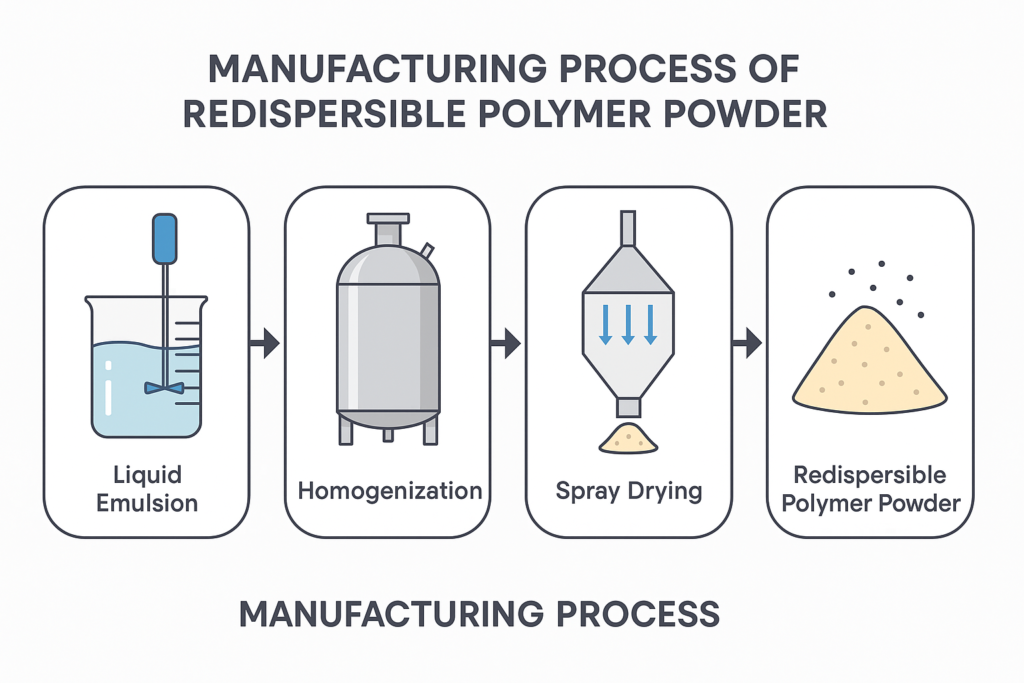

The full form of RDP in construction is "Redispersible Polymer Powder." This name describes its key property: the ability to disperse again (redisperse) into polymer particles when mixed with water, after having been dried from an original liquid polymer emulsion into powder form.

Redispersible Polymer Powder got its name from its unique manufacturing process and behavior. The journey from liquid polymer to powder and back to an active polymer is fascinating and essential to its functionality. Understanding this process helps explain why RDP works so effectively at crack prevention.

The manufacturing begins with creating a water-based polymer emulsion - tiny polymer droplets suspended in water. This liquid emulsion is then spray-dried using specialized equipment that instantly removes water while preserving the polymer's ability to redisperse later. Anti-caking agents (typically fine mineral powders) are added during this process to prevent the dried polymer particles from sticking together.

The resulting powder appears simple but contains sophisticated polymer chemistry. When water is added during mortar preparation on the construction site, the powder "redisperses" - the polymer particles detach from the carrier minerals and form a new emulsion within the mix. As the mortar cures, these polymers create flexible bridges between the cement particles.

This redispersion capability distinguishes RDP from other polymer additives. Unlike liquid additives that can degrade over time or react prematurely with cement, RDP remains stable in dry form until intentionally activated. This provides several practical benefits:

- Extended shelf life compared to liquid additives

- Ability to create pre-mixed dry mortars at the factory level

- Reduced transportation costs (not shipping water)

- Precise dosing in factory conditions

- Consistent performance across varying job site conditions

The full term "Redispersible Polymer Powder" also helps distinguish it from non-redispersible polymer powder1s, which lack the critical ability to reform into an effective polymer network when wetted.

What is the 20/30/40 Rule in Concrete?

Problem: Concrete cracking causes costly repairs and customer complaints. Many contractors follow outdated practices that don't address the fundamental causes of concrete failure.

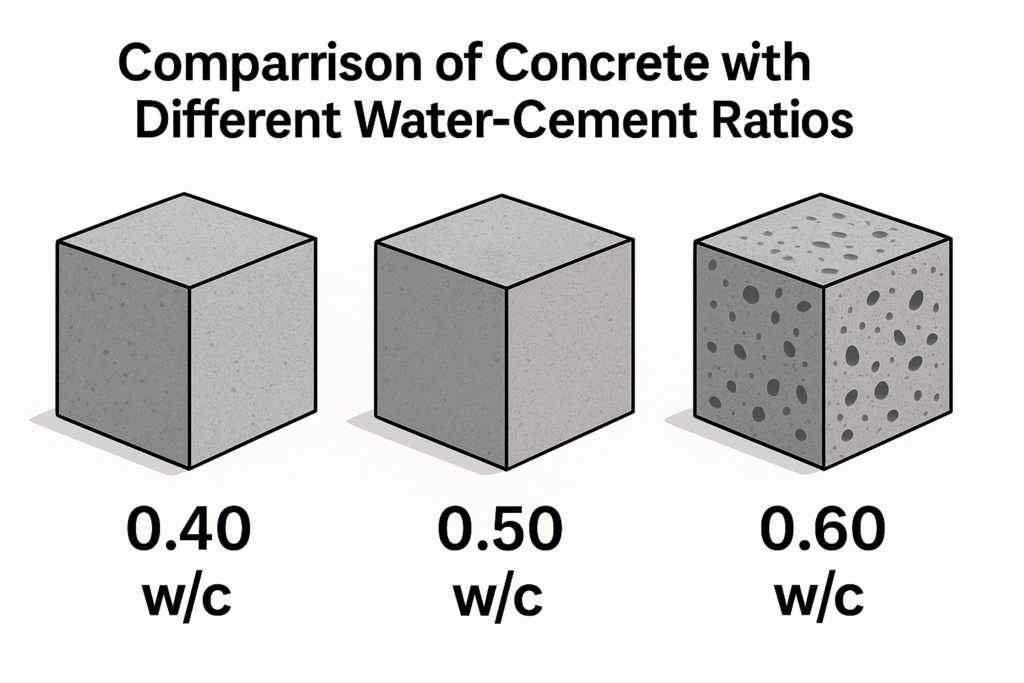

The 20/30/40 rule in concrete refers to critical water-cement ratio guidelines: use maximum 20 liters of water per 50kg cement bag for foundations, 30 liters for structural elements, and 40 liters for non-structural work. While this rule helps with basic concrete quality, adding RDP provides superior crack prevention through flexibility rather than just strength.

The 20/30/40 rule addresses concrete strength through water management, but it doesn't fully solve the cracking problem. This is where redispersible polymer powder offers a complementary approach that works synergistically with proper water-cement ratios.

Traditional concrete design focuses primarily on compressive strength. While strength is important, it doesn't necessarily prevent cracking. In fact, extremely strong concrete can be more brittle and therefore more prone to cracking when subjected to tensile forces. RDP addresses this limitation by improving concrete's tensile properties and flexibility.

When used together with proper water-cement ratio practices, RDP creates a balanced material that is both strong and flexible. I've observed that contractors who combine these approaches achieve the best long-term results with minimal callbacks for crack repairs.

The mechanism behind RDP's effectiveness goes beyond simple water management. While the 20/30/40 rule minimizes excess water that leads to shrinkage cracks, RDP actively works to:

- Bridge micro-cracks as they begin to form

- Distribute stress across a wider area rather than concentrating it at weak points

- Improve bond strength between concrete and reinforcement materials

- Enhance adhesion to existing substrates in repair situations

- Reduce water permeability, preventing freeze-thaw damage that leads to cracking

In practice, I recommend following the appropriate water-cement ratio for your application type while also incorporating RDP at 2-5% of cement weight for optimal crack resistance. This combined approach addresses both the initial quality of the concrete and its long-term performance under real-world conditions.

Who Makes Redispersible Polymer Powder?

Problem: Sourcing reliable RDP can be challenging. Poor quality products don't deliver promised benefits, leading to project failures and damaged reputations for contractors and suppliers alike.

Redispersible polymer powder is manufactured by specialized chemical companies including Wacker Chemie, Dow Chemical, Akzo Nobel, Celanese, and regional producers like Kehao in China. Quality varies significantly between manufacturers, affecting performance in crack prevention and other properties.

The manufacturing of high-quality redispersible polymer powder requires substantial expertise and specialized equipment. As someone working within this industry at Kehao, I can share that production quality directly impacts how effectively the final product prevents wall cracking.

The production process involves several critical stages that determine final performance:

- Polymer emulsion synthesis - creating the base polymer with the right molecular weight and composition

- Spray drying under precisely controlled conditions

- Addition of anti-blocking agents to prevent agglomeration

- Quality control testing for redispersibility, particle size, and performance

Leading global manufacturers have developed proprietary technologies and formulations that enhance specific properties. For example, some manufacturers focus on creating products with exceptional water resistance, while others optimize for extreme flexibility or cost-effectiveness.

When selecting an RDP supplier, construction professionals should consider these factors:

| Selection Factor | Why It Matters | What To Look For |

|---|---|---|

| Consistency between batches | Ensures predictable performance | Suppliers with strict quality control |

| Technical support | Helps optimize formulations | Manufacturers offering formulation assistance |

| Product range | Matches specific project needs | Variety of polymer types for different applications |

| Certification | Ensures compliance with standards | ISO certifications6, product testing reports |

| Manufacturing capacity | Reliable supply chain | Producers with multiple production lines |

As a manufacturer with six production lines, we at Kehao focus on producing RDP that delivers consistent performance for various applications, especially in demanding climates found in our export markets like Saudi Arabia, UAE, and India. The hot, dry conditions in these regions make crack prevention particularly challenging, requiring RDP with specific performance characteristics.

When evaluating RDP quality, construction professionals should request technical data sheets showing key properties like flexibility, adhesion strength, and water resistance. Reputable manufacturers provide this data and can demonstrate how their products specifically address crack prevention in different applications.

Conclusion

Redispersible polymer powder truly is a game-changer for preventing wall cracks. By creating a flexible network within rigid cement materials, it absorbs stress and bridges microcracks before they become visible problems. Select quality RDP from reputable manufacturers for best results.

-

Explore the science behind RDP to understand its role in preventing wall cracks and enhancing construction materials. ↩ ↩

-

Understand the benefits of flexible polymer networks in enhancing the performance of construction materials. ↩

-

Learn about self-leveling compounds and how they contribute to smooth and durable surfaces. ↩

-

Discover the advantages of EIFS in improving energy efficiency and aesthetics in buildings. ↩

-

Discover the versatility of cement-based materials in construction and their importance in building durability. ↩

-

Explore the significance of ISO certifications in ensuring quality and compliance in construction materials. ↩