Polypropylene fiber is a versatile and widely used synthetic fiber known for its unique properties and applications in various industries. In this blog, we will explore what polypropylene fiber is, its characteristics, and its uses, providing you with a comprehensive understanding of this essential material.

What is Polypropylene Fiber?

Polypropylene fiber, also known as PP fiber, is a type of synthetic fiber made from polypropylene, a thermoplastic polymer. This fiber is produced through a process called melt spinning, where polypropylene is melted and extruded through spinnerets to form continuous filaments. These filaments can then be processed into staple fibers or used in continuous filament forms.

Key Characteristics of Polypropylene Fiber

Polypropylene fiber possesses several distinct characteristics that make it a preferred choice in many applications:

1.Lightweight: One of the lightest synthetic fibers, polypropylene has a low density, making it ideal for lightweight and high-performance applications.

2.High Strength and Durability: Despite its lightweight nature, polypropylene fiber exhibits excellent strength and durability. It can withstand significant stress and strain without breaking or deforming.

3.Chemical Resistance: Polypropylene fiber is highly resistant to chemicals, including acids, alkalis, and organic solvents. This resistance makes it suitable for use in harsh chemical environments.

4.Moisture Resistance: Unlike many natural fibers, polypropylene does not absorb moisture. This property makes it an excellent choice for applications where moisture resistance is crucial, such as in geotextiles and outdoor fabrics.

5.Thermal Insulation: Polypropylene fiber has good thermal insulation properties, helping to maintain temperature stability in various applications.

6.UV Resistance: With the addition of UV stabilizers, polypropylene fiber can be made resistant to degradation from UV exposure, extending its lifespan in outdoor applications.

Applications of Polypropylene Fiber

Polypropylene fiber's unique properties make it suitable for a wide range of applications across different industries:

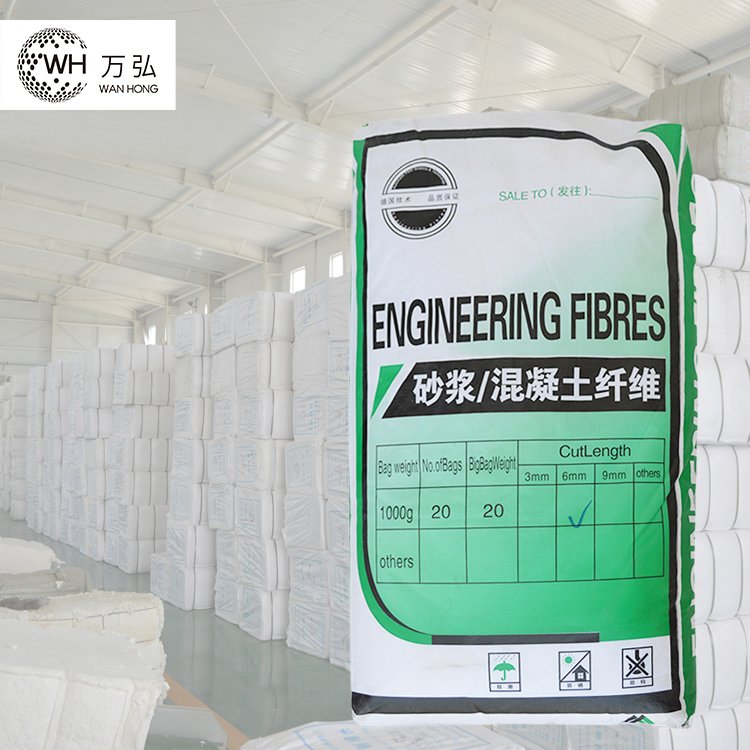

Construction: In the construction industry, polypropylene fibers are used to reinforce concrete, enhancing its tensile strength and crack resistance. This application is particularly common in road construction, flooring, and precast concrete products.

Textiles: Polypropylene fibers are used in the production of nonwoven fabrics, which are utilized in various products such as carpets, upholstery, and automotive interiors. They are also used in geotextiles for soil stabilization and erosion control.

Packaging: Polypropylene fiber is employed in the production of woven sacks and bags for packaging agricultural products, cement, and other bulk materials.

Automotive: In the automotive industry, polypropylene fiber is used in the manufacturing of interior components, such as seat covers, carpets, and insulation materials, due to its lightweight and durable properties.

At WHHPMC, we pride ourselves on producing high-quality polypropylene fibers that meet the diverse needs of our customers. Our state-of-the-art factory, equipped with four production lines, ensures consistent quality and customizable options to suit your specific requirements.

For more information about our polypropylene fiber and other products, visit our website at www.whhpmc.com or contact us at Ada@whhpmc.com. Let's build a better future with high-quality, durable, and innovative materials.