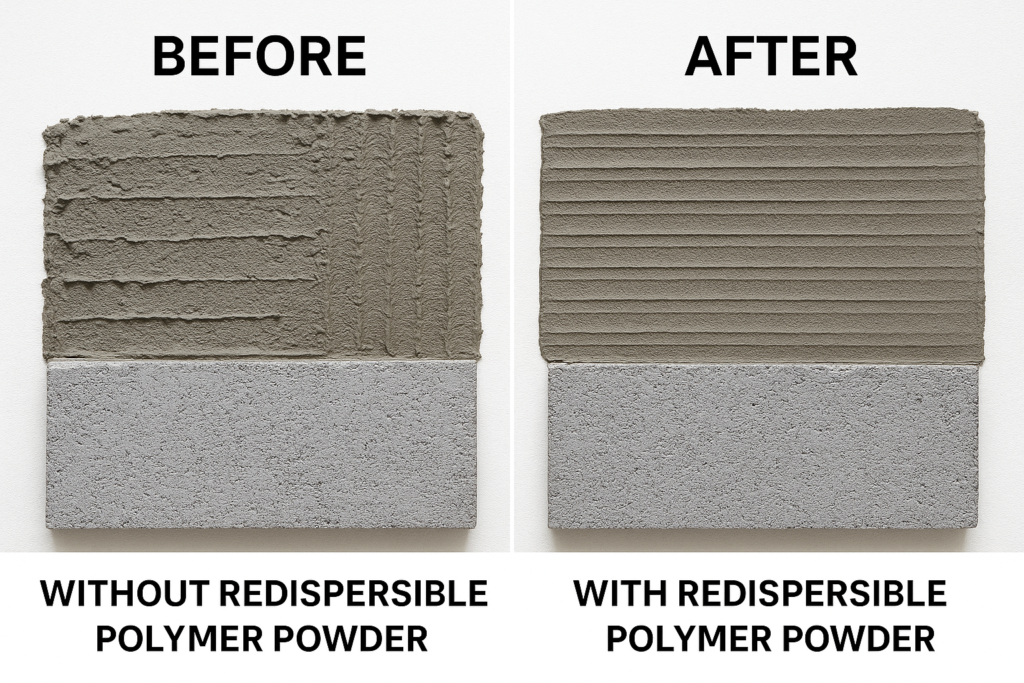

Are you struggling with poor adhesion and flexibility in your mortar mixes? Many contractors face this problem daily, leading to cracked surfaces and costly repairs. Redispersible polymer powder1 could be your solution.

Redispersible polymer powder1 is a specialized additive that enhances adhesion, flexibility, and water resistance in dry mortar applications2. When mixed with water, it redisperses into polymer particles that form films during drying, creating stronger bonds between construction materials.

As a manufacturer with over 15 years in the construction chemicals industry3, I've seen how the right redispersible polymer powder can transform ordinary mortars into high-performance building materials. Let me share what makes this powder so valuable for your construction projects and why choosing the right supplier matters for your business success.

What Makes a Quality Redispersible Polymer Powder Manufacturer?

Finding a reliable supplier can be challenging when you don't know what to look for. Poor quality powder can ruin entire batches of mortar and waste your money. How do you identify a trustworthy manufacturer?

A quality redispersible polymer powder manufacturer maintains strict quality control systems, offers consistent product specifications, provides technical support, and can supply customized formulations. They should have production certifications like ISO 9001 and offer transparent product documentation and testing reports.

At our factory in China, we've built our reputation on consistent quality and reliability. Our six production lines run 24/7 to ensure timely delivery for clients worldwide. We invest heavily in R&D to stay at the forefront of redispersible polymer powder technology.

Our manufacturing process follows strict quality control procedures with multiple testing points. Each batch undergoes thorough analysis for particle size distribution, redispersibility, and performance in various applications. This attention to detail ensures you receive products that meet your exact specifications every time.

We also understand that different markets have different needs. That's why we offer customized formulations based on your specific requirements and local conditions. Many of our clients in Saudi Arabia, UAE, and other Middle Eastern countries appreciate our ability to adjust formulations for extreme temperature conditions.

What Is Redispersible Polymer Powder and How Does It Work?

When looking at white powders, it's hard to tell which one will improve your mortar. Many distributors don't fully understand the chemistry behind these products. What exactly makes redispersible polymer powder so special?

Redispersible polymer powder1 is a spray-dried polymer emulsion that converts back to its original state when mixed with water. It forms polymer films during the drying process that create flexible bridges between cement particles and aggregates, significantly improving adhesion, flexibility, and crack resistance in cement-based materials.

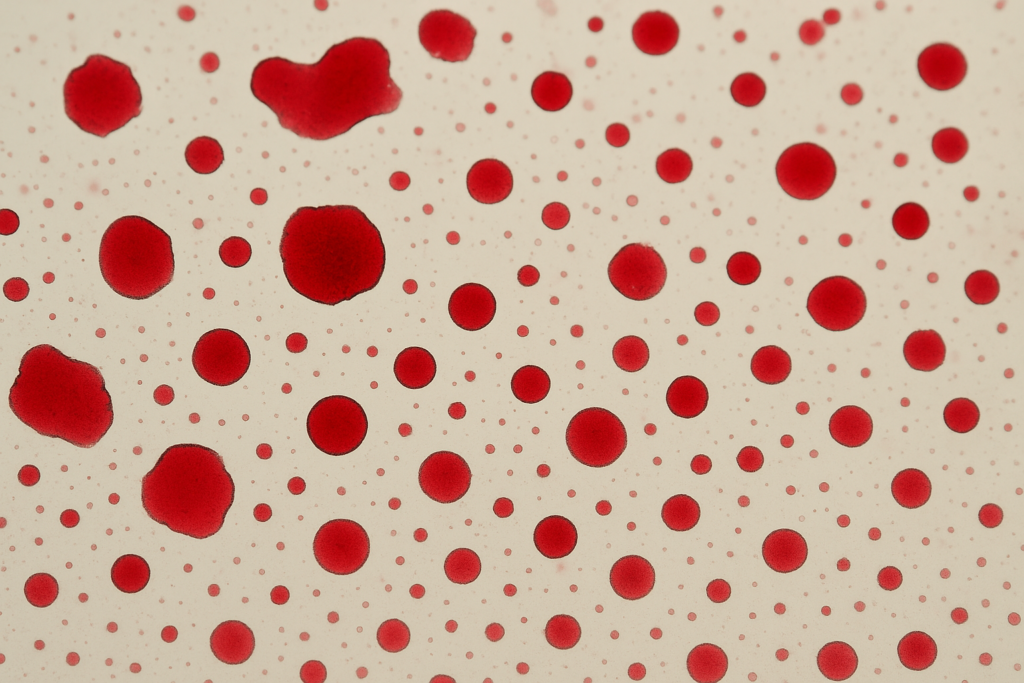

The science behind redispersible polymer powder is fascinating and explains why it's become indispensable in modern construction. During manufacturing, we start with a liquid polymer emulsion - typically vinyl acetate-ethylene (VAE), styrene-acrylic, or pure acrylic polymers. This liquid undergoes a sophisticated spray-drying process where the water evaporates, leaving behind tiny polymer particles coated with protective additives.

When you add water to your mortar mix containing our redispersible polymer powder, these particles "wake up" and redisperse into the mixture, creating a fresh polymer emulsion. As the mortar dries, these polymer particles form continuous films that bind the cement and aggregates together. This film formation is the key to improved performance.

The polymer films serve multiple functions simultaneously. They create flexible bridges between rigid components, allowing the cured mortar to handle movement without cracking. They also form a network that reduces water penetration while maintaining breathability. Additionally, the polymer enhances the mortar's adhesion to various substrates - even difficult ones like glass, metal, or existing concrete surfaces.

Different polymer types offer specific benefits. For example, our VAE-based powders excel in general-purpose applications, while our acrylic-based options provide superior exterior durability and water resistance for challenging environments.

What Product Details Should You Know About Redispersible Powder?

Technical specifications can be overwhelming when choosing the right polymer powder. Many buyers make expensive mistakes by selecting products solely based on price. What specific properties should you evaluate?

Key product details include polymer type (VAE, acrylic, or styrene-acrylic), particle size (typically 80-120 μm), minimum film formation temperature (MFFT), glass transition temperature (Tg), and ash content4. These properties determine performance characteristics like flexibility, water resistance, and compatibility with cement systems.

Understanding the technical specifications of redispersible polymer powder helps you select the right product for your specific application. Our product line includes several grades with varying properties to match your requirements.

The polymer base is perhaps the most crucial factor. VAE (vinyl acetate-ethylene) polymers offer excellent balance between cost and performance, making them ideal for general applications like tile adhesives5 and self-leveling compounds6. Acrylic and styrene-acrylic polymers provide enhanced water resistance and exterior durability, making them better suited for exterior insulation finishing systems (EIFS) and waterproofing membranes.

Particle size distribution affects how well the powder mixes into your formulation. Our advanced milling technology ensures uniform particle size distribution in the 80-120 μm range, giving you consistent mixing and performance. We can also provide customized particle sizes for special applications.

The Minimum Film Formation Temperature7 (MFFT) indicates the lowest temperature at which the polymer can form a continuous film. This is critical for applications in variable climate conditions. We offer products with MFFT values ranging from 0°C to 15°C to suit different environments. For our clients in colder regions, we recommend our low-MFFT products that can cure properly even in lower temperatures.

Glass transition temperature (Tg) determines the flexibility of the cured polymer. Higher Tg values result in harder, less flexible films, while lower values create more elasticity. Depending on your application's requirements for rigidity or flexibility, we can recommend the appropriate Tg value.

Ash content indicates the amount of mineral fillers and affects both cost and performance. Our standard products have optimized ash content to balance performance and value.

What Are the Top 3 Benefits of Redispersible Polymer Powder?

Construction projects face multiple challenges from poor adhesion to water damage. Many traditional additives solve one problem but create others. What makes redispersible polymer powder so versatile?

The top three benefits of redispersible polymer powder are: 1) Enhanced adhesion to difficult substrates like smooth concrete and old surfaces; 2) Improved flexibility that prevents cracking during building movement and thermal changes; and 3) Increased water resistance while maintaining breathability.

Beyond these primary benefits, redispersible polymer powder transforms ordinary cement-based materials in numerous ways that directly impact your project's success and longevity.

Enhanced adhesion is perhaps the most valuable benefit. Our clients consistently report significant improvements in bond strength when using our powder. Technical tests show up to 300% improvement in adhesion strength compared to unmodified mortars. This is particularly important for vertical applications like tile adhesives and renders, where failure means costly repairs and reputation damage. The polymer creates chemical bonds with substrates that mechanical adhesion alone cannot achieve.

Improved flexibility addresses one of cement's biggest weaknesses: brittleness. Traditional cement-based materials crack under movement, whether from building settling, thermal expansion, or vibrations. Our redispersible polymer powder creates elasticity within the cured material that absorbs these movements. Laboratory testing shows that mortars modified with our powder can accommodate up to 3-5 times more movement before cracking compared to standard mortars. This dramatically extends the lifespan of your applications.

Water resistance is critical for durability in most construction applications. The polymer films formed within the mortar create barriers that significantly reduce water penetration while still allowing water vapor to escape. This balance between water resistance and breathability prevents trapped moisture problems that can lead to mold growth and material degradation. Our clients in high-humidity regions like the Philippines and Vietnam particularly value this property.

Additional benefits include reduced shrinkage during curing, improved workability during application, and better resistance to freeze-thaw cycles. These properties combine to create construction materials that are easier to work with and last substantially longer.

How Is Redispersible Polymer Powder Used In Drymix Mortar?

Using the right amount of polymer powder is crucial for performance. Many first-time users either use too little (losing benefits) or too much (wasting money). What's the correct approach to incorporating this additive?

Redispersible polymer powder is typically added at 1-5% of the dry mix weight, depending on the application. It should be thoroughly blended with dry ingredients before water addition. Higher percentages (3-5%) are used for demanding applications like tile adhesives and waterproofing mortars, while 1-2% is sufficient for renders and masonry mortars.

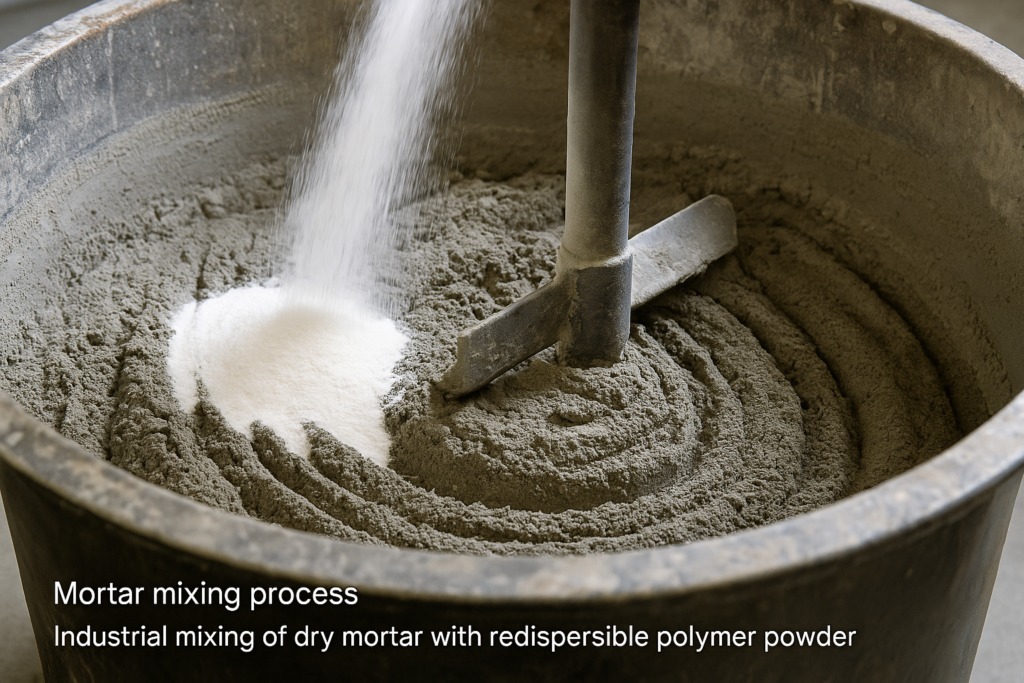

The integration of redispersible polymer powder into drymix mortars follows a specific process to ensure maximum effectiveness. In industrial production settings, we recommend using a high-shear mixer to achieve uniform distribution of the polymer particles throughout the mixture. This even distribution is essential for consistent performance across the entire batch.

Dosage recommendations vary based on the specific application and performance requirements. I've provided our clients with detailed formulation guidance based on extensive testing and real-world applications:

| Application Type | Recommended Dosage (% of cement weight) | Key Benefits |

|---|---|---|

| Standard renders/plasters | 1-2% | Improved workability, reduced cracking |

| Tile adhesives (interior) | 2-3% | Enhanced adhesion, extended open time |

| Tile adhesives (exterior) | 3-5% | Superior water resistance, freeze-thaw durability |

| Self-leveling compounds | 1-3% | Better flow properties, reduced shrinkage |

| Repair mortars | 3-5% | Excellent adhesion to old concrete, flexibility |

| Waterproofing mortars | 5-10% | Maximum water resistance, crack-bridging |

| EIFS adhesives | 2-4% | Impact resistance, thermal movement accommodation |

The sequence of mixing also matters significantly. For optimal performance, first mix all dry components (cement, sand, fillers) together, then add the redispersible polymer powder and mix thoroughly before adding water. This ensures the polymer particles are evenly distributed before they begin to redisperse.

Water content must be carefully controlled as well. While polymer-modified mortars generally require slightly less water than unmodified versions, reducing water too much can prevent proper redispersion of the polymer. Our technical support team can help you determine the ideal water-to-cement ratio for your specific formulation.

Temperature during mixing and application also affects performance. Most of our products perform optimally at temperatures between 5°C and 35°C. For applications outside this range, we offer specialized grades designed for extreme conditions.

Why Choose a Reliable Redispersible Polymer Powder Factory in China?

International sourcing comes with risks of inconsistent quality and delayed shipments. Many buyers have faced production halts due to supplier issues. How do you find a manufacturer you can rely on long-term?

A reliable Chinese redispersible polymer powder factory offers advantages like cost-effective pricing, consistent quality control, large production capacity, and flexible customization options. Look for manufacturers with export experience, proper certifications, transparent communication, and a track record of timely deliveries.

As the production manager of our facility in China, I've spent years refining our manufacturing processes to meet the demands of international clients. China has become a global hub for construction chemical production due to several key advantages that directly benefit our customers.

Our factory's scale of operations allows economies of scale that translate into competitive pricing without sacrificing quality. With six dedicated production lines running continuously, we achieve production efficiencies that smaller manufacturers cannot match. This capacity also ensures we can meet large volume orders even during peak demand seasons.

Quality control is integrated at every production stage. We implement a three-tier quality assurance system: raw material testing, in-process controls, and finished product verification. Each batch undergoes comprehensive testing including particle size analysis, redispersibility evaluation, and application performance testing. This rigorous approach results in a remarkably low defect rate of less than 0.3%, compared to the industry average of 1-2%.

Our location in China's chemical manufacturing hub gives us access to high-quality raw materials and specialized technical talent. We've invested in advanced German and Swiss equipment for our production lines, combining the cost advantages of Chinese manufacturing with European technology standards.

Export logistics expertise is another significant advantage. We've established efficient shipping routes to our major markets, including Saudi Arabia, UAE, Iran, India, and Brazil. Our dedicated logistics team handles all export documentation, ensuring smooth customs clearance and minimizing delays. We maintain relationships with multiple shipping companies to secure competitive rates and reliable schedules.

For clients concerned about supply chain stability, we offer inventory management programs where we maintain stock reserves based on your projected needs, ensuring you never face production delays due to material shortages.

How Can You Buy Redispersible Polymer Powder with Flexible Delivery Options?

Ordering from international suppliers can be stressful when delivery timelines are critical. Many construction projects face costly delays due to material shortages. How can you ensure reliable supply?

To purchase redispersible polymer powder with flexible delivery options, look for suppliers offering multiple packaging sizes (25kg bags to 1000kg jumbo bags), various shipping methods (sea, air, rail), consolidated shipments, and inventory management programs. Request clear lead times and tracking systems to monitor your order status.

We understand that timely delivery is as important as product quality, especially in the construction industry where project timelines are strictly monitored. That's why we've developed flexible purchasing and delivery systems designed to accommodate different business needs.

Our order process begins with understanding your specific requirements - not just product specifications, but also your timeline, budget constraints, and logistical preferences. We offer sample testing programs that allow you to verify product performance before committing to larger orders. This approach has helped many of our clients in Pakistan, Mexico, and Georgia find the exact product formulation for their specific applications.

Packaging options are diverse to match your handling capabilities and storage facilities. Our standard 25kg moisture-resistant paper bags are perfect for those with limited storage space or who prefer working with smaller quantities. For larger operations, we offer 500kg and 1000kg jumbo bags that reduce packaging waste and handling time. All packaging includes UV protection and moisture barriers to maintain product integrity during transportation and storage.

Shipping flexibility is a core component of our service. For urgent needs, we maintain air freight partnerships that can deliver to most major markets within 5-7 days. Standard sea shipping typically requires 15-30 days depending on destination. We've recently expanded our offerings to include rail transport options through the China-Europe railway network, providing a balance between cost and speed for our European customers.

Our order tracking system provides real-time updates from production through delivery. Clients receive automated notifications at key milestones, and our customer service team is available 24/7 to address any concerns or provide shipping updates.

For regular customers, we offer just-in-time delivery8 programs where we maintain your inventory at our warehouse and ship according to your production schedule. This approach has helped many of our clients reduce their storage costs while ensuring continuous material availability.

How Does Our Redispersible Polymer Powder Meet Environmental Standards?

Environmental regulations are getting stricter worldwide. Non-compliant materials can lead to project rejections and fines. How can you ensure your construction materials meet current and future standards?

Our redispersible polymer powder meets environmental standards through low VOC content (<0.1%), formaldehyde-free formulations, compliance with REACH and RoHS requirements, and recyclable packaging. Our products contribute to green building certifications like LEED by improving energy efficiency through better insulation system performance.

Environmental responsibility has become central to our product development philosophy. As regulations become more stringent across our export markets, we've positioned ourselves as leaders in eco-friendly construction chemicals that don't compromise on performance.

Our standard product line features VOC content below 0.1%, significantly lower than the 1-2% commonly found in conventional products. This improvement comes from our innovative manufacturing process that eliminates the need for certain solvents traditionally used in polymer production. The result is a healthier working environment for applicators and better indoor air quality in finished buildings.

All our formulations are 100% formaldehyde-free, addressing growing concerns about this potentially harmful compound in building materials. We've also eliminated alkylphenol ethoxylates (APEOs) and other environmentally persistent chemicals from our production process. These improvements required significant R&D investment but have positioned us ahead of regulatory curves in most markets.

We maintain comprehensive compliance with international standards including REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe, RoHS (Restriction of Hazardous Substances), and various national green building standards. Our laboratory constantly monitors regulatory developments to ensure continued compliance as standards evolve.

The environmental benefits extend beyond the product formulation to its application performance. Buildings constructed with our redispersible polymer powder-modified mortars typically demonstrate better energy efficiency9. The improved adhesion and flexibility create more effective thermal insulation systems10 that reduce heating and cooling needs. These performance characteristics help projects achieve points in green building certification systems like LEED and BREEAM.

Our packaging also reflects our environmental commitment. We use paper bags with minimum 30% recycled content and have recently introduced a partially biodegradable liner option. For bulk packaging, our jumbo bags are designed for easy recycling after use. We're currently developing a take-back program for packaging in certain markets to further reduce the environmental footprint.

Our manufacturing facility employs energy-efficient production methods with heat recovery systems that reduce overall energy consumption by approximately 25% compared to conventional processes. Water used in production is fully treated and recycled, creating a near-zero discharge operation.

For clients with specific environmental requirements, we can provide detailed documentation including Environmental Product Declarations (EPDs) and Health Product Declarations (HPDs) to support green building certifications.

What Packaging and Sizes Are Available for Redispersible Polymer Powder?

Improper packaging can lead to product degradation and wasted materials. Many users struggle with storage and handling issues. What packaging options best protect the powder while meeting your operational needs?

Redispersible polymer powder typically comes in moisture-resistant 25kg paper bags, 500kg and 1000kg jumbo bags with PE liners, and occasionally in plastic containers for smaller quantities. Proper packaging should include moisture barriers, UV protection, and clear labeling with batch numbers, production dates, and usage instructions.

Packaging is far more than just a container - it's a critical component in preserving product performance and enabling efficient handling throughout your operation. Over years of working with diverse clients across different climates and handling environments, we've developed packaging solutions to address specific challenges.

Our standard 25kg multi-layer kraft paper bags include an inner PE liner that provides effective moisture protection - crucial for maintaining the powder's redispersibility. The bags are heat-sealed rather than stitched, creating a more reliable moisture barrier. Each bag undergoes burst testing to ensure it can withstand normal handling stresses during transportation and storage. This size is ideal for smaller operations or for clients who blend different formulations in smaller batches.

For industrial-scale operations, our 500kg and 1000kg FIBC (Flexible Intermediate Bulk Container) jumbo bags offer significant handling efficiencies. These bags feature four-point lifting loops, flat bottoms for stable stacking, and discharge spouts designed for controlled emptying. The jumbo bags include UV stabilizers to prevent degradation during outdoor storage and are designed to standard pallet dimensions for efficient transportation.

All our packaging includes comprehensive labeling with product information, technical specifications, safety data, batch numbers, and production dates. QR codes link to online technical documentation and safety information in multiple languages. This detailed information ensures proper handling and application at every stage.

Storage considerations are built into our packaging design. The bags are constructed to be stackable without crushing, and the moisture barriers maintain effectiveness for up to 24 months in proper storage conditions. We recommend storing the powder in dry conditions below 30°C and using it on a first-in, first-out basis.

For clients in particularly challenging climates, such as our customers in the high-humidity regions of Southeast Asia, we offer enhanced packaging with additional moisture protection layers and more robust sealing methods. This specialized packaging has proven effective even in monsoon conditions.

Custom packaging solutions11 are also available, including different bag sizes, client-specific branding, and specialized labeling to meet local regulatory requirements in different markets.

What Are Other Uses of Redispersible Polymer Powder in Construction?

Traditional applications like tile adhesives are well known, but many users miss opportunities for broader use. What other applications could benefit from this versatile additive?

Beyond common uses, redispersible polymer powder enhances repair mortars for concrete rehabilitation, improves 3D printing concrete mixes12, strengthens gypsum-based products, enhances acoustic insulation compounds, and creates more durable decorative finishes. It also improves screed performance and enhances cement-based waterproofing systems.

The versatility of redispersible polymer powder continues to surprise even experienced construction professionals. As we work with clients across different specialties, we've seen innovative applications that demonstrate the material's exceptional adaptability.

Concrete rehabilitation has become a major growth area for our products. As infrastructure ages worldwide, repair solutions that bond seamlessly with existing concrete are increasingly valuable. Our redispersible polymer powder creates repair mortars with exceptional adhesion to old concrete surfaces, with bond strengths exceeding 1.5 MPa even on smooth substrates. The flexibility of the polymer-modified repairs accommodates the different movement characteristics between new and old materials, preventing the edge cracking common with traditional repair methods.

The emerging field of 3D concrete printing has also adopted our products. The polymer modification provides the perfect balance of pumpability, shape retention after extrusion, and interlayer adhesion required for this advanced construction method. Several of our customers in UAE and Singapore are pioneering 3D-printed building components using our specialized grade designed specifically for printable mixes.

Gypsum-based products gain significant performance improvements with our redispersible polymer powder. Traditional gypsum products typically suffer from brittleness and poor water resistance. Adding just 2-3% of our powder transforms these limitations, creating gypsum boards and compounds with significantly improved impact resistance and moisture tolerance. This has opened new application possibilities for gypsum in areas previously considered unsuitable.

Acoustic insulation compounds represent another growing application. The elasticity provided by the polymer significantly improves sound absorption performance by creating a more resilient material structure that dampens sound waves more effectively. Independent testing has shown up to 30% improvement in sound reduction index compared to unmodified formulations.

Decorative finishes benefit greatly from redispersible polymer powder modification. The improved adhesion allows thinner application layers, reduced cracking, and better resistance to weathering. The polymer also enhances color stability in pigmented finishes by reducing efflorescence (the white salt deposits that can mar colored surfaces).

Self-leveling screeds gain critical performance advantages from our products. The polymer improves flow characteristics during application while reducing shrinkage during curing. This combination results in smoother finished surfaces with fewer cracks and better dimensional stability – particularly important for installations involving underfloor heating systems.

Cement-based waterproofing systems achieve significantly higher performance with polymer modification. The flexible polymer fills micro-cracks and creates a continuous water barrier while maintaining breathability. This makes them ideal for wet areas like bathrooms, swimming pools, and water tanks.

Conclusion

Redispersible polymer powder transforms ordinary mortars into high-performance building materials with enhanced adhesion, flexibility, and durability. By choosing a reliable manufacturer with quality products and flexible delivery options, you can improve your construction projects while meeting environmental standards13.

-

Explore this link to understand how redispersible polymer powder can enhance your construction projects. ↩ ↩ ↩

-

Get insights into effective dry mortar application techniques for optimal results. ↩

-

Stay updated on the latest trends and innovations in the construction chemicals sector. ↩

-

Find out how ash content influences the performance and cost of construction materials. ↩

-

Get expert tips on maximizing the effectiveness of tile adhesives in your projects. ↩

-

Explore the benefits and applications of self-leveling compounds in modern construction. ↩

-

Learn why MFFT is crucial for the performance of polymer powders in various climates. ↩

-

Discover the advantages of just-in-time delivery for inventory management and cost reduction. ↩

-

Discover how the right materials can lead to significant energy savings in construction. ↩

-

Learn about effective thermal insulation systems to enhance building performance. ↩

-

Explore innovative packaging solutions that enhance product performance and safety. ↩

-

Discover the innovative applications of 3D printing in modern construction. ↩

-

Stay updated on environmental standards to ensure compliance and avoid project delays. ↩