Are you struggling with poor workability and short retention time in your construction materials? Many mortar and paint manufacturers face these exact issues, leading to wasted product and unhappy customers.

Methyl hydroxyethyl cellulose (MHEC)1 is a modified cellulose ether that improves workability, water retention, and consistency in construction products. It's widely used in tile adhesives2, wall putty3, skim coats4, and other building materials to enhance performance and extend working time.

As a leading MHEC manufacturer in China with six production lines, I've helped countless clients across Saudi Arabia, UAE, India, and other developing countries solve their construction material challenges. Let me guide you through everything you need to know about this essential construction additive.

Why Choose a China MHEC Supplier For Your Construction Business?

Do your construction materials fail to meet customer expectations? Are inconsistent raw materials causing quality problems in your production line? This creates unhappy customers and damages your reputation.

Chinese MHEC suppliers offer competitive advantages including strict quality control, customizable specifications, bulk production capacity, and cost-effective pricing. Leading manufacturers provide comprehensive certificates (ISO, SGS) and technical support tailored to specific application requirements.

My factory specializes in hydroxypropyl methylcellulose5 and related cellulose products including MHEC. We've invested heavily in production technology and quality control systems to ensure consistent product performance. Our technical team works directly with customers to develop customized solutions for specific applications.

Benefits of Working with Chinese MHEC Suppliers

| Benefit | Details |

|---|---|

| Quality Control | Strict QC processes with ISO certification |

| Production Capacity | Large-scale facilities with 6+ production lines |

| Technical Support | Application-specific formulation assistance |

| Customization | Tailored viscosity, substitution degree, and particle size |

| Cost Efficiency | Competitive pricing with economies of scale |

| Logistics Expertise | Experience with international shipping requirements |

When selecting a Chinese MHEC supplier, I recommend evaluating their production capacity, quality control procedures, and international shipping experience. Request samples before placing bulk orders to verify performance in your specific formulations. The best suppliers will provide comprehensive technical data sheets and application guidance to ensure optimal results in your products.

What Are The Top 5 Highlights Of MHEC Powder That Make It Superior?

Is your construction project suffering from poor water retention and workability issues? Are your materials drying too quickly, making application difficult and results inconsistent? These common problems affect project timelines and quality.

MHEC powder excels with its superior water retention capacity, excellent thickening properties, temperature-dependent solubility, enhanced workability in mortar systems, and strong adhesion promotion. These properties significantly improve construction material performance and application characteristics.

In my experience working with construction material manufacturers across developing markets, the technical properties of MHEC make a substantial difference in final product performance. Let me break down the key advantages that set MHEC apart from other cellulose ethers.

Technical Specifications of Premium MHEC Powder

| Property | Specification | Benefit |

|---|---|---|

| Viscosity Range | 10,000-80,000 mPa·s | Customizable for different applications |

| Methoxyl Content | 25-32% | Controls water retention properties |

| Hydroxyethyl Content | 4-12% | Enhances compatibility with other ingredients |

| Moisture Content | ≤6% | Ensures product stability |

| Ash Content | ≤5% | Indicates purity level |

| pH (2% solution) | 5.5-8.0 | Compatible with cement chemistry |

I've observed that the specific ratio between methoxyl and hydroxyethyl substitution is crucial for optimizing performance in different applications. For tile adhesives2, higher hydroxyethyl content improves flexibility, while wall putties benefit from higher methoxyl content for better water retention. The particle size distribution also affects dissolution rate and final viscosity development - factors that directly impact your production efficiency and product quality.

How Can MHEC Powder Be Used In Different Construction Applications?

Have you noticed cracks in your finished walls or poor adhesion in tile installations? Is water separation in your mortar causing inconsistent results? These issues often stem from inadequate additives in your formulations.

MHEC powder is versatile in construction, functioning as a thickener, binder, film former, and water-retention agent. It's used in tile adhesives to prevent premature drying, in wall putties for smooth finishes, in exterior insulation systems for workability, and in self-leveling compounds6 for flow control.

Through working with clients across different construction sectors, I've gained insights into optimizing MHEC usage for specific applications. The dosage and grade selection significantly impact performance outcomes.

MHEC Dosage Recommendations by Application

| Application | Recommended MHEC Dosage | Preferred Viscosity | Key Benefits |

|---|---|---|---|

| Tile Adhesives | 0.2-0.4% | 30,000-60,000 mPa·s | Extended open time, slip resistance |

| Wall Putty | 0.3-0.6% | 15,000-40,000 mPa·s | Smooth finish, crack prevention |

| EIFS Mortars | 0.2-0.5% | 20,000-50,000 mPa·s | Workability, sag resistance |

| Self-leveling Compounds | 0.1-0.3% | 10,000-30,000 mPa·s | Flow control, surface quality |

| Gypsum Plasters | 0.1-0.2% | 15,000-30,000 mPa·s | Working time extension, consistency |

| Cement Renders | 0.2-0.4% | 30,000-50,000 mPa·s | Reduced water demand, adhesion |

When implementing MHEC in formulations, consider the interaction with other additives. For example, I've found that MHEC works synergistically with redispersible polymer powders in tile adhesives, enhancing both adhesion and flexibility. In wall putties, combining MHEC with proper fillers improves sandability and reduces shrinkage. Temperature during application also affects MHEC performance - higher temperatures require grades with stronger water retention properties to maintain workable conditions.

How Does MHEC Compare To Methyl Cellulose And Hydroxyethyl Cellulose?

Are you confused about which cellulose ether best suits your specific application? Do you wonder why some products perform better than others in certain conditions? Selecting the wrong cellulose derivative can waste money and compromise quality.

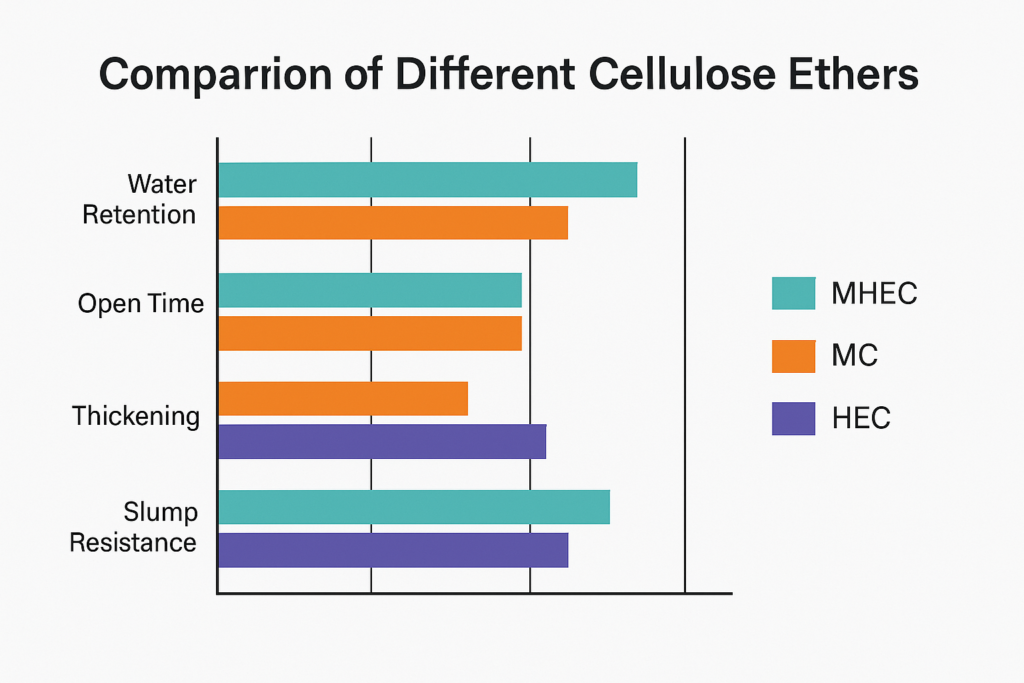

MHEC combines the water retention properties of methyl cellulose with the enhanced solubility of hydroxyethyl cellulose. It offers better cement compatibility than MC and stronger water retention than HEC, making it ideal for cement-based products requiring extended working time and good workability.

In my years working with various cellulose ethers, I've conducted numerous comparative tests to understand their performance differences across applications. This practical experience has revealed important distinctions that affect final product quality.

Comparative Analysis of Cellulose Ethers for Construction Applications

| Property | MHEC | Methyl Cellulose (MC) | Hydroxyethyl Cellulose (HEC) |

|---|---|---|---|

| Water Retention | Excellent | Very Good | Moderate |

| Workability | Excellent | Good | Good |

| Cement Compatibility | Excellent | Good | Very Good |

| Temperature Tolerance | Good | Moderate | Good |

| Dissolution Speed | Moderate-Fast | Slow | Fast |

| Anti-sagging Properties | Excellent | Good | Moderate |

| Cost Efficiency | Moderate | Economical | Higher |

| Surface Finish | Excellent | Good | Good |

The choice between these cellulose ethers should be application-specific. For example, I recommend MHEC for tile adhesives because its balanced water retention and workability properties create the ideal open time for installation. For wall putties, MHEC provides better surface finish and crack resistance compared to MC, while offering more cost-effective water retention than HEC. In terms of dissolution behavior, MHEC's modified structure provides a good balance between ease of incorporation and delayed viscosity development, which helps control mixing processes in production.

What Package And Delivery Options Are Available For MHEC Products?

Have you experienced damaged products due to poor packaging? Are delivery delays disrupting your production schedule? These logistical challenges can create serious problems for your business operations.

MHEC powder is typically available in 25kg kraft paper bags with PE liner for moisture protection. Bulk options include 500kg or 1000kg big bags for large orders. Palletized and shrink-wrapped packaging ensures safe international shipping, with delivery times of 15-30 days depending on destination.

Managing international shipments of chemical products requires careful attention to packaging details and shipping regulations. My factory has developed optimized logistics solutions based on years of experience shipping to over 30 countries.

MHEC Packaging and Shipping Specifications

| Packaging Type | Specifications | Benefits | Best For |

|---|---|---|---|

| Standard Bags | 25kg kraft paper with PE liner | Easy handling, moisture protection | Most orders |

| Big Bags (FIBC) | 500kg/1000kg with discharge spout | Reduced handling, bulk discount | Large volume users |

| Palletization | 40 bags (1MT) per pallet | Forklift handling, stability | Container shipments |

| Container Options | 20ft (16MT) or 40ft (26MT) | Volume efficiency, security | International orders |

| Documentation | COA, MSDS, CO, Packing List | Customs clearance, quality assurance | All shipments |

Beyond standard options, we offer customized packaging solutions7 including your company branding on bags. This is particularly valuable for distributors who resell to end users. For moisture-sensitive destinations, we can provide additional protection layers or desiccants. Our logistics department coordinates with shipping lines to secure competitive rates and optimal routes, monitoring shipments through delivery. We maintain inventory of standard grades to support short lead times for repeat orders, typically shipping within 7-10 days after order confirmation.

How Does MHEC Improve Wall Putty And Skim Coat Performance?

Does your wall putty crack after drying? Are your skim coats difficult to apply smoothly? These application problems create unhappy customers and increase project costs.

MHEC improves wall putty8 and skim coat performance by enhancing water retention, preventing premature drying and cracking. It creates optimal consistency for smooth application, improves sag resistance on vertical surfaces, and promotes strong adhesion to various substrates including concrete and gypsum boards.

I've worked with numerous wall putty manufacturers to optimize their formulations. The right MHEC grade and dosage can dramatically improve both application properties and final results.

MHEC Impact on Wall Putty Properties

| Property | Without MHEC | With MHEC | Improvement Factor |

|---|---|---|---|

| Working Time | 20-30 minutes | 60-90 minutes | 3x longer application window |

| Water Retention | 65-75% | 92-98% | Consistent curing throughout |

| Sagging on Vertical Surfaces | Significant | Minimal | Better thickness control |

| Cracking Tendency | Moderate-High | Low | Fewer callbacks/repairs |

| Surface Smoothness | Requires skill | Easier to achieve | Improved aesthetics |

| Adhesion Strength | Moderate | High | Reduced delamination risk |

The optimal MHEC grade for wall putty typically has a viscosity of 20,000-40,000 mPa·s with a carefully balanced methoxyl and hydroxyethyl substitution ratio. I recommend starting with a 0.3% dosage and adjusting based on specific requirements and local conditions. Hot and dry climates may require up to 0.5% for adequate working time. MHEC also improves compatibility with other additives like calcium carbonate fillers and improves sandability of the finished surface. For exterior applications, MHEC grades with higher hydroxyethyl content provide better resistance to moisture variation while maintaining excellent adhesion properties.

Why Is MHEC Critical For High-Performance Tile Adhesives?

Is your tile adhesive failing to hold heavy tiles on vertical surfaces? Do tiles lose bond strength when exposed to moisture? These failures create expensive repairs and damage your reputation.

MHEC is critical for tile adhesives as it provides essential open time extension, prevents premature drying, and ensures proper cement hydration. It enhances vertical slip resistance for heavy tiles, improves adhesion strength, and creates the right consistency for both thin and thick-bed applications.

In my experience developing tile adhesive formulations for different markets, MHEC plays a crucial role in meeting international standards like EN 12004 and ISO 13007.

MHEC Performance in Tile Adhesive Applications

| Property | Impact of MHEC | Industry Standard Requirement | Recommended MHEC Grade |

|---|---|---|---|

| Open Time | Extends by 15-30 minutes | ≥20 minutes (EN 12004) | 40,000-60,000 mPa·s |

| Slip Resistance | <0.5mm vertical slip | <0.5mm (T-rated adhesives) | Higher viscosity grades |

| Tensile Adhesion Strength | Improves by 25-40% | ≥0.5 N/mm² (Class C1) | Balanced substitution ratio |

| Transverse Deformation | Enhances flexibility | ≥2.5mm (Class S1) | Higher hydroxyethyl content |

| Water Resistance | Improves wet adhesion | No requirement for C1, higher for C2 | Hydrophobic grades |

| Mixing Water Demand | Reduces by 5-10% | Application-specific | Medium viscosity grades |

When formulating tile adhesives with MHEC, it's important to consider the synergy with other additives. For example, combining MHEC with redispersible polymer powder at the right ratio maximizes flexibility and adhesion while maintaining cost-effectiveness. The particle size distribution of MHEC affects dissolution speed during mixing, with coarser grades preferred for preventing lumps in machine mixing. For specialized applications like glass mosaic tiles or natural stone, we recommend MHEC grades with higher methoxyl content to minimize water migration that could cause staining or efflorescence.

How Does Wanhong Ensure Stable Supply Of MHEC Chemicals?

Have you faced production delays due to raw material shortages? Do quality inconsistencies from your suppliers cause trouble in your manufacturing process? These supply chain issues can seriously harm your business.

Wanhong ensures stable MHEC supply through strategic raw material sourcing, multiple production lines with 10,000+ ton annual capacity, comprehensive quality control systems9, and significant finished product inventory. Our vertically integrated production model and long-term supplier relationships minimize disruptions even during market fluctuations.

As a factory with six production lines, I've implemented robust systems to ensure consistent supply for our international clients. Our approach addresses multiple aspects of the supply chain.

Wanhong's Supply Chain Stability Measures

| Strategy | Implementation | Customer Benefit |

|---|---|---|

| Raw Material Security | Multiple vetted suppliers, 3-month inventory | Production continuity |

| Production Redundancy | 6 independent production lines | No single point of failure |

| Quality Consistency | Automated process controls, batch testing | Reliable product performance |

| Capacity Utilization | 70-80% standard utilization | Flexibility for urgent orders |

| Inventory Management | Safety stock of finished products | Quick shipping for urgent needs |

| Production Planning | Rolling 3-month forecast system | Alignment with customer demands |

| Logistics Partnerships | Multiple shipping carriers and routes | Flexible delivery options |

We've invested in vertical integration to control more of our supply chain. For example, our in-house raw material processing reduces dependence on external suppliers for critical components. Our production facilities include backup power systems and preventive maintenance schedules to avoid unexpected downtime. We also maintain strategic stock points in major markets to shorten delivery times for common grades and specifications.

Our quality management system tracks every batch from raw material to finished product, with comprehensive testing at multiple stages. This ensures that any potential issues are identified and resolved before products ship to customers. For long-term customers, we implement customized inventory programs based on forecasted needs, often maintaining dedicated stock for their specific requirements.

What Construction Grade Cellulose Product Solutions Does Kehao Offer?

Are you struggling to find a supplier who can provide the full range of cellulose products your construction business needs? Does working with multiple suppliers create inconsistency in your final products? This fragmented approach increases costs and quality control challenges.

Wanhong offers a comprehensive construction grade cellulose product line including MHEC, HPMC, CMC, HEC, and redispersible polymer powder. Our solutions cover applications from tile adhesives and grouts to renders, plasters, joint compounds, and exterior insulation systems with technical support for formulation optimization.

Over years of working with construction material manufacturers, I've developed a deep understanding of how different cellulose products interact within various formulations.

's Construction Cellulose Product Portfolio

| Product | Key Applications | Available Grades | Special Features |

|---|---|---|---|

| MHEC | Tile adhesives, Wall putty | 10,000-80,000 mPa·s | Balanced water retention and workability |

| HPMC | General construction, Renders | 5,000-200,000 mPa·s | Versatile performance, multiple viscosities |

| CMC | Joint compounds, Ceramic extrusion | Technical grades | Excellent binding properties |

| HEC | Latex paints, Liquid systems | Multiple viscosities | Fast dissolution, clear solutions |

| Redispersible Powder | Flexibility enhancement | VAE, VA/E/VC, Acrylic | Improves adhesion and flexibility |

| Polypropylene Fiber | Crack resistance | Various lengths | Reinforcement for mortars and concrete |

Our technical team provides customized solutions based on specific application requirements and local conditions. For example, we've developed specialized MHEC grades for hot climate regions that maintain water retention despite high temperatures and low humidity. For customers developing multi-component systems, we ensure compatibility between our various products, like matching the appropriate MHEC with specific redispersible polymer types for optimal synergy.

We also offer formulation consulting services, helping customers optimize not just cellulose content but the entire product formula. This includes advising on filler selection, cement compatibility, and additive interactions. For new market entrants, we provide starter formulations that can be refined based on local raw materials and application requirements.

Frequently Asked Questions About MHEC

Are you unsure about how to properly use MHEC in your formulations? Do technical concerns about compatibility and performance keep you from making optimal choices? These knowledge gaps can lead to costly mistakes in product development.

MHEC should be added to dry mixtures before liquid addition and requires proper dispersion to prevent lumping. It's stable in alkaline environments like cement but may lose viscosity in acidic conditions. The typical dosage ranges from 0.2-0.6% depending on the application, with higher amounts increasing water retention but potentially causing stickiness.

Based on the most common questions I receive from customers, here's practical information to help you maximize MHEC performance in your products.

Essential MHEC Technical Information

| Question | Answer | Practical Implication |

|---|---|---|

| Storage Stability | 24 months in original packaging | Plan inventory accordingly |

| Mixing Order | Add to dry mix before water | Prevents lumping |

| Dissolution Temperature | Above 20°C optimal | May need warm water in cold conditions |

| pH Stability | Stable in pH 3-12 | Compatible with most construction materials |

| Effect of Hard Water | Minimal impact on performance | Can be used with various water sources |

| Biological Resistance | Resistant to enzymatic degradation | Good shelf life in final products |

| Health & Safety | Non-toxic, low dust grades available | Safe handling with basic precautions |

In my experience, many application problems stem from improper dispersion techniques. For best results, MHEC should be thoroughly blended with other dry ingredients before water addition. In production environments with high humidity, we recommend using coarser particle grades to reduce lump formation during mixing.

Temperature affects both dissolution speed and final viscosity. In cold conditions, MHEC dissolves more slowly but ultimately develops higher viscosity. For consistent year-round production, some manufacturers adjust their formulations seasonally or use temperature-controlled water in their mixing process.

When switching between MHEC suppliers or grades, always conduct small-scale tests before full production implementation. Even products with identical viscosity specifications may perform differently due to variations in molecular structure and substitution patterns.

Conclusion

MHEC is an essential additive that transforms ordinary construction materials into high-performance products. By choosing the right grade and working with a reliable Chinese supplier like Kehao, you'll ensure consistent quality, stable supply, and technical support for your construction material manufacturing needs.

-

Explore this resource to understand how MHEC enhances construction materials and improves performance. ↩

-

Find expert insights on optimizing tile adhesive performance for better results in your projects. ↩ ↩

-

Get tips on selecting wall putty that ensures smooth finishes and long-lasting results. ↩

-

Understand the role of skim coats in achieving high-quality wall finishes and surface preparation. ↩

-

Explore the uses of hydroxypropyl methylcellulose in various construction applications. ↩

-

Discover how self-leveling compounds can enhance the quality of flooring installations. ↩

-

Explore how customized packaging can enhance your brand visibility and customer satisfaction. ↩

-

Find out how MHEC enhances wall putty properties for better application and durability. ↩

-

Explore best practices for implementing quality control systems to ensure product consistency. ↩