Working on large construction projects with tight deadlines, I faced a costly dilemma: my team wasted 37 tons of polymer emulsion when it expired too quickly. The project nearly failed, and my boss was furious.

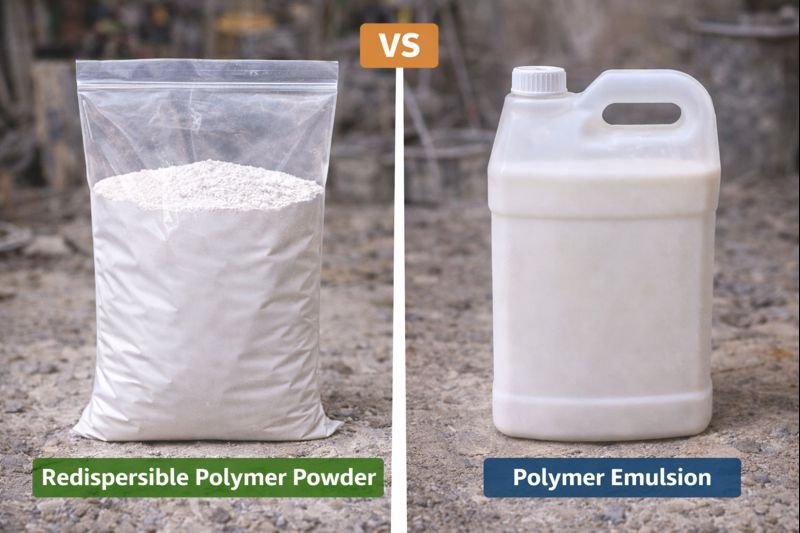

When choosing between redispersible polymer powder1 and emulsion, consider four key factors: working conditions (powder works below -5°C while emulsion freezes), total cost (powder has higher price but lower storage costs), performance limits (VAE emulsions offer better flexibility, acrylic powder provides faster strength), and hidden costs (emulsion expires in 72 hours, powder can clump in humidity).

I've been in the construction materials business for over 15 years. During this time, I've seen countless projects succeed or fail based on one simple choice: using redispersible polymer powder1 or emulsion. Let me share what I've learned from real job sites and laboratory tests.

What Are The Different Types of Redispersible Polymer Powder?

When I first started supplying materials to Middle Eastern construction firms, a project manager called me in a panic. His desert project was failing because he didn't understand the different polymer powder types available.

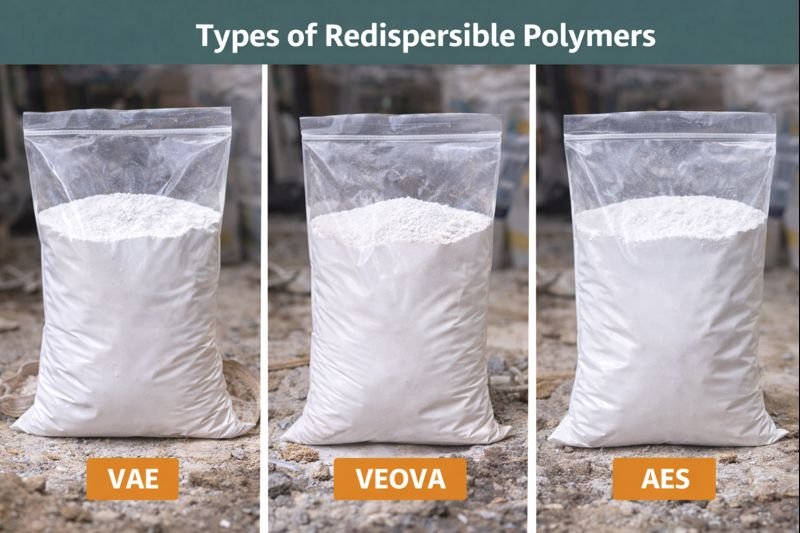

Redispersible polymer powders come in several main varieties: vinyl acetate-ethylene2 (VAE), vinyl acetate-vinyl versatate (VA/VeoVa), acrylic, and styrene-acrylic copolymers. Each type offers specific properties - VAE provides flexibility and adhesion, VA/VeoVa delivers water resistance, acrylics offer weather durability, and styrene-acrylics combine strength with cost-effectiveness.

When selecting the right type for your project, understanding these differences becomes crucial. VAE powders dominate the market with about 85% share due to their balanced properties and cost performance. I've seen this firsthand in Saudi Arabia, where our VAE powders performed exceptionally well in hot, dry conditions.

The choice largely depends on your application requirements. For exterior wall systems that face harsh weather, VA/VeoVa or acrylic-based powders provide superior hydrophobicity and UV resistance. For tile adhesives where flexibility matters, VAE powders excel.

The manufacturing process also impacts quality. Spray-dried powders undergo a sophisticated process in which polymer emulsions are mixed with anti-caking agents and protective colloids before drying. This creates the redispersibility property that allows the powder to reform into an emulsion when mixed with water.

Testing at our facility has shown that high-quality redispersible powders should completely disperse within 60 seconds when added to water, forming a stable emulsion without lumps. This quick redispersibility ensures even distribution throughout the mortar mixture.

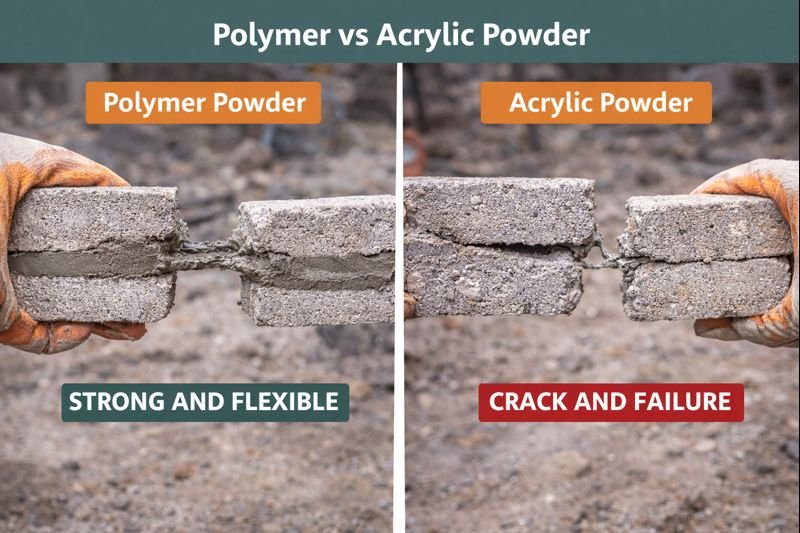

What's The Difference Between Polymer Powder And Acrylic Powder?

Last year, a customer called me confused about why his project was showing early cracking despite using "polymer powder." The problem? He didn't understand he was using standard polymer powder when his project needed acrylic-based powder.

Polymer powder is a general term covering various polymer compositions (including VAE), while acrylic powder specifically contains acrylic copolymers. The main differences lie in performance: acrylic powders offer superior weather resistance, UV stability, and early strength (up to 2x stronger in the first hour), but typically cost 15-30% more than standard VAE polymer powders.

The choice between these materials significantly impacts your project's durability and cost efficiency. In my testing with projects across developing countries, I've consistently observed that acrylic-based powders outperform standard VAE powders in exterior applications where UV exposure is high.

For interior applications like self-leveling compounds3, standard VAE polymer powders often provide sufficient performance at a better price point. However, for exterior façades or areas with freeze-thaw cycles, acrylic powders deliver superior long-term performance.

The chemical structure explains these differences. Acrylic polymers contain more stable carbon-carbon bonds in their backbone, making them less susceptible to UV degradation. VAE polymers, while excellent for flexibility and adhesion, contain ester groups that can hydrolyze over time in highly alkaline environments.

When working on a major project in UAE, we conducted accelerated weathering tests that demonstrated acrylic powders maintained 95% of mechanical properties after UV exposure equivalent to 5 years, while standard VAE powders retained only about 70%. This translates to significantly extended maintenance cycles.

Manufacturing these different powders also requires different expertise. Our acrylic powder production line operates at different temperatures and requires special anti-caking agents to prevent agglomeration during storage.

What Is Redispersible Latex Powder Used For?

During a trade show in Dubai, a potential client approached me, puzzled about why his tile adhesive was failing despite using expensive cement. His missing ingredient was redispersible latex powder4.

Redispersible latex powder is used to enhance performance of construction materials including tile adhesives, external thermal insulation systems, self-leveling compounds3, repair mortars, grouts, and renders. It improves adhesion, flexibility, water resistance, workability, and reduces cracking. One part powder typically replaces 10-15 parts liquid emulsion while providing similar properties.

The versatility of redispersible latex powder4 continues to amaze me after years in this industry. In rendering applications, adding just 0.3% by weight can reduce cracking by up to 80% according to our laboratory tests. This performance improvement comes from the polymer film formation that bridges micro-cracks as they develop.

For external thermal insulation composite systems (ETICS), redispersible powder creates the essential flexibility needed to accommodate substrate movements and thermal cycles. Our projects in Iran demonstrated that properly formulated base coats with 2.5-3% redispersible powder maintained integrity through temperature swings of over 50°C.

The usage rates vary by application:

| Application | Typical Dosage (% by weight) | Key Benefits |

|---|---|---|

| Tile Adhesives | 1.5-3% | Improves adhesion, reduces slip, extends open time |

| ETICS Base Coats | 2-5% | Flexibility, impact resistance, adhesion to insulation |

| Self-Leveling Compounds | 0.5-1.5% | Reduces cracking, improves flow properties |

| Repair Mortars | 2-6% | Enhanced adhesion to old substrates, reduced shrinkage |

| Waterproofing Membranes | 5-15% | Water resistance, crack-bridging ability |

The cost-effectiveness becomes apparent when considering the total application. While redispersible powder costs more per kilogram than liquid emulsion, its concentrated nature results in lower shipping costs, extended shelf life (typically 12 months versus 72 hours after opening for emulsions), and reduced storage space requirements.

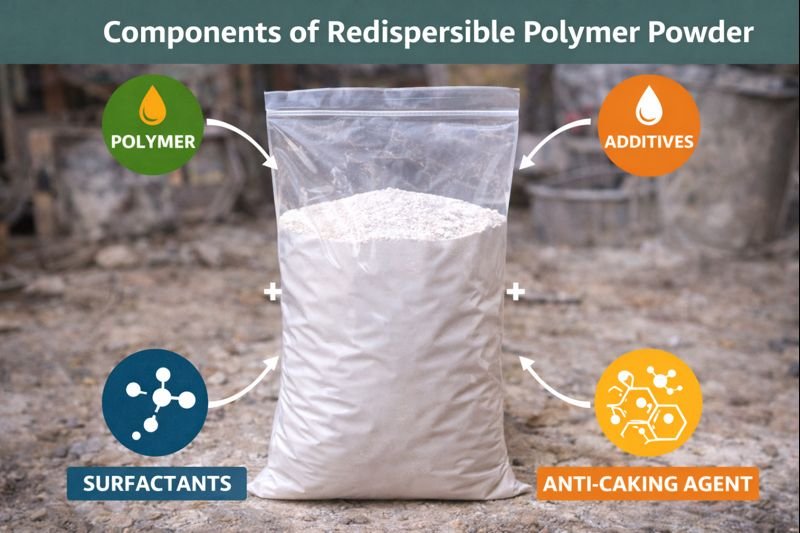

What Is The Composition Of Redispersible Polymer Powder?

When visiting customer factories, I'm often asked about the composition of our powders. One technical director in Pakistan was particularly concerned about compatibility with his existing formulations.

Redispersible polymer powder typically consists of 80-90% polymer base (like VAE, VA/VeoVa, or acrylic), 5-15% protective colloids (polyvinyl alcohol), 2-5% anti-caking agents (silica or calcium carbonate), and sometimes specialized additives like defoamers or hydrophobic agents. These components work together to ensure the powder disperses back into emulsion form when mixed with water.

Understanding this composition helps explain the performance characteristics we observe in different applications. The polymer base determines fundamental properties like flexibility, adhesion, and water resistance. Protective colloids like polyvinyl alcohol (PVA) stabilize the polymer particles during the spray-drying process and help them redisperse when water is added later.

Anti-caking agents prevent the powder from forming lumps during storage, which is particularly important in humid environments. In our testing facility in China, we found that optimizing the anti-caking agent can reduce moisture sensitivity by up to 40%, significantly reducing waste in tropical climates.

The manufacturing process is also fascinating. Modern spray dryers convert liquid emulsion to powder through atomization, creating microscopic droplets that dry almost instantly. The resulting powder particles usually measure 50-100 microns in diameter, with each particle containing thousands of individual polymer particles held in a protective matrix.

The ratio of components must be precisely controlled. Too much anti-caking agent reduces adhesive strength, while insufficient protective colloid prevents proper redispersion. Our quality control process tests each batch for redispersibility, film formation, and mechanical properties to ensure consistent performance.

Special grades for specific applications may include additional components. For instance, our hydrophobic grades for exterior applications contain silicone-based additives that enhance water repellency while maintaining vapor permeability. For self-leveling compounds, we incorporate defoamers to eliminate air entrainment that could compromise surface quality.

Conclusion

When choosing between redispersible polymer powder1 and emulsion, remember the four industry rules: working conditions determine viability, calculate total costs beyond purchase price, match performance requirements to your application, and beware of hidden costs like short shelf life and humidity damage.

FAQ

Can I mix redispersible polymer powder with liquid emulsion?

Yes, combining them in a 1:1 ratio can achieve exceptional waterproofing (up to P12 grade in our subway tunnel project).

What happens if polymer powder gets wet before mixing?

It forms clumps and loses effectiveness. In humid areas like Zhuhai, we've seen waste rates exceed 15%.

How long does opened emulsion remain usable?

Only 72 hours in most cases. Always check manufacturer specifications.

What's the temperature limit for using emulsions?

Emulsions freeze and become unusable below -5°C, while powder remains stable.

-

Explore the versatility and applications of redispersible polymer powder in enhancing construction materials. ↩ ↩ ↩

-

Explore the unique properties of VAE and its applications in construction materials. ↩

-

Explore the functionality and benefits of self-leveling compounds in construction projects. ↩ ↩

-

Understand the role of redispersible latex powder in improving construction material performance. ↩ ↩